| Pages:

1

..

19

20

21

22

23

..

26 |

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

Sometime this week I'll be revisiting the cinnamon oil to benzaldehyde method utilizing insitu steam distillation, same method I used before with good

results. I'll be taking a few photos of the new run, but I'm not sure if the mods want me posting pictures of a technique that's already been

documented in this thread (server space, and all that). I don't mind posting pics of the new experimental run if that's okay?

I'm setting up the equipment today, so will be starting soon. Last time I managed somewhere around 80% conversion to benzaldehyde (mass I think,

rather than molar conversion) from cinnamaldehyde, so it'll be interesting to see how I get on this time around. I'm using a different cinnamon bark

oil supplier this time, but again I'll be distilling the cinnamaldehyde from the cinnamon oil as I did before. I'll be processing one single kg bottle

of cinnamon oil into benzaldehyde. The final product will be double vacuum distilled and stabilized with a dash of hydroquinone for storage.

|

|

|

Bot0nist

International Hazard

Posts: 1559

Registered: 15-2-2011

Location: Right behind you.

Member Is Offline

Mood: Streching my cotyledons.

|

|

while im not a mod, I feel a "peach syle" pictorial would be a welcome addition to this lengthy thread. Perhaps even an artical for prepublication. It

seems that "*** to benzaldehyde" questions are popular with newbies around here. Can't think of why, though...

U.T.F.S.E. and learn the joys of autodidacticism!

Don't judge each day only by the harvest you reap, but also by the seeds you sow.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

Not sure what about a "peach style", but I can do a CycloKnight style retro-aldol follow up to my earlier pictorial(s) some years back.

http://www.sciencemadness.org/talk/viewthread.php?tid=2223&a...

Whenever I revisit old teks, since I already know what works, in the interest of improvement I sometimes opt to change one variable to see what (if

anything) works better. Its already been recommended that I could try raising the pH higher, so I can give that a go and see if the benzaldehyde

conversion is higher.

If anyone has any suggestions as to what might improve this method (quoted below), then this is the time to let me know and I'll give it a whirl.

To begin with, I'll be using the old method I posted in page 6 of this thread back in 2006.

| Quote: |

I’ve significantly improved the original batch method I posted last year, what follows is my latest method.

This approach uses the same setup as the last steam distillation variation graphically depicted in in this thread.

Basically, the items used were:

hot plate, pressure cooker steam generator & associated tubing, etc

3L 3-neck RBF & mantle

vigreux column, right angle bend & still head

condenser

Vacuum pump & glassware for purfying the final product & recycling unreacted cinnamaldehyde.

chemicals: 2 litres tap water, lecithin, cinnamon oil, NaOH

Essentially, a large reaction vessel and a means of steam & vacuum distilling are all the equipment really required.

Begin by setting up all equipment, add 2 L water & ~1.5g lecithin.

The first variation is to use OTC sodium hydroxide instead of sodium carbonate, simply add the alkali to adjust the pH within the range of 12-13, only

small amounts are required.

The second variation is to slowly drip in the cinnamon oil during the course of the reaction, the benzaldehyde being steam distilled as it forms.

Begin the addition once the pH adjusted solution has heated to boling temperature and the steam is passing though the solution.

The third variation is to stop the cinnamon oil addition after 5 min, then check the distillate. If benzaldehyde is clearly distilling over, then

continue with the addition.

A crude test is to simply taste the steam distillate as it drips into the receiving vessel, if it burns your tongue off, then you're doing well. If it

tastes sweet, then significant quantities of cinnamon are being carried over. Should this not change after a short while, then double check the pH !

Provided that the pH is correct and the cinnamaldehyde content is high (70%+) then benzaldehyde laden distillate should start collecting almost

immediately after the addition has begun.

However, if it is not, wait for the benzadehyde to start collecting, THEN continue with the addition. This prevents unnecessary amounts of

cinnamaldehyde being steam distilled at the start of the process, which is a serious problem with the old batch mode reaction.

Note that by slowly dripping the cinnamon oil instead of adding it all at once to the reaction mix, single run conversion is increased by 20-30%.

Ensure the rate of cinnamon oil drip rate is approximately equivalent to the quantity of oil being steam distilled, thus maintaining high dilution in

the reaction mixture.

After 300 to 500 ml of cinnamon oil had been added, the drip rate is stopped and the steam distillation continued until all the aldehyde has been

steam distilled from the reaction mix. If using less than 2L of water, then adjust proportionally to maintain the same dilution. At this point, dump

the mix and replace with clean pH adusted water with at least ~1.5g lecithin.

This step removes tar and other junk that slows down the reaction and reduces benzaldehyde production. Significantly reduced tar formation will also

result from periodically carrying out this step (very imporant if high yields are desired).

Also note that with this method, the pH tends to slowly drop over time during the course of the steam distillation, so check the pH every couple

hours, and top up with NaOH if and when required. Its preferable to simply add small amounts concentrated NaOH solution when topping up, using a

dropper makes the alkali addition much simpler since NaOH pellets will rapidly collect moisture and stick to the sides of the reaction vessel.

Efficiency is further improved if the steam distillate (after oil separation) is also extracted with DCM, though this isn't absolutely necessary.

Once the the product oil is pooled, vacuum distillation will remove the benzaldehyde - no need to vacuum distill the recycle cinnamon aldehyde, just

drip it into the steam distillation vessel, just as with the cinnamon oil feed. Expect the quantity of unreacted cinnamon aldehyde to be circa 25%,

but if the reaction mix was kept clean during the process then it may be considerably less. The benzaldehyde distillate is clear, & much purer

than the original solvent extraction method that doesn't employ the steam distillation. Give the batch solvent extraction a rest folks, use the steam

distillation variation if producing benzaldehyde from cinnamon oil!

Far, far less work.

Using the above approach, overall molar conversion to benzdehyde is at least 80%.

I’ve managed higher conversion efficiencies (~90%), but the reaction efficiency is subject to variation according to varying reaction conditions,

i.e. feed rate, reaction mix volume (i.e. dilution), and the quantity of cinnamon oil fed to the reaction mix before changing the solution. >80%

seems to be a realistic overall figure.

Also...

Remember to keep the reaction mix free of tar & cinnamon oil impurities as much as possible to give consistent high yields.

If dripping the aldehyde into the mixture isn't practical for any reason, you can periodically add the cinnamon oil in small batches, say 20-50 ml at

a time to give good conversion, but expect a little more cinnamonaldehyde to distill over. |

|

|

|

questions

Hazard to Others

Posts: 103

Registered: 12-2-2011

Location: Australia

Member Is Offline

Mood: curious

|

|

AWSOME cyclonight

What I recomend is to drip say 200ml of cinamon oil into the boiling solution of water with NaOH and steam being blow through it as you did earlier,

but this time, make the ph of around 13.5 to 14 and maybe you mght get pure benzaldehyde out the other side. I'm certain you'll loose some product in

the process but if you can get say a quick, 60ml to 100ml of pure benzaldehyde out of say 200ml of cinamon oil without having to do a vacuum

disstilation, than to me that process is better than any because it would be a quick and easier way of getting a quick small amount of benzaldehyde

when we need it. I'm happy to loose say 140 ml of cinnamon oil if I know I'll get 60ml of pure benzaldehyde from it in a simple, quick process that

doesnt require as much effort, time, equipment and money.

GO FOR IT CYCLONIGHT !!!!!!!!

I'm your biggest fan

Asking questions is the best way to understand anything.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

No problem, any and all input appreciated.

I plan to first run through the 1 kg of oil using the previous tek just to see how much benzaldehyde it will yield from 1 litre of oil, but I'll do a

surplus run (200 ml or so) with extra oil I have and I'll report back the single pass conversion efficiency at the higher pH.

Well anyhow, we're rolling now. Benzaldehyde is flowing nicely, got around 70 ml so far and its only been a few hours since I fired it all up. Lots of

pictures taken, will post the images and write up later in the week after this little project is completed.

|

|

|

questions

Hazard to Others

Posts: 103

Registered: 12-2-2011

Location: Australia

Member Is Offline

Mood: curious

|

|

You rock Cycloknight

[Edited on 17-4-2013 by questions]

Asking questions is the best way to understand anything.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

General setup:

Between the free oil in the steam distillate and solvent extractions, there's about 400 ml so far.

Separating steam distilled oil from condensate:

[Edited on 17-4-2013 by CycloKnight]

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

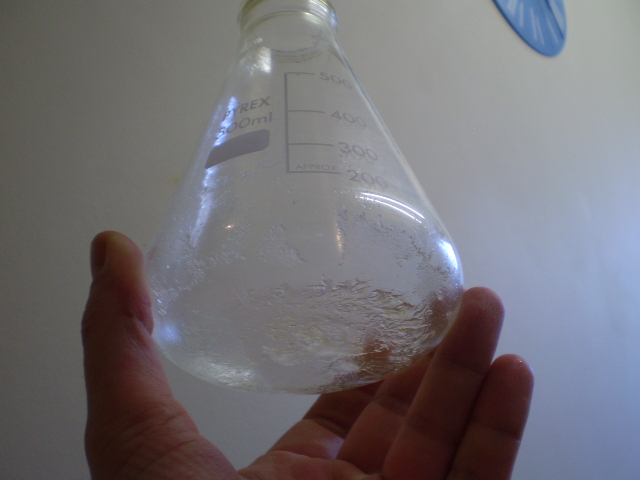

Volumetric flask making itself useful

As each litre of condensate comes off, the residual oil at the bottom is drawn off and kept separate, and then the condensate is extracted with two 30

ml portions of dichloromethane. The pooled DCM extracts are kept together, and later the DCM will be reclaimed and the aldehyde residue vacuum

distilled.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

1 kg cinnamon oil feedstock

Either later this evening (London time) or tomorrow the full kilo of cinnamon oil will have gone through the reaction mix, so then after vac

distilling and recycling unreacted cinnamaldehyde I should have the final tally.

|

|

|

questions

Hazard to Others

Posts: 103

Registered: 12-2-2011

Location: Australia

Member Is Offline

Mood: curious

|

|

THESE PICS ARE AMAZING !!!!!

Asking questions is the best way to understand anything.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

Okay finally have some results now. I'll post the pics in a few days.

No sooner had I set up all the equipment and began the vac distillation of the cinnamon oil, the mag stirrer failed on the stirrer mantle. This has

slowed down things somewhat, and I won't be able to reprocess the recycled (unreacted) cinnamaldehyde since I've run out of time. The cinnamon oil

was used as is, without vac distilling.

From 1000 g of cinnamon oil, slowly dripped into the pH 12.5 solution whilst steam distilled over 22 hours over 3 days, yielded 560 g of free oil

(separated from steam condensate using a separating funnel), and nearly a litre of dichloromethane extracts (2*30ml DCM used per litre condensate).

The DCM extracts were distilled to recover the DCM, yielding about 150 ml of oil remaining (estimated, forgot to weigh).

That oil from the DCM extracts, combined with the free oil, was then vacuum distilled. This proved impossible without magnetic stirring, so had to use

an oil bath. The bumping was very severe, even with the vigreux column it was impossible to distill of the benzaldehyde without the aldhyde bumping

into the receiver. With mag stirring, it was fine.

Bath temperature was 129 deg C, vacuum was shown as 65 mbar (absolute pressure, but gauge probably isn't that accurate) and benzaldehyde came over at

around 105 deg C.

Total benzaldehyde collected = 568 g.

Total residue remaining = 154 g (to be recycled later in next retro-aldol reaction).

Assuming residue is cinnamaldehyde, then that equates to 79% benzaldehyde, and 21% cinnamaldehyde.

Cinnamaldehyde ~ 132.16 amu

Benzaldehyde ~ 106.12 amu

1000 g cinnamon oil (assuming 100% cinnamaldehyde) is 7.56 mol.

Therefore 100% efficiency equates to 7.56 mol benzaldehyde, which is 803 g.

Total single pass benzaldehyde is 568 g, so single pass molar efficiency was 70.7 %. If the starting cinnamon oil wasn't 100% cinnamaldehyde, then the

true figure will be higher.

This doesn't take the unreacted cinnamaldehyde into account, so if/when that's recycled the overall conversion will be somewhat increased.

If the unreacted low volatile oil is cinnamaldehyde, then reprocessing should yield

154 g * (0.722) = recoverable oil of which 79% will be benzaldehyde, 87.8 g.

This combined with original yield of 568 g, would then be 655 g, increasing the overall molar efficiency to 81.6 %.

The reaction flask solution was changed each morning, and not changed nor pH adjusted for the entire day. pH was adjusted by adding a round teaspoon

of NaOH. Also, two lecithin pills were dropped in.

On the first day I experimented a bit, and added the cinnamon oil in 20 cc doses, but I stopped as this was reducing efficiency (and more tar too) and

causing too much cinnamaldehyde to distill over. Maximum efficiency is attained by using a very slow drip rate. I dripped in about 40 ml or so per

hour.

About 33 ml of free oil was deposited for each litre of steam condensate. Cinnamon oil drip rate was adjusted to match.

About 6 g of benzaldehyde will dissolve in 1 litre of pure water, and there are always oil droplets floating in solution, hence the reason for the DCM

extractions. Towards the end I found that a single 30 ml DCM extraction gets most of the oil out, so two DCM extractions is probably a bit excessive.

It might be handy to know the vapour pressures at 100 deg C.

Benzaldehyde ~ 8 kPa

Cinnamaldehyde ~ 0.6 kPa

Water ~ 101.3 kPa

Took me a while to find the aldehyde values at 100 C, so thought would include them here. These can be used along with each oil concentration in the

boiling solution (if known) to calculate the theoretical distribution in the steam condensate (assuming perfect mixing).

[Edited on 20-4-2013 by CycloKnight]

|

|

|

questions

Hazard to Others

Posts: 103

Registered: 12-2-2011

Location: Australia

Member Is Offline

Mood: curious

|

|

AMZING !!!!!!!!!!

Asking questions is the best way to understand anything.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

Lets cook up some benzaldehyde..

Photo update to my last post.

Chemicals needed:

1 kg cinnamon oil

10g NaOH

10g lecithin

Equipment needed:

Pressure cooker

Hob (1500W)

Heating mantle (or oil bath)

Glassware (3L RBF, vigreux column, stillhead, condenser, separating funnel(s), stoppers, fittings & glass tube for steam injection to corrosive

cinnamaldehyde/benzaldehyde mixture)

Aquarium tubing

Aquarium water pump (for cooling condenser)

Receiving vessel(s)

Vacuum pump will be required for final vac distillation, though in a pinch, steam distillation could be used instead (with neutral pH solution instead

of 12.5 pH).

Disused kitchen corner

Get the gear out

General setup

Chemicals, from left to right, lecithin, cinnamon oil and sodium hydroxide.

There's virtually no pressure, so any tubing fitting will do.

The aquarium tubing is run from the pressure cooker to a straight glass tube through a stopper in the 3L round bottom flask. Simples.

Cinnamon oil. The more the merrier, but for this experiment I've used 1 kg.

The pH is set once per day, to around 12.5 (this required 1 rounded teaspoon of NaOH granules), and then checked every few hours with the pH paper

skewer.

I find that the pH remained fine without topping up until emptying and replacing the solution the following day. 2 lecithin capsules were also added.

Ready to rock'n roll.

Go slowly, about one drop of cinnamon oil every few seconds is a good start.

16 drops per ml, aim for around 40ml addition per hour.

The purpose of the heating mantle heating the 3L RBF is to keep it hot enough that it won't condense steam from the pressure cooker and a little extra

heat is needed to keep condensate from the insides and vigreux column reflux from filling the RBF up with water. A medium heat setting is all that's

needed.

Going good.

Extracting each litre of condensate with dichloromethane as the condensate is produced.

Here we're producing about a litre of condensate per hour. There's about 33 ml of free oil sitting at the bottom of each litre that comes off, and

there will be about 6 ml benzaldehyde dissolved (DCM will remove it).

First tap off the free oil:

Then do at least 1 x 30ml DCM extraction to get the oil droplets and dissolved oil out, before you throw this down the sink (I did 2 x 30 ml

extractions, but 1 is probably enough).

I occasionally used a large conical flask to store the condensate litres when it wasn't convenient to extract them right away. I would just fill the

large 3L conical flask, and then do 3 x 1L extractions in quick succession.

1000g of cinnamon oil and 3 days later I have 560 g steam distilled oil (free oil) and about a litre of dichloromethane extracts.

Time to distill off the dichloromethane from the extracts, and then vacuum distill the residue and the condensate oil.

This oil (from DCM extractions combined with free oil) was later determined to be 79% benzaldehyde, with the remainder comprised mostly of unreacted

cinnamaldehyde.

Stirrer mantle broke shortly after beginning this project, so had to make do with an oil bath.

Vac pump

Benzaldehyde

More refractive benzaldehyde porn...

Nearly enough to fill a 750 cc bottle, 568 g.

Leftover cinnamaldehyde mixture from vac distillation

Total product from 1 kg of cinnamon oil, 568 g benzaldehyde and 154 g of cinnamaldehyde residue still to be recycled in the next lot.

[Edited on 28-4-2013 by CycloKnight]

|

|

|

madcedar

Hazard to Others

Posts: 116

Registered: 10-9-2009

Member Is Offline

Mood: No Mood

|

|

CycloKnight

Thank you for going to the trouble to re-visit this procedure. Many people will benefit from your post. Love the lab bench.

Kind Regards

|

|

|

questions

Hazard to Others

Posts: 103

Registered: 12-2-2011

Location: Australia

Member Is Offline

Mood: curious

|

|

Yeah, true. I must agree with Madcedar, it was a good journey this whole procedure and thankyou so much mate for taking us through it

Asking questions is the best way to understand anything.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

No worries chaps, this retro-aldol variation is actually one of my favourite reactions so it's all good fun. With the smell of cherries propagating

the house, sometimes it does seem more like cooking that chemistry...

...except when the following morning you check your product beaker (that you forgot to rinse), only to find your exotic sauce cuisine oxidised to

benzoic acid crystals.

Having fun in the kitchen it may be, baking brownies it isn't.

As a wise person once said "You ain't in Kansas anymore, Dorothy.".

One last point regarding the drip rate.

I mentioned before to try to balance drip rate with visible oil in the steam condensate, just remember to add an extra 20% to the drip rate (assuming

1 litre per hour steam condensate) to account for dissolved benzaldehyde in the steam condensate (~6 ml litre).

No point adding more oil if it won't steam distill, what doesn't steam distill will inevitably turn to tar in the flask, so overdoing it will reduce

the % yield of benzaldehyde.

|

|

|

CycloKnight

Hazard to Others

Posts: 128

Registered: 4-8-2003

Member Is Offline

Mood: Still waiting for the emulsion to settle.

|

|

Here are a couple short video I made during the run, no sound though.

Steam distillation

http://www.youtube.com/watch?v=0zdW0CunIyQ

Steam condensate rate

http://www.youtube.com/watch?v=stEECSuoUPg

|

|

|

Davyrocket

Harmless

Posts: 20

Registered: 10-5-2013

Member Is Offline

Mood: Euphoric if it works

|

|

omg jfc

5 hours later reading this thread and a bottle of johnny walkers done!...

and still no futher forwared ....

i am not looking for spoon feeding however if i could only have 1 mouthfull of spoon feed info on the best direction to benzaldehyde from my location

in \\uk that would be most appreceated....

i cant go this diriction i cant go that direction..all because of my ffff location and chem avalability..

if some kind chemist out there from the uk

could even pm me on a good route for me to go

or post....as there probebly more than just me in the same

posistion...

i would be much greatfull to them

and i prommis not to post anymore crap untill i come up

with somthing good

thx davyrocket

ps nico my boy feel fre to tell me to piss of and move post

i would if it where me

|

|

|

Bot0nist

International Hazard

Posts: 1559

Registered: 15-2-2011

Location: Right behind you.

Member Is Offline

Mood: Streching my cotyledons.

|

|

You cant get toluene and oxidants in the UK? You have the internet, obviously, so cant you just order some cinnamon oil or even bulk cinnamon, or

almond attracts. If you cant source these basic precursors, then how do you plan to get to your assumed target molecule. Probably easier to walk the

streets looking for what you want... Sorry if I have assumed to much, but your starting to sound like a "lazy cook." No offence intended, just my

perception. Don't let the whiskey make you post sloppy or flame either. we are (mostly) all rational adults here.

U.T.F.S.E. and learn the joys of autodidacticism!

Don't judge each day only by the harvest you reap, but also by the seeds you sow.

|

|

|

Davyrocket

Harmless

Posts: 20

Registered: 10-5-2013

Member Is Offline

Mood: Euphoric if it works

|

|

Bot0nist i am far from beeing a lazy cook

i am actualy planning to start a science course this september

even at my age of 32, however you are probably right about the whisky...

if some one could even post me or pm a patient

that would be suitable for uk chems.....

i would not stop reading and studying until

i masterd it...or untill my eyes poped out my sockets

its just like my head is going to explode with it

but look i dont want to ff up a perfectly good post with my retorical bs....

i was thinking with a benzelalcholo starter

and sorry for being a assssss

Bot0nist

its maybee the irish breaking out of me

sry for spelling

thx the rocket

|

|

|

questions

Hazard to Others

Posts: 103

Registered: 12-2-2011

Location: Australia

Member Is Offline

Mood: curious

|

|

All the same, inorder to make benzaldehyde, you still need all the right equipment, glassware ect, its not something anyone can do without all the

right stuff

Asking questions is the best way to understand anything.

|

|

|

manimal

Hazard to Others

Posts: 180

Registered: 15-1-2008

Member Is Offline

Mood: ain't even mad

|

|

Quote: Originally posted by madcedar  | CycloKnight

Thank you for going to the trouble to re-visit this procedure. Many people will benefit from your post. Love the lab bench.

Kind Regards |

It's good to see you.

|

|

|

vmelkon

National Hazard

Posts: 669

Registered: 25-11-2011

Location: Canada

Member Is Offline

Mood: autoerotic asphyxiation

|

|

Has anyone tried with commercial grade toluene?

Someone mentioned in this thread that they contain thiotoluenes and this interferes with the reaction.

My source of MnO2 would be from batteries.

I do have some KMnO4, if it can be used directly in this reaction.

I was thinking of the reaction between toluene + MnO2 + H2SO4 as mentioned in the first post, not the cinnamaldehyde --> benzaldehyde.

What is a thiotoluene? Is it something like this?

http://www.chemicalbook.com/ProductChemicalPropertiesCB15115...

|

|

|

questions

Hazard to Others

Posts: 103

Registered: 12-2-2011

Location: Australia

Member Is Offline

Mood: curious

|

|

Quote: Originally posted by vmelkon  | Has anyone tried with commercial grade toluene?

Someone mentioned in this thread that they contain thiotoluenes and this interferes with the reaction.

My source of MnO2 would be from batteries.

I do have some KMnO4, if it can be used directly in this reaction.

I was thinking of the reaction between toluene + MnO2 + H2SO4 as mentioned in the first post, not the cinnamaldehyde --> benzaldehyde.

What is a thiotoluene? Is it something like this?

http://www.chemicalbook.com/ProductChemicalPropertiesCB15115... |

I tried all the methods using tolune and cinamon and the truth is, you need all the right equipment in order to get it to work. It's just not fun if

you have to impovise

Asking questions is the best way to understand anything.

|

|

|

vmelkon

National Hazard

Posts: 669

Registered: 25-11-2011

Location: Canada

Member Is Offline

Mood: autoerotic asphyxiation

|

|

Quote: Originally posted by questions  | I tried all the methods using tolune and cinamon and the truth is, you need all the right equipment in order to get it to work. It's just not fun if

you have to impovise  |

I have equipment but I don't have lab grade chemicals.

I can prepare "activated MnO2" but I don't have high purity H2SO4 and toluene.

|

|

|

| Pages:

1

..

19

20

21

22

23

..

26 |