| Pages:

1

..

18

19

20

21

22

23 |

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Interesting, but IMO the decomposition temperature of 65C is a deal breaker (also the extremely high sensitivity).

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  | | Interesting, but IMO the decomposition temperature of 65C is a deal breaker (also the extremely high sensitivity). |

Microtek, how large were your UrazineP crystals and how would you compare the sensitivity to the nickel aminoguanidine perchlorate?

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

The UZP crystals were about 0.1 mm (but of course a distribution of sizes), and the sensitivity of my NAP is much lower - I have trouble setting the

NAP off with steel on steel hammer blows, whereas UZP detonates with firm taps under these conditions. My comments above were directed at

trinitroaminotrinitrobenzene.

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  | | The UZP crystals were about 0.1 mm (but of course a distribution of sizes), and the sensitivity of my NAP is much lower - I have trouble setting the

NAP off with steel on steel hammer blows, whereas UZP detonates with firm taps under these conditions. My comments above were directed at

trinitroaminotrinitrobenzene. |

I know, I changed the subject a bit. Considering the issue UZP has in going full order, needing higher quantities do you see this as a practical

material at all? Seems like it would be too sensitive then. Even handling a couple of grams of NAP is a serious decision.

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Well, I don't think the sensitivity issues are insurmountable - nitroglycerine is much more sensitive than UZP and has found quite a bit of use. I

think the hygroscopicity is a bigger issue since the semi solvated UZP is VERY corrosive and might well be quite incompatible with other HEDMs or

binders. Perhaps if we can find a suitably insensitive and non-hygroscopic perchlorate salt that might co-crystallize with UZP, or one that is

melt-castable and forms a non-porous structure.

This is only really worth pursuing if the calculated performance can be realized, so I need to analyze what is going on with the low performance. For

this, I need to fully develop my test setup for VOD and that requires a series of carefully identical tests to determine the reproducibility and

accuracy of the measurements. Also, I need to see how my setup works with more than two probes, since this will be required to map the acceleration of

the shock wave. That is what I'm working on at the moment.

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  | Well, I don't think the sensitivity issues are insurmountable - nitroglycerine is much more sensitive than UZP and has found quite a bit of use. I

think the hygroscopicity is a bigger issue since the semi solvated UZP is VERY corrosive and might well be quite incompatible with other HEDMs or

binders. Perhaps if we can find a suitably insensitive and non-hygroscopic perchlorate salt that might co-crystallize with UZP, or one that is

melt-castable and forms a non-porous structure.

This is only really worth pursuing if the calculated performance can be realized, so I need to analyze what is going on with the low performance. For

this, I need to fully develop my test setup for VOD and that requires a series of carefully identical tests to determine the reproducibility and

accuracy of the measurements. Also, I need to see how my setup works with more than two probes, since this will be required to map the acceleration of

the shock wave. That is what I'm working on at the moment. |

Good thoughts microtek! Why not prepare a 10 gram sample of PETN and UZP and compare witness plates? Do you think Urazine periodate could have better

stability?

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I do plan on some tests at a slightly larger scale, but I will begin at maybe 2 g. If the scale is in fact the problem, it should be possible to see

some improvement by just increasing the diameter or the length of the charge a little bit. Before I do that though, I will map the VOD profile, since

that should provide some clues as to the most effective improvements.

I don't have any experience with periodates (or easy access to them).

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

I wait with anticipation!

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

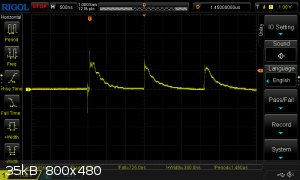

Here is the result of my first attempt with more than two probe points. The spacing is 10 mm between each pair. As can be seen from the screen shot,

the time between the two first points is 1.45 us and between the second pair it is 1.60 us. This corresponds to VODs of 6897 m/s and 6250 m/s

respectively. These values are reasonable for hand pressed charges of PETN with a small diameter (and with weak containment), but the fact that the

second measurement is lower than the first is unexpected. Some possible explanations could be uneven charge density due to hand pressing, overdriven

detonation from the primary, strange transient effects from reflection of shockwaves or maybe measurement error. Of these, I think the first is the

most likely, since I didn't put much effort into consistent pressing.

|

|

|

dettoo456

Hazard to Others

Posts: 256

Registered: 12-9-2021

Member Is Offline

|

|

Sorry since I’m not the best at understanding explanations without diagrams, but in your last post regarding the testing circuit, were the two

probes set opposite of the charge on both ends (like a probe <-> charge <-> probe)? Or were they one probe behind the other, both being

parallel to the charge (probe <-> probe <-> charge)? You may want to use piezos too; although they are more finicky and expensive but are

used more often for this sort of VOD/pressure testing as they’ll ignore variability that can come with detonation products causing differences in

plasma/heat formation. If my advice is retarded just ignore it (I’m no energetics wiz let alone electronics or sensitive circuit testing genius so a

grain of salt is recommended as such) but good luck either way.

Also in regards to the hygroscopicity, core-shell-explosive design can be interesting regarding primaries and in this case the high VOD of UZP can

overcome any small problems with polymer coatings such as n-methylpyrrolidone or poly-dopamine which can be easy to apply with just heat, solvent, and

maybe some ultrasonic stimulation.

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by dettoo456  | Sorry since I’m not the best at understanding explanations without diagrams, but in your last post regarding the testing circuit, were the two

probes set opposite of the charge on both ends (like a probe <-> charge <-> probe)? Or were they one probe behind the other, both being

parallel to the charge (probe <-> probe <-> charge)? You may want to use piezos too; although they are more finicky and expensive but are

used more often for this sort of VOD/pressure testing as they’ll ignore variability that can come with detonation products causing differences in

plasma/heat formation. If my advice is retarded just ignore it (I’m no energetics wiz let alone electronics or sensitive circuit testing genius so a

grain of salt is recommended as such) but good luck either way.

Also in regards to the hygroscopicity, core-shell-explosive design can be interesting regarding primaries and in this case the high VOD of UZP can

overcome any small problems with polymer coatings such as n-methylpyrrolidone or poly-dopamine which can be easy to apply with just heat, solvent, and

maybe some ultrasonic stimulation. |

Go on about the UZP….

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

@Dettoo:

This test setup is like this: The charge is a coloumn of PETN or other substance. Down the side of the coloumn, two rows of holes are made at precise

intervals (so two holes at the base of the charge, two holes 5 mm above this, two more holes above this and so on. See the photo for clarity). One

probe consists of two copper wires inserted in a pair of holes at the same height. a 9V battery is connected along with a resistor to the wires (so

one wire is positive, the other is negative, but because of the spacing between the two holes, the circuit is open). When the CJ-zone reaches the

probe (remember that's a pair of holes), the conductive plasma closes the circuit and the voltage across the resistor increases. It is this rise in

the voltage that is recorded by the oscilloscope.

I did consider piezo sensors (and also fiber optics), but seeing the crisp and clear signal from the ionisation probes, I don't see the need. I think

that the micro scale I'm working at gives me an advantage because I can have the oscilloscope placed within one meter of the test. This means that I

don't need long wires and problems with induced currents and lots of electronic noise.

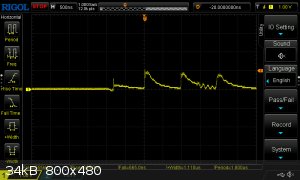

I'm attaching another test, this time with 4 probes at 5 mm spacing. I have now figured out how to export the raw data from the scope, so I can make

more precise calculations on the VOD. This time I used a 2.5 kg weight to compress the charge at small intervals to get as uniform a density as

possible. This means that I only get 0.6 MPa of loading pressure, so the VOD is obviously going to be quite low. The average VOD between probe points

are as follows:

5988 m/s between 1 and 2

5181 m/s between 2 and 3

4854 m/s between 3 and 4

(the first peak is quite small, but that is probably because the probe wire were not as firmly imbedded in the charge).

I think this indicates that the VOD actually does decrease down the charge, probably as a result of the weak containment, but I need some more tests

to be certain.

[Edited on 5-4-2022 by Microtek]

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Reading through some papers and encyclopedias, I found that the critical diameter of any explosive is strongly dependent on particle size. Since

mechanical sensitivity is also dependent on particle size, producing an ultra fine UZP batch may prove to improve both the dissapointing performance

and address some of the sensitivity issues of UZP.

The problem is that it is not easy to do a particle size reduction based on crash precipitation (since dissolving UZP would freebase the urazine and

UZP would only reform if all the water was removed). There is of course mechanical grinding, but that is not something I relish with a highly

sensitive explosive. Maybe UZP can be ground safely under a non-polar solvent. I think I'll experiment a little at the milligram scale and see if I

can make it explode under gasoline (with appropriate precautions obviously).

As an aside, particle size effects may also explain the observations on PETN, since a coarse grained charge that is weakly confined would be

relatively close to its critical diameter (especially at low density, since critical diameter is also inversely dependent on charge density).

[Edited on 9-4-2022 by Microtek]

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  | Reading through some papers and encyclopedias, I found that the critical diameter of any explosive is strongly dependent on particle size. Since

mechanical sensitivity is also dependent on particle size, producing an ultra fine UZP batch may prove to improve both the dissapointing performance

and address some of the sensitivity issues of UZP.

The problem is that it is not easy to do a particle size reduction based on crash precipitation (since dissolving UZP would freebase the urazine and

UZP would only reform if all the water was removed). There is of course mechanical grinding, but that is not something I relish with a highly

sensitive explosive. Maybe UZP can be ground safely under a non-polar solvent. I think I'll experiment a little at the milligram scale and see if I

can make it explode under gasoline (with appropriate precautions obviously).

As an aside, particle size effects may also explain the observations on PETN, since a coarse grained charge that is weakly confined would be

relatively close to its critical diameter (especially at low density, since critical diameter is also inversely dependent on charge density).

[Edited on 9-4-2022 by Microtek] |

Yes. I have suspected that the particle size was the reason for high sensitivity. Interesting about performance as well. Why can it not be crashed?

Surly some solvent dissolves it? Is there any chance of making it in a larger bath of perchloric acid and instantly cooling? You could mix in with

wax, 30 percent. Crush the wax mixture and dissolve the wax through a solvent??

Maybe lithium metal center would stabilize. Lithium Urazine perchlorate.

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

It is not difficult to dissolve UZP, but if you do, the compound is destroyed. The problem is that urazine is more of an acid than a base, so it

really doesn't want to form a salt with perchloric acid. By driving off the water, and because HClO4 is such a strong acid, you can make it do so

anyway, but the second you dissolve it, they go their separate ways (so to speak).

It is possible that you can recrystallize it from hot concentrated perchloric acid, but I don't see an advantage in doing so.

|

|

|

dettoo456

Hazard to Others

Posts: 256

Registered: 12-9-2021

Member Is Offline

|

|

The only way to get the higher density required to achieve the stated properties is most likely melt casting (although most melt cast energetics can

be suceptible to acid decomposition and on top of that melt casting primaries is a death wish) or something similar to anti-solvent recryst that might

work for primaries or energetics in the booster range (think PETN, NHN-although insoluble, and tetryl). Basically, you might be able to use a

dissolved energetic in a TLC sprayer under high N2 or Argon flow and spray onto a vertical or diagonal facing PTFE sheet. —> Like scraping spray

paint particles off of a non stick surface to yield very small particulate. The sheet would have to be allowed to dry and hopefully the HClO4 would

evaporate and the UZP would stick to the PTFE sheet. Scraping would also have to be very careful and use of a PTFE scraper could help tremendously.

Good luck with whatever you try though and good luck trying to achieve those lofty m/s’s  Don’t get yourself burned or scalded though Don’t get yourself burned or scalded though

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I tried wetting UZP with detergent gasoline, and tested the sensitivity of the substance under these circumstances. I only did rather subjective

tests, but found that I was not able to set off UZP under gasoline by grinding it in a porcelain mortar and pestle (I obviously only tested about 100

mg and wore protective gear). When placing about 50 mg of UZP wetted with gasoline in a fold of Al foil, it took determined pounding with a hammer on

a steel anvil to set off small amounts of it. I would say that it is less sensitive than RDX when wet with gasoline. I will try grinding up some UZP a

little at a time and test its performance to see if particle size reduction is a viable way forward.

@dettoo:

Actually, high density (above 2.0 g/cc) is easily achieved even with the large crystals. Ordinary pressing is all that is required.

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Any news microtek? If you do a VOD test on the ground UZP also do a witness plate as we cannot verify the accuracy of the VOD quite yet.

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Primary explosive with a sensitivity of 10J impact and 120N Friction. Also thermally stable to 350C

Can anyone grab and post the paper or talk about the synth? It’s basically a primary explosive with less sensitivity than RDX!

https://onlinelibrary.wiley.com/doi/full/10.1002/prep.202200...

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

That synth is easy, but requires a quite exotic pyrimidine to make one of the precursors. They describe it as "commercially available", but I don't

think you will find it other places than in lab supply shops. I think I'll be sticking to AGNiP.

In other news, it seems my hypothesis about the critical diameter of the rather coarse UZP was correct.

I ground up a little more than one gram of it under detergent gasoline. I did it in small portions to reduce the seriousness of any accidental

initiation from the grinding, but nothing untoward happened. After drying in a dessicator, I was left with a fine white powder.

Previously, I had designed and CNC machined a couple of fixtures for supporting the brass tubes that I'm doing my brisance tests in (and another for

the VOD test charge holders). This was necessary because the unsupported brass tubes expand under pressure, making the density of the charge difficult

to calculate. These new holders are very solid, and fit the tubes in a light interference fit, meaning that the brass tubes can only expand a few

micrometers.

Anyway, I pressed the powdered UZP into the tube at a quite high pressure, and easily got it well above 2 g/cc. When detonated, it produced a dent of

4.64 mm depth. The coarse UZP at a similar density made a 2.91 mm dent, so the simple act of pulverizing increased the performance by almost 60%. This

dent depth is greater than for any of the other explosives I have tested, so the question is now if I can overcome the hygroscopicity.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

Great results, Microtek. 4.64 mm is incredible the depth. How much provide ETN ? My ETN 1g give at density 1.69g/cc depth 5,34 mm. In alu block.

But diameter is 8 mm. (Against your 7?) Lithex gived depth 4.17 / 1.4g/cc. Lithex is also very hygroscopic. But is not crucial problem, because after

filling is isolated in metal cavity. For main charge it can be problem. For detonator less.

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  | That synth is easy, but requires a quite exotic pyrimidine to make one of the precursors. They describe it as "commercially available", but I don't

think you will find it other places than in lab supply shops. I think I'll be sticking to AGNiP.

In other news, it seems my hypothesis about the critical diameter of the rather coarse UZP was correct.

I ground up a little more than one gram of it under detergent gasoline. I did it in small portions to reduce the seriousness of any accidental

initiation from the grinding, but nothing untoward happened. After drying in a dessicator, I was left with a fine white powder.

Previously, I had designed and CNC machined a couple of fixtures for supporting the brass tubes that I'm doing my brisance tests in (and another for

the VOD test charge holders). This was necessary because the unsupported brass tubes expand under pressure, making the density of the charge difficult

to calculate. These new holders are very solid, and fit the tubes in a light interference fit, meaning that the brass tubes can only expand a few

micrometers.

Anyway, I pressed the powdered UZP into the tube at a quite high pressure, and easily got it well above 2 g/cc. When detonated, it produced a dent of

4.64 mm depth. The coarse UZP at a similar density made a 2.91 mm dent, so the simple act of pulverizing increased the performance by almost 60%. This

dent depth is greater than for any of the other explosives I have tested, so the question is now if I can overcome the hygroscopicity.

|

Fantastic news! It far outperforms RDX! Can you try the ground UZP with 15 percent aluminum as that boosted performance of the large crystals?

|

|

|

MineMan

International Hazard

Posts: 1030

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Laboratory of Liptakov  | Great results, Microtek. 4.64 mm is incredible the depth. How much provide ETN ? My ETN 1g give at density 1.69g/cc depth 5,34 mm. In alu block.

But diameter is 8 mm. (Against your 7?) Lithex gived depth 4.17 / 1.4g/cc. Lithex is also very hygroscopic. But is not crucial problem, because after

filling is isolated in metal cavity. For main charge it can be problem. For detonator less. |

According to microtek picric acid had a depth of 3.73 and RDX 4.14… so the difference in power of UZP to RDX is more than RDX to Picric acid. This

is extraordinary, truly a new class.

Microtek would you be willing to give Urazine dinitramide a try? There must be a better ion than perchlorate? I am determined to find someone to try

Urazine periodate.

Importantly but not mentioned. How did the mechanical sensitivity change with the ground UZP, should be safer

[Edited on 20-4-2022 by MineMan]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1447

Registered: 2-9-2014

Location: Tel Aviv University

Member Is Offline

Mood: old jew

|

|

If will for UZP confirms the repeatability of production and the repeatability of brizance, the reliability of DDT and so on, it will be a great

benefit in the field of amateur research. And due to the brizance almost a revolutionary invention.

Development of primarily - secondary substances: CHP (2015) neutral CHP and Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024) Diper

60 (2025)

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I haven't measured the mechanical sensitivity in any rigorous manner, since I am not really satisfied with the methods I have available. My impression

is that it is somewhat less sensitive when finely ground, but then, that is the case in general so it would be strange if it wasn't for UZP.

I did prepare a plastique containing 93% UZP and 7% binder/plasticizer, and left it in the open in my lab at a relative humidity of 40% and a

temperature of 23C. After 3 days, the mass has increased by about 3%, so there is some hygroscopicity, but under these rather dry conditions, it is

manageable. I have now moved the sample to a room with 55% relative humidity, and will monitor the moisture absorption over the coming days.

Also, I have done a test of the repeatability of my VOD setup. I made a batch of PETN based plastique with 10% binder/plasticizer (I chose plastique

because it has good flow properties under moderate pressures) and took three samples of exactly one gram each. These samples were each pressed into a

VOD sleeve similar to the one I posted about earlier (I updated the design to use Dupont pin connectors for the probe points. They have a shoulder a

certain distance from the point, so it is easy to insert them to the exact same depth). I pressed the charges in a vice and approximated the same

loading density (1.6 g/cc) by monitoring the overall length of the assembly (digital caliper), and pressing to within 0.1 mm of the same length. I

pressed 300mg pure PETN on top and 50mg AGNiP on top of that.

Then I inserted three probes with 5mm spacing and initiated electrically (bridgewire).

The VOD was measured to 8425, 8147 and 8646 m/s respectively, giving a mean velocity of 8406 m/s, so a variability of +- 260 m/s but also an apparent

overestimation of the velocity which should have been in the 7700-7900 m/s range. Still, the variability of the measurement was only +- 3% and a

systematic overestimation can be corrected for. I will experiment with greater spacing between probes, but even at the present state I think it is

time to test UZP, probably in a polymeric matrix like the PETN.

|

|

|

| Pages:

1

..

18

19

20

21

22

23 |