| Pages:

1

..

18

19

20

21

22

..

68 |

MRUD

Harmless

Posts: 10

Registered: 28-2-2007

Member Is Offline

Mood: No Mood

|

|

Specification as listed:

Diameter of con: 30mm

High: 35mm

Standoff ~32mm

Charge: 30g PETN initiated with 1g HMTD

Con was made from copperplate 1mm thick by cutting out and forming it.

|

|

|

mfilip62

pierced by a crossbow under a bridge while eating Billy goats

Posts: 140

Registered: 25-8-2006

Member Is Offline

Mood: I like turtles!

|

|

Are shaped charges good for digging up holes in the ground about 1-2m deep!(wine bottle SC for example)

My idea is to dig one crater(0,5-1m width,1,5-2m deep) with some explosive,but i cann not digg the hole for placeing it.

Ground is too hard and contains a lot of rocks.

(Please dont ask me what for do I need a hole;nothing special,I did not kill anybodye! ) )

Thanks

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

| Quote: | Originally posted by mfilip62

Is it true,that (conical) liner should bee;"As thin as posible!"

|

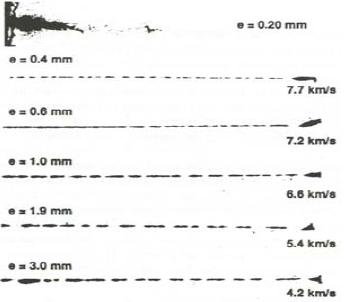

That is an interesting question for which I've found no indiscriminate answer thus far. FoSC states that the liner thickness should be between 2 and

6% of the charge diameter and further states that the optimal thickness is different for every setup, liner angle, explosive used etc...

In general, the thinner the liner the faster the liner wall velocity and jettip velocity become. (see attached picture) Until the linerwall velocity

hits the sonic criterium of about 1.2 times the speed of sound of the liner material used, in which case no jet is formed. The thickness for which it

reaches this point depend on the detonation pressure of the explosive and the cone angle of the liner. This is probably why explosives with high

detonation pressures can perform so much better, they can be pretty close to the sonic criterium with a thicker liner than less brisant explosives

can, which means more extruded mass with the same speed, which in turn means better streching (jet lenght) and more kinetic energy. I've seen some

programs and publications about how to maximize jettip velocities, so apparently this is indeed a key factor for optimal penetration. From what I can

understand there is a correlation between jettip velocity and the jet length (penetration depth), probably the increased velocity gradient aids in

better jet stretching. Such charges that are close to the sonic criterium during liner collapse are called "extreme" but put contraints on the

precision of the charge in order to function well. The mass extruded from a thin liner is less of course then that of a thicker liner so is bound to

be more sensitive to early particulation due to errors in the charge or liner. From my own experience with spun formed liner I have found that a liner

thickness of 1.2% of charge diameter was about the limit for a semtex like explosive with 180-190 kbar, but gave less penetration than 2.5-3%. I

couldn't go much lower than that while keeping the charge diameter small at 30 mm, as spinning of copperplate thinner than 0.5 mm is almost impossible

to do without tearing the metal...

Anyway, it is absolutely impossible to optimize the liner thickness of your improvised SC as an amateur. There are so many factors at work here

needing the whole shockwave dynamics/hydrocode mathematics to describe materials under these pressures, liner angle and precision, gurney

energy/detonation pressure of the explosive, acceleration time of the liner wall, grain texture and orientation of the copper, etc, not even talking

about waveshapers. The programs used to solve such complex problems need a lot more cpu power than the avarage PC unfortunately...

[Edited on by nitro-genes]

[Edited on by nitro-genes]

[Edited on by nitro-genes]

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Nitro-genes: When you spin your liners, how small can you make the non-conical part at the apex? I have been able to get down to around a 3 mm

hemispherical apex, but this is fairly large considering that my charges are only 10 mm in diameter (no sub-calibration). I'm still experimenting to

improve my spinning skills (it's quite a lot of fun anyway) so any pointers you have would be greatly appreciated.

I got quite good results from laminated copper foil (19 mm into mild steel from 1.6 g pressed PETN using a very simple but precisely machined 9.65 mm

charge) but a spun formed liner is so much more elegant. And also more durable.

|

|

|

Deceitful_Frank

Hazard to Self

Posts: 82

Registered: 5-11-2005

Member Is Offline

Mood: Pensive

|

|

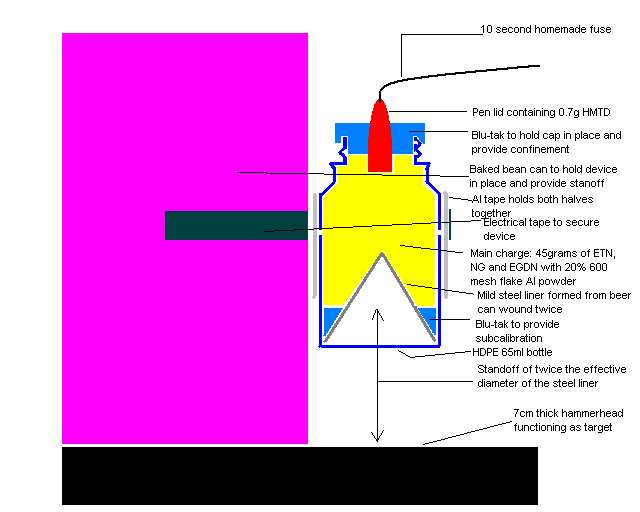

My third shaped charge

240 grams (approx 133ml) of 96% sulphuric acid was placed into a 600ml borosilicate beaker and using a bath of iced water, chilled to 5 celcius.

Meanwhile, 80.07 grams of ammonium nitrate was ground to a fine consistancy and sifted to an even, light free-flowing powder using a regular kitchen

flour sieve. A similar grain size to caster sugar was achieved.

20.03 grams of erythritol was also ground by hand in a pestle and mortar to a mesh size resembling icing sugar.

When the acid was sufficiently cold, the nitrate was added in portions beginning at around 5 grams but quickly increasing to around ten grams at a

time. The temperature was closely watched and allowed to rise to around 25 celcius to aid fast dissolution of the nitrate, stirring was rapid and even

of course.

When completed the nitration bath was again cooled to around 5 celcius before the addition of the erythritol.

The erythritol was added at a rate of around a gram at a time to begin, increasing to maybe 2 grams at a time until 15 of the 20 grams had been added.

Making sure that with each addition, all remaining erythritol had already gone into solution.

After 15 grams had been added the consistancy of the mix had become so thick that smaller and more careful additions became necessary. I feel that

this is one area of the synthesis where care, good consistant stirring and concentration can really improve yeild. After some 25 minutes all of the

erythritol had been added, the temperature had settled at around 16 celcius and the mix resembled beige toothpaste.

The whole deal was then stirred thoroughly and placed in a bath of luke warm water to raise the temperature to 25 celcius, removed from this bath and

allowed to stand at room temperature for 30 minutes. After this time the mix's consistancy had thined a little to smooth porridge and could then be

poured into one litre of iced water with yet more rapid stirring.

The 600ml nitration beaker was then rinced out with more cold water, added to the rest and the whole lot was made up to around EIGHT litres in a clean

polythene waste paper bin.

After allowing an hour for the fine seddiment to settle to the bottom of the bin it was all decanted through and then filtered with three large coffee

filters and allowed to dry for a day at room temperature over a pile of old newspapers.

This gave approximately 32 grams of near dry crude ETN. I am guessing that residual acid in my crude ETN would have prevented it from drying any more

than into a soft clumpy powder... and so on to recrystalization.

One clean 454g jam jar was selected and into it went the near-dry crude ETN and 120ml (110ml would have been enough for this lab) of mineralized

(containing gasoline) pink methylated spirit. The lid wa sealed and the whole deal was held under the hot kitchen tap at 55 celcius to heat the meths

and dissolve most of the ETN. A large pan of water was then heated to 60 celsius, removed from the heat and the sealed jar was then placed into the

pan, partially submerged and left to cool overnight.

The result after filtering and drying was 22.07 grams (46% yeild... can definitely be improved) of beautiful beige crystals that appeared to take the

form of short thick needles maybe four times as long as they were thick. These crystals tended to clump together in groups of half a dozen or so. I

suppose the powder wasn't exactly free flowing but needed tipping to around 60 degrees before movement was observed. The bulk density of this purified

ETN was around 0.9 so not quite high enough for making decent plastique. I did toy with the idea of setting aside 25% and instantly precipitating from

acetone crashing into water to obtain ultra fine ETN to add back to the original sample and fill in some of those gaps... Definitely on my to-do list.

Speaking of those gaps, I decided to try filling them with nitrated liquid polyol. A 50:50 mix of EG and glycerol was nitrated to give a blasting oil

that benifited from the ease of manufacture and resistance to LVD of EGDN but with the high density and yeild plus lack of vapour pressure of NG... a

most excellent mix!

The composition of the main charge was 44% ETN, 36% EGDN/NG and just for kicks I thew in 20% 600 mesh german flake Al. I knew that this would lower

the brisance slightly but I have long since wanted to try aluminized explosives and everyone loves a BIG bang

Right.... thats enough for tonight... to be continued.... again!

[Edited on by Deceitful_Frank]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Great video Frank, your director skills are obviously much better than mine, hopefully pictures and more about the charge setup and result will

follow.

Offtopic: What does the crystal shape of ETN look like when recrystallized this way?

| Quote: | Originally posted by Microtek

Nitro-genes: When you spin your liners, how small can you make the non-conical part at the apex? |

I found a trick to make the cones as pointy as you want, even for liners as small as 15 mm diameter. I'm going to include a very detailled description

of how to produce good liners by spinning as there are some more helpfull things that I hadn't mentioned so far. I must say however that I noticed no

performance drop for liners having a large hemispherical part, in fact they seem to be somewhat more tolerant in jet formation towards errors in

symmetry and explosive homogenity.

For making the hemispherical part as small as possible:

First spin the liner until it is firmly attached to the mandrel. Then anneal the copper again and remove the contramandrel holding the liner against

the mandrel. This allows you to work on the tip with the working tool. It is difficult to describe precisely how to extend the hemisperical part into

a pointy cone, but it is important that you make rowing sweeps from the base of the hemispherical part of the cone towards the tip with a large amount

of pressure. The liner may become detached from the mandrel, rotating only on a part of the mandrel but this is normal.

When the tip of the cone is finished, clamp it very softly (else you will crush the tip of the cone!) again with the contra-mandrel and make some

sweeps over the entire liner to make sure it is perfectly symmetrical after working on the tip. Then it is very important to anneal the liner one more

time to remove any stresses in the metal that can disrupt jet formation, like the after annealing in the los alamos report. Then I usually take a

cutting tool to remove some of the base of the liner to make the base perfectly level after which I apply gentle pressure on the liner surface with

some fine grained sanding paper (600), and later steel wool to finish the surface. This removes any specks of copperoxide from annealing that you

press into the surface of the liner with the working tool. It is best to remove all oxide with some HCl after each annealing, but usually I'm lazy and

just use sanding paper and steelwool to remove the oxide dimpels from the liner surface while it spins in the lathe.

I've found a nice way to remove the oxide from the inside of the cone as well.  Take a thin strand of steelwool and put it between mandrel and liner, while you press the liner against the mandrel by hand. (with the strand of

steelwool in between) This does sand down the mandrel as well but it can be reshaped very fast with a large straight blade chisel. (Take care not to

touch the spinning mandrel with the chisel while it spins towards the chisel blade, it tends to ruin your mandrel and make your chisel stick into the

ceiling

Take a thin strand of steelwool and put it between mandrel and liner, while you press the liner against the mandrel by hand. (with the strand of

steelwool in between) This does sand down the mandrel as well but it can be reshaped very fast with a large straight blade chisel. (Take care not to

touch the spinning mandrel with the chisel while it spins towards the chisel blade, it tends to ruin your mandrel and make your chisel stick into the

ceiling  ) )

This may sound like a lot of work, but it actually takes about 15 minutes at most for every liner with all the tools ready, especially small liners of

15-17 mm can be produced very fast and consistent...

The result should look something like this, 15 mm diameter, 0.5 mm thick copper and an apex angle of about 55 degrees. I've made better ones btw, but

this one was the only one I had left for that same reason. They pierce little over 5 cm's of steel in combination with extra fine PETN + 15% PIB @

around 210 kbar, 2.5 CD standoff and a charge diameter of 16 mm ID and 17 mm OD (PVC adapter for 5/8 inch PVC tubing)...

[Edited on by nitro-genes]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

This is what the penetration of a such a small 17 mm diameter charge looks like. It penetrated through 5 cm of steel and only a few extra cm's further

into the soil.

Unlike with laminated cones is the penetration for two identical spun formed liners very consistent regarding the penetration depth. This is precisely

what I was looking for as well, because this allows you to take away one more uncertainty factor from the equation determining the performance of the

charge as a whole. Thus making the influence of things like detonation pressure, liner shape and thickness, etc, much easier to see...

[Edited on by nitro-genes]

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Thanks for the pointers nitro-genes.

I find that if I keep the annealing temperature down to just a faint hint of oxidation sets in (just a slightly darker copper sheen far below glowing)

the metal is less prone to tearing when I spin it. I usually don't have to reanneal before finishing, and I get a mirror finish just from using the

flat side of the tool.

What do you use for lubricating the spin? until now I've just used a paraffine candle and it seems to work OK.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Your method of annealing sounds good, the oxide coating is really annoying. I do the annealing with a butane gas burner, and right before the copper

starts to glow red hot the surface becomes covered with a layer of the black copper(II)oxide, which washes of pretty fast with 10% HCl. More annonying

is the red copper(I)oxide which is formed most likely because of reduction of the copper(II)oxide by the paraffin lubricant when annealed. It washes

of much more difficult...

Also use a piece of candle paraffin as the lubricant. Oils and other liquid lubricants make quite a mess when applied on the spinning mandrel...

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I wonder if using a block of graphite as the bearing tool

when spinning these cones could simplify things .

Some of the higher density stuff might be strong enough ,

especially if a slab of it was secured to a reenforcing backing of some sort .

Soapstone is another material that might work .

[Edited on 3-5-2007 by Rosco Bodine]

|

|

|

MRUD

Harmless

Posts: 10

Registered: 28-2-2007

Member Is Offline

Mood: No Mood

|

|

Impressing, very impressing nitro-genes.

If i hadn't seen it, i wouln't belive.

Have to learn much more. My best success was, penetrating 2cm steel with an 3cm diameter cone and 30g PETN.

http://img103.imagevenue.com/img.php?image=53646_DSCF0248_12...

http://img40.imagevenue.com/view.php?image=53656_DSCF0253_12...

Do you have the spec. of the cone?

Greetings

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

@ Rosco:

With bearing tool, do you mean the form or mandrel? One of the best materials that I used was the clear setting epoxy resin for preserving insects. I

used to use the yellowish quick repair epoxy, but it gets too hot for castings of the size needed, and becomes very brittle or cracks during

hardening, especially with too much hardener. The clear epoxy is VERY strong though and hardening takes much longer, thus less heat is produced. You

need a sharp chisel for shaving it into shape on the lathe and doesn't chip or wear down as fast as the quick repair epoxy. This makes it very

versatile as well as that the mandrel can be changed into different shapes and sizes very fast. I've been thinking about adding some metal oxide to

the epoxy to improve abrassion resistance, though it would ruin your chisels and cutting tools as well. If you want to make just one type of liner

this would be a good option though...

@MRUD:

2 cm is pretty good for one of the first charges.

The reason why it doesn't cut much deeper than that is because seen by your pictures there is no real jet formation, only some coppersplattering doing

the damage. I'm quite sure with some minor adjustments you could get some real jet formation and get through 5 cm as well!

You mentioned PETN as the explosive filling, but how did you use it? Did you use a binder, and was the PETN recrystallized? You really need the

explosive to be as homogenous as possible to get a good coherent jet. Using loose PETN and/or large crystals will give tiny variations in

accelleration of the liner surface disturbing the jet formation. If you would use PETN without recrystallization (when it is very fine, like flour),

and add exactly 20% of a binder I'm pretty sure you can go much deeper! For very fine PETN directly from the nitration you can use the sticky

ballbearing-greese as a good binder, alternatively you could use a binder made out of 1 part beeswax and 2 parts motoroil and melt that together.

Don't use less than 20% binder for your PETN and press it gently in the charge. With this setup you would use about 1.5 times charge diameter

standoff. It will make a large difference, given the rest of the charge is precisely assembled as well. If you manage to press it with binder to

around 1.3 it will also mean the difference between a detonation pressure of about 90 kbar (without binder at a density of 1) and 150! (with binder at

1.3)

[EDIT]

Stop fucking around Frank, we want those pictures, NOW!!!

The composition of ETN/EGDN/NG looks pretty dense and powerfull, how much of the ETN dissolved into the EGDN/NG? With PETN/NG there is not a lot of

dissolution going on, but with ETN it could form a sort of a gel by the looks of it...

[Edited on by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@nitro-genes

What I was thinking was a dry lube sort of material

as a bearing surface on the tool tip itself , the part

that otherwise can grab , gall , or groove the spinning

metal it relies on lubrication to prevent . Maybe graphited bronze . I was trying to think of something that could

bear against the copper while it is still *very hot* , even to the point of being heat softened , where it wouldn't take a lot of tool pressure at all

, that graphite would work . What I was thinking was a tool surface that could

work in applying a spinning technique to a hot forging

advantage , working at a temperature where the copper is actually heat softened , not just annealed ....to shorten the work . But the dry lube would

work against the cooler material in the finishing also .

Of course a steel mandrel and holder would be needed for

the hot forging/spinning combination part of my idea , where you would basically torch heat the spinning disk to the

softening point and then spin it down quickly while it was still soft .

[Edited on 3-5-2007 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

The annealing temperature for copper is too high I think to reach from friction heat only. You can get to 100-150 degrees C. at most with a large

amount of force applied. I've ruined one of my epoxy mandrels this way as it starts to soften considerably at these temperatures. Of course I could

repair the damage very quickly with a chisel and some sanding paper. The problem with a steel mandrel is that a lot of the heat would dissipate to to

the steel mandrel and contra-mandrel where the liner is attached to, as copper and steel are pretty heat conductive...

[Edited on by nitro-genes]

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I use a steel mandrel and Al counter-mandrel (my lathe is a metal working one). When I do anneal the liners during production, I do it while it is

still clamped and spinning - but as I mentioned I only soft anneal it; at those temps I don't have any problems with heat conduction.

It's good to hear that you think the spun formed liners perform uniformly, nitro-genes. It means that I will be able to carry out my original plan of

comparing the shaped charge effectiveness of different HEs at the 10 mm CD scale.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Could you throw in some pictures of your results? It would be really nice to see the results of your spinning efforts as well.

Spinning stuff is incredibly entertaining to do, I might try spinning some other stuff as well, just for fun. I'm working on a mandrel for EFP liners

now, but although someone was kind enough to provide me with some specifications for hemispherical based EFP liners, it is difficult to make it out of

the polyester mandrel. Does anyone know if there is a special working tool for on a lathe to make hemisphere like shapes?

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

This is an attempt to show some of my spun copper liners. I'm having some difficulties in getting it to work, so if someone could tell me what I'm

doing wrong I'd be grateful.

These are most of my cones (the ones that were good enough to call cones anyway) in rough cronological order from left to right, top to bottom. The

grid is 5 mm square, and all the circular blanks were 0.5 mm in thickness while the cones are a uniform 0.38 mm at the base. The Al ones were just

practice.

This is just a closer view of the last three cones. The rightmost one was a fully annealed one that was softer than I anticipated. Because of this, I

accidentally pinched it off by applying too much force.

As you can see, I get an ugly apex but I have started experimenting with your method nitro-genes, and I think I'll get the hang of it soon.

[Edited on 6-5-2007 by Microtek]

[Edited on 6-5-2007 by Microtek]

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Mightn't it be easier to spin close copper pipes to form the really small sized cones, I'm waiting for someone to try that. Maybe it will cause

problems with thickening of the apex?

Nitrogenes, thats exceptional work, congrats.

[Edited on 7-5-2007 by Axt]

|

|

|

gnitseretni

Hazard to Others

Posts: 283

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

i attached a small pfd file about metal spinning that i once stumbled on. It's not much but i thought i'd add it anyway in case its useful to someone

here.

Attachment: MetalSpin.pdf (149kB)

This file has been downloaded 2290 times

|

|

|

Microtek

National Hazard

Posts: 920

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

Axt: Thanks for the help with posting pictures, now I just need to learn to crop them a little better.

Nitro-genes: Could you provide details about the tool you use? I have a feeling that the tool may well be the most important factor in getting a good

and reproducible spin.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Microtek:

You could make pretty liners out of all the liners on the picture in the middle! Some irregularities at the apex like that don't really mater. Once

the liners are reasonably attached to the mandrel, remove the contra-mandrel, smooth the apex out by applying smooth strokes on it with the working

tool and you will have a good liner! When annealed the copper is soft enough to easily divide all the excess copper at the apex by applying some well

directed strokes...

For small liners you need a very small tool as well. Else you'll work on the entire liner surface at once, putting way too much pressure on the copper

when it is still only clamped by the contramandrel. When you start to press on the outer edge of the copper plate right away the workarm is much

longer than when you start to work on the middle only, so you create way to much force. As you can imagine there is only one way for the copperplate

to be pushed to, and that is towards the contramandrel, resulting in the copper excess near the contramandrel in your pictures. This will knock it off

the mandrell, or tear the metal. So you really have to start working near the tip of the cone first and work your way to the outsides. Because once

the copper nearest to the contra-mandrel (the tip of the cone) has become attached to the mandrel, this can't happen anymore because now the mandrel

supports the coppersheet as well. I would say that the tip of the tool would need to be about 4-5 mm wide maximum for these small liners, it will make

all the difference. For the larger liners I simply took a 10 mm diameter brass rod and sanded one of the edges off to an angle of about 30 degrees.

Be sure you make the tool not too thick either, else you cant reach the copper that is near the contramandrel...

So:

Small tool, work on the tip of the cone first untill it has become attached to the mandrel, apply less pressure, and make less strokes from the base

of the cone towards the apex...

Once you know it is like riding a bike, and it becomes quite enjoyable!

Type "metal spinning" on youtube and you'll see two good introduction movieclips about metal spinning.

http://www.youtube.com/watch?v=Gwrk0SwDJhI

One more thing: Most metal spinning lathes have a rotorhead with 3 "teeth" sticking out to clamp the mandrel. You probably allready know, but be VERY

carefull not to touch it with the working tool. I've made a large diameter end on my mandrel to shield them off and prevent the tool from accidentally

slipping of the mandrel into them...

[EDIT] Stumbled upon an incredibly usefull Chinese article about optimization factors for the design of EFP charges. No mathematical bullshit, but

real tables linking liner curvature and liner thickness to EFP speeds and performance! The tables are not chinese and in mm, so if anyone could make

something out of it...

Noone happens to be an expert in Chinese language I guess?

Anyway, here is is:

http://www.paper.edu.cn/download_feature_paper.php?serial_nu...

[Edited on by nitro-genes]

|

|

|

quicksilver

International Hazard

Posts: 1820

Registered: 7-9-2005

Location: Inches from the keyboard....

Member Is Offline

Mood: ~-=SWINGS=-~

|

|

| Quote: | Originally posted by Axt

Mightn't it be easier to spin close copper pipes to form the really small sized cones, I'm waiting for someone to try that. Maybe it will cause

problems with thickening of the apex?

|

I have attempted to spin-closed copper pipe for a variety of purposes and have been unsuccessful. There have always been a opening and if enough room

exists for the tool to cover the end, the pipe starts to bend.....has anyone tried this before and got a good closure?

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

The problem is that a tube is a very strong shape by nature, so I can imagine you would need a considerable amount of force to close it. The copper

pipe used for plumbing is rarely thinner than 1 mm which would require large diameter tubing to make effective liners regarding wallthickness.

Copper tubing that is used in heat exchangers like waterboilers etc is usually much thinner, if I'm able to find it I'll give it a try...

[Edited on by nitro-genes]

|

|

|

Axt

National Hazard

Posts: 861

Registered: 28-1-2003

Member Is Offline

Mood: No Mood

|

|

Hobby shops carry thin copper tubing, though its more common in brass I'll have a look see and find out. What I was envisioning was something

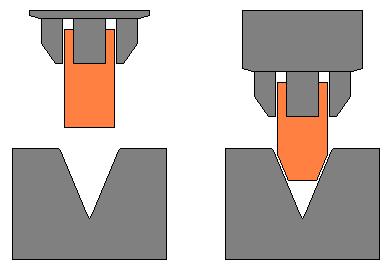

resembling the attached picture where a drill press is used to press the pipe into a die, should prevent bending.

There was a picture posted before of commercially available spin closed pipe ends so it can be done, just a matter of finding out how. There is US

patent 4627257, though its for a rather complex machine for spinning flat pipe ends.

EDIT: http://www.customtee.com/images/new_products/endcap_2.jpg

[Edited on 9-5-2007 by Axt]

|

|

|

gnitseretni

Hazard to Others

Posts: 283

Registered: 5-1-2007

Location: Colombia

Member Is Offline

Mood: No Mood

|

|

Hmmm....

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnu...

Ideal for making hemispherical liners?

|

|

|

| Pages:

1

..

18

19

20

21

22

..

68 |