| Pages:

1

2

3 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Garage Chemist:

I enjoyed your pictures of PCl3 production - congratulations on your success!

Your fume hood interests me as I am in the middle of making one myself. If yours is home made could you tell us a bit about it, i.e., 1) internal

dimensions, 2) materials of construction, 3) do you have a sliding window (I didn't see one), 4) air flowrate 5) type (constant air flow,

variable air flow, etc), 6) what you like and don't like about it, and 7) any recommendations to other builders.

I currently have my design for a hood enclosure out to a metal fabricator for bid. It will be made from 14 gauge (0.064" (1.6 mm) aluminum. (1.6 mm) aluminum.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Have you ever actually done chemistry experiments near aluminum?

That's sort of like making a high temp combustion boat out of magnesium.

Stainless steel maybe, but much better would be cement board made for ceramic tile backer, or epoxy fiberglass if weight is an issue.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

No I have not. But aluminum is used for all kinds of cookware, e.g., frying pans, dutch ovens, etc. I think the top of some stirrer/hotplates is

also aluminum. Granted these are heavier than 14 gauge sheet. What has been your experience?

I would like to use stainless steel but am trying to keep the cost down. I am planning on placing a ss catch pan in the bottom of the hood.

Cement backer board or even wallboard (gypsum) are attractive possiblities.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

| Quote: |

Have you ever actually done chemistry experiments near aluminum?

|

What kind of chemistry did you have in mind?

IMO this would be a great choise for a home lab hood, mainly due to low weight. One can always paint it if you're worried about corrosion.

I have used a hood thats made of wooden/Al pipes skeleton covered with polyethylene sheet, for a good while.. There was no noticeable corrosion on

aluminium. Although it all depends on how big is the load.. I tried to keep it low due to neighbours.

| Quote: |

I would like to use stainless steel but am trying to keep the cost down.

|

But Al is alot more expensive than steel. I'd guess that 0,5mm steel would be enough if it's mounted on somekind of support (skeleton.. or

how is it called).

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

Acids, alkalies, fertilizers, other salts, all cause corrosion on aluminum. Chlorides cause pitting and stress cracking in stainless steel. Portable

benchtop fumehoods are typically made of fiberglass. For best fire and chemical resistance I'd go with 1/4" cement backer board, maybe

coated with automotive or industrial epoxy. Asbestos board used to be the material of choice, except for hoods used for perchloric acid, which use

stainless steel to avoid buildup of explosive perchlorate salts.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

My fume hood is made of pressed wood plates (don't know the english word for "preßspanplatten" . .

The fan is simply the "dunstabzugshaube" from our old kitchen. It originally carried the steam produced when cooking outside of the house

through a vent pipe (so its intended purpose was similar to that of an actual fume hood). However, there was originally some kind of filter mat in it.

I removed it, and now it moves much more air than before because of less air resistance.

A hole had to be made in the wall of my garage in order for the vent pipe (PP sewer piping) to be put through.

The speed of the fans (it's actually two in one casing) is controllable in four steps. I don't know the flowrate, but it's not

exceptionally high.

There is no sliding window on it, the PMMA window is stationary.

More pics of my hood: http://versuchschemie.donau-it.de/topic,4457,-Mein+Abzug.htm...

My recommendations for other builders:

DO WHATEVER FLOATS YOUR BOAT.

You need to define the dimensions of the fume hood according to the type of apparatus you want to build and operate in there.

You can use whatever fan is available given that it moves enough air for you to feel safe from toxic fumes.

And don't try to attach any type of scrubber or filter to the air outlet. It will either not work or it will severely obstruct the air flow, I

promise you.

Instead, use a stronger fan to dilute the fumes.

And last but not least: don't put too much money into it. Better save some money for glassware. You will never be able to do real chemistry

without a ground- glass distillation setup. I always pity the people who say that they are doing "chemistry" and try to make, for example,

nitric acid without distillation or in an improvised still. Even a small still (mine has only 160mm condenser length and NS 14/23 on all joints) is

of extraordinary usefulness.

[Edited on 12-9-2005 by garage chemist]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you garage chemist. FYI I think the word you were looking for is "plywood."

I looked at the pictures - the lawn chairs and shrubbery off to the side is a nice touch.

Frogfot: I did some pricing for sheet metal this morning. The results for a 4'x10'x0.063" sheet:

stainless steel: $228

aluminum: $93

So for me aluminum is cheaper.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

That's a strange metal supplier. Mine takes money for kg of metal (plus some money depending on size of order), and Al is defineatly more

expensive by weight. I'm currently bying metals from local recycling center, they take only for kg prise.

| Quote: |

Acids, alkalies, fertilizers, other salts, all cause corrosion on aluminum.

|

The fumehood walls is normally in contact with minute amounts of corrosive things. Unless your reaction vessels explode often.

Anyway, it's best to paint any metal..

| Quote: |

And don't try to attach any type of scrubber or filter to the air outlet. It will either not work or it will severely obstruct the air flow, I

promise you.

|

Easy for you to say..

I live in an appartment house, and the neighbours can pretty much sence when I fart in my appartment..

[Edited on 13-9-2005 by frogfot]

|

|

|

Eclectic

National Hazard

Posts: 899

Registered: 14-11-2004

Member Is Offline

Mood: Obsessive

|

|

DetMar Bilge Blower

Ok, I've gotten two of these to experiment with. They are basically a permanet magnet 12 VDC motor with fan mounded inside a 4" (100 mm)

molded pipe section.

The motor can be voltage throttled, and I suspect can be driven from 115 VAC with a simple circuit consisting of a capacitor, resistor, and diode.

This could be controlled with a standard lamp dimmer. If the tabs for attaching flex hose are cut off, there is a good fit with 4" PVC SWD drain

pipe (only $5 or so for 10 feet). More later, maybe with photos if any one is interested.

[Edited on 14-9-2005 by Eclectic]

|

|

|

TheBear

Hazard to Self

Posts: 78

Registered: 17-10-2002

Location: Sweden

Member Is Offline

Mood: distilled

|

|

I'm constructing a new fume hood and I would really appreciate any suggestions for improvements. It's made out of galvanized steel plates and

aluminium bars:

I'm thinking of mounting cement backer boards on the inside of the walls and on the bottom and "ceiling" of the hood as well. The cement backer board

is "minerit" board and is supposed to be water resistant. But any acid spills would probably ruin it in no time at all. So I think I would like to

paint them. Expoxy paint was suggested by Eclectic. Is it compatible with minerite, does it provide good adhesion (pH 11 on the surface is stated for

minerit, and "alkali resistant paint" is recommended). What about silicate based paints? Would that improve acid resistance of the cement based board?

Im also thinking of of just painting the galvanized steel plates, or perhaps doing both? What do you suggest?

Here is some data for minerit: http://www.americanfibercement.com/minerit.html

By the way, just ordered some plexiglass to be cut up for a sliding windows and a fixed window. When finnished, I could upload a picture of the fume

hood if there is any interest.

[Edited on 20-2-2006 by TheBear]

[Edited on 20-2-2006 by TheBear]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I have had my fume hood in frequent use now for 4-5 months so feel that I can comment on its performance.

1) Air flow is strong, but not too strong and seems to be well distributed.

2) Because I have good airflow I feel that the choice of wall and ceiling material is not so important. Contaminants are quickly diluted and carried

out of the enclosure. I see no evidence of corrosion on the walls or ceiling.

3) Yesterday I inadvertantly forgot to turn on the blower while dissolving tacks in HCl at boiling. My 1000 mL beaker was covered with a watch glass.

I went to watch TV for an hour or so. When I went out to the garage the air was so bad that I could barely get to the hood to turn on the blower and

cut the heat. After about an hour with the blower on it was as if nothing had happened. No evidence of corrosion on the epoxy painted walls/ceiling.

4) I really like the stainless steel pan I use for the floor of the hood. This has rounded edges and the walls are 25mm high. I'm always spilling a

little reagent on this but it cleans up easily and shows almost no corrosion.

Comments on your design:

1) I would tend to not install the backerboard but paint the galvanized steel with epoxy instead. Simpler and easier to clean.

2) Is this big enough? Mine is 1.33m wide which is plenty big if I didn't store all my liquid reagents in it along the sides. With this storage it

is just big enough for any complex glassware setup. And my glass is only 19/22 taper size.

3) Give some thought to your airflow pattern. Will you be installing any baffles to direct flow. What will be your face velocity. Will it be a

constant volume type or is airflow restricted when you change position of the window?

4) How does air get into your room when the blower is running? I installed a screened, louvred vent (~ 30cm x 60cm ) that vents into my house attic

at the peak. Outside air then comes in through the soffet vents, travels through the house attic, and then through the louvred vent into the garage.

If I stand below that louvre I can feel the airflow when the blower is running. But I am moving 400-500CFM. If you are using a much smaller blower

this may not be necessary.

No matter what you do you will be much better off than not having any hood.  If

you have any questions please fire away! If

you have any questions please fire away!

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Flip

Hazard to Others

Posts: 116

Registered: 7-12-2005

Member Is Offline

Mood: No Mood

|

|

Once in a chem lab I saw a "fume hood" that was really just a 4x3x2 plastic box with some large hose attachments, open to the front with a plastic

screen that slid up and down. Looked lightweight and portable. I'll see if I can't make a phone call tommorow and get a brand name on it, but it

didn't look too expensive, and you could have a ventilation system set up with different types of fans that might blow the vapors into a bucket of a

solution or even out a window : )

Has anyone seen what i'm talking about?

|

|

|

TheBear

Hazard to Self

Posts: 78

Registered: 17-10-2002

Location: Sweden

Member Is Offline

Mood: distilled

|

|

Thanks for your comments Magpie. I've reconsidered since reading your post. I won't or will at least wait with installing additional boards covering

the walls. For now I might actually use it "as is" and see how things develops, if any leakage is seen (all sides aren't completly sealed) or if the

steel starts corroding.

|

|

|

Flip

Hazard to Others

Posts: 116

Registered: 7-12-2005

Member Is Offline

Mood: No Mood

|

|

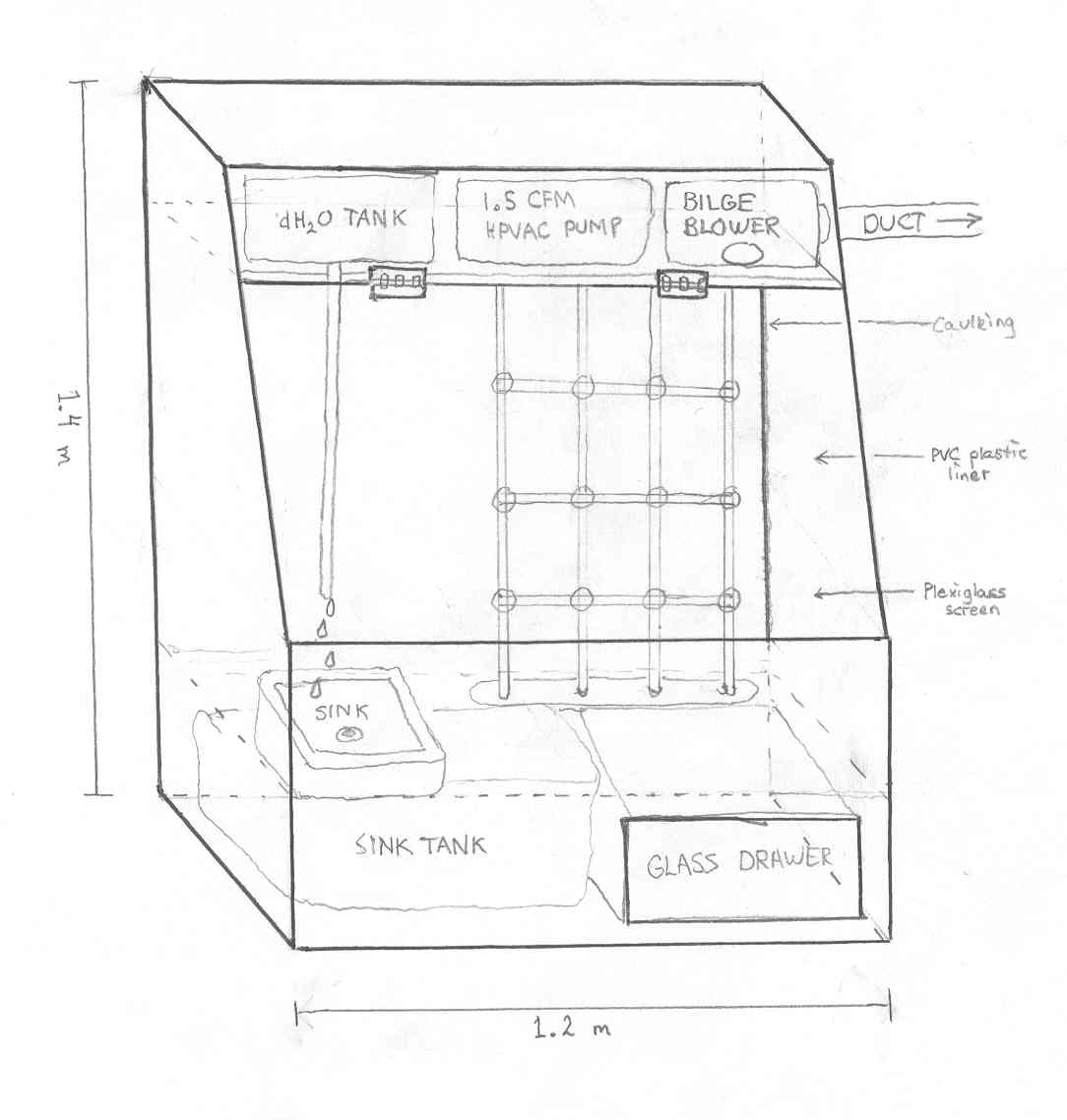

Here is something I sketched up a couple of days ago. I'm going to build it out of wood, and use an epoxy paint or PVC sheeting on the inside.

|

|

|

TechnologicallyRetarded

Harmless

Posts: 13

Registered: 14-8-2009

Member Is Offline

Mood: No Mood

|

|

These plans are looking great! I too really need to get one of these up and running.

In my rudimentary drawings, I stop when I reach 'duct'.

Do you have any plans for scrubbing fumes - not for the 'eco-points', but for keeping neighbors alive - or do you plan to let them flow into the

surroundings?

I'm not going to lie: my main concern is safe removal of NOx. Are there any extra bits I would need to add for that?

|

|

|

MeSynth

Hazard to Others

Posts: 107

Registered: 29-7-2011

Member Is Offline

Mood: http://www.youtube.com/watch?v=5ZltqlVuDIo

|

|

Quote: Originally posted by Flip  | | Here is something I sketched up a couple of days ago. I'm going to build it out of wood, and use an epoxy paint or PVC sheeting on the inside.

|

That picture kicks ass....

|

|

|

MeSynth

Hazard to Others

Posts: 107

Registered: 29-7-2011

Member Is Offline

Mood: http://www.youtube.com/watch?v=5ZltqlVuDIo

|

|

for a really fast temporary fume hood all you need is a card board box, a bathroom vent fan from home depot, some aluminum ducting, some aluminum

tape, some painters plastic (used to catch paint), and some glue.

after your done all you have to do is remove the ducting from the fan and cut out the vent fan then jump on it repeatedly and toss it in the trash.

the painters plastic is used to line the inside and to act as a semi see through air barrier to allow for efficient air flow.

THE BEST think you can do when it comes to fumes is use a distillation apparatus. Instead of boiling off solvents you distill them off in a closed all

glass setup with glass joints with a tube connected to vacuum nipple directed toward some kind of vent or hanging out of a window if your desperate.

As opposed to the guy who boils off a liter of volatile hydrocarbons and stinks up his entire block with it. You know who you are... *serious face*

To go the extra mile you can pass the fumes or gases through scrubbing solution and/or passing the fumes or gasses through an activated carbon filter.

The scrubbing solution and carbon can then be taken care of by your cities hazardous waste program or dumped into the middle of your cities busiest

intersection. The latter is not advisable...

|

|

|

Un-Sub

Harmless

Posts: 7

Registered: 30-10-2011

Member Is Offline

Mood: No Mood

|

|

My Designs

These are the designs I will be Fabricating soon! Let me know what you people think!

Will it work?

This is the air scrubber I will be using.

Air Scrubber

this is the design for my Fume hood.

Attachment: IMG_0001.pdf (798kB)

This file has been downloaded 865 times

[Edited on 30-10-2011 by Un-Sub]

This is the design on my exterior diffuser.

Attachment: IMG_0002.pdf (591kB)

This file has been downloaded 806 times

[Edited on 30-10-2011 by Un-Sub]

[Edited on 30-10-2011 by Un-Sub]

[Edited on 30-10-2011 by Un-Sub]

|

|

|

Un-Sub

Harmless

Posts: 7

Registered: 30-10-2011

Member Is Offline

Mood: No Mood

|

|

OK. I got my photos converted and uploaded. I need someone who knows something about fume hoods and diffusers to take a look and give me some feed

back!

The hood will be small, ( 24"H x 24"D x 36"W ) I believe that is 12³f, and the blower pushes 160³f/m. The shell will be 1/8" steel plate and the

doors and view top will be plexiglass.

Do you think this diffuser will work, or will it be a problem with the fumes combining with the water and creating acids and such?

Now remember, this will be after the fumes have passed through an 8" diameter activated carbon fiber filter!

So, what do you guys think?

Will it work?

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

Will it work for what? You really need to say what you're trying to do. If you're trying to

set up a distillation rig with two feet of vertical clearance, you'll have, er, trouble.

Fume hoods are ventilation devices. With 160 cfm, you're hardly moving much air. What's the face velocity with the doors open? What's your dilution

ratio for an expected gas generation "event" within the hood?

Remember that particles can be generated within the hood. Most hoods exhaust particles from the hood along with the rest of the gas stream.

Filtration, if needed, happens later. What you've got set up looks certain to clog in many plausible circumstances.

As for the scrubber, it's all about contact time and surface area. That means you want tall and narrow over short and wide. It's easier to scrub

arbitrary atmospheres with mists rather than bubblers.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Quote: Originally posted by garage chemist  |

And don't try to attach any type of scrubber or filter to the air outlet. It will either not work or it will severely obstruct the air flow, I promise

you.

Instead, use a stronger fan to dilute the fumes.

|

I think that is good advice.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Un-Sub

Harmless

Posts: 7

Registered: 30-10-2011

Member Is Offline

Mood: No Mood

|

|

@Watson.Fawkes

I am not sure what it will be used for, I am new to chemistry and can't say what exact experiments will be done in it. Since I know jack about

chemistry I will be starting on Youtube replicating some of NurdRage's experiments. It will not be used for distillation.

As for the face velocity, I don't know, it hasn't been built or the parts bought yet. I am trying to figure out what will work w/o spending a fortune.

Like...a couple hundred bucks!

I can't just dilute the fumes with high air flow, I also have to get rid of the smell, I live in an apartment complex.

As for the dilution ratio for an expected gas generation "event" within the hood......ummm....what?

As for the clogging problem, what would you suggest using and at what point in the exhaust system?

As for the mist instead of a bubbler, what about both? Would it work to add a water pump into the box with a hose running up top to a mist head?

@Magpie

I have to have some kind of filtration, my lab is going to be built on my Apartment patio, I don't want to render my neighbors unconscious or worse

and I have to get rid of the smell!

Tell me where I'm going wrong and what to do to fix it!

[Edited on 1-11-2011 by Un-Sub]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

It is possible to use a scrubber, industry uses them commonly. But they must be carefully designed, or expect a lot of trial and error until you get

the system balanced. A packed scrubber will flood, just like a distillation column, if the gas velocity is too high.

You would have to mostly know accurately what your air flow rate will be. 160cfm is a nominal value at some assumed pressure drop. This not rocket

science but some engineering is involved. Otherwise you could be in for some lengthy and expensive trial & error until you get the scrubber sized

correctly. That is why my first advice was to avoid it.

Also, do you plan to operate with the doors closed and just use the glove ports, or will you have the doors open? Your answer will affect the flow

rate significantly.

In the winter your exhaust is going to be a horribly visible stream of fog, like a clothes dryer exhaust. Are you OK with that?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Un-Sub

Harmless

Posts: 7

Registered: 30-10-2011

Member Is Offline

Mood: No Mood

|

|

@ Magpie

Would the scrubber be better if it were installed vertically instead of horizontally? What do you think the minimum airflow should be for 12 cubic

feet of space? I can purchase a different scrubber that is longer and more narrow if it would be better.

what about something like this:

ebay air scrubber

I plan to use it with gloves and with the door open, depending on the experiment, but I can put in more intake vents and make them larger if needed.

How many do you think I would need and how large?

As I stated earlier, I have not even started on this project yet. I want to make sure everything is right before I start the fabrication process!

As for the exhaust being seen, that doesn't matter at all, as long as the air is clean and doesn't smell bad!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

That is wise.

Here's some documents you should review:

http://www.s-k.com/pages/pro_07_02.html

look at the bulletin 7S toggle.

Don't bother with the ejector, but look at the packed column and the "venturi scrubber" designs - just for ideas.

http://ehs.columbia.edu/FinalLabDesign4-09.pdf

Note the statement at 7.4

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

| Pages:

1

2

3 |