| Pages:

1

2 |

ChemistryGhost

Hazard to Others

Posts: 113

Registered: 5-7-2012

Member Is Offline

Mood: Supercooled

|

|

Can cinnamic acid be obtained from cinnamaldehyde by reacting with aqueous sodium hydroxide. Would it yield sodium cinnamate and cinnamyl alcohol?

"Imagination is more important than knowledge" ~Einstein

|

|

|

Dr.Bob

International Hazard

Posts: 2734

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ChemistryGhost  | Can cinnamic acid be obtained from cinnamaldehyde by reacting with aqueous sodium hydroxide. Would it yield sodium cinnamate and cinnamyl alcohol?

|

I am guessing that would yield a mess. Aldehydes are one of the easiest things around to oxidize. Just leave the bottle open to the air a while,

and it will be partially oxidized to the acid. If you want to speed it up, you can use any strong oxidant, Jones, likely permanganate, or even just

bubble air through the aldehyde. It is hard to seal a bottle of aldehyde well enough to prevent this from happening even due to traces of air.

|

|

|

Amos

International Hazard

Posts: 1406

Registered: 25-3-2014

Location: Yes

Member Is Offline

Mood: No

|

|

Esters. Esters that smell nice. Maybe some more practical things too...

|

|

|

bbartlog

International Hazard

Posts: 1139

Registered: 27-8-2009

Location: Unmoored in time

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ChemistryGhost  | Can cinnamic acid be obtained from cinnamaldehyde by reacting with aqueous sodium hydroxide. Would it yield sodium cinnamate and cinnamyl alcohol?

|

Cannizzaro Reaction. No. Cinnamaldehyde has a hydrogen in the alpha position and therefore is not part of the scope of this reaction.

Oxidation should work, you just have to figure out which reagent would minimize attacks on the double bond and arene ring. Basic reaction conditions

seem unlikely to be favorable ... maybe one of these two:

http://en.wikipedia.org/wiki/Pinnick_oxidation

http://dx.doi.org/10.1002/cjoc.200890199 (but I don't trust this paper)

The less you bet, the more you lose when you win.

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by bbartlog  | Quote: Originally posted by ChemistryGhost  | Can cinnamic acid be obtained from cinnamaldehyde by reacting with aqueous sodium hydroxide. Would it yield sodium cinnamate and cinnamyl alcohol?

|

Cannizzaro Reaction. No. Cinnamaldehyde has a hydrogen in the alpha position and therefore is not part of the scope of this reaction.

|

*buzzer*

Cinnamaldehyde -is- subject to the Cannizzaro reaction as it is a non-enolizable aldehyde. It may have a hydrogen on the alpha-position, but keto/enol

tautomerism is never going to make an allenyl alcohol from the vinyl proton.

Of course, you have a competing retro-aldol condensation to benzaldehyde and acetaldehyde. detailed elsewhere on this site. Refluxing carbonate

solution works best if this is desired, IIRC. Room-temp grinding with NaOH or KOH would probably best promote the Cannizzaro.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

DraconicAcid

International Hazard

Posts: 4333

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

I made some methyl cinnamate. A solid at room temperature, which really didn't smell like anything to me.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I made ethyl cinnamate from cinnamic acid by mimicing a procedure in Pavia et al for methyl salicylate. According to my notebook: "Ester

had a rich fruity smell."

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Texium

Administrator

Posts: 4581

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Maybe it will smell stronger if dissolved in some methanol. I wouldn't imagine that the pure solid ester would have much of an odor to it.

Although I imagine that at some point in the production of it you would have had such a solution that you would have smelled, so perhaps not.

|

|

|

DraconicAcid

International Hazard

Posts: 4333

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Tried that. Even put some on a filter paper and waved it under my students' noses to see if they could detect anything. Nope.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Pumukli

National Hazard

Posts: 705

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Hm. Last year someone posted a report on an odorless raspberry ketone batch. Now this odorless cinammic esther. Doesn't it ask for a deeper

investigation?

|

|

|

zed

International Hazard

Posts: 2283

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

I would imagine Hydrogen Peroxide would perform this oxidation nicely. Or not.

I doubt that low concentration H2O2 would have enough punch to effect that double bond. Though maybe. Performic acid surely would.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Over the last few days I made another batch of cinnamic acid per Brewster (exp 71). Per procedure I used a paraffin bath to hold a temperature of

175°C for 7hrs with the help of a PID controller. Again, there was a massive amount of undissolved NaOAc. I still suspect this is a mistake by

Brewster, ie, charging so much NaOAc (12g). The benzaldehyde charge was 10.1ml, and Ac2O 11ml.

The yield was 5.7g (Brewster 9g) for a %yield of 38.5%. This is much better than my previous yield of 25% (see upthread).

I was fastidious in my lab technique but my homemade benzaldehyde and pyridine are several years old, so am surprised by the better yield. MP was

134°C per literature.

[Edited on 12-6-2017 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

DraconicAcid

International Hazard

Posts: 4333

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Quote: Originally posted by DraconicAcid  | | Tried that. Even put some on a filter paper and waved it under my students' noses to see if they could detect anything. Nope.

|

Just following up on this- I found that if I put a bit of the solid in a beaker of warm water, it smelled nicely of strawberries.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Chemi Pharma

Hazard to Others

Posts: 349

Registered: 5-5-2016

Location: Latin America

Member Is Offline

Mood: Quarantined

|

|

A mild oxidant to obtain aldehydes or acids from alcohols and acids from aldehydes is nickel peroxide, or nickel oxide hidroxide, made from nickel

salt and bleach.

It's an OTC procedure to produce cinamic acid from cinnamaldehyde or cinnamyl alcohol, among an extense row of aldehydes or acids from it's alcohols

or aldehydes, depends upon wich enviroment to use:

Alkaline aquous enviroment afford acids salts from alcohols and aldehydes and anhydrous organic solvents enviroment such as benzene, ether,

dichlorometane or petroleum ether gives aldehydes from alcohols.

Although this method gives poor yields starting from aliphatic saturated alcohols, the yields increases with benzilic and insaturated alcohols.

The studies sais also that low temperatures helps the oxidation, by this method, of benzilic alcohols with aliphatic chain, like 2-phenetyl alcohol

and 3- phenylpropyl alcohol into the respective acids withouth the cleavage of the methylenic groups adjacent to the benzilic ring, like happens with

common oxidating agents as KMnO4, Jones reagent, persulfate, oxone or peroxides.

Great way to afford kilos of phenyl acetic acid from the common and cheap 2-phenetyl alcohol, sold at perfumary fragrance stores.

I'm bringing below two papers attached that studies the mechanims of the reactions and show examples how to exactly produce cinnamic acid from cinamyl

alcohol and cinnamaldehyde in excellent yields at the experimental section:

Attachment: alcohol Oxidations with nickel peroxide (NICL2 + NAOCL).pdf (567kB)

This file has been downloaded 602 times

Attachment: Alcohol Oxidation to acids with NiCl2 + hypochlorite.pdf (653kB)

This file has been downloaded 650 times

|

|

|

Loptr

International Hazard

Posts: 1348

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

I am in the middle of moving and can't test this out since everything is packed away, but based on some reading about the oxidation of aldehydes

through their hydrates, wouldn't it be feasible to prepare cinnamic acid using a modification of this synthesis of coumarin? Is an actual oxidizing

reagent actually needed for this reaction?

Replace the chlorosulfuric acid with p-toluenesufonic acid. Addition of the p-toluenesulfonic acid to the cinnamic acid shouldn't take place, and

coumarin won't form.

| Quote: |

Synthesis of coumarin

This reaction was conducted by adopting method from Sudarma.

To stirred solution of cinnamaldehyde (1) (1003 mg, 7.8mmol) in dichloromethane (20mL) was added chlorosulfuric acid (2mL) drop by drop. The solution

was stirred at room temperature for 30 min then refluxed for 15 min. The solution was evaporated and water (10mL) then added, basified to pH 8 with 1M

sodium hydroxide, then extracted with dichloromethane. The organic phase was dried and evaporated to dryness to give brown gum (685mg).

TLC and GC-MS analysis showed coumarine (44.63%).GC-MS: M+ .146, cal for C9 H6 O2. Major fragments: 118 (base peak), and 65 (Figures 3 & 4).

|

[Edited on 28-3-2019 by Loptr]

"Question everything generally thought to be obvious." - Dieter Rams

|

|

|

DraconicAcid

International Hazard

Posts: 4333

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

You mean this paper? lupinepublishers.com/chemistry-journal/pdf/AOICS.MS.ID.000144.pdf

I don't know how reliable their results are, but their proposed mechanism is crap. They show "scheme 1" for the oxidation of cinnamaldehyde to

cinnamic acid by the addition of a hydroxide ion to the carbonyl, and then a hydride ion just "falls off" with no oxidizing agent. You need an actual

oxidizing agent.

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Loptr

International Hazard

Posts: 1348

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

Quote: Originally posted by DraconicAcid  | You mean this paper? lupinepublishers.com/chemistry-journal/pdf/AOICS.MS.ID.000144.pdf

I don't know how reliable their results are, but their proposed mechanism is crap. They show "scheme 1" for the oxidation of cinnamaldehyde to

cinnamic acid by the addition of a hydroxide ion to the carbonyl, and then a hydride ion just "falls off" with no oxidizing agent. You need an actual

oxidizing agent. |

Yeah, that is the paper that grabbed my interest. I understand the proposed mechanism is crap, and why I didnt post the actual paper. However, I do

know how sensitive aldehydes are to oxidation, so I was curious if it was possible for the oxidizer to be oxygen from the air at reflux temperatures

in this case.

Of course the oxygen is going to oxidize the aldehyde, but is this effective?

[Edited on 28-3-2019 by Loptr]

"Question everything generally thought to be obvious." - Dieter Rams

|

|

|

DraconicAcid

International Hazard

Posts: 4333

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Not if you actually want it to. If you want your cinnamaldahyde to stay pure, then of course it will oxidize to the acid. If you're trying to

oxidize it to the acid, it will just sit there thumbing its carbonyl at you. I tried several different oxidants before settling on sodium chlorite

(see the previous page of this thread, where I'm told it's the well-known Pinncik reaction and that I was doing it wrong).

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Loptr

International Hazard

Posts: 1348

Registered: 20-5-2014

Location: USA

Member Is Offline

Mood: Grateful

|

|

Quote: Originally posted by DraconicAcid  | | Not if you actually want it to. If you want your cinnamaldahyde to stay pure, then of course it will oxidize to the acid. If you're trying to

oxidize it to the acid, it will just sit there thumbing its carbonyl at you. I tried several different oxidants before settling on sodium chlorite

(see the previous page of this thread, where I'm told it's the well-known Pinncik reaction and that I was doing it wrong). |

Yes, I am familiar with your work on cinnamaldehyde oxidation with sodium chlorite. I have done this reaction myself as well. Very simple.

I was also thinking of trying out the NiCl2/NaOCl method posted here recently, too.

How were you doing it wrong?

"Question everything generally thought to be obvious." - Dieter Rams

|

|

|

DraconicAcid

International Hazard

Posts: 4333

Registered: 1-2-2013

Location: The tiniest college campus ever....

Member Is Offline

Mood: Semi-victorious.

|

|

Apparently I was using far too much hydrogen peroxide. But, hey, it still works for the majority of my students, and if it isn't broken, why fix it?

Please remember: "Filtrate" is not a verb.

Write up your lab reports the way your instructor wants them, not the way your ex-instructor wants them.

|

|

|

Fery

International Hazard

Posts: 1016

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

I did the same synthesis as Magpie and Waffles SS, just without pyridine.

The catalyst base I used was Na acetate, no need to use pyridine. K acetate should be better as K cinnamate is better soluble than Na acetate. Neither

me achieved the yield claimed in literature.

At first I post all links and info I had available, then my experiment itself in the following post

https://webcache.googleusercontent.com/search?q=cache:MsU4k3...

https://labmonk.com/synthesis-of-cinnamic-acid-from-benzalde...

benzoic acid (contaminant) solubility in water 1.7 g/L (0 °C) 2.7 g/L (18 °C) 3.44 g/L (25 °C) 5.51 g/L (40 °C) 21.45 g/L (75 °C) 56.31 g/L (100

°C)

route from benzaldehyde and ethylacetate into ethyl cinnamate using sodium+absolute ethanol (very likely the base is Na ethoxide):

http://orgsyn.org/demo.aspx?prep=cv1p0252

http://orgsyn.org/Content/pdfs/procedures/cv1p0252.pdf

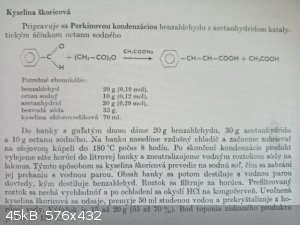

here look for page 181, chapter 4.7.7 Perkin reaction, this seems to be superior source for this synthesis with a lot of practical +

explanation, if you would like to read only 1 source from all here available, read this one

https://www.pdfdrive.com/advanced-practical-medicinal-chemis...

https://www.pdfdrive.com/download.pdf?id=41004348&h=ebab...

I'm attaching the book for case it will disappear

Attachment: Advanced Practical Medicinal Chemistry ( PDFDrive.com ).pdf (3MB)

This file has been downloaded 551 times

|

|

|

Fery

International Hazard

Posts: 1016

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

To 250 ml RBF (perhaps 100 ml is better, less air, less benzaldehyde oxidation to benzoic acid, on the other hand the reaction was quite spattering so

250 ml volume helped here a bit) was placed 20 g benzaldehyde (0,188 mol) + 30 g acetic anhydride + 10 g powdered anhydrous Na acetate (12 g K acetate

should be better). Condenser attached (air condenser should be enough but I used Claisen condenser with water circulation) and closed with drying tube

filled with anh. CaCl2. The flask was heated on oil bath warm 180 C for 8 hours (T varied between 175-185 C, variation does not have significant

impact on the reaction as the temperature inside flask depends on refluxing temperature inside). Still warm reaction mixture was poured into 200 ml of

cold water in 1 L beaker (do not allow the product to cool down in the flask as it solidifies) and the flask was washed with little of boiling water

which was added into the beaker too. To the beaker was slowly added concentrated solution of 87 g Na2CO3 . 10 H2O in water with CO2 evolution -

cinnamic acid neutralized to litmus indicator paper. NaOH cannot be used (Cannizzaro, unreacted benzaldehyde would produce benzoic acid and

contaminate the product). It was poured into 1 L flask, volume adjusted to 600 ml and unreacted benzaldehyde was steam distilled out, approx 250 ml of

distillate collected from which recovered 6,1 g benzaldehyde as bottom layer (wet weight, not purified further), most of it was in first 100 ml of

distillate, then slightly turbid distillate came from condenser but after 250 ml the turbidity was very small and no scent of benzaldehyde. As

cinnamic acid is in Na salt that prevents it from steam distilling.

Volume in flask adjusted to 400 ml, heated to boil and immediately very quickly filtered using heated funnel. On cooling down Na cinnamate tends to

crystallize (perhaps it could be purified in the form of its Na salt). 60 ml of 35% HCl added into hot solution (to congo red indicator) at which the

cinnamic acid precipitated. The volume was adjusted with water and heated to boil so all the product dissolved (1400 ml total volume). Then it was

slowly cooled down to room temperature and then put into fridge overnight at 4 C. Crystals obtained in a form of lustrous leaves, vacuum filtered,

they had a volume of approx 25 ml on the sintered glass funnel. Recrystallized from 1400 ml of boiling water, now the crystals in very fluffy form,

with a total volume of approx 150 ml. Air dried on filter paper until the weight stopped to cease (man, 5 days !!!), then packed into 50 ml vial

pressing crystals by a spoon.

Yield 11,4 g (0,077 mol = 41%)

m.p. 134-135 C.

The benzaldehyde used for the reaction should be free of benzoic acid (contamination of the product). It was purified by washing with solution of

Na2CO3, drying with anh. Na2SO4, vacuum distilled (vacuum is preventing oxidation to benzoic acid).

But according the solubility of benzoic acid, 5 g of benzoic acid could be removed from the product in almost 3 L of water used for 2 crystallizations

as 1 L of water dissolves 1,7 g of benzoic acid at 0 C.

Solubility of cinnamic acid is only 0,5 g in 1 L of water at 25 C (better soluble in boiling water).

the method which I used from my chem book (sorry, it is not in eng)

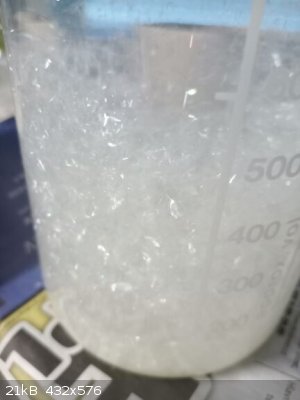

reaction (the oil in bath is very old and dark)

reaction done

getting rid of unreacted benzaldehyde by steam distillation

Na cinnamate in solution prior acidfication with HCl

first crystallization

|

|

|

| Pages:

1

2 |