| Pages:

1

2

3

4

..

7 |

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

It looks as though the product recrystalized from ethanol will have at least one molecule of ethanol of crystalization... the commercial form is

(according to Commercial Organic Analysis) the monohydrate. I wonder what form it is in if recrystalized from methanol.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Sounds like a good idea.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

BTW Perrin/Armarego et al. 7th ed.'s full entry:

Sodium ethylsulfate [546-74-7] M 166.1. Recrystallise it three times from MeOH/Et2O and dry it in a vacuum. [Beilstein 1 H 326, 1 I 164, 1 III 1317, 1

IV 1325.]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

That won't take long. I guess I'll pick up some ether on my way to the lab....

|

|

|

byko3y

National Hazard

Posts: 721

Registered: 16-3-2015

Member Is Offline

Mood: dooM

|

|

JJay, alkyl sulfates are extensively researched compounds, because they are surfactants - unlike a regular carboxylic acid salts, alkyl sulfates of

calcium and magnesium are water soluble, thus alkyl sulfates retain their surfactant activity in a hard water.

Pretty much the only way of purification (already mentioned) is to recrystallize the alkyl sulfate from alcohol-ether, although sodium sulfate

admixture is not a problem because of low solublity in ethanol (0.4-0.5 g/100g), as well as sodium bisulfate is insoluble, provided the alcohol is

anhydrous (dehydrated within reaction by Na2SO4). The reason to perform crystallization is to remove traces of inorganic sulfates and salts of other

metals.

Quote: Originally posted by JJay  | | It looks as though the product recrystalized from ethanol will have at least one molecule of ethanol of crystalization... the commercial form is

(according to Commercial Organic Analysis) the monohydrate. I wonder what form it is in if recrystalized from methanol. |

Alkyl sulfates are relatively stable at basic ph, they are even more stable in solid basic form.

Ethanol can be removed by vacuum or boiling (not higher than 100 °C).

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

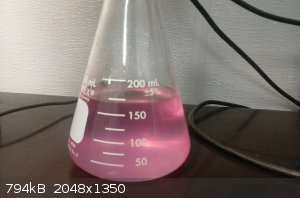

I got delayed yesterday, and right now, I am distilling off the ethanol. I haven't seen any crystals form yet, so it looks like sodium ethyl sulfate

may be highly soluble in ethanol. As the solution becomes more concentrated, it is turning pink due to a few drops of phenolphthalein indicator that I

added when I was neutralizing the ethylsulfuric acid (the phenolphthalein probably wasn't necessary and hopefully won't be too hard to remove).

Sodium ethyl sulfate is a supposedly rather nonhazardous detergent-like product with a sweet taste, but I'm not going to verify the taste. There is a

smell that is reminiscent of laundry detergent near the distillation apparatus.

Update: I've reduced the ethanol solution to around 170 mL, and it appears to be pretty concentrated and is likely anhydrous. I don't have time to

finish the work up right now but hopefully will in the next couple of days.

[Edited on 4-1-2016 by JJay]

|

|

|

byko3y

National Hazard

Posts: 721

Registered: 16-3-2015

Member Is Offline

Mood: dooM

|

|

I think you gonna need a vacuum if you want to obtain completely ethanol-free crystals, because ethyl sulfate does not seems to form crystals easily,

while vapor pressure at low concentrations is proportional to concentration.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I have a high-vacuum pump and a water aspirator. I am pretty sure it is possible to drive off nearly all of the ethanol with boiling water

temperatures, but recrystalizing from methanol/ether should do it. The question then is whether there is methanol in the crystal lattice.

I am currently working on constructing a new lab and will finish this experiment when it is functional.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

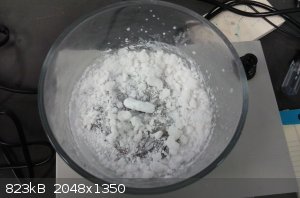

I haven't finished building my lab yet, but I figured I would start the workup. I distilled off the remaining ethanol and discovered that the solution

contained more water than I had expected. So I distilled off the water until crystals started to form, after which I transferred the solution to a

dish and warmed it gently to drive off the remaining water. The sodium ethyl sulfate precipitated as flakes.

This is the crude, slightly wet product. I will have to finish building my lab before I do the final purification.

[Edited on 19-1-2016 by JJay]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Today I heated about 100 grams of crude sodium ethyl sulfate in 450 mL of methanol with stirring. This formed a cloudy suspension... I suspect the

contaminants are sodium bicarbonate and sodium sulfate, but I don't really know how much contamination there is, and I'm not really sure how much

methanol to use.

This suspension is extremely hard to filter... the suspended particles form a layer on the filter that is almost impermeable, and the filtrate quickly

gels in the flask under vacuum.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Sounds like you need more solvent. Hot solvent.

BTW my earlier comments were unrelated to where sodium bisulfate is the source of sulfuric acid; just the textbook route, where step 2 is removal of

sulfate with CaCO3. It's a tedious step if you're making a lot, but when done carefully, everything else is simple.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

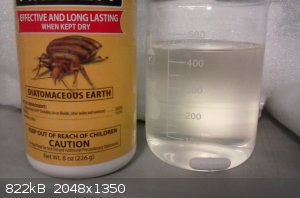

I ended up adding about 150 mL more solvent. The impurities are still very hard to filter. I ended up filtering through paper, changing the paper

several times and then switching to a glass frit. Some spillage and loss occurred during the many filtrations. The filtrate is still a bit cloudy but

is much better than it was.

Update: I added a little diatomaceous earth (actually bed bug killer; I probably shouldn't call it celite) to the fritted filter and swished it around

with some methanol, and now the filtrate is coming through it clear, with a slight yellow tinge.

[Edited on 17-3-2016 by JJay]

[Edited on 17-3-2016 by JJay]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Recrystalization didn't go so great... I've seen crystals several times, but filtering them out of solution is not easy. They tend to disintegrate in

the filter funnel. I think it's from the ether evaporating and the remaining methanol melting the crystals.

I'm think I'm going to have to use a more proper ice bath... perhaps ice / calcium chloride hexahydrate... and probably use a higher concentration of

ether. Gravity filtration would probably also help keep the ether from evaporating, and I think it would work fine... some of the crystals were more

than a quarter inch across.

So it looks like I'll need to get some more ether... and perhaps make some more sodium ethyl sulfate.

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

Yeah, um… I've definitely got some chemistry going on now, thank you, evil for that nice visual wake-up call!

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

I feel like there is an absurd amount of work going on here without having ever looked at prior work on the stuff.

http://www.sciencemadness.org/talk/viewthread.php?tid=15837

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I read somewhere that it is a good substance for practicing recrystalizations. Of course, that probably wouldn't be necessary for making

nitroethane....

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

...I just realized that Aldrich sells sodium ethyl sulfate for $50/gram, and I just burned through 100 grams of it. Haha!

[Edited on 21-3-2016 by JJay]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Quote: Originally posted by S.C. Wack  | Sounds like you need more solvent. Hot solvent.

BTW my earlier comments were unrelated to where sodium bisulfate is the source of sulfuric acid; just the textbook route, where step 2 is removal of

sulfate with CaCO3. It's a tedious step if you're making a lot, but when done carefully, everything else is simple. |

I tried a variation on Cohen's textbook procedure for potassium ethyl sulfate (in Practical Organic Chemistry) with 200 mL of 95% sulfuric acid and

600 mL anhydrous ethanol. It was a lot of work, but right now I am looking at about 500 mL of crude, saturated NaEtSO4 solution. It really wasn't that

hard, and that's actually consistent with his yields....

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

It looks like I am the only one interested in this topic....

600 mL anhydrous denatured ethanol was placed in a 1L flask, and it was fitted with a 2-neck Claisen adapter. 200 mL of 95% sulfuric acid was placed

in an addition funnel and it was fitted to one neck. A reflux condenser fitted with a drying tube was placed in the other neck. The sulfuric acid was

allowed to drip into the ethanol slowly over 12 hours, and then the flask was placed in a water bath, which was slowly heated to boiling over 1h and

maintained at boiling temperature for 2.5h. Very little reflux took place. The solution turned yellow, then orange, then dark red, then almost black

(it is thought likely that this occurred due to decomposition of the denaturant). The contents of the flask were cooled slightly and poured into 3.5L

water in a polypropylene bucket. Freshly precipitated calcium carbonate was added in small portions until no further reaction was evident, and then

the mixture was allowed to settle and decanted from the precipitate. 1L water was mixed with the precipitate, the mixture was allowed to settle, and

the liquid was decanted and the supernaturants were combined. Most of the red-orange impurity stuck to the sides of the bucket or to the precipitate,

leaving only a yellow color. Sodium carbonate was added in small portions until the solution measured pH 9, after which the mixture was filtered and

the filtrate concentrated to 1L in a PTFE-coated pan on a hot plate, then decanted into a 1L beaker. The solution was further concentrated on a water

bath until liquid withdrawn on a small spatula immediately hardened at room temperature. Yield: 275 grams. Purity is not known; assuming 90% purity,

this represents a yield of about 40% on sulfuric acid.

[Edited on 11-4-2016 by JJay]

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

I'm personally interested in what you're doing, although I haven't tried making sodium ethyl sulfate yet. It's a useful intermediate to diethyl

sulfate, which I may be making (if I feel that I can do this safely), on my quest for a total synthesis of an ionic liquid.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Sodium ethyl sulfate is also useful for making diethyl sulfide and as a mild alkylating reagent. And some people have used it for making nitroethane,

which is hard to buy and might have some legitimate uses.

Sodium ethyl sulfate is also expensive... the cheapest I have found is $4/gram for 95% purity... analytical grades cost in excess of $50/gram.

[Edited on 11-4-2016 by JJay]

|

|

|

Metacelsus

International Hazard

Posts: 2539

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

I once considered making diethyl sulfate in much the same way, and decided against it. For me, it's too much of a risk. It's safe if everything goes

right, but very bad if an accident happens.

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Yeah, I've read through all of the posts here on DES, as well as from several other sources. I'd be using it as an alkylating agent to make something

like 1,3-diethyl imidazolium hydrogen sulfate. The fact that it's such a strong alkylating agent means that it's good at doing other things too, like

growing an extra arm out the back of your head. Naturally, if I worked with it at all, I'd be working in a fume hood.

If sodium ethyl sulfate is a strong enough alkylating agent as is, that would certainly be a plus, as I'd be hydrolyzing the ethyl sulfate anion to

hydrogen sulfate after akylation anyway. I haven't seen this approach used in the literature so far, though. I guess it wouldn't hurt to try it and

see (famous last words). Methyl hydrogen sulfate is probably a much stronger alkylating agent than the corresponding ethyl one, and might be a better

one to start with.

There are some posts where I've seen people heating sodium ethyl sulfate strongly enough to make DES, apparently without realizing what they had just

made. I couldn't help but cringe a bit. In any case, I'm hoping to craft a one-pot reaction, that doesn't involve moving carcinogenic materials from

one piece of glassware to another.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Denatured alcohol is not always recommendable; at hardware stores here this is over 50% methanol.

The method I used was similar to if not from Mann and Saunders (great, underappreciated book), where 12 g. CaCO3 is added over 20 minutes. This is

what I mean by tedious, and it is necessary. They recommend a fine sieve; a flour sifter is handy.

Cohen adds "chalk ground into a thin paste with water." and it is unclear if this is better.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

The denatured alcohol that I used contained no methanol, but I'd probably suggest using non-denatured if you have any available. For the

neutralization, I used a freshly precipitated paste made by mixing sodium bicarbonate and calcium chloride solutions in a 20L bucket. The

supernaturant was decanted from the precipitate, which was washed 3x with an abundance of water and allowed to settle to jelly-like suspension. I have

read that when care is not taken in neutralizing with calcium carbonate, up to a 10x excess may be required, but the freshly precipitated chalk

reacted pretty close to quantitatively when added in small portions, stirring with a PTFE-coated rod.

|

|

|

| Pages:

1

2

3

4

..

7 |