| Pages:

1

..

16

17

18

19

20

..

33 |

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

p-DDNP Yield & Deflagration

The yield of p-DDNP from yesterdays diazotization is 9.31g or about a 97% yield. The yield seems dry, though maybe a little too high, so I will check

the weight again tomorrow to see if any more moisture is lost.

Attached is a video of about 20mg deflagrating. It is very energetic, but left a lot of residue.

Attachment: p-DDNP Deflagration.avi (6.6MB)

This file has been downloaded 1025 times

Here are a couple of interesting snapshots from the video:

[Edited on 19-6-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

The residues seems familiar, also the remaining yellow stain. Most likely, it is from oxidation byproducts formed or incomplete deacetylation, but I

haven't got around to testing during which step(s) these are formed. Since not everything was in solution after deacetylation I would guess that

either impurties were present, or not everything was deacetylated. (The latter would be my best guess) I always see some sooth formation from the

crude p-DDNP, but not to this extend. Could be the nitration, deacetylation or diazotization itself. It is the reason though I wanted to recrystallize

the iso-picramic, since it would distinguish between the diazotization or previous steps being the culprit.

Since there are indications that the free iso-picramic acid is air sensitive, it may turn out that performing the deacetlyation in an airtight

container with large excess of 30-50% SA at room temperature for several days may be a better option for deacetylation.

According to the Daphney paper Rosco posted, iso-picramic can be recrystallized from hot water, which would be a good start. Regarding purifiying the

crude DDNP: Best p-DDNP I got was from dissolving about 5 grams in 100 ml boiling acetone and then dripping in slowly a double volume of ice cold

water. Result is small yellow needles that flash much more energetic and leaves only a film of sooth on the paper. An interesting note is that the

remaining acetone/water mix when basified seems to have the same colour as the isopicramic salt, forming deep red/violet solution to pinkish when

strongly diluted, suggesting that one of the major impurities during diazotization is unreacted iso-picramic itself.

I must say, that recrystallization from acetone and ice water produces the best DDNP I've seen so far, both for p-DDNP and o-DDNP, IIRC this is also

how it is purified for mill spec. Funny thing is also that the very pure stuff seem less flame sensitive, sometimes just crackles somewhat before the

whole batch flashes violently when touched with the glowing splint.

[Edited on 18-6-2015 by nitro-genes]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Interesting about the suspected iso-picramic acid impurity. I would like to try extending the diazotization time in that case. The diazotization of

iso-picramic acid may very well not behave exactly the same as for picramic acid, kinetically and possibly in other ways too.

note:

The yield of p-DDNP wasn't completely dry. It dropped to about 8.90g, or about a 93% yield, counting what was used for the deflagration test in the

last 24 hours or so.

[Edited on 19-6-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Yes, although paradoxically, the iso-picramic diazotization at 0 deg C, seems faster than that for o-DDNP under the same conditions. Whereas in my

experience, o-DDNP takes agood 5-10 minutes at 0 deg C to diazotize, p-DDNP is much faster. It seems almost instant, which could be the underlying

problem, resulting in pDDNP coated isopicramic particles. I even thought about adding a bit of an inert solvent for the pDDNP to overcome this

problem, but there are few OTC possibilities. A thing I noticed though, is that the more apparent the pinkish sheen is for the crude p-DDNP, the more

impurities are present. The colour of the p-DDNP should be equal to o-DDNP produced by the COPAE method, so a yellow colour with only slight

orange/brown shade.That is why the soluble sulfate salt seemed promising for the diazotization, although in this case an orange impurity seems to be

formed, maybe due to the excess acid N2 --> OH --> =O or coupling of free isopicramic sulfate with the diazonium salt (just uneducated guesses

) )

My guess is that the diazotization is also a main culprit for impurities. Notice that even commercial DDNP is brown in colour. Results from the

chinese paper or Urbanski (diazotization for o-DDNP at 30 deg C, dripping 5-8% HCl over 2 hours) produces a freeflowing product (as was the aim) but

also a very dark brown product (leaving a lot of residues on burning). My guess is that diazotization this way produces a free flowing product only by

in situ formation of crystal modifiers by partial oxidation products. IOW: you sacrifice purity for a free flowing product. Stupid suggestion maybe,

but maybe free flowing DDNP is not for direct use in detonators, but a better option for transport and subsequent purification. Not sure on this one

though, on the other hand, maybe the impurities don't hamper performance too much. I read somewhere though that US mill spec o-DDNP is acetone/ice

recrystallized, which also in my hands produces the absolute best grades of both o and p DDNP.

[Edited on 18-6-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Acetic acid may help with the solubility issues. The cycling of the materials through manipulations of soluble salts and crystallized are important

also as separations and purifications. Since the nitration is uneventful I mentioned tripling the scale, which would provide more of the crude

acetylisopicramic acid.

A strategy for economical neutralization of the entire nitration mix could use a baking soda solution very slowly gradually added by drops with

stirring due to foaming until a point where the sulfate value is neutralized by sodium to an extent sufficient to have an excess basicity marked by

the odor of some evolving ammonia from the decomposition of ammonium bisulfate and any unreacted ammonium nitrate also, using sufficient added water

if needed to have everything in solution  at the bp. with

ammonia in excess evolving. Then into the cold to precipitate the in situ formed ammonium salt of acetylisopicramic acid as the the least soluble

constituent, which will tend to be salted out by the sodium sulfate dissolved. If the dilution is not great enough then the hydrated sodium sulfate

Glaubers Salt will be a complication because it could likely precipitate too. The mixture might have to be reheated above 32C with stirring and

filtered warm above 32C if the Glauber salt becomes a contaminant. Sodium Hydroxide would be superior and produce no foaming if substituted in the

same scheme which would go more quickly. at the bp. with

ammonia in excess evolving. Then into the cold to precipitate the in situ formed ammonium salt of acetylisopicramic acid as the the least soluble

constituent, which will tend to be salted out by the sodium sulfate dissolved. If the dilution is not great enough then the hydrated sodium sulfate

Glaubers Salt will be a complication because it could likely precipitate too. The mixture might have to be reheated above 32C with stirring and

filtered warm above 32C if the Glauber salt becomes a contaminant. Sodium Hydroxide would be superior and produce no foaming if substituted in the

same scheme which would go more quickly.

The filtered ammonium acetylisopicramate crystals could be dissolved in boiling water and a 101% neutralization quantity of HCl added gradually to the

hot stirred solution which should precipitate the acetylisopicramic acid in pure form as fine crystals. Not knowing the solubility in the cold for the

acetylisopicramic acid, this may not be efficient, so there is a "plan B" as follows:

In the alternative it may be possible to simply deacetylate the ammonium acetylisopicramate directly using sufficiently greater amount of H2SO4 to

neutralize the ammonia value. When the deacetylation is complete, then dilute and neutralize again using baking soda solution, with everything

in solution at bp and marked again by ammonia evolving. Then add to the stirred still hot solution the calculated quantity of HCl just in

excess of amount required for neutralization and the free isopicramic acid should precipitate as fine crystals with the supernatant solution going

very pale transparent yellowish colored at completion / endpoint.

Rosco breathes on fingernails and buffs them on collar

[Edited on 6/18/2015 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I was about to say that the soot didn't seem that excessive and that the deflagration seemed very energetic, but after looking at snapshots from the

earlier video of unpurified o-DDNP deflagrating there really is no comparison. The o-DDNP burned with a much bigger flash and much less smoke and

residue. I remember that the o-DDNP video was taken with less ambient light, so the flash may have looked extra big and bright, but the amount of soot

was definitely a lot less regardless.

o-DDNP Deflagrating

[Edited on 19-6-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I think you may have an impure sample because of the heavier residue. The oxygen balance is identical for both isomers and the heats are about the

same so the soot should be about the same almost no discernible difference.

Something I was thinking about was the ice cold diazotization that was done in experiments making R-salt by Axt, which was a kind of "shock

diazotization" of very cold reactants done by the "dump in a lump" addition scheme. I have wondered what would happen if that sort of diazotization

was done to make DDNP of either isomer.

[Edited on 6/18/2015 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Yes I agree, I understand that p-DDNP and o-DDNP are isomers so they are simply arranged differently and have the same number and types of atoms in

each molecule.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

@ Rosco: I noticed you also attached the relevant passage from the Daphney paper, regarding solubilities of the picramic and isopicramic, in a

previous post. Using ethanol or the potassium salt may be interesting a well, though IIRC, they also mention somewhere that the best crystals were

obtained from hot water. I'll give it try, I've got more than 100 grams of the isopicramic by now anyway.

[Edited on 18-6-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I have a jug of 68% HNO3 on hand, so when I do this I'll probably just use the same method as the Leopold Cassella British Patent GB24409 search

titled GB190324409A

http://worldwide.espacenet.com/publicationDetails/biblio?CC=...

and not have any dissolved byproduct salts to be any issue. Really there are several different ways to approach the nitration. It just occurred to

me in looking at this how to manipulate the solutions and get the ammonium acetylisopicramate to form in situ. In an early suggestion I'm sure I

suggested for the neutralization of the entire quenched nitration mixture you could just add about the calculated amount of sodium hydroxide solution

needed to neutralize the sulfate value. The ammonia byproduct from that will be more than sufficient to neutralize and form the ammonium salt of the

acetylisopicramic acid which is what should be the red crystals. The free acetylisopicramic acid mp is 182C, but I don't have the mp for the ammonium

salt.

I think I'm right about just going straight to the deacetylation using the ammonium acetylisopicramate salt, using a little extra H2SO4 which is going

to split off the ammonia first and be tied up as ammonium bisulfate soluble in the deacetylation mixture, where it will not precipitate on later

dilution. There's no problem with diluting to the point no Glauber Salt should precipitate in the cold when the sulfate values in the deacetylation

mixture are neutralized with a sodium value, and at that point the isopicramic acid should drop out of solution as the free acid because the soluble

isopicramic acid sulfate from the deacetylation will have its sulfate value neutralized and precipitate at that point as the free isopicramic acid,

with byproduct sodium sulfate and ammonium sulfate in solution. The titrations are going to seem to be off because of the ammonia value present and

it won't require quite as much sodium value to accomplish the neutralizations because the ammonia will be doing its share in the neutrailizations.

The reaction equations will show what is needed and the final precipitation solution for the free isopicramic acid could be titrated to be sure it is

a little acidic and assure none of the precipitate is ammonium isopicramate but is in fact the free isopicramic acid.

I haven't even drawn the first equation out for any of this yet but have been doing it all so far in my head. It's getting to the point I'll have to

put pencil to paper and start doing some reaction mapping and solubility charting.

I think handling these manipulations where everything is for certain in solution during the transition reactions marked by color changes, the

separations and manipulatrions should be straightforward and very pure materials result on one pass.

[Edited on 6/19/2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Did the nitration also with 68% HNO3, yield was similar and foaming after adding the ice was still present. A noticeable difference using NA/SA

instead of AN/SA though was that the formed DNAc stays completely in solution until it is precipitated by adding the ice, while with AN/SA, the

product partially separates at the end of nitration.

What would be your guess of the foaming after nitration, regarding temperatures and reactant quantities? What you mean with reaction mapping and

solubility charting? Could you think out loud on this one, would be cool to learn something here.

I've also added 20 ml of 68% nitric acid to 5 grams of DNAc, it's been steering at 0 deg C for 2 hours and RT for 8 hours now and the colour has gone

from a distinct orange/yellow, to a sort of sulfur yellow. Faint gas production is evident, sounds like a glass of soda. Could this possibly be the

trinitro variant, the colour would sort of match the description from the paper from Klapotke for the Trinitroacetamidophenol they produced.

"N-(4-Hydroxy-3,5,6-trinitrophenyl)acetamide (6): Compound 5

(12 g, 62.1 mmol) was dissolved in nitric acid (100 mL, 65%) at

0 °C. This temperature was kept for 5 h, and then the solution’s

temperature was slowly risen to ambient temperature (6–8 h) and

stirring continued for further 12 h. A yellow precipitate was

formed. The suspension was poured on crushed ice (500 g). After

the ice was molten, the suspension was filtered and washed with

only small amounts of ice-cold water to remove the nitric acid.

Compound 6 was obtained as a bright-shining yellow powder (10 g,

56 %)"

[Edited on 19-6-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The presence of the accumulating soluble ammonium bisulfate byproduct and unreacted dissolved ammonium nitrate is salting out the lower solubility

dinitroparacetamol (acetylisopicramic acid) in the nitration mixture using the solid nitrate and sulfuric acid, the solution load of dissolved solids

accounts for that precipitation. Actually that can be helpful to a nitration rather than being any problem.

About the foaming I'm not sure but it could be nitrosylsulfuric acid from too low a water content which could be avoided at a higher water content

nitration mixture, or that might not work if the dinitration requires being pushed at the low water content being used, in which case it may be an

unavoidable cost of doing business for the nitration. Side reactions can make 100% of theory equal to a 70% yield every time if the side reaction is

identified correctly and that factored into the calculation. Tweaking these reactions is just a whole lot of educated guesses and trial and error, a

real science of mistakes toward finding what works best. It can be a hair pulling ordeal trying to wring out a few extra per cent when side reactions

are thwarting every attempt. It may be with sulfuric acid there then the nitration is self limiting because a certain amount of oxidation instead of

nitration is also occurring. I had thought that maybe adding some urea nitrate into the nitration mixture might nip that crap in the bud, but the

problem is that the urea might react preferentially with and tie up the acetylisopicramic acid which is likely highly reactive. I think to some

extent unwanted diazotization is occurring at an inconvenient time in the nitration mixture at a point where decomposition is the result and there may

be nothing can be done about it. Cold and getting the reaction completed quickly would minimize that loss.

On the 2,3,6-trinitro-p-acetylaminophenol question no I don't think you will get a trinitrate from nitration of paracetamol without first acetylating

it further to the diacetyl compound as Klapotke did, or using the alternative easier approach and first mononitrating the paracetamol using sodium

nitrite to the 3-nitroparacetamol which may then be nitrated to the 2,3,6-trinitro-p-acetylaminophenol.

On the reaction mapping and solubility charting I mean looking at the reaction equations and products and byproducts solubility in the completed

mixtures and what dilution volumes are needed as a minimum for manipulations that produce the desired separations, where what you want to get is

distinctly apart and isolated from what you want separated as byproduct. You know in advance what strength solutions to use for various steps so that

hopefully no surprises with mixed products result and you get pure materials cleanly separated from a synthesis you have engineered intelligently.

Mapping the reactions is like the algebraic sum of all of it that can be expressed as a flow chart kind of process diagram. It is probably a variant

of Boolean algebra like for hardware logic "flow charts". It is a type of machine logic. System analyst type of work.

[Edited on 6/19/2015 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Nitro-Genes, since you are the only one with reasonably pure p-DDNP I think it would be only right that you should perform a couple of explosive

tests. See if you can initiate some picric acid.  Either that or you could send

me some p-DDNP in the mail.....just kidding. Either that or you could send

me some p-DDNP in the mail.....just kidding.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Don't have any TNP anymore, but I do wonder if acetone/ice water recrystallized o-DDNP might be able to initiate TNP more easily. Analogous to LA,

even a few % of inert by products may greatly affect the acceleration of the primary. Just cram in as much DDNP as you can in boiling acetone, decant

the solution from ay remaining DDNP and slowly add ce water while stirring, I guarantee you'll see a different product.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

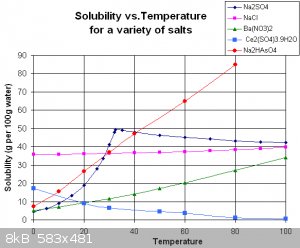

Here is a solubility chart for sodium sulfate which is soluble to the extent of 4.7% (anhydrous basis) solution at 0C and any more load in the

solution will crystallize out as a decahydrate.

The work up of neutralized solutions should be dilute enough to really not go near that cold saturation maximum loading.

Attachment: Na2SO4 Solubility.pdf (116kB)

This file has been downloaded 696 times

@nitro-genes You say you have probably a hundred grams of the isopicramic acid, so can you do a measured test regarding the stability on incremental

dilution of the soluble sulfate of the isopicramic acid? A good ballpark figure there is needed for determining a limit of extent of dilution that

can be used for the acetylation mixture particularly so it can be filtered without loss.

The combined solubility of Na2SO4 and NaCl may come into play depending upon the scheme for the manipulations.

Isopicramic Acid: abstracted summary information from Dabney

m. p.170°. Crystallises in bundles of fine brownish-yellow needles,

having a golden lustre when moist, very readily soluble in alcohol.

100 parts water at 22° dissolve 0.082 of acid : at just below the

boiling point 0.812 part of acid. Solutions bluish red.

This crystallises in dark brown plates or needles, melts apparently

with some decomposition at 170°, is sparingly soluble in cold water,

soluble in benzene and naphtha, readily soluble in hot water or in

alcohol; the solutions have a cherry-red colour. It appears to com

bine with acids, dissolving in them to form yellow solutions, but the

compounds so formed could not be isolated. It unites with alkalis,

forming crystalline salts, whose solutions are of a deep bluish-red

colour. The potassium salt crystallises in bluish-black needles, and

is very soluble in water. Both acid and salts explode when heated.

[Edited on 6/19/2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Sure, I'll give it a try, though it may not be as straightforward as purely acid concentration, but also acid:isopicramic ratio and temperature. That

would make things a lot more complicated. What would be your suggestion? Maybe I'll start with a 1:1 ratio of 50% v/v H2SO4 solution:picramic acid and

RT?

Thought about the neutralization with concentrated ammonia, as was performed the first time I did the nitration, but don't underestimate the exotherm

produced, you would either need to go incredibly slow or add fairly quick and chill the solution O/N to precipiate the ammonium salt again, as most

will go into solution probably. Using a carbonate will probably produce much less of an exotherm, since a lot of heat will dissipate with the CO2

produced.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Here a picture of 5 grams of DNAc reacting O/N at room temperature in 20 ml 68% nitric acid (left) and 2.5 grams of DNAc reacting with about 5 mole

eqv of nitrite in 10% acetic acid O/N. (Right) Its not dry yet.

The product from nitric acid is a sulfur yellow, yield looks not very promising, about 50% estimatefd. I was just curious what would form from DNAc

and nitric instead of starting with the diacetylated product. Any guesses what would have formed? I was curious whether p-DDNP might form directly by

slow deacetylation and diazotization, but it surely isn't DDNP. Worst case possibility seems that the DNAc is oxidized to picric acid, although the

product dissolves in water with a different colour than TNP. I'll try to determine a rough melting point when its dry. Anywhere near 120 should point

towards picric, although I don't know melting point of the trinitroacetaminophenol.

The nitrite reaction product on the right has about the same colour as the DNAc started out with. Upon setteling, the solution above the precipitate

became a very dark orange. Upon drying it shows some dark red colouration as can be seen in the picture with some difficulty. My guess is that some

remaining nitrite produces some NO which oxidized to NO2 with the air, leading to formation of a different product. I did the reaction in a semi

closed environment overnight to prevent this.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by nitro-genes  | Don't have any TNP anymore, but I do wonder if acetone/ice water recrystallized o-DDNP might be able to initiate TNP more easily. Analogous to LA,

even a few % of inert by products may greatly affect the acceleration of the primary. Just cram in as much DDNP as you can in boiling acetone, decant

the solution from ay remaining DDNP and slowly add ce water while stirring, I guarantee you'll see a different product.  |

Earlier in the thread you will see that I have recrystallized o-DDNP several times from acetone. The o-DDNP was normally quite pure even without

purification and I didn't notice a huge difference in explosive properties between the purified and unpurified samples.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Yeah your right, was the colour recrystallized this way a sort of bright yellow, orange/brown or dark brown? From acetone icewater, i got bright

yellow needles with slight orange sheen, from acettone evaporation more of an orange brown.

Anyway, I determined the melting points of the compounds above. Mind that these are incredible unreliable as they were done on the hotplate. The

orange stuff melts at around 170 ish, so similar to isopicramic acid and DNAc, the yellow stuff melts at around 180 ish, with decomposition. When I

had them both on the plate at the same time, the yellow stuff melts later than the orange stuff. Hmmm, picric goes out the window I guess. Upon adding

50% SA and heating it smells of AA, (EDIT, actually only a slight smell of AA was noticed that dissapeared very quickly, not like DNAc

acetylation at all, the compound does not carry an acetaminogroup anymore, but burns at least as energetic as DNAc or picramic acid, suggesting the

nitro groups are still intact, any ideas anyone?)

[Edited on 19-6-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Quote: Originally posted by nitro-genes  | Sure, I'll give it a try, though it may not be as straightforward as purely acid concentration, but also acid:isopicramic ratio and temperature. That

would make things a lot more complicated. What would be your suggestion? Maybe I'll start with a 1:1 ratio of 50% v/v H2SO4 solution:picramic acid and

RT?

Thought about the neutralization with concentrated ammonia, as was performed the first time I did the nitration, but don't underestimate the exotherm

produced, you would either need to go incredibly slow or add fairly quick and chill the solution O/N to precipiate the ammonium salt again, as most

will go into solution probably. Using a carbonate will probably produce much less of an exotherm, since a lot of heat will dissipate with the CO2

produced. |

You will recover the isopicramic acid used for the test so don't be stingy and introduce measurement errors for a small sample.

Suggest using isopicramic acid 3 grams in a 100ml beaker with a stir bar. Cover with exactly 20 ml H2O (or slightly greater exactly recorded quantity

convenient) and start stirring.

Based on theory it should take about half the weight of the isopicramic acid as H2SO4 to form the soluble isopicramic acid sulfate if the mole ratio

is 1:1 for that "salt" which may not in actuality be any actual salt as we think of it, not really a distinct compound but more of an "expression"

regarding an abstract hydrolytic condition for the isopicramic acid where its solubility is entirely pH dependent.

Put an eyedropper into an empty small beaker and note the tare weight for the empty beaker and eyedropper.

For the titration I would suggest weighing 10 grams H2SO4 and add to it 40 ml H2O to form an approximate 20% H2SO4 solution. Going slowly, pausing

for a few minutes between additions to observe the effect, start adding by increments using the eyedropper portions of the 20% H2SO4 until the stirred

sample is all in solution. Note the weight for the remaining vessel with eyedropper and unused portion of 20% H2SO4 to calculate how much weight of

20% H2SO4 was required to put the 3 grams of isopicramic acid into solution.

Write down the measurements.

Next simply begin a slow incremental dilution with distilled H2O, likewise from a pre-weighed quantity like 100 ml of H2O, pausing to observe the

effect between dilutions, to look for any clouding or precipitation as the stirred solution is gradually diluted. When a change is observed then note

the weight of the dilution water remaining, accounting for the weight of the container and eyedropper, to see how much H2O was used for the dilution

to reach the point where clouding or precipitation was observed. Write down these measurements.

You can recover the isopicramic acid used for the test by just neutralizing using a base the test solution which will precipitate the test material

which can be filtered out.

Before you do recover the isopicramic acid from the test, you could check and see if the still dissolved isopicramic acid may precipitate as a low

solubility perchlorate, by adding a dissolved

soluble perchlorate like ammonium perchlorate. I have speculated that such a perchlorate of isopicramic acid may form and could have interesting

explosive properties.

[Edited on 6/19/2015 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by nitro-genes  | Yeah your right, was the colour recrystallized this way a sort of bright yellow, orange/brown or dark brown? From acetone icewater, i got bright

yellow needles with slight orange sheen, from acettone evaporation more of an orange brown.

|

Solution in acetone crashed into water gave a fairly bright yellow. Slow precipitation by evaporation gave darker brown color. Slow precipitation by

slow dilution gave darker color too, but still fairly yellow, much lighter than with evaporative recrystallization (just went back and checked).

note:

I just changed one of the p-DDNP deflagration snapshot images at the top of this page. I examined the video more carefully and found the image I had

posted earlier was not very representative of the deflagration. It was quite energetic, with a fairly big flash, but still too much carbon and other

residue.

[Edited on 19-6-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Sounds familiar

For the solubilty test in diluted SA, it seemed a good idea to start with very pure isopicramic (I was also just curious whether it would be soluble

in warm water as daphney suggested). Strangely, I tried to dissolve 2 grams in 250 ml destilled water at 90 deg C., but almost nothing dissolved, even

with long stirring. Could it be that Dapney had a different compound? Other ideas? Maybe this suggests that temperature doesn't matter as much as I

thought for the pH dependend solution.

[Edited on 19-6-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Quote: Originally posted by nitro-genes  | Sounds familiar

For the solubilty test in diluted SA, it seemed a good idea to start with very pure isopicramic (I was also just curious whether it would be soluble

in warm water as daphney suggested). Strangely, I tried to dissolve 2 grams in 250 ml destilled water at 90 deg C., but almost nothing dissolved, even

with long stirring. Could it be that Dapney had a different compound? Other ideas? |

It wouldn't be the first time the decimal point is published a place or two off.

This is the reason why the dissociation test for the soluble acid "salt" of isopicramic acid is important needed data. It is a solubility property

that can be exploited during purification and separations / isolations / ect. It isn't just idle curisosity but is an important reaction parameter to

know.

Dabney reported isopicramic acid being ten times as soluble at the bp as at room temp but the solubility is so low for both conditions that even the

order of magnitude difference will not make water a convenient solvent for recrystallization, unless the solubility is enhanced by cycling the pH

through the soluble acid salt or by forming a soluble picramate, and titrating to again precipitate the free isopicramic acid.

Isopicramic Acid: abstracted summary information from Dabney

m. p.170°. Crystallises in bundles of fine brownish-yellow needles,

having a golden lustre when moist, very readily soluble in alcohol.

100 parts water at 22° dissolve 0.082 of acid : at just below the

boiling point 0.812 part of acid. Solutions bluish red.

This crystallises in dark brown plates or needles, melts apparently

with some decomposition at 170°, is sparingly soluble in cold water,

soluble in benzene and naphtha, readily soluble in hot water or in

alcohol; the solutions have a cherry-red colour. It appears to com

bine with acids, dissolving in them to form yellow solutions, but the

compounds so formed could not be isolated. It unites with alkalis,

forming crystalline salts, whose solutions are of a deep bluish-red

colour. The potassium salt crystallises in bluish-black needles, and

is very soluble in water. Both acid and salts explode when heated.

[Edited on 6/19/2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Thanks for the info, the 250 ml and 2 grams isopicramic was based on this, but it certainly didn't dissolve. I reckoned that water would be cheap, so

large volumes would be less of a problem. The solution in destilled water also had more of an orange brown colour than bluish red, hmmm.. maybe

destilled water was not a general practice in these days. The ammonium salt seemed a good option, as it seems very insoluble in cold water, the

problem is that it seperates as a very bulky translucent deep purple crystalline mass, that is why I suspected it is a x-hydrate.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Trust but verify on the reported data. It is odd how the ammonium salt for the acetylisopicramic acid is reported a good choice for initial

purification and I think unless the quenched nitration mixture using the NH4NO3 + H2SO4 for nitration, is excessively neutralized, it is the ammonium

acetylisopicramate salt that will be gotten after that quenched and neutralized nitration mixture is diluted and heated until all is in solution and

then cooled.

Meldola and Stephens report that the acetylisopicramic acid is sensitive to and decomposed by excessive base, so it is important to stop the

neutralization of the quenched nitration mixture when ammonia evolution is detected. The benzoylisopicramic acid analogue of Dabney is reported as

being a strong acid which will decompose carbonates so if the quenched nitration mixture is excessively neutralized by a sodium value, the ammonium

salt of the acetylisopicramic which has (probably) formed from the byproduct ammonia will likewise have its ammonia displaced by incoming sodium to

form the sodium salt of acetylisopicramic acid, which is more soluble and also vulnerable to decomposition from the stronger base that is sodium

compared with the ammonia. (theoretically) I think the quenching and neutralization will proceed by such scheme and if carefully done the ammonium

acetylisopicramate will crystallize out pure on the first pass. If not then its recrystallization from boiling water would be trivial.

And I think the ammonium acetylisopicramate salt can then be deacetylated directly as I have described.

I can write the synthesis for this approach when I have the test results on the pH related solubility for the isopicramic acid.

[Edited on 6/20/2015 by Rosco Bodine]

|

|

|

| Pages:

1

..

16

17

18

19

20

..

33 |