| Pages:

1

..

13

14

15

16

17

..

20 |

gboneu

Harmless

Posts: 30

Registered: 12-5-2015

Member Is Offline

Mood: No Mood

|

|

When i was using at som TCCA (Trichloroisocyanuric acid) which is used in pools as Chlorine tablets, When i used Ethanol with this in over 5 min. A

student reaction occurred and my lab was smelling Acetaldehyde .xD So i believe that controlling the Temperature might me the trick and you can use

it, Though you mey need a catalyst because a little of anhydrous oxalic acid was present and the ethanol wal 99,5% (Anhydride) You can try ir out with

95% ethanol, and no Oxalic acid.

NOTE: I didn't heat the reaction, it just went by it's self

[Edited on 12-5-2015 by gboneu]

|

|

|

xfusion44

Hazard to Others

Posts: 223

Registered: 6-8-2014

Location: Europe

Member Is Offline

Mood: Nostalgic

|

|

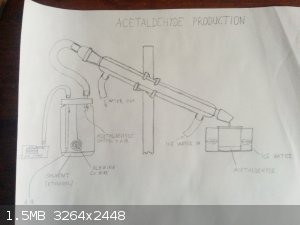

Hi, today I've got an idea on how to make acetaldehyde, using copper catalyst. I'll add my drawing below... I think I'll try it, but I need to buy

aquarium air pump and hose barb to ground glass joint adapter (I don't know where I'd be able to get one though - size 29/32). I'd be happy for you to

let me know what do you think about this setup - do you think it would work?

Thanks

[Edited on 24-5-2015 by xfusion44]

[Edited on 24-5-2015 by xfusion44]

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

Quote: Originally posted by xfusion44  | Hi, today I've got an idea on how to make acetaldehyde, using copper catalyst. I'll add my drawing below... I think I'll try it, but I need to buy

aquarium air pump and hose barb to ground glass joint adapter (I don't know where I'd be able to get one though - size 29/32). I'd be happy for you to

let me know what do you think about this setup - do you think it would work?

Thanks

[Edited on 24-5-2015 by xfusion44]

[Edited on 24-5-2015 by xfusion44] |

That looks like a pretty good method as for affordability. Keep in mind

however that you will also end up with a lot of Acetone in your product, so it will likely have to be purified extensively. You shouldn't need a

ground glass adapter for the tube to condenser, use a cork fitted with thevtube. And push that into the socket. Nice

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Beautiful sketch!

What's to prevent a fire (explosion) in that jar?

As the previous commenter said you will have by-products like acetone and unreacted ethanol in the condensate. How will you separate them from the

acetaldehyde?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

xfusion44

Hazard to Others

Posts: 223

Registered: 6-8-2014

Location: Europe

Member Is Offline

Mood: Nostalgic

|

|

Thanks to both of you

@hawkguy

I'm a little bit confused now. I thought that ethanol would produce acetaldehyde, and acetone something else? Do they both produce acetaldehyde?

Otherwise, I don't think that there would be a lot of acetone in acetaldehyde, because I would not boil it during this process, I'd just leave it to

evaporate slowly and efficiently - am I wrong?

@Magpie

I also thought about possible explosions, but haven't yet come up with idea about how to minimize the risk. Probably one would just need to accept the

risk when performing this - safety equipment would be necessary here.

BR, xfusion

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

see: http://www.sciencemadness.org/talk/viewthread.php?tid=55&...

(post of organikum)

Also, see jimmymajesty's fine work, this thread

Quote: Originally posted by xfusion44  |

Probably one would just need to accept the risk when performing this - safety equipment would be necessary here.

|

I'll be standing at the door with a face shield on.

No, I would not do this experiment unless first convinced I would not have an explosion.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

xfusion44

Hazard to Others

Posts: 223

Registered: 6-8-2014

Location: Europe

Member Is Offline

Mood: Nostalgic

|

|

@Magpie

Thanks!

Maybe you could just press the lid on top of the jar and seal the gap with PTFE - this should act as a safety valve, so that in case of explosion it

would just blow the lid off of the jar.

[Edited on 24-5-2015 by xfusion44]

|

|

|

WGTR

National Hazard

Posts: 972

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

If you want to try something quick and dirty, I would suggest this configuration over doing it in a jar.

The wad of copper wire on the left is intended to function as a flame arrester. It should stay cool during normal operation in order to provide this

function. The copper wire on the right is a wad of very fine wire (to provide as much surface area as possible). These wads of wire are pushed down

into the glass tube, which is then bent appropriately with a propane torch. The left side goes into a rubber stopper in an Erlenmeyer flask that

contains ethanol. The ethanol is heated slightly in a warm water bath to increase its volatility. In the same stopper, a glass tube is pushed under

the ethanol surface, and air is slowly bubbled through. This forms a fuel/air mixture. During operation, the copper on the right can be

heated gradually with a propane torch. If the fuel/air mix is correct, the copper will glow even when the torch is removed. This is kind of fun to

look at in the dark.

Just because it is safer than doing it in a large jar doesn't mean it is completely safe. Certainly use a face shield. Leather welding gloves are a

good idea if it is necessary to adjust things during operation. Even better, a Plexiglas blast shield can be added for extra safety.

|

|

|

xfusion44

Hazard to Others

Posts: 223

Registered: 6-8-2014

Location: Europe

Member Is Offline

Mood: Nostalgic

|

|

@WGTR

Thanks for the idea

Does it work well? Where does the right side of the tube go? To the condenser? How about efficiency?

BR, xfusion

|

|

|

byko3y

National Hazard

Posts: 721

Registered: 16-3-2015

Member Is Offline

Mood: dooM

|

|

+1 for question about effectiveness. Catalyst has a limited activity, so there's also a question about whether ethanol should be boiling, or maybe

some inter carrier or air is passed through it without ethanol boiling. I think something like 70°C and air will do the job. Because boiling ethanol

is hard to control, and higher amount of oxygen will lead to oxidation into CO2.

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

Quote: Originally posted by xfusion44  | Thanks to both of you

@hawkguy

I'm a little bit confused now. I thought that ethanol would produce acetaldehyde, and acetone something else? Do they both produce acetaldehyde?

Otherwise, I don't think that there would be a lot of acetone in acetaldehyde, because I would not boil it during this process, I'd just leave it to

evaporate slowly and efficiently - am I wrong?

@Magpie

I also thought about possible explosions, but haven't yet come up with idea about how to minimize the risk. Probably one would just need to accept the

risk when performing this - safety equipment would be necessary here.

BR, xfusion |

Sorry, I thought you were doing the reaction with Acetone. Thats the way I've done it before, because of its boiling point, and I haven't had any

explosions with it like I have with Methanol or Ethanol..

|

|

|

Nicodem

|

Thread Split

25-5-2015 at 07:02 |

WGTR

National Hazard

Posts: 972

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Quote: Originally posted by xfusion44  | @WGTR

Thanks for the idea

Does it work well? Where does the right side of the tube go? To the condenser? How about efficiency?

BR, xfusion |

No, it does not work very well. Yes, the right side of the tube goes to a condensor. The efficiency (or my patience) was poor enough that I couldn't

get quantitative amounts of acetaldehyde from it. At the same time, it will be more effective than a copper spiral in a jar, and much safer. It will

also give an idea of how air flow and fuel mixtures affect its general operation. And yes, one can smell some pretty pungent products coming out the

other end.

Now, to explain the previous a little better: Temperature control was very difficult with this setup. Yes, the initial heating was accomplished with

a torch. However, the thin wire of the catalyst offered poor heat transfer, so localized overheating would occur during operation. The bulk of the

wire catalyst was not used evenly. Most of the reaction would occur at one localized area in the bulk wire, usually at the leading edge. The

self-sustainability of the reaction was determined by the air-fuel ratio. This in turn was determined by the alcohol temperature and the

effectiveness of the air bubbler. As byko3y mentions, it is easy to overoxidize the product.

The air volume was very low. I would estimate about 1 cm^3 per second, but that is probably too fast for this particular setup. When one considers

the low air flow involved and that alcohol vapor is a only small fraction of this, it's not surprising that one will wait a very long time for that

first mL of acetaldehyde. In "Catalysis in Organic Chemistry" (Sabatier) pg. 654, a column full of copper catalyst 25-30mm in diameter, 1 m in length

was used to prepare 500g of acetalydehyde per day. That gives an idea of how slow this process can be.

I gave up on the idea of oxidative dehydrogenation, and instead focused on direct dehydrogenation. The latter process requires the continual addition

of heat to continue, so it is less likely to overheat. It also avoids the use of oxygen, so the products are free of acetic acid, water, etc. I

detailed the construction of this idea here:

https://www.sciencemadness.org/whisper/viewthread.php?tid=55...

Also, JimmyMajesty's setup is quite impressive, and works on similar princicples. He has done well with the output condensor design, which is

something I have yet to do properly. The acetaldehyde product will contain a large amount of unconverted ethanol. For this reason it is always

necessary to seperate out the ethanol from the products, and send it back to the boiler. The condensor will need to be able to separate out this

alcohol from the acetaldehyde, and also to efficiently condense out the aldehyde. This is easier said that done, as one can see when reading back

through JM's posts in this thread.

I would strongly advise reading through Sabatier's book on catalysis. It was such an instructive and interesting book, that I almost read it

cover-to-cover in one sitting. It is available for free all over the internet. It will help you more than I possibly could in a thread.

That is a nice drawing, by the way.

Quote: Originally posted by byko3y  | | +1 for question about effectiveness. Catalyst has a limited activity, so there's also a question about whether ethanol should be boiling, or maybe

some inter carrier or air is passed through it without ethanol boiling. I think something like 70°C and air will do the job. Because boiling ethanol

is hard to control, and higher amount of oxygen will lead to oxidation into CO2. |

The temperature I was using was about 40-60C. It has to be adjusted to change the air-fuel ratio. I would generally get the alcohol concentration as

high as I could, while it would still allow a self-sustaining reaction in the catalyst.

|

|

|

xfusion44

Hazard to Others

Posts: 223

Registered: 6-8-2014

Location: Europe

Member Is Offline

Mood: Nostalgic

|

|

@Hawkguy

That's exactly why I asked you about using acetone. If the product is the same, it's really better to use acetone because of its lower BP. But when

I'm using acetone instead of ethanol, the smell is more pungent and I think, a little bit different, or is it just me?

@WGTR

Thanks!

Looks like you have a lot of experience with acetaldehyde production  Well, you

could use copper foil in the jar or even copper wool, but as we already know, it's not very safe to do it with the jar method Well, you

could use copper foil in the jar or even copper wool, but as we already know, it's not very safe to do it with the jar method

BR, xfusion

|

|

|

WGTR

National Hazard

Posts: 972

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Quote: Originally posted by xfusion44  | Thanks!

Looks like you have a lot of experience with acetaldehyde production  Well, you

could use copper foil in the jar or even copper wool, but as we already know, it's not very safe to do it with the jar method Well, you

could use copper foil in the jar or even copper wool, but as we already know, it's not very safe to do it with the jar method

BR, xfusion |

You're welcome! There's more than one way to do things like this. I think that JimmyMajesty's setup has been the most practical overall, as he has

made the most here using direct dehydrogenation (as far as I know).

Certainly, as you try things out, post pictures and ask questions if needed. I enjoy seeing people's practical setups on this topic.

|

|

|

xfusion44

Hazard to Others

Posts: 223

Registered: 6-8-2014

Location: Europe

Member Is Offline

Mood: Nostalgic

|

|

@WGTR

Thanks! When I try this, hopefully I'll remember to take some pictures

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

Hey if Aldehyde/ Ketones can be collected by a destructive distillation of a corresponding Calcium salt, can Acetaldehyde be produced from Calcium

Acetate?

|

|

|

gdflp

Super Moderator

Posts: 1320

Registered: 14-2-2014

Location: NY, USA

Member Is Offline

Mood: Staring at code

|

|

No, you don't get acetaldehyde, you get acetone. http://www.sciencemadness.org/talk/viewthread.php?tid=16216 It was suggested earlier in this thread, but calcium formate is required as well and

yields are pathetically low. http://www.sciencemadness.org/talk/viewthread.php?tid=55&...

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

Rats I thought I found an easy shortcut. Well, back to the Dichromate style oxidation then.

|

|

|

clearly_not_atara

International Hazard

Posts: 2836

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

From Advanced Organic Chemistry, Fieser & Fieser, (c) 1961, found at a used book sale (^,^):

12.6 - Tosylate method - Kornblum found (1959) that primary saturated alcohols are converted into aldehydes in 60-85% yield by

oxidation of the tosylates with dimethyl sulfoxide (DMSO) in presence of sodium bicarbonate at 150C. Benzylic tosylates are oxidized smoothly at 100C.

The required esters can be produced from the halides; for example, by reaction of n-octyl iodide dissolved in acetonitrile with silver tosylate.

Ethyl halides might be more reactive than octyl, so the iodide might not be necessary... also if you have tosyl chloride or even [m]ethanesulfonyl

chloride you're probably set. Ethyl tosylate can also be prepared by the reaction of ethyl orthoformate with toluenesulfonic acid and fractional

distillation.

https://www.erowid.org/archive/rhodium/chemistry/sulfonic.es...

Silver tosylate can be prepared by salt metathesis from silver nitrate and sodium tosylate; AgOTs precipitates. See:

http://onlinelibrary.wiley.com/doi/10.1002/047084289X.rs030/...

Be aware: the autoignition temperature of acetaldehyde is 185 C. Don't blow yourself up. But ethyl tosylate is more reactive than

longer alkyls thus shouldn't have to get so hot.

[Edited on 2-8-2015 by clearly_not_atara]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Without the googly part, that's

https://www.ideals.illinois.edu/bitstream/handle/2142/4460/e...

There is also the earlier

https://www.ideals.illinois.edu/bitstream/handle/2142/4543/e...

Related paperwork using copper turnings, etc. (formaldehyde is also made from methanol)

Catalytic Partial Oxidation of Alcohols in the Vapor Phase—III

W. Lawrence Faith, D. B. Keyes

Ind. Eng. Chem., 1931, 23 (11), pp 1250–1253

DOI: 10.1021/ie50263a014

Catalytic Partial Oxidation of Alcohols in the Vapor Phase.IV

W. Lawrence Faith, P. E. Peters, D. B. Keyes

Ind. Eng. Chem., 1932, 24 (8), pp 924–926

DOI: 10.1021/ie50272a022

Attachment: ie50263a014.pdf (145kB)

This file has been downloaded 1298 times

Attachment: ie50272a022.pdf (161kB)

This file has been downloaded 850 times

[Edited on 15-11-2015 by S.C. Wack]

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Hi im working on a pentaerythritol synthesis and i am looking for information if you can calculate the % of acetaldehyde in a solution by using the

sodium sulfide method as you would to calculate a formeldehyde solution.

I have googled for info but havent had much luck finding any info online.

Thanks nux.

[Edited on 9-12-2015 by nux vomica]

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

Quote: Originally posted by nux vomica  | Hi im working on a pentaerythritol synthesis and i am looking for information if you can calculate the % of acetaldehyde in a solution by using the

sodium sulfide method as you would to calculate a formeldehyde solution.

I have googled for info but havent had much luck finding any info online.

Thanks nux

[Edited on 9-12-2015 by nux vomica] |

What would the Acetaldehyde be dissolved in... Ethanol?

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Yes its a mix of unreacted ethanol and acetaldehyde, I collect the distillate that comes off below 60° c but it would be better to know the % of

acetaldehyde in the solution so I can calculate how much to collect , and to check purity of the final product.

|

|

|

Hawkguy

Hazard to Others

Posts: 326

Registered: 10-10-2014

Location: British Columbia (Canada eh!)

Member Is Offline

Mood: Body is Ready

|

|

Quote: Originally posted by nux vomica  | | Yes its a mix of unreacted ethanol and acetaldehyde, I collect the distillate that comes off below 60° c but it would be better to know the % of

acetaldehyde in the solution so I can calculate how much to collect , and to check purity of the final product. |

Try making paraldehyde and measuring it that way

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Hawkguy  | Quote: Originally posted by nux vomica  | | Yes its a mix of unreacted ethanol and acetaldehyde, I collect the distillate that comes off below 60° c but it would be better to know the % of

acetaldehyde in the solution so I can calculate how much to collect , and to check purity of the final product. |

Try making paraldehyde and measuring it that way |

I will have to look into that method, as I already use the sodium sulfide method with my formaldehyde solutions I was hoping it wold work with

acetaldehyde as well.

|

|

|

| Pages:

1

..

13

14

15

16

17

..

20 |