| Pages:

1

..

12

13

14

15

16

..

33 |

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

I wonder if 3-diazonium-2,4,6-trinitrophenol does exist...thus a DDNP variant with the diazo in meta of the phenol and with 3 nitros... thus based on

meta-amino-phenol.

I also have good synthetic ideas about 3,5-diazido-2,4,6-trinitrophenol.

Depending on the stability of iodoxy group vs phenol, nitro and diazonium group...one may also invesigate 3,5-diiodoxy-DDNP and 3,5-diiodoxy-TNP.

[Edited on 21-5-2015 by PHILOU Zrealone]

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Nitro-genes, Rosco, no big deal, from the other side of the computer screen it can sometimes be hard to tell if I have insulted someone or not.

I will see about digging out some sodium picramate tomorrow. I should read up a little more and give this new isomer a try soon too.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Your old witness plate looks like a typical witness protection program success story  You can stop shooting it any more, it looks like you got it You can stop shooting it any more, it looks like you got it  Maybe retire it as a wind chime. We are taking up a collection to get you a new one.

Maybe retire it as a wind chime. We are taking up a collection to get you a new one.

Cycling the acetylisopicramic acid through a recrystallization of the ammonium salt for isolation and purification could be a benefit. And this might

work for the isopicramic acid following the deacetylation as well. Some other salt like the potassium or sodium could work as well for aqueous

recrystallization and purification.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

That witness plate brings back good memories. It really is time for a new one though, 'tis true. The funny thing is I have at least two or three more

of that same type, without holes, but it is always old holey that surfaces first some how or other.  Even though I have admitted to having other witness plates, please everyone feel free to send me money and toys, don't

hesitate. Even though I have admitted to having other witness plates, please everyone feel free to send me money and toys, don't

hesitate.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

You should keep it, like I also do with most of my witness plates, one day you'll be old and grey and you open a dusty box at the attic and remember

the fun you had while doing this kind of stuff. Some things, like explosive imprints of leaves and other organic stuff would be almost art in a way.

Anyway, p-DDNP really offers a nice OTC synthesis of a potentially world class primary, even the nitrite can be prepared easily from lead and KNO3 or

NaNO3 (quoting myself  ) --> ) -->

"

Potassium nitrite synthesis

Outside and wearing gloves, 250 grams of lead (20% excess) was melted in a stainless steel vessel after which 100 grams of KNO3 was added at once. The

mixture was stirred until all the KNO3 had melted and formed a clear layer floating on top of the molten lead. Some yellow/brown PbO started

immediately to form, however, upon prolonged heating there was little to no further formation of PbO.

I decided to heat the mixture stronger and within about 10 minutes a strong exothermic reaction became evident. In a beautifully controlled manner and

without any gas formation, the entire mixture became red hot. The mixture was well stirrable and this was done so for another couple of minutes to

ensure reaction of all the KNO3 present. (The lead has a tendancy to sink immidiately to the bottom again)

It is important to keep stirring to the point of solidification, since it makes extracting the KNO2 much easier! The mixture was ground together with

several additions of water, until all the PbO was present as a fine powder at the bottom and filtered to remove any PbO. The light yellow filtrate was

then boiled to dryness (takes long time, due to hygroscopicity) and yielded about 65-70 grams of KNO2, minor plumbate contamination can be removed by

bubling through CO2 for some time."

[Edited on 21-5-2015 by nitro-genes]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

@Philou: 3-diazonium, 2,4,6 trinitrophenol must exist, since it is used as an intermediate in the synthesis of KDNBF, mentioned earlier. I've only

seen it used to prepare the azido compund and uses very strong diazotising conditions at low temperatures, I reckon it would't be very stable.

What was your idea about the synthesis of 3,5-diazido-2,4,6-trinitrophenol, sounds interesting

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I found this article a while back somewhere in this forum. I have never used this method, since I already have over 50lbs of sodium nitrite, but it

looks like a decent method to me. Always planned to give it a try just for fun.

Attachment: Sodium Nitrite Synthesis1899.pdf (180kB)

This file has been downloaded 659 times

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Quote: Originally posted by nitro-genes  | @Philou: 3-diazonium, 2,4,6 trinitrophenol must exist, since it is used as an intermediate in the synthesis of KDNBF, mentioned earlier. I've only

seen it used to prepare the azido compund and uses very strong diazotising conditions at low temperatures, I reckon it would't be very stable.

What was your idea about the synthesis of 3,5-diazido-2,4,6-trinitrophenol, sounds interesting  |

I'm working on a good reply for this tread...reading a good book from Gringard about diazo, azo, hydrazo, hydrazine, hydroxylamine, oximes,...

What synthesis of KDNBF? I have found one from meta-azido-nitrobenzene and one from benzofuroxane nitratation and reaction with alcaline carbonate...

[Edited on 21-5-2015 by PHILOU Zrealone]

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Sorry had some syntheses mixed up I think...Done to much over the last few weeks, and my reading is not up to date

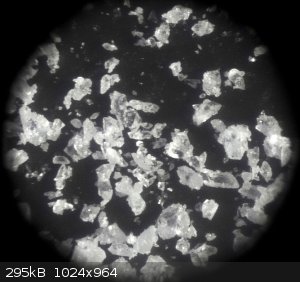

Can't get the p-DDNP flashing without carbon deposits, so I started over from scratch and not skipping any steps. Tried crystallizing acetaminophen

from ethanol, but it has the nasty habbit of forming very stubborn supersaturated solutions form ethanol and ethanol water mixtures..

The cleanest and still fast method with the brand of tablets I used is to extract 25g of acetaminophen (weight of tablet junk not included) with 125

ml of boiling methylated spirits. After stirring for about 5 minutes the solution is filtered hot and then added to another beaker. Then I boil it

down with stirring to about 50 ml at which point slight clouding of the solution can be observed. Then I added 50 ml of water and keep boiling. When

nearly all the ethanol is evaporated (takes about 15 minutes with hotplate on highest setting), there is a sharp induction point for crystallization

to commence, within about 10 minutes nearly all of the acetaminophen precipitates as a reasonably course sand like precipitate, it is left ot cool and

then filtered and washed generously with cold water. The filtrate is a really slightly yellow (p-aminophenol from hydrolisis?) and milky, I suspect

that the stearic acid and other junk may have formed some emulsion which can be washed away. It is most likely an emsulsion of the waxes/stearic acid

etc since it doesn't settle on standing a long time. The crystals looked very clean and glassy under a binocular, I will try to make a picture of it,

which is kind of impossible with a full frame DSLR.

This method may result in hydrolysation of some of the product, but it doesn't smell acidic, is snow white, free flowing and looks really clean under

the binoc. Picture attached

[Edited on 21-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

This reference would provide a good strategy for purification.

http://pubs.acs.org/doi/abs/10.1021/je990124v

From the summary I would think the following:

Something that might work fine is to disrupt the tablets with a mist of distilled water to just dampen uncoated tablets, and mash them up as they

soften and crumble and then spread out the material to air dry.

Then dissolve the material in hot methanol like in a jar with a threaded lid sitting in a pan of hot water. When the paracetamol component dissolves,

simply allow the solution kept warm to sit undisturbed and the insoluble material will settle out and the relatively clean solution can be decanted

hot. I wouldn't even try to filter this material.

Pour the hot methanol solution into an evaporation tray and let the paracetamol crystallize from evaporation. Or, in the alternative if it is desired

to crystallize the paracetamol from the methanol solution and filter, it could be precipitated by adding toluene to reduce the solubility. Kept warm

the more volatile methanol would escape, gradually increasing the proportion of toluene in the solvent and further decreasing the solubility of the

paracetamol in the mixed solvent becoming richer in toluene as more methanol evaporates. Harvest the crystals before all of the solvent has evaporated

by simply dumping onto a blotter, and discard the blotter with whatever it caught, and air dry the crystals.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

It were most likely impurities from the tablets, I redid the whole procedure with the newly isolated acetaminophen and there is a huge difference in

the intermediate product appearances. The dinitroacetaminophen is a really orange colour instead of yellow/orange and no sticky residues are present

after crashing in water, the deacetylation mix becomes a deep red instead of brownish red and upon neutralization a brick red powder separates

quantitatively as a fine crystalline glistening product.

The problem with evaporation is that stearic acic, wax, plegmatized starch and povidone are all to some extent soluble in methanol/ethanol/water

which would contaminate the product upon evaporation. Crystallization of acetaminophen using OTC solvents is problematic sine it is one of the most

stubborn supersaturation compounds I've seen. The procedure outlined above works, I tried 3 times in a row, producing the same clean product every

time. It probably works because the impurities form a milky emulsion that can be washed away, although this procedure may work not with all tablet

brands. I bought several packages and weighed 10 pils to see which contained the least amount of rubbish. Surprisingly, after extraction with boiling

ethanol, the insolubles filter really easy, yielding a completely clear solution.

The article about the solubility of paracetamol can be found halfway true this thread --> https://www.sciencemadness.org/whisper/viewthread.php?tid=62...

I'll make a detailed writeup soon, going true all the steps.

[Edited on 22-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I am not one to criticize success. What works for you works for me.

Sorry I missed that before and see you have already been there, done that. The same issue can be encountered for aspirin being cleaned up for

nitration. The mystery impurities after nitration can appear in picric acid gotten from aspirin also. Red goo is better avoided and more easily

avoided at the beginning than is it easy to get out the mystery goo impurity later.

With aspirin the binders seem low solubility in the nearly saturated warm solution of the aspirin in denatured alcohol, and simply settle out as a

dust fine sediment in the warm solvent. If a tall cylindrical jar is used and the jar of hot solvent is tilted, the sediment collects on one side of

the bottom of the jar and nearly all the solvent can be decanted in one clean pouring away almost down to the last 20 ml or so of liquid.

I look forward to the writeup sorting out the finer details. This is very interesting what may turn out to be an "improved" performance and improved

stability variant isomer of DDNP.

The topic of p-DDNP came up over 10 years ago but was never really given a good look. It has been like an itch that needed to be scratched for a

decade now receiving attention

Another one of my old "itches" is guanidine perchlorate as a base charge initiated by triaminoguanidine perchlorate used as a primary. I like the

obvious chemical compatibility and simplicity for that pair of materials which should have very good energy output also and would seem difficult to go

wrong.

One thought I wanted to reiterate is concerning the water content for the nitration mixture which would be present with the described by patent and

literature described nitrations where sulfuric acid was present as a component of the nitration mixture. Water content and warm temperature work

against the formation of nitrosyl sulfuric acid, which is a diazotization agent, and the nitration product in this case is vulnerable to

diazotization. The issue that could arise in a sulfuric acid containing nitration mixture is that a partial diazotization of the nitration product

could occur while it is still in the nitration mixture, which could cause losses since the conditions are also favorable for decomposition of that

diazo product as soon as it is formed. So water content to a certain extent that does not hinder the dinitration but does hinder the formation of

nitrosylsulfuric acid, could actually result in a higher yield for the dinitration product, compared with what may be produced by a more aggressive

and lower water content nitration mixture. There is a tradeoff about the nitration mixture which probably has a "sweet spot" kind of optimum water

content which leads to maximum yields for the dinitration product, avoiding the nitrosyl sulfuric formation which would probably attack the newly

formed acetylisopicramic acid and decrease the ultimate yield.

In the alternative nitration using glacial acetic acid and fuming nitric acid, where no sulfuric acid is present, the complication presented by

nitrosyl sulfuric acid is eliminated so that alternative method of nitration would likely produce a more pure product.

[Edited on 22-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Water content is very good point that you bring up, there is considerable foaming of the nitration mix after crashing in water, and only 70-80% yields

are obtained.I reasoned that since water is likely one of the reactants involved in oxidation that it should best be avoided, but there may be on

optimum of water content that allows smooth nitration without oxidation, while preventing the formation of nitrosylsulfuric acid. Maybe it is just a

solubility issue of the NOx, similar in this respect seems that 95% RFNA releases all dissolved NOx when dilutet to the mono hydrate. :-)

[Edited on 22-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah but just because d 1.5 HNO3 is specified doesn't mean it wasn't white that they used  RFNA is actually not all HNO3 even though it may be d 1.5 or more. RFNA is actually not all HNO3 even though it may be d 1.5 or more.

All you need to convert WFNA to RFNA is a little sunshine.

Good to remember light sensitivity for HNO3 that when nitrations are done outdoors, or when HNO3 is being distilled. Ain't no sunshine when she's

gone (colorless)

File this under "the safelight imperative" regarding the predictable decomposition of HNO3 favoring formation of the nitrosyl sulfuric acid or

"nitrous fumes", which is STRONGLY favored by direct sunlight, and even distinctly present but to a lower extent in shaded indirect daylight.

Outdoors is good but keep it in the shade like the deep dark woods as much as possible.

https://www.youtube.com/watch?v=E6emVq0RZec

<iframe sandbox width="640" height="480" src="https://www.youtube.com/embed/E6emVq0RZec?rel=0" frameborder="0" allowfullscreen></iframe>

Aqua Fortis Latin "strong water"

Chemistry has its roots in mysticism and alchemy

The most ancient priests and oracles of science are not modern cosmologists and physicists

We are the ancients of ages past, present, and yet to be

https://www.youtube.com/watch?v=eqcWztXpVa4

<iframe sandbox width="640" height="360" src="https://www.youtube.com/embed/eqcWztXpVa4?rel=0" frameborder="0" allowfullscreen></iframe>

[Edited on 22-5-2015 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I have noticed the same thing, sunshine can rapidly decompose nitric acid turning clear acid to yellow quickly. I have found it a bit strange that it

was not discussed much, from what I have seen, since many amateur chemists are performing nitrations and distillations involving HNO3 outside

presumably.

Not sure if this has already been posted here.

Attachment: Paracetamol Solubility in Various Solvents.pdf (91kB)

This file has been downloaded 6310 times

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah the "low actinic" glassware and the brown or amber glass have been around for a long time for a reason. A few things are very light sensitive and

highly concentrated HNO3 is notorious. I have some apothecary ground glass in the red glass that looks older than the journal literature, maybe older

than the printing press. It gets used occasionally with a bit of halocarbon grease on the grindings. Fuming HNO3 is a proven performer for freezing up

ground joints and seems to be a great penetrating solvent that will wash off any grease eventually, so PTFE sleeves and tape are good and so are solid

PTFE seals and stoppers.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Well, regret to say...but maybe it's is not the holy grail after all, I thought it would DDT in about 100-150 mg amounts, but lighting 500 mg is a big

Oempf, but no detonation.  P-DDNP may actually be very similar to o-DDNP in

properties, although how it reacts under confinement and different recrystallization techniques remains interesting. Anyway, photo of isopicramic acid

attached, weird thing is that it looks much more yellow when strong light hits it, I'll take daylight picture tommorow. The video of the ignition of

500 mg is also shown. P-DDNP may actually be very similar to o-DDNP in

properties, although how it reacts under confinement and different recrystallization techniques remains interesting. Anyway, photo of isopicramic acid

attached, weird thing is that it looks much more yellow when strong light hits it, I'll take daylight picture tommorow. The video of the ignition of

500 mg is also shown.

Attachment: 500 mg p-DDNP_Trimmed.avi (1.7MB)

This file has been downloaded 1052 times

[Edited on 22-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I am not convinced there is not some yet to be revealed difference based on the earlier side by side comparison of the o-DDNP and the p-DDNP. However

that could be a misleading comparison in the same way as the result for the potassium tetrazeno derivative of the o-DDNP, with o-DDNP which is still

puzzling.

Will confinement kick the p-DDNP beyond what confinement does for o-DDNP ?? Or will the snakebit gremlin appear as occurred for the potassium

tetrazeno derivative of o-DDNP??

Life is like a box of chocolates, you never know what you're going to get, says the mother of Forest Gump!

It seems the lower critical mass to DDT unconfined would have translated to higher performance confined. And we observed it is mysterious what

happens, not only there in that test but for the reported higher performance of basically the same compound with only an added hydroxyl. It could be

the confinement related performance differs for the o-DDNP and the p-DDNP. Or the only advantage for p-DDNP may be the greater thermal stability. I

am still puzzled by the reported detonation at 190C with "extreme violence". Similarly vague descriptions exist for other materials without any

sample quantity or conditions being specified which is not helpful to really understanding what is the actual performance, like weight tests for an

initiator where the actual story becomes more clear.

[Edited on 22-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

250 mg ignition (has some cool frames)

100 mg semi confined (aluminium bowl)

2-5 mg confined in aluminium foil (didn't want to make too much noise)

A video of some clean o-DDNP would be really welcome

Attachment: 250 mg p-DDNP_Trimmed.avi (1.2MB)

This file has been downloaded 945 times

Attachment: 100 mg p-DDNP semi confined_Trimmed.avi (1.4MB)

This file has been downloaded 939 times

Attachment: About 5 mg confined aluminium foil_Trimmed.avi (1.8MB)

This file has been downloaded 966 times

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Oh, almost forgot, and an side by side comparison of o-DDNP (left) and p-DDNP (right).  Both were made using exactly the same diazotising conditions. Both were made using exactly the same diazotising conditions.

Attachment: 250 mg o-DDNP (left) and 250 mg p-DDNP (right)_Trimmed.avi (2.9MB)

This file has been downloaded 975 times

[Edited on 22-5-2015 by nitro-genes]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I was hoping for p-DDNP to be an unequivocal primary explosive like lead azide, but at the same time I wasn't overly optimistic either.

Here is a video I took of about 10mg of o-DDNP deflagrating. Sorry for the video being out of focus. This particular batch did leave some pretty heavy

carbon residue, maybe I remembered wrong and the earlier batches did as well. Yield of DDNP based on sodium picramate monohydrate(?) was only about

86%, which I believe is because I wasn't careful enough to keep the temperature low enough during the diazotization reaction. I used the method from

"DDNP a Detonating Explosive" outlined here:

http://www.sciencemadness.org/talk/viewthread.php?tid=439&am...

Attachment: DDNP Deflagration.avi (3.8MB)

This file has been downloaded 888 times

[Edited on 23-5-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Thanks for uploading the video!  Really nice to see other peoples results. The

first comparison video I uploaded was a really bad experimental batch. It seems p-DDNP does not significantly accelerate faster as loose powder,

maybe confined there may be a difference. Little dissapointed, standing there with ear and eye protection, expecting a bang. Was a lot of fun though

and both the dinitroacetaminophenol (sort of grapefruit colour, very strong dye) and isopicramic acid and it's salts are amazingly colourfull dyes. Really nice to see other peoples results. The

first comparison video I uploaded was a really bad experimental batch. It seems p-DDNP does not significantly accelerate faster as loose powder,

maybe confined there may be a difference. Little dissapointed, standing there with ear and eye protection, expecting a bang. Was a lot of fun though

and both the dinitroacetaminophenol (sort of grapefruit colour, very strong dye) and isopicramic acid and it's salts are amazingly colourfull dyes.

Saw the mention of p-DDNP exploding with extreme violence at 190 deg C, but conditions and quantities were not mentioned. Almost all primaries

accerate faster when strongly heated, their already not to strong bonds trembling from excitement, only the slightest push suffices.  In the article, maybe they slowly heated the stuff, had it confined or used a

really large quantity, back in the old days these things were used as intermediates for dyes and I seem to remember reading that it's explosive nature

was discovered much later after it was first synthesized. Could be they made 100 grams of the stuff and just had no idea... In the article, maybe they slowly heated the stuff, had it confined or used a

really large quantity, back in the old days these things were used as intermediates for dyes and I seem to remember reading that it's explosive nature

was discovered much later after it was first synthesized. Could be they made 100 grams of the stuff and just had no idea...

[Edited on 23-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Confinement has benefit and the snap of 5 mg sample shows that. But it appears the literature report about the thermally induced detonation with

"extreme violence" at 190C is a misleading exaggeration.

What are the initiating properties for p-DDNP in comparison with o-DDNP is where the real story will be told.

p-DDNP could be better than o-DDNP under confinement. But even if it is only as good as or not much worse than the o-DDNP, then better stability for

the p-DDNP would still make it useful, and more useful than the o-DDNP for some applications where the better heat tolerance and longer storage life

would be required.

Possible mixed crystal form for the two different isomers combined could have a desirable property and there are the derivatives of p-DDNP also which

may be the same or better compared with the derivatives for o-DDNP.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

No problem, and thanks to you for doing the tests you did as well. It is hard to know exactly what was done in some of those early tests described in

old articles or if the reporting was even completely accurate and truthful, though I think most times it was reasonably truthful. There are indeed a

lot of very interesting colors with these reactions. In my opinion the results could be very different with confinement.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There were concerns about the stability of the o-DDNP when mixed or in contact with azide or other unequivocal primary explosives where it might be

useful as a synergistic mixture or as sensitive coupling charge and in tandem with an azide to give the DDNP a hot start and skip the DDT mode which

is the kindling phase for the DDNP to reach high order and show its efficiency as a powerful initiator.

The better stability of p-DDNP could make it more useful in such schemes and possibly in a "green detonator" it could be used in tandem with DBX-1 for

example. Silver azide is another possibility.

|

|

|

| Pages:

1

..

12

13

14

15

16

..

33 |