| Pages:

1

..

11

12

13

14

15

..

48 |

Xenoid

National Hazard

Posts: 775

Registered: 14-6-2007

Location: Springs Junction, New Zealand

Member Is Offline

Mood: Comfortably Numb

|

|

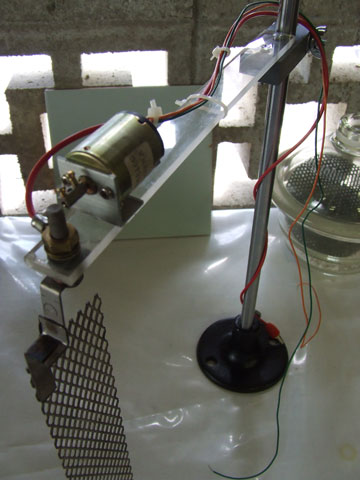

Don't Rotate - Vibrate!

With regard to bubble elimination during plating.

When I finally get around to experimenting with LDO plating, I intend to vibrate the anode rather than rotate it. The anode is mounted at the end of a

semi-flexible plastic strip (perspex - 20cm x 2cm x 4mm) along with a small motor with an offset weight on the shaft.

The motor is quite good quality, from an old VCR and appears to be nominally 6V but operates from about 3 - 9 volts. By connecting to a variable power

supply you can vary the "buzzzzzz" on the anode. I may need to put a slightly heavier weight on the shaft when the anode is immersed in liquid but

otherwise it should do the trick to prevent bubble build up.

Please, no vibrator jokes -

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

Xenoid, that is an awesome idea! I never would have thought of that. Your rig is assembled, you need to try it! Are you lacking chemicals or

something?

By running the vibrator motor with a variable DC supply, you can fine-tune it during the actual plating process so as to achieve a sort of low

frequency, higher amplitude "waving motion" through an arc of maybe a mm or two. I think that would work better than a higher frequency. To get a

low frequency, you'd need a larger weight on the motor, and maybe some sort of a thinning of the support arm. Very clever concept.

What are some thoughts on heating methods for the bath? I've got a standard all glass immersible aquarium heater, but I suspect it'd need to be

hacked so as to bypass the thermostat. One device I've always wanted is a variac, a variable AC transformer, for this sort of job. Bypass the heater

thermostat, hook the heater up to the variac, and use the variac to control the heater output.

The MMO --> perchlorate test cell has a faint dusting of perc, meaning the solution is saturated, and it's starting to fall out. The liquor tests a

strong positive using methylene blue for perchlorate. It's been 40 hours so far at 15 amps, (600Ah) and the liquor started as pure chlorate, no

dissolved perc. The bath temperature is about 60C. 2.5 liters at 60C should hold about 200 grams of perchlorate, probably less as we are dealing

with mutual solubilities here. For the sake of the argument, let's assume the cell has produced 180 grams of potassium perchlorate.

At 100% efficiency, it requires 53.25 Ah to convert 1 mole of chlorate to perchlorate. Simplifying the math a bit yields:

Efficiency of a POTASSIUM chlorate --> perchlorate cell

E = Efficiency

W = Weight of yield, in grams

Ah = Ampere-Hours used

E = (38.42 * W) / Ah

The very early, preliminary, and very much guessed-at efficiency is: 11.5%

This presumes that the cell is in the state that I believe it to be, namely saturated with 180 grams of perc and just now beginning to fall out a bit.

There is no smell of ozone. In fact, there is no smell at all that I can detect. I'm going to let it run another day or three and see if perchlorate

does in fact continue to accumulate. But efficiency-wise, it's not looking good.

[Edited on 19-11-2008 by Swede]

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

Swede: I use my hotplate/stirrer for heating the bath.. I've found that a setting of just over "1" gives me about 65C after a couple hours. I usually

heat it up on a higher setting and then back off.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

IIRC, in Beer's MMO patents he states a belief that the MMO coatings are porous with a large surface area. I wonder if this could be the reason for

the low efficiency?

Maybe ClO3 ions, because of their size relative to typical MMO pore size, do not have access to most of the active surface of the MMO coating, so it

has no choice but to make more O2/O3 (more than it would if all species had equal access to the surface)?

Are the surfaces of PbO2 coatings relatively non-porous? Maybe PbO2 is useful for ClO4 production mainly because of this physical property?

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

I pulled the plug on the test cell. Since this morning, there was no additional visible perchlorate production. There remains a light dusting, about

a teaspoonful floating around in there. It was going nowhere.

Without any reasonable efficiency, I see no reason to continue testing or modifying any parameters like pH or temperature, or using additives. MMO

alone (this formulation at least) is not sufficient for perchlorate production.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Rats. Well I'm sorry to hear that. Sounds like it went from making ClO4 at low efficiency, to not making any more ClO4 at all. Can I ask, what was the

cell voltage and current when you began vs when you pulled the plug?

Also, is there any visible wear of the MMO coating?

Edit:

I had a few more thoughts about your MMO test.

Your cell did make perchorate, but it apparently stopped doing so at some point. If the coating was not damaged, then I take this to mean that the

efficiency is a strong function of the chlorate level.

Maybe if you were using NaClO3 rather than KClO3, at a much higher concentration, the cell might have made lots of perchlorate at an efficiency much

higher than 11.5%

So although your results were discouraging, it's possible the MMO anode might still be useful in a cell using NaClO3, especially if the chlorate

concentration is kept up.

[Edited on by jpsmith123]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There's quite a few MMO formulations which are selective and efficient for producing O or Cl for example but won't efficiently produce perchlorate.

Bismuth as Bi2O3 is probably your friend as the cheapest doping material reported to be catalytic for perchlorate as a component of an MMO coating. It

reportely also has benefit in coplating with PbO2.

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

jpsmith, the voltage (at 15 amps) hardly varied at all throughout the run, about 6V. I think your observation about using sodium rather than

potassium might be worth exploring, but my guess would be even then, the efficiency is not going to be above 30 or 40%

The MMO coating looked fine visually. The Ti cathode face next to the anode had a very light gray smut on the surface which wiped off with my

fingers. I don't know what the smut was, and I'm hoping it's NOT MMO material. I'll take a closer look today at the anode, vs a section of unused

mesh.

The transition of chlorate to perchlorate (on a molar basis) happens much faster than chloride to chlorate, only 52 Ah/mole for perchlorate, vs 161

for chlorate. In this exact same cell, using a jewelery-plating Pt anode, the bottom of the cell had accumulated a thick layer of perchlorate after

only 48 hours had passed.

My gut feel in these cases is to look to industry. I haven't heard of MMO being used for commercial perchlorate yet. I think if it was practical,

they would be doing it. Perhaps there are formulations that do make perc, but with unacceptable wear rates.

Edit: I am shopping for titanium tubing for research/anode purposes. Frankly, the difficulty in sealing flat strap hangers to the lids of cells is

becoming quite annoying, and the use of round tubing would permit the use of viton o-rings to seal, as well as a simple drilled hole in the cell lid,

vs. a tiny milled slot, which is difficult to do properly.

I've worked both CP and alloy titanium... the CP variety is much softer and easier to work, and I do prefer it, but it is much harder to find. Does

the use of alloyed Ti create problems in these cells? Any recommendation on suppliers of Ti tube?

There's an eBay guy called Titanium Joe, but he's in Canada. Nothing wrong with that except customs. My favorite supplier of CP Ti sheet:

http://www.aedmotorsport.com/Titanium/CPGrade2Sheet.htm#A

This guy has a huge number of assorted cuts of CP sheet. The only limiting factor is the thicknesses are all 0.039" to 0.041", slightly thinner than

I'd like but still a good thickness for electrode use.

[Edited on 20-11-2008 by Swede]

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

Before Xenoid suggested vibrating an anode during plating, I was already 90% done with a deluxe rotational rig. Given all the work that went into

this, I'll probably give it a try. I still have to set up a good plating tank using sheet Cu cathodes.

The hard part about a rotating setup is good, solid, continuous electrical contact with the rotating shaft. I decided to use 3/8" (~ 10mm) hard Cu

tubing, and an extruded aluminum column. I thought about making a springy Cu finger to press against the shaft, but then decided to do it properly,

with a carbon brush.

I milled a brush holder out of aluminum, slotting the rear to hold the circular spring cap:

The extruded aluminum is good stuff, because it is T-slotted, and allows the repositioning of the motor head to various locations on the vertical

upright, which is affixed to a piece of plywood. The motor is enormous and total overkill, but it is the best one that I had. I took two surplus

timing sheaves and mounted them on the gearmotor and Cu shaft...

The small brush assembly is inverted and mounted on the horizontal boom arm:

The continuity checks well with an ohmmeter. All that remains is to slot the end of the Cu rod and mount that to the anode strap, and set up a good

plating bath.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Swede, that is certainly an impressive mechanical setup you've got there...obviously a lot of time and effort went into it. I hope in the end it pays

off for you.

Speaking of PbO2, does anyone remember what kind of efficiency Dann2 stated that he got with his PbO2-over-SnO2-over-Ti anode? I don't remember the

number, but I seem to recall that it was disappointing. Also, IIRC there was some noticeable wear on the anode or sludge on the cathode or something.

Anyway, PbO2 may work better over MMO than SnO2 but that remains to be seen.

As far as "looking to industry" is concerned, keep in mind that industry is almost single-mindedly concerned with "efficiency" whereas for us that is

generally of lesser importance; for example, industry no longer uses graphite to make chlorate but for amateurs more chlorate is made with graphite

than anything else I think.

What I find so frustrating about anodes for perchlorate is that it seems more art than science...it's all empirical...nobody seems to know exactly

what's going on.

|

|

|

watson.fawkes

International Hazard

Posts: 2793

Registered: 16-8-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Swede

The MMO coating looked fine visually. The Ti cathode face next to the anode had a very light gray smut on the surface which wiped off with my

fingers. I don't know what the smut was, and I'm hoping it's NOT MMO material. I'll take a closer look today at the anode, vs a section of unused

mesh. |

Although it's occurred to me before, it hasn't been too important to mention until now. You might

consider, when you construct your cells, making the electrodes individually removable so that they can be weighed. If you're losing MMO through any

mechanism, it would show up on the scale.

What else is attached isn't relevant as long as you can get a consistent tare weight. This means that you could seal a strip electrode into plastic as

you've been doing, but, say, make that plastic a disc with a rebate for an o-ring.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

The (gruesome) details of the Ti/SnO2/LD anode runs are here:

http://www.geocities.com/CapeCanaveral/Campus/5361/chlorate/...

The CE for going from (Na) Chloride all the way to Perchlorate was 17%. That's not too bad as they only get 55-62%% CE from the industrial

manufacturing facility that was doing the same thing. They would have of course used pH control, I did not.

I think that back when the folks in Navada where making Perchlorate from Chloride, they were getting electricity for half nothing from the Hydro dam

owners that were begging people to take some power off there hands.

Sometimes I wonder have we latched onto the (lazy) idea of going from Chloride to Perchlorate, without any intermediate processing, too much.

See here for original by Upuda and folks.

http://www.geocities.com/lllwolly/further/jes1976.html

+

http://www.geocities.com/CapeCanaveral/Campus/5361/chlorate/...

Note that they add NaF in order to raise the overpotential for Oxygen evolution at the (LD) Anode. (stop it happening)

I has wrongly thought it was to stop reduction at the cathodes?, o dear.

The efficiency of by (Pure) Na Perchlorate cell was not too hot. It varied from day to day. See link at top. Bear in mind I was 'more testing the

anode than making Perchlorate'.

Perhaps pH control would have helped? I did use additive.

Going all the way to low concentration of starting material (let it be Chloride when making Chlorate or Chlorate when making Perk.) is always going to

be a low CE business when compared to industry who are not going to do it unless they can get power for half nothing.

The anode should be made with a much thicker coating of LD on it but that's another story.

@ Swede. The coating setup is looking more and more impressive.

YOU WILL NOT BE GETTING ANY PICTURES OF MY COATING SETUP + BENCE BACKGROUND!!!

Anyways I am in the process of setting up a cell using poor-mans-MMO* that I intend to pH control to see what erosion will be like.

Dann2

*Graphite

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Nice spinning jig. A floor standing drill press with a flange

bearing on the rotating vise table would work too, passing

the shaft through the table to a second chuck below.

When you do the actual plating are you going to use a coaxial arrangement of tubular cathode of some sort?

One of the advantages I believe is likely for the coaxial electrode assembly, having a pumped electrolyte, which I have mentioned, is that by changing

the electrolyte composition to a lead nitrate-bismuth nitrate plating bath, the anode can be plated in situ, and then the tubing and pump and

reservoir emptied and rinsed, refilled with the brine used for the oxysalt production. If the inlet and outlet holes for the electrolyte flow were

angled and surrounded by chambers like hollow collars at each outside end portion of the cathode tubular housing, a cyclonic flow of the electrolyte

would possibly achieve the same effect across the surface of the anode during plating, as would spinning the anode in a static or stirred plating

bath. Also I am thinking there may be enough intermixing of hydrogen and chlorine in the

electrolyte exiting the electrode assembly during electrolysis of brine, that a turbulent flow in a transparent glass coiled tube like a graham

condenser , illuminated by a halogen lamp, may reconstitute the HCl needed to hold the electrolyte pH relatively stable. So there are a couple of

more possible advantages to a coaxial cell arrangement.

Another of course is the localized heating would keep the electrode clear of crystallization , which would occur in the

cooling solution in its receiving tank from which the electrolyte is returned by the magdrive circulator pump

back to the coaxial anode assembly , in a continuous loop. Supplementing the electrolyte with fresh feedstock

materials, testing and adjusting pH if needed, and regulating temperature, as well as harvesting crystallized

product from the process would be easier using a pumped electrolyte and a coaxial electrode assembly. This could run continuously at an optimum

operating point as opposed to a batch process which runs a lot of the time

at an inefficient range of concentration for the electrolyte

and other less than optimum parameters. For convenience

in carting away the product you could just use a poly wheel barrow as the reservoir and cooling tank, having a pair of wheelbarrows side by side so

that when one is full you simply switch over to the other  so that the process

remains so that the process

remains

uninterrupted.

The coaxial arrangement would also allow for use of tubular titanium for both the anode and cathode and the orientation

could be reversed possibly to advantage using the inside

of the outer tube as the anode , since this is agreeable in

shape and form for the plating of PbO2 moreso than any other shape, due to the natural deposition properties of the PbO2 it tends to form the most

dense and durable deposit

when plated onto the inside of a tubular form anode. This is the form used industrially for producing massive PbO2 anodes which are later stripped by

being sawn in curved slats something like the curved pieces in a venetian blind,

by lengthwise sawing of the substrate into segments, and then etching away the *iron* substrate . But the same idea

should work just fine on a DTO or possibly a spinel coated

Ti substrate, the DTO being preferable IMO, with some Bi doping there also.

[Edited on 21-11-2008 by Rosco Bodine]

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

| Quote: | The coaxial arrangement would also allow for use of tubular titanium for both the anode and cathode and the orientation

could be reversed possibly to advantage using the inside

of the outer tube as the anode , since this is agreeable in

shape and form for the plating of PbO2 moreso than any other shape, due to the natural deposition properties of the PbO2 it tends to form the most

dense and durable deposit

when plated onto the inside of a tubular form anode. This is the form used industrially for producing massive PbO2 anodes which are later stripped by

being sawn in curved slats something like the curved pieces in a venetian blind,

by lengthwise sawing of the substrate into segments, and then etching away the *iron* substrate . But the same idea

should work just fine on a DTO or possibly a spinel coated

Ti substrate, the DTO being preferable IMO, with some Bi doping there also. |

RB, I like the way you think!  Taking industrial processes and scaling them

down. The thought of plating the inside of a tubular form with LD is an interesting one. Given a tube of say 50mm ID, give that a nice LD coating,

install a coaxial cathode of 25mm OD. Apply a very high current density, and by varying the flow, you just might be able to create a "1-pass" system,

meaning the electrolyte passes through (probably vertically) once, and given the high current density, the effluent is depleted of chloride or

chlorate. Taking industrial processes and scaling them

down. The thought of plating the inside of a tubular form with LD is an interesting one. Given a tube of say 50mm ID, give that a nice LD coating,

install a coaxial cathode of 25mm OD. Apply a very high current density, and by varying the flow, you just might be able to create a "1-pass" system,

meaning the electrolyte passes through (probably vertically) once, and given the high current density, the effluent is depleted of chloride or

chlorate.

The used effluent exits and flows to a cooling chamber, where the crystals settle in the case of potassium. 50 to 100 amps, and a flow rate

calculated to deplete the starting species with one pass through the system.

One way to set such a system up would be to have the tubular electrodes in a cannister, like a water-filter container.

Watson.fawkes - I thought of trying to weigh the anodes. My best scale has a 0.01g resolution. With a larger anode, it might work, but I wish I had

a milligram scale or balance.

Plating tank: I'd like to find a durable container of 2 to 4 liter capacity, with an effective lid, that will both store and be able to heat, and

plate, LD. Glass can be set on a lab heater, but glass is expensive. Plastic requires an immersion heater. I'll probably end up using a 2 or 4

liter beaker for now, and just storing the toxic liquor in a nalgene or similar HDPE container.

We've discussed rotating anode plating already, but I did have a thought... If I can find a section of copper tube of sufficient diameter, by cutting

it into two sections, I can create the proper shape of two hemispheres. If not, I'll just bend some sheet copper.

If rotation fails, I'll try vibration or simply stir the electrolyte.

All: There is a guy on ebay that's selling items of interest, including lead nitrate ($10 for 500 grams!) and Bismuth metal. His store is Chem-Wise

Chemical Solutions. He also has NaF but the shipping is lethal.

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Well after reading some more of Dann2's prolific perchlorate propaganda, it seems that (to the extent results from PbO2 and Pt studies can be

generalized) ClO4 formation is favored by: (1) high anode current density, (2) high ClO3 concentration, and amazingly, (3) high ClO4 concentration.

(Also, the more I read about it, the more I'm convinced that the processes going on at the anode in a perchlorate cell are not fully understood).

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

One pass could only work for perchlorate, unless you plan on forming all chlorate anodically (inefficiently)..

That guy seems to be sold out of lead nitrate already! I've been thinking about that 10kg package on chemsavers for $120, to split up amongst us (and

anyone else who might want some). That's a LOT of lead nitrate, but it's only $6/lb.

I've been kicking some ass on my lid adaptor since yesterday, I hope to put the cell in action tonight. I'll charge it with some commercial chlorate

I've got. Wish me luck.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

US3506561 Fibrous Alumina Conductive Catalyst Carrier

Here's one which I don't believe has been posted before although I did post the patent for fibrous alumina sol preparation in the old cobalt oxide

anode thread, I think with

regards to using this as a "modifier oxide" or perhaps in regards to making a cobalt aluminate hybrid spinel of some sort.....I don't remember

exactly. Anyway this fibrous alumina hydrate is another inorganic polymer which forms as microscopic whiskers having a thixotropic effect and forming

a sol-gel system, which on drying leaves a tightly adherent

felt of randomly oriented fibers, which dehydrate on baking

to a chemically resistant, conductive, enamel like coating,

which is however porous and can entrap particles of other

catalyst oxides or finely divided metals like palladium black,

platinum or lead oxide, formed in situ from thermodecomposible precursor salts which have been mixed into the fibrous alumina hydrate sol. This sol

seems very similar to the Pytlewski polymers based on tin oxide ,

in that it acts as a wetting agent even to teflon and is even capable of bonding teflon to metals. But for our interest it would seem that it's

possible usefulness is for making a PbO2 baked anode. See column 6 line 47 of the patent.

Supposedly this works on different substrate materials like graphite, or steel, or perhaps aluminum, and titanium may not be strictly necessary as a

substrate. The fibrous alumina

has been patented for use as a photographic plate coating process material for aluminum plates, where the deposited

fibrous alumina has a matte appearance after bonding to

the indigenous shiny oxide film of polished aluminum, and

provides a porous hard film which can then bond the photgraphic gel coat emulsion. So this fibrous alumina may solve adhesion problems in baked anode

schemes, as a bonding layer for the substrate or as an inert matrix for carrying catalysts. I think with certain dopants, on baking it probably also

forms aluminate spinels at least partially.

Inorganic polymers hmmmm, the stuff even sticks to teflon .....now that's some superduper super glue

See US4500444 column 2 line 14 referencing the bonding capabilities.

[Edited on 23-11-2008 by Rosco Bodine]

Attachment: US3506561 fibrous alumina electrode coating.pdf (202kB)

This file has been downloaded 795 times

|

|

|

Swede

Hazard to Others

Posts: 491

Registered: 4-9-2008

Member Is Offline

Mood: No Mood

|

|

Very interesting... This is worthy of further study. It appears that it is relatively easy to create an especially thick, structurally sound coating

which would protect any underlying substrate. I'm going to print it out and really give it a good read.

Tentacles, I look forward to your run. Can you snap a few pics while you're at it? How much commercial chlorate do you have? A 5 gallon bucket cell

is going to require a lot of chlorate. Or is your adapter for a 2.5 gallon setup?

The problem with test runs is the "loss" of chlorate... I've probably got a kilogram of chlorate tied up in failed perchlorate runs. I've just been

dumping it (chlorate + perchlorate liquors) into empty milk jugs, waiting for an anode capable of finishing the job.

I think before I proceed further, I need to acquire a milligram scale, probably one of the cheap jobs off eBay, so as to measure anode erosion.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yeah this is an interesting ceramic precursor, partially soluble fiber which could be a key component in making durable baked ceramic coatings.

If you do a google patent search under fibrous alumina it will bring up a lot of interesting stuff. This same sol is used as a rigidizer for

refractories like kaowool, and evidently a small percentage of it added to certain dip and bake coating precursors, reenforces the coating and

increases the adhesion by the presence of the microscopic whiskers of gamma alumina which remain as a bonding matrix after pyrolysis, and are believed

to possibly react somewhat with the materials they are bonding. IIRC this is the stuff which is used to bond the catalyst material to the honeycomb

substrate in a catalytic converter and it will also cement teflon to glass or metal , but most interesting for us is that it aggresively bonds with

other

metallic oxides like the surface oxide on a metal or the catalytic coating oxides pyrolytically produced from precursors, via a reactive molecular

reaction where the

gamma alumina whiskers appear to serve as something

like a "ceramic solder" which superficially "alloys" itself on baking with the materials it bonds as an intermediate filler material. It is sort of

like whiskers of hot melt glue which melt only superficially, fusing with whatever they are in contact, and forming a reactive bond, which then

solidifies and further fusion of the alumina whisker ceases, so it remains as a reenforcing fiber matrix on cooling.

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

I realize it's a tad off topic, but I wonder if that alumina stuff is what the "pre treatment" is for preparing pans (and such) for powder coating

with teflon?

I finished the adaptor last night, all except for a pH probe holder. Going to wait on that until I figure some stuff out.. Like a larger pipe tap. The

probe is .499" and that's just a bit too big to craft a compression fitting that has 3/8" NPT threads. The other fittings came out very well. I even

put in a fill/dip port (which I will probably eventually use for dosing HCl, with a clever adaptor.

I've only used about 14" of my 5' length of PVC rod, too. Used a few inches of my CPVC rod because it was handy.

Pics:

http://pyrobin.com/files/sdc10045.jpg

http://pyrobin.com/files/sdc10049.jpg

http://pyrobin.com/files/sdc10050.jpg

I used twisted up heavy (orange) PTFE tape to seal the lid adaptor. I just partially screwed on the lid, then wrapped the string around the screws

(and back over itself a bit).

Now comes the hard part - digging out my GD aqarium pump, and finding my heavy copper wire. I picked up some brass bolts for the electrical

connections.

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Take a look at the patent example one pasted here.

They are actually using a Chlorate solution to strip MMO (Ru Oxide).

The current density is high though at 600ma per square cm.

______________________________________

EXAMPLE 1

The coated metallic electrode comprising a titanium substrate having a ruthenium oxide coating thereon which was to be cleaned was used as an anode,

and a current was passed between said anode and steel cathodes, in 50 percent by weight of an aqueous solution of sodium chlorate at 60 A./dm. 2 of

anode current density, for 30 minutes. During this treatment, the bath temperature rose from 20° C. to 25° C. Bath voltage rose gradually from 5.5

volts, and after 25 minutes from the start of the treatment, began to rise rapidly and was 7.5 volts at the end of the treatment. (FIG. 1 is referred

to.) The anode was removed from the bath, and rinsed with water and dried. The weight loss on the substrate while the current was passed was

determined to be 0.1 percent. Thereafter, the thus treated metallic electrode was dipped into 5 percent by weight of an aqueous solution of

hydrofluoric acid for 3 minutes to complete stripping of the coating. The weight loss of the substrate during this treatment was 1.6 percent. After

the former treatment, the coating remaining on the surface of the substrate was completely stripped by dipping into the hydrofluoric acid solution and

by rinsing with water, and the surface of titanium substrate was seen to be the same as that of an original substrate.

________________________________________

Dann2

Attachment: Surface preparation process for recoating of used coated metallic electrodes - Patent RE28849.mht (203kB)

This file has been downloaded 1075 times

|

|

|

jpsmith123

National Hazard

Posts: 764

Registered: 24-6-2005

Member Is Offline

Mood: No Mood

|

|

Well that certainly doesn't instill confidence. (BTW the patent also claims that the process will remove "iron group metal oxides", presumably

including Fe3O4).

I suppose a perchlorate cell will erode *any* anode material...and like so many other things the problem is reduced to a matter of degree.

It would be nice to find some inexpensive, efficient coating than can be easily electrodeposited over a commercial MMO anode, used to make ClO4, and

then re-coated after a few runs. Maybe PbO2 is the answer but I just don't like that stuff.

Edit:

Maybe Rosco's right about Bi2O3; it might be a good candidate for a top layer over MMO. Does anyone know if it can be easily anodically

electrodeposited?

[Edited on by jpsmith123]

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

Well, it's hooked up and running at 18.1A / 6.2V - no idea why the current is so low for this voltage. Anode is about 5/8" from the cathodes. Maybe I

should have put them closer together.. Not that I can't make a new one. Swede, what was your cathode to anode spacing?

Oh, and yes, I do in fact know the cathodes are a bit staggered - it just worked out that way because of the width of my CPVC sheet and the width of

the straps on the cathodes.

edit: Now that I think of it, the current could be more of a factor of solution than anything else - I only had a bit over 1100g of KClO3, less than

I'd thought. I only used about 18.5L of water, and added 1.5g/l NaF. Getting lots of ozone and there's a pink tint to the electrolyte. WTF?

[Edited on 23-11-2008 by tentacles]

|

|

|

dann2

International Hazard

Posts: 1523

Registered: 31-1-2007

Member Is Offline

Mood: No Mood

|

|

Hello,

Are hard drive platters coated with Pt or an alloy contining Pt.

There seems to be some Pt is some of them. Would they do as a substrate. Drill them like a grid and away you go.

Souns too good to be true/workable.

http://shop.ebay.com/sis/_W0QQ_kwZ110Q20HardQ20DriveQ20Platt...

The BismutH Oxide for Perchlorate has only been mentioned on one patent that I have ever seen. See the last example. It envolves plasma spraying etc.

It has been mentions for plating with ld by adding the Nitrate to the plating tank but you are still dealing with Lead compounds.

Dann2

Attachment: US 4272354 Bismuth_DTO perchlorate anode.pdf (253kB)

This file has been downloaded 750 times

|

|

|

tentacles

Hazard to Others

Posts: 191

Registered: 11-11-2007

Member Is Offline

Mood: No Mood

|

|

dann: Apparently older/some HDD platters used a cobalt-platinum-something alloy, that was up to 40% platinum as I recall. I've tried dissolving some

old HDD platters in HCl (get rid of the useless metals first, I always say) and as nothing insoluble remained, am skeptical about finding the proper

type. Most likely the HDDs that used such expensive materials were the drives of the 80's and early 90s. You know, the 5 1/4" monsters that were

multi-thousands at release.

Got home and the power supply had kicked off the overvoltage switch so I backed it down to 6.15V - the protection seems to kick on at 6.20V and I

guess 6.18 was toeing the line too closely. The current is down to 12.5A for some reason, but that could be because the solution has cooled. I used

hot water to make the electrolyte. Our tap water here is about 65 PPM TDS, pretty clean stuff.

edit: I did take a peek at the anode and it appears unchanged, and there is no crud or residue on the cathode. The bubbler is still blasting out

air... An airstone/diffuser of some sort would really circulate the water much better than the huge chunks of air I've got coming up.

[Edited on 24-11-2008 by tentacles]

|

|

|

| Pages:

1

..

11

12

13

14

15

..

48 |