| Pages:

1

..

11

12

13

14

15

..

33 |

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Thanks for the patent, the dinitro acetaminophenol/H2SO4 solution was almost brown/black/red in colour and was put in the fridge, nothing has

crystallized out yet. I'll check it tomorrow, about to hit the sack.

[Edit] suddenly remebered that picramic acid is soluble in h2s04, after caustic soda (main part) and sodium bicarbonate neutralization a rustbrown

powder was obtained, it is more brownish red as opposed to picramic acid which is more red than brown, with sodium hydroxide the colour is an amazing

deep red, with hint of violet. Will do the diazotisation tomorrow, as its drying now. Also will make some pictures :-)

[Edited on 19-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yes pictures are good and keep careful notes.

Here's some insight into the chemistry involved.

There are some subtleties involved about the color transitions involving the behavior as a dye indicator for pH observed for picramic acid or

isopicramic acid. These amino acids like glycine, (aminoacetic acid) can function both as cation with a stronger acid to form a salt like glycine

nitrate, or can function as an acid anion with a more basic cation to form a salt like sodium aminoacetate. That's amphoterism. The aminoacid can

form a salt going or coming, can be the locomotive or the caboose.  Or it can

stand alone neat as the free aminoacid. Or it can

stand alone neat as the free aminoacid.

So there are 3 distinct forms in which we can see the aminoacid appear. Depending on the conditions, all of the aminoacid may be present as one

distinct form, or as more than one form in mixture. The color changes and conditions can identify which of the 3 forms is present at the time when

only one form should exist, defined by the conditions.

The dye indicator property usually applies to the picramate or isopicramate salt when a base is the cation and the picramate or isopicramate is the

anion, for example sodium picramate or sodium isopicramate. To the limit of their solubility such salts function as powerful intensely colored dyes,

more intensely colored in the more basic range and fading to the more pale color of the free aminoacid when the base cation is displaced by a stronger

mineral acid, when that base migrates and associates with that stronger acid, leaving the lower solubility and less intensely colored picramic or

isopicramic acid as the free aminoacid in the solution, probably in part precipitating as a solid residue, due to low solubility in the solution which

is becoming increasingly acidic with the mineral acid.

However as the mineral acidity increases further, the free aminoacid being amphoteric can also function as a cation in association with a stronger

acid than itself, and begins to dissolve and probably exhibit a different order color change as

for example occurs with formation of isopicramic sulfate, which will remain in solution even after being diluted, and will not return to free

isopicramic acid and precipitate, until acted upon by a base to associate with the stronger acid and displace it.

How the color change occurs in this second scheme where the amphoteric isopicramic sulfate forms increasingly soluble and concentrated solution is

something I do not know. So you will have to "ball park" guess what are your neutralization equivalents based on how much of what strong acid/s you

are using and undershoot the bulk neutralization and titrate manually to produce the color changes and precipitations which should be logical when you

observe.

The attached (again) article from Chemical World describes the de-benzoylation procedure which is possibly applicable also to the de-acetylation. It

describes a spot test used to monitor the progress of the reaction by solubility on dilution of a sample and this may be a useful test also for the

deacetylation.

Because of the volatility of acetic acid the de-acetylation will likely proceed more easily than the de-benzoylation.

A vacuum and/or passing through a bubbler inert gas, or riskier ordinary air might help strip away the volatile acetic acid and speed up the

de-acetylation.

Earlier I speculated that this compound may be an example of "lost art" that has been gathering dust for a hundred years and has become an academic

obscurity, and I think that's right. But I also think this iso-DDNP could be an oldie but a goodie.

The iso-DDNP may prove superior in significant ways to the usual DDNP in both explosive properties and storage stability. For example in thermal

stability tests at just above the BP of H2O, 110C, the iso-DDNP has 6 times the stability of the usual DDNP. At lower temperatures more consistent

with natural environmental storage temperature ranges, the iso-DDNP could easily be dozens or more times storage stable than the usual DDNP. If the

initiating properties are also better as expected for the iso-DDNP, then it can be appreciated how the iso-DDNP would be the superior initiator.

Also speculated earlier about the potential for a mixed isomer cocrystallization with the better known DDNP, and am still intrigued what may occur

there as a potential for better crystalline form and density, and potential improved properties if such a mixed isomer crystal does form.

AFAIK there is nothing in the literature about this, and very little about the iso-DDNP either.

So this is follow up experimental "re" search with some new aspects as a bonus and it also involves a green energetic.

Attachment: Pages from The_Chemical_world pg327.pdf (247kB)

This file has been downloaded 651 times

[Edited on 19-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Yes, I wonder whether the dinitroacetaminophenol formed may also be amphoteric, maybe one of the reasons why neutralization of the entire nitration

mix is performed according to several papers and patents, although it does seem to precipitate out when crashed in water as an yellow/orange solid.

Another thing that may be beneficial in neutralizing is that when the nitration mix is crashed on ice, some NO2 is formed, maybe due to decomposition

of nitrosylsulfuric acid formed during nitration analogous to the syynthesis of picric acid, which may oxidize part of the product. After crashing in

ice it may be beneficial to leave the nitration/ide mix for some time with vigorous stirring to get rid of it ASAP. Acetaminophen itself is incredibly

sensitive to NOx oxidation, the formed NO2 after crashing in crushed ice oxidized small remaining acetaminophen from the weighing container it was in,

which was 30 cm's away, forming a deep red colouration.

The deacetylation when performed in sulfuric acid has another benefit, most of the remaining stuff extracted from the paracetamol tablets seems

insoluble in the deacetylation mix and can easily be filtered out.

If p-DDNP is superior to o-DDNP in almost every aspect, I do wonder why this is not used on larger scale, DDNP is almost exclusively used and

researched in China for example, the existence of p-DDNP and it's properties must be known and studied, can there be a catch or is large scale

production of p-DDNP less feasible?

[Edited on 19-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The acetylated isopicramic acid obtained directly from nitration of the paracetamol could very possibly be amphoteric also. Good point. Given your

observation that the acetylated isopicramic acid precipitates from the diluted nitration mixture which is very strongly acidic for its unreacted

sulfuric acid content, it is indicated however that any amphoterism would be very much lower for the acetylated isopicramic acid, than has been

reported as a distinct property of the deacetylated isopicramic acid which readily forms a soluble sulfate.

You will learn by observation during the reactions and manipulations what are the visual "markers" that may be indicators of progress of the

reactions. Temperatures are included markers usually for where things are going and when effective endpoints have arrived.

There are Chinese followers of this forum so I would expect they are looking at this iso-DDNP now if they haven't already done the research. The cost

for the iso-DDNP production may be a little more, but the quality may offset the cost.

It could come down to simple economics where only costs alone are governing.

During the past years when many manufactured items available in the world are coming from China as a result of the massive industrialization there, it

has been for me a mixture of admiration for the technology and quality for some things, and a displeasure for other things where slight changes could

greatly improve the durability and serviceability for equipment that has been deliberately made "disposable" and difficult or impossible to maintain

or service or repair, so that disposal and replacement has been made necessary. That is my "pet gripe" about the "progress" represented by some

designs for more expensive manufactured goods from China. In fairness however it seems to be a global trend, and is definitely not an ecologically

sound "design strategy" but is a greed motivated kind of "engineering". This should never be a design strategy applied to appliances or vehicles, to

make difficult their maintenance or repair, but it has sadly become the routine to encounter such design and engineering being deliberately

implemented by various product manufacturers. It may serve company profits to implement such designs but it is detrimental to the consumers and to

the environment. There, I've said my piece. Engineers have a kind of ethical credo, just like medical doctors. First do no harm.

The few reported properties of the iso-DDNP definitely look promising. If it does simply detonate from heat instead of requiring a larger mass to

undergo a DDT like is the case for the usual DDNP, that would tend to make it much more efficient as an initiator. The improved stability could also

make it useful as a component in ammunition primers, depending upon the sensitivity and crystalline form. The economics involve more than just the

difference in costs for the two isomers purely on a weight basis.

[Edited on 19-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Redid the synthesis today, only double the amounts and without neutralization

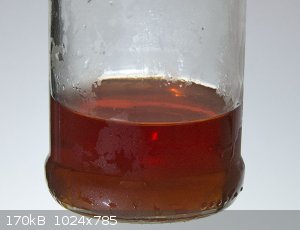

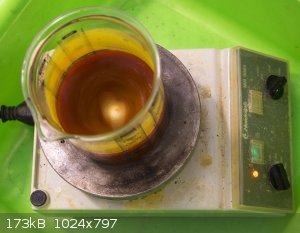

Photo 1: 20 grams of ethanol extracted acetaminophen was added to 120g 98% H2SO4 and heated to 70 degrees for 15 minutes to dissolve and sulfonate

yielding a golden caramel brown solution

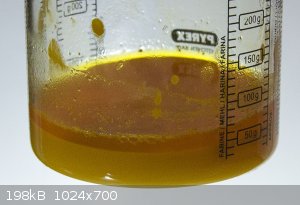

Photo 2: 24 grams of AN was dissolved in 60 grams of H2SO4, cooled to below 0 deg C and slowly added to the SA/Acetaminophen while keeping temperature

between 5-10 deg C. Halfway through the nitration a deep yellow/red, almost black solution was obtained

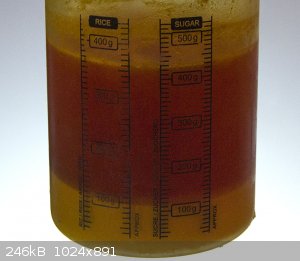

Photo 3: After all of the AN/SA was added, the nitration mix returned to an orange/brown colour

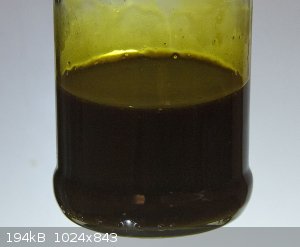

Photo 4: The nitration mix was crashed in ice/water and fut in the fridge. After settling the dinitro acetaminophen settled to the bottom of the

beaker as yellow/orange solid

Photo 5: After filtering and washing three times with cold water, the product was transfered to a beaker containing 50 ml 98% H2SO4 and 50 ml of water

Photo 6: The beaker was put on the hotplate while stirring and heated to a temperature just below the boiling temperature of the water/SA solution

(120 deg. C)

Photo 7: Deactelyation after 45 minutes, very pronounced acetic acid smell, solotion turned a very deep orange/brown

Next, After cooling the solution was neutrailized using cooled NaOH solution and bicarbonate, precipitating a large amount of rust brown powder

(forget to take picture, srry  ) The colour during neutralization changes very

suddenly and dramatically when the pH comes below a certain point. The difference really is a few drops of bicarbonate solution, amazing to see :-) ) The colour during neutralization changes very

suddenly and dramatically when the pH comes below a certain point. The difference really is a few drops of bicarbonate solution, amazing to see :-)

Photo 8: final yield after drying, 20.3 grams of putative isopicramic acid.

The staining power of this compound appears even stronger than that of o-picramic acid. Producing a deep red with blueish tone in basic solution. Less

than 1 mg under basic conditions produces a very strong colour in a glass full of water. When strongly diluted, the colour almost becomes in between

purple and pink.

The isopicramic acid was diazotized according to COPAE method and is drying now :-)

[Edited on 19-5-2015 by nitro-genes]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Very nice, I would be really interested in seeing the results from some explosive tests if you do them.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Well, the p-DDNP is dry, I dried it over a hot waterbath. It flashed pretty fast, but not as fast as the o-DDNP I made and leaves more residue.

Because of this I suspected that the isolated isopicramic acid was made up of multiple compounds, and Irecrysallized the isopicramic acid from

ethanol. It crystallized very peculiar, like small spherical goblets attached to each other, which may be another indication that some other impurity

is present, as can also be seen from the picture (yellow and red stuff). There are several probabilities, 1 is that simply deacetylation was

incomplete, the colour of the impurity resembles that of dinitro acetaminophenol, although reheating part of it with SA produced no smell of acetic

acid. Whatever it is, unforntunately it co-crystallizes with the isopicramic acid, also seems so with the second crop of crystals although much less.

Other possibillitites are that the nitration produced a mix of mono and dinitro compunds, partly oxidized stuff resulted from the nitration, the

deacetylation may have been to rigourous resulting in decomposition or some stuff from the tablets is still present. (Although the latter is unlikely

IMO) Anyway, close, but no cigar.

[Edited on 19-5-2015 by nitro-genes]

[Edited on 19-5-2015 by nitro-genes]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

The second crop looked better, I've again did the diazotisation (this time using sulfuric acid since it is stronger and partly solubilizes the

isopicramic acid, this DDNP is faster than with COPAE method for isopicramic acid. It could also be that p-DDNP needs more strong diazotisation

conditions than o-DDNP. Anyway, this stuff does indeed seem faster than o-DDNP! When 1/8 of a match head is heated it makes a fast pop rather than

flashing like o-DDNP does in minute quantities, also the flame colour of the p-DDNP seams more bright so to speak. I'll make a comparison video of the

p- and o-DDNP when dropped on a heated hotplate and ignited and also see the difference in ignition temperature. The larger batches need to dry first.

I'll keep somewhat in sunlight to see light sensitivity and in contact with some metals and maybe weight loss at different temperatures in the oven,

impact, friction tests etc... Also indeed a brisance test in 10-500 mg amounts like Henning brand suggested would be nice to do, although the first

(but more boring) thing to do would be to optimize all the steps of the synthesis. The yield could definitely be improved for this synthesis, I wish I

had dried and weighed the dinitroacetaminophenol intstead of directly going for the decetylation, it could shed some light on where there may be

improvements in the synthesis. Cool stuff! :-)

[Edited on 19-5-2015 by nitro-genes]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Bad quality o-DDNP from some experimental crystallization techniques, I didn't want to do the synthesis again. Still... p-DDNP is much faster! Both

are 50 mg amounts the left is o-DDNP ignition, the right the p-DDNP. By the sound of the flash I would say that the p-DDNP wouldn't need much more

unconfined to make DDT. Wow, nice!

Attachment: o-DDNP and p-DDNP.avi (3.2MB)

This file has been downloaded 938 times

[Edited on 20-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Hmmm.....this is looking promising. The iso-DDNP seems to have more pop. Probably has a lower critical mass for going high order.

Interesting. I think the process might be refined.

20.3 grams is a 77% yield which should be over 90% so something is off.

Your mole weights are as follows: paracetamol 151.16 acetylisopicramic acid 241.16 and isopicramic acid 199.12

One thing I suggest changing is the initial step of heating to sulfonate the paracetamol. There could be a couple of issues possible for doing that.

Deacetylation early could occur and if the acetyl group is protective of the amino during nitration, losses could occur. Also the displacement of a

sulfonate may not occur during mild nitration conditions. I suspect the paracetamol may be vulnerable to oxidation losses during nitration similarly

as is resorcinol.

I didn't check to see if you adjusted the H2SO4 amount to account for part of the H2SO4 getting expended to make the HNO3 content in situ. The patent

used azeotropic or about 60% HNO3 so there is some H2O content included there also, but what effect or benefit it may have is an unknown. A little

extra H2SO4 even beyond that being expended for the HNO3 should be used to better accomplish the same effect of the mixed acids and keep closer the

solids content of the reaction mixture.

Your first synthesis reported in the other thread is more keeping with the process of GB24409 and US3641154

Try to copy the patent conditions and see if it cleans up the end product, by possibly improving the intermediates.

The diazotization conditions controlled in the same way of producing the more dense and coarse variant of DDNP may also benefit the iso-DDNP.

[Edited on 20-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Yes I was aware of the other reported syntheses where no sulfonation step is performed, however, several of the patents I found actually start with

the sulfonic acid derivative of acetaminophen, this most likely rules out the possibility that the sulfonic acid group is not displaced during

nitration. Deacetylation due to the sulfonation step is not happening, I took whiffs of smell during the sulfonation step and did not smell any acetic

acid at all (smelling is bad practice I know, but very informative sometimes). I noticed that without some heat applied, very little acetaminophen

will actually dissolve in the SA, or maybe I should have just been more patient. If you look at the pictures, the solution above the dinitro

acetaminophen after crashing in ice and settling, is really orange. I suspect that this is the main culprit of the lower yield, but does not explain

the other compound that is present. In fact, when the nitrating mix was neutralized yesterday, very near neutralization the solution went almost

clear, I think part of the dinitro acetaminophenol is just soluble in the nitration/water mix maybe due to its amphoteric character, even when cooled

below 0 deg C.

[Edited on 20-5-2015 by nitro-genes]

[Edited on 20-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Please share the patents you are seeing report this.

It may be the holding time was too short for the nitration. Slow is how these nitration can go at lower temperatures. And it can help to have a brief

time at a warmer temperature to finish the nitration, but it also may introduce an additional nitro group.

EDIT: I should correct my earlier speculation about the introduction of a third nitro group being possible with a warmer or stronger nitration

mixture when paracetamol is being nitrated. Meldola reportedly performed experiments to produce a trinitro variant and found it was NOT possible to

further nitrate the acetyl derivative of isopicramic acid beyond the dinitro compound.

Therefore there is no advantage and could be disadvantage for nitration schemes that would more aggressively nitrate paracetamol at the risk of

producing oxidation byproducts, probably resinous and troublesome unwanted materials, as an impurity.

[Edited on 20-5-2015 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The p-DDNP did seem to have more pop, however, I don't think either of those samples of DDNP in the video burned very cleanly. The o-DDNP I tested

burned very cleanly leaving only a thin grey smoky coating on paper. It deflagrated in much the same way as mercury fulminate does making a loud whomp

type sound. It is a little hard to tell from the video, but it looks like both samples are fairly impure.

[Edited on 20-5-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

It is known that DDNP does not make DDT unconfined unless more than a few grams or so are ignited. Impure or not, I'm positive that 100-150 mg of the

p-DDNP would have made DDT.

Maybe you could make a video of 50 mg of your DDNP on white paper, just curious how much faster DDNP is when completely clean, would be a nice

comparison.  Maybe I should recrystallize the DDNP like you did to get rid of the

sublimated sulfur contamination from the S/vaselin heating, maybe that would clean things up Maybe I should recrystallize the DDNP like you did to get rid of the

sublimated sulfur contamination from the S/vaselin heating, maybe that would clean things up

[Edited on 20-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The ammonium salt of the acetylisopicramic acid has low solubility in cold water and good solubility in hot water and can be used for initial

purification by recrystallization.

From this information it may be known that sulfonation is not required, nor is sulfuric acid. Paracetamol may be dissolved in the minimum amount of

glacial acetic acid and nitrated in the cold maintained by an ice bath, gradually adding a nitrating mixture containing twice the amount of theory of

d 1.5 HNO3 diluted with twice its volume of glacial acetic acid. The nitration completes in the cold in a few hours.

[Edited on 20-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

yes, acetaminophen is very soluble in glacial acetic acid as opposed to cold SA, I've found no listings of incompatibilities for acetaminophen with

concentrated sulfuric acid nor did I have any indication for this during the synthesis. Acetylation of salicylic acid is generally performed using

acetic anhydride with H2SO4 catalyst at 100 degrees, although this is more dilute though. I'm pretty sure that the decreased yield is either from the

nitration or from only partial precipitation after crashing in ice. Next time I will save the filtrate and neutralize this to see how much is left in

here. Maybe using only -20 cold ice to crash the mixture in will also precipitate more. I added substantially more water/ice than anticipited to keep

the mixture below 10 deg C upon dilution, which is also a probable cause of yield loss. The ammonium salt may be a good alternative for

recrystallization from water as opposed to ethanol, thanks!

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I never noticed that much sublimed sulfur made it past the first bit of the steel delivery tube at the generator end. Notice that I happened to be

running the H2S generator outside in winter as well and IIRC the ambient temperature and consequently the delivery tube temperature were normally

around -10C. I don't have any DDNP made at the moment, but I do have 20g or so of sodium picramate in storage so I could make some easily. You are

doing some interesting work and I wasn't trying to take it from you, but there looked to be some pretty heavy particulate combustion residue in the

video, however it was a bit hard to tell for sure.

You are right, it may just take a little more mass for the p-DDNP to make DDT.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

You mean less mass for the p-DDNP to DDT? (as compared with o-DDNP?) See edit below regarding this

The o-DDNP is the more commonly known DDNP isomer from picramic acid, the 2-amino 4,6 dinitrophenol.

The 2 position amino or later diazo is ortho to the 1 position phenol hydroxyl, therefore the "ortho" designation for o-DDNP which is the usual DINOL

or common DDNP

The p-DDNP is the more stable and sassier isomer from isopicramic acid, the 4-amino 2,6 dinitrophenol

The 4 position amino or later diazo is para to the 1 position phenol hydroxyl, therefore the "para" designation for p-DDNP which is the iso-DDNP

EDIT: I now undersatnd what you mean as not comparative of the ortho and para compounds but just referring to the one sample weight for the p-DDNP

which was tested for ignition effect at 50mg .....saying that three times the amount would likely high order.....meaning a "little more" weight for

the sample would likely DDT.

I will leave my description for the structure anyway for others who may also need the clarification.

[Edited on 20-5-2015 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Well he said above, in the description with the video, that he felt the p-DDNP was close to making DDT and that a little larger charge mass may have

made it so it would have. I see that what I wrote could be a bit ambiguous if the earlier comment was not noticed.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I understand. My earlier post was edited, but I am leaving the description for the isomers for possible usefulness to others. There is actually at

least one more isomer of DDNP reported, but we can save that one for later and not derail this more interesting discussion for what is probably the

best of 3 known isomers.

From what I have gleaned from the literature, this p-DDNP should prove superior to the o-DDNP. If nothing else it is an alternative initiator at

least as good as o-DDNP and is possible to synthesize from a commonly available precursor which is paracetamol. No reduction of a nitro compound is

required to produce the amino acid precursor for diazotization, which simplifies things in that regard.

The synthesis from paracetamol should not present any unsolvable difficulty. But there are probably details and refinements for the manipulations

which may be worked out to optimize the procedure. It is already known that the end product purity has great bearing on the performance of the

material, so it can be expected that fine tuning of the synthesis should lead to a better performance for the highly pure end product, and that

crystalline form and density may be important also.

The reactions which are known for DDNP to produce azide and tetrazeno type derivatives could also be investigated to see if the p-DDNP analogues have

better performance.

A eutectic low mp mixture forms for picric acid and o-DDNP and may likewise occur for p-DDNP. What may be the effect with styphnic acid is not known,

but such mixtures could result in a more sensitive, more powerful mixture for a base charge in compound detonators.

A possible candidate solvent, other than acetone, for purification of DDNP is nitromethane, to which might be dropwise added methanol or toluene or

xylene or naphtha as a solubility decreaser to cause gradual slow crystallization forming larger crystals instead of a crash precipitation of small

crystals as a low bulk density material, as would be obtained from a diazotization where crystal growth does not occur unless the diazotization is

optimized for crystal development.

On a lighter note. It occurred to me that the nanny state regulators of hobby chemistry experimenters are presented with a kind of double whammy

migraine for the proposition of p-DDNP from over the counter acetaminophen. As if ordinary aspirin isn't already a concern as a "strategic raw

material" hmmm.....now here comes tylenol as another "headache remedy"

The reaction of extra special agent Gumby charged with the official duty of tracking unauthorized off label use from diversion of benign OTC

materials is probably something like this

[Edited on 20-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

NP, I was not after a whose ding-dong is bigger discussion, is was genuine interest because I've never seen videos of DDNP ignited on white paper,

which is very revealing and the exact reason I did it this way  . I don't know

how very pure DDNP flashes, so this would be really interesting to see. The DDNP I produced flashes very similar to other DDNP videos I've seen

though. . I don't know

how very pure DDNP flashes, so this would be really interesting to see. The DDNP I produced flashes very similar to other DDNP videos I've seen

though.

I'm not doing anything with larger charges anymore, so I never really got a good reason to make my DDNP very pure by recrystallization for example.

Moreover, this is tough because any residual sulfur forms an incredibly fine precipitate which is almost impossible to filter IMO. If you could make a

movie of a 50 mg amount flashing on white paper that would be really appreciated, seriously. I thought about doing the sulfur/vaselin heating, but was

afraid of the sulfur sublimate contaminating the NaOH solution, which would result in a bright orange solution instead of pale yellow for normal Na2S

solutions.

I'll make a new movie clip since I produced both o-DDNP and p-DDNP exactly the same way for a better comparison, the colour from the p-DDNP is almost

the same, although is has a slightly more purple/pink tint to it. Also planning to make some dextrinated pellets, like Rosco suggested earlier, to see

whether the compressed p-DDNP is able to make DDT. Regarding the synthesis from acetaminophen, the optimization of the synthesis from AN/SA really

requires a lot of effort since there a several steps involved and the starting material is a complex mix of all kinds of stuff. For all I know it may

be that a certain brand of paracetamol tablets produces less impurities from ethanol extraction, although it may be that the nitration using AN

requires different conditions and reaction times indeed, or maybe deacteylation of the dinitro acetaminophenol requires a different protocol. If more

people could perform the synthesis and share their experiences that would be great!

This has so much potential and possible follow up experiments that it is impossible for one person to do anyway.

[Edited on 20-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There are alternatives to H2S generation which do not involve thermal cracking of hydrocarbons. Simply treating with H2SO4 a "lime sulfur" or sodium

polysulfide produced from NaOH and sulfur will evolve H2S which can be bubbled into an NaOH solution, tracking the neutralization by weight gain for

the vessel containing the solution being neutralized. The free sulfur byproduct stays in the H2S gas generator and does not sublime at ordinary

temperature. I think there were several schemes described earlier for producing the sulfide reducing agent.

And there are alternative schemes for reduction that involve no sulfur at all.

@nito-genes I am predicting that Hennig is going to require a new witness plate.

A random musing kind of thought is that either isomer DDNP might make an interesting third component in AP putty.

[Edited on 20-5-2015 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

The "standard" so to say to generate H2S gas on a lab scale is to use FeS, it can possibly be very simply produced from heating sulfur and steelwool,

or maybe ground up steelwool. No other gasses would be produced upon dripping in acid to produce free H2S, wanted to try this sometime, only in more

oxygen-free environment to prevent formation of iron sulfate by oxidation from the air. :-) https://www.youtube.com/watch?v=NxAeQneITNA

[Edited on 20-5-2015 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Amalgamated aluminum dropped into a xylene solution of sulfur might produce Aluminum Sulfide which need only be treated with H2O to produce H2S. I

just pulled that experimental synthesis off the top of my head from thin air, so don't ask for references.

This might not work because of the tug of war between the aluminum and the mercury for the sulfur, which could deactivate the amalgam by forming

mercury sulfide. I'm not sure but it is possible the mercury would combine and deactivate the amalgam.

[Edited on 20-5-2015 by Rosco Bodine]

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

2 Al +3 S -flame-> Al2S3 + heat

Al2S3 + 3 H2O --> Al2O3 + 3 H2S

Al2S3 + 6 H2O --> 2 Al(OH)3 + 3 H2S

Fe + S -flame-> FeS + heat

FeS + 2HCl --> FeCl2 + H2S

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

| Pages:

1

..

11

12

13

14

15

..

33 |