| Pages:

1

2

3

4 |

blazter

Hazard to Self

Posts: 71

Registered: 3-9-2002

Member Is Offline

Mood: No Mood

|

|

homebrew aspirator

After seeing various recirculating aspirator setups i've noticed that the authors of the howtos didn't mention where they actually obtained the

aspirator unit. Now, i have seen them for sale at online vendors, but im wondering if a similar unit could be constructed from readily available

hardware store supplies? I'm thinking about a "T" connector and a few reducers, or simply making a "T" by drilling some copper tubing and soldering a

smaller tube in it. Is this more work than its worth assuming it MIGHT work? Also, anyone have any suggestions for dimensions/reduction ratios?

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

Given that you can get a real aspirator for something like $10, it does seem like more effort than it's worth. I have a soft spot in my heart for

homemade equipment, though.

Actually, here's another question: just how would you go about attaching an aspirator to a normal home faucet, or even an outdoor spigot? My faucets

don't have the nifty ridged, tapering connectors that lab ones do.

|

|

|

NERV

Hazard to Others

Posts: 152

Registered: 22-9-2002

Location: USA

Member Is Offline

Mood: Fluorinated

|

|

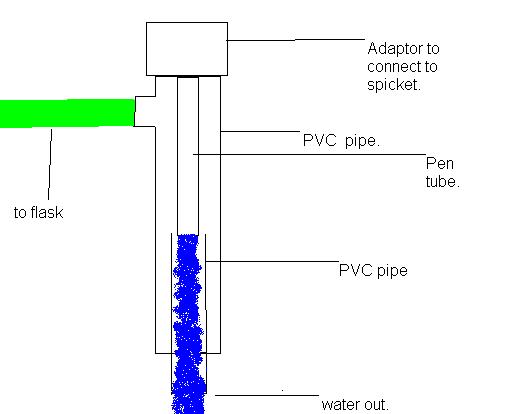

Here is a possible way to make a home made aspirator.

|

|

|

blazter

Hazard to Self

Posts: 71

Registered: 3-9-2002

Member Is Offline

Mood: No Mood

|

|

Thanks for the info NERV. A nice drawing but may i ask a quick question about the dimensions? Specifically, what diameter does the PVC pipe have to

be that receives the water from the pen tube? I assume something like 1/2 inch would be too large.

The logistics of hooking up flexable tubing or rigid PVC pipe to a hose or threaded faucet shouldn't be too difficult. It's possible to buy threaded

adapters to flexable PVC or one could go the really cheap way and cut off the end bit of a hose and use hose clamps to secure it to a piece of 1/2inch

or possibly 3/4inch rigid PVC (i'm not sure off the top of my head which would fit better).

|

|

|

NERV

Hazard to Others

Posts: 152

Registered: 22-9-2002

Location: USA

Member Is Offline

Mood: Fluorinated

|

|

Well I don’t have a pen to measure the diameter of right now, but I would say the receiving should be about a 1/4 of an inch, or so wide.

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

perhaps this helps

the pics which have been here are in the attachment of the overnext post. Some confusion, sorry.

ORG

[Edited on 21-5-2003 by Organikum]

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

addon

Some more information on the pictures.

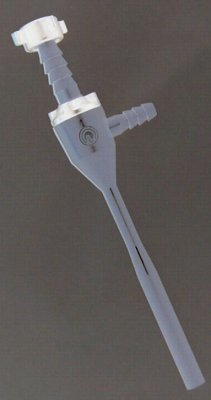

The industrial device is a liquid driven one (water mostly). It is intended to work with a closed end, says it is connected to a tube and not just

left open to air. So if this design is adapted it´s preferable to keep the end below the water surface for optimal results.

The second one is originated in a SIEMENS portable vacuum device and operates with compressed air. There is in this special case no difference to a

liquid driven device, except the diameter of the nozzle which should be bigger with water.

What diameter shall the the nozzle have by principle? Depends on your water supply. It should be as wide as possible without getting a reasonable

lowered pressure on the water line measured min. 50cm away from the aspirator. It makes sense to determine this before building the aspirator. Mostly

you won´t need or want the max. nozzle as you won´t need these amounts of air sucked out fast. The reachable vacuum stays the nearly same.

If there is interest I can post some more information on the topic.

Here is a link to the in my eyes best webpage on chemical engineering including information on this too.

Don´t miss the distillation pages! CheResources

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

as the pics are gone

with the ftp I had my files on, I add them here as attachment.

I packed some more construction drawings and two tables for vacuum to reach with what pump.

sorry for the inconveniance and the three posts in line.

ORG

Attachment: Aspiratores.rar (116kB)

This file has been downloaded 3717 times

|

|

|

blazter

Hazard to Self

Posts: 71

Registered: 3-9-2002

Member Is Offline

Mood: No Mood

|

|

Cool

Wow, didnt expect full blueprints! very good info indeed. If i get time I think i'll try constructing one from pvc tubing and the pen tube method.

Currently I'm spending my free time on the tube furnace project (the thermocouple electronics and MoO3 is going to get ordered soon for that)

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

For a quick buildt but functional device

You may use this for dimensioning:

xx

It´s in millimeters

The aspirator ready buildt looks like this if metal tube is used:

xx

This is functional, and tested. There are optimisations possible of course but for most applications this will do fine. For higher vacuum I would

suggest to stage up a fridge compressor in line with the aspirator. This setup should deliver effective vacuum in the range of <15 torr.

Thats better as many of the praised "yellow jacket" pumps are able to do for costs below 50?/$ including all tubing.

As soon as I have some spare time I will do some tests on optimizing an aspirator, as I am now sure that the vapour pressure of water doesn´t limit

the maximal reachable vacuum, but the velocity does. I will try to adapt some principles of Viktor Schauberger´s work on water and vortexes, where he

describes ways to reduce the resistance in tubes to near zero. It´s no quack, water powered electricity plants working by these principles exist.

Has anybody a bright idea how to calibrate a vacuumeter? To build one by means of a thermocouple is easy.....

ORG

xx - pics gone. I repost them as attached file - have a look down the thread.

[Edited on 8-4-2003 by Organikum]

|

|

|

PoDuck

Harmless

Posts: 8

Registered: 17-2-2003

Member Is Offline

Mood: No Mood

|

|

I think that the previous post is actually a good design. Basically, you need to make a venturi design, and the professional ones and the one above

seem to have a chamber like design to keep the water from having a chance to leave the inlet hole so easily. Before I got to the bottom of the page,

and saw this design, I was going to suggest a design that would work by having a male threaded end to work with the normal household faucet, and

instead of a T, have kind of a y shape like the attached picture. This would create less turbulence at the entry point since the angle is lower where

the water would hit, and would be less likely to find it's way up the tube to your chemicals.

<img src="http://poduck.dyndns.org/aspirator.gif" width="127" height="300"><br />

With this, you could make it out of copper tubing and solder. It would not be as unreactive with most corrosive gasses as PVC, but it would be more

sturdy.

[Edited on 18-2-2003 by PoDuck]

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Venturi and copper

Actually all aspirators use the venturi principle to function. And you may use copper or what you like to use the material is not critical - if you

fear corrosion paint it.

But sorry to tell, your design won´t work as it misses the nozzle for velocity and more important the outlet has an far to wide diameter. The air

would just flow up at the sides and you have no vacuum at all. The smaller diameter of the outlet is the seal. If you would like to use the whole

diameter of the waterline you would have to widen the part where the air inlet is for applying the venturi and it would be not very strong for lacking

velocity. The form of the air inlet isn´t critical at all - suckback is prevented by an separate one-way valve (ball-type).

I think also you have an misconception regarding the difference between an aspirator and an air-pump which are very similar but not identical:

A aspirator is for applying and holding upright of a vacuum what includes only very little airflow whereby an air-pump is optimized for processing

maximal amounts of air what includes an permanent airflow. One works on a maximal pressure difference the other on maximal flow.

There is naturally no exact borderline between the two devices.

Essential for an aspirator are:

- A nozzle for the working fluid gaining velocity.

- A chamber where the venturi is applied.

- A narrowing working as seal for preventing pressure equalization.

Complaints please to Mr Venturi who made this up.

ORG

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

missing pictures repost

the missing pics from above as attached file.

Attachment: Aspiratores.rar (17kB)

This file has been downloaded 2072 times

|

|

|

Eliteforum

National Hazard

Posts: 571

Registered: 18-11-2002

Location: United Kingdom

Member Is Offline

Mood: Enjoying the journey

|

|

I have various copper connectors (compression fittings) if anyones intrested?

Here's a list of what I have:

x1 15mm screw in end cap

x2 15mm T connectors

x1 15mm to 22mm ball valve

x1 15mm 90degree elbow joint

x1 15mm to 22mm reducer/enlarger

x1 22mm endcap with a all valve in the end.

x1 15mm endcap

All these are brand new and haven't been used.

If your intrested, let me know.

All that glitters isn't gold.

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

thanks for the offer Eliteforum, but I doubt it being economically making sense to send the parts in the czech republic....

(in the end the customs even want me to pay duties on it)

Found this:

cute, isn´t it?

[Edited on 21-5-2003 by Organikum]

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

update

This is a bought aspirator (the picture is negative for security reasons - and for that it may not look so unbelievable boring...)

And this is this aspirator disassembled - naked to the bone - huh!

The one mysterious part - right in the middle row of three - is a rubber thingie which shall work as suckback inhibitor - a primitive integrated

one-way valve. This part in reality diminishes the vacuum and power overall significantly and suckback takes place nevertheless. Thats astonishing for

a professional laboratory device.

I removed the rubbershit and a cheap ballvalve from the aquarium supply actually WORKS inhibiting suckback.

If there is interest I can measure the parts and post the dimensions.

|

|

|

n00dle

Harmless

Posts: 1

Registered: 5-9-2003

Location: sdf

Member Is Offline

Mood: No Mood

|

|

A good fridge compressor will do a 1 torr vaccum. (Boil water at room temperature.)

Problem is, it's designed to work in a hermetically sealed environment. If you use it in normal atmosphere, the compressor side will make the

water in the air freeze, and then turn the insides of the compressor into mush as it trysto act as an ice cube blender.

I'd REALLY be interested if someone could suggest a way to say, remove the compressor, and regarge it, and use it to drive another device as a

vaccuum pump. Like a passive system, so the fridge compressor will be happy in a 0% water environment, yet you can still passively use it for any

humidity range.

Just a thought

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Never heard of this freezing problem before. You should tell this the manufacturers of rotary vain vacuumpumps - they will be glad to get to know why

their machines are not working... LOL

Or short and cruel:

NONSENSE.

Realistic are 50torr by using a single fridge compressor, 10torr by using two staged. You may be able to get it better but thats what you can expect

with a not much effort rig.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Vacuum station/ aspirator - homemade.

My miserable junkyard refrigerator vacuum pump failed when I needed it most!

I decided to build a vacuum station. Went to the hardware store, and built this:

The pump is 1/4 hp and I found out that it needed a bigger water deposit, otherwise water would splash all over.

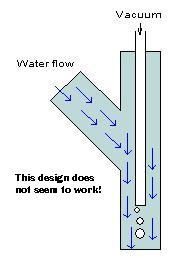

I tought that it would be easy to built an aspirator using PVC fittings so I've built something like this:

I found out it does not work! I don't know why! I have seens schematics of comercial aspirators, but they don't make sense. Why would a flow

of liquid suck air around it to funnel it into the exit tube? There has to be some trick there!

Does anybody have any experience building aspirators with hardware store materials? Or know exactly how they work? Please, armchair scientists,

don't give me something stupid like "it's the Bernoille principle, my dear".

My work until now looks like this (notice the Y conection of my failed aspirator):

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

D'OH!!

Now repeat after me.

Hydrodynamics is extremely complex.

Hydrodynamics is extremely complex.

Hydrodynamics is extremely complex.

There are more reasons than ticks on a hound dog that would keep the thing you made that looks like an aspirator doesn't function as one,

placement of drawpipe, apeture size etc.

But rather than going into that train wreck of a discussion (there will be alot of suggestions in this thread), consider buying a 20 dollar

aspirator.

It will draw strong and all the bugs will already have been worked out.

Making your own vacuum pump is tres difficile!

I'm not saying you're stupid for trying, just that you may find the time/effort ratio.........

well....

good luck

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

| Quote: | Originally posted by Hermes_Trismegistus

Now repeat after me.

Hydrodynamics is extremely complex.

<snip>

|

Thank you for pointing that out.

| Quote: |

<snip>

But rather than going into that train wreck of a discussion (there will be alot of suggestions in this thread), consider buying a 20 dollar

aspirator.

It will draw strong and all the bugs will already have been worked out.

|

Ha,ha,ha! Poor Hermes!

You are a good contributor to this forum, Hermes, and I'm sure you will regret having posted this words.

You can buy anything, but that's not the idea here, that's why this message board exist!

| Quote: |

Making your own vacuum pump is tres difficile!

I'm not saying you're stupid for trying, just that you may find the time/effort ratio.........

well....

good luck |

Thank you again. You seem to have first hand experience with this subject and I understand it's not trivial.

[Edited on 29-8-2004 by Tacho]

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

Pump of your design draws away as much air in volume as the water pumped through. Until negative pressure inside lower than water pressure, then stop.

Normal pump has always-on airflow, drawing air away by trickle, regardless of water pressure.

Bernouille's equation still comes bashing my face...

[Edited on 2004-8-29 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

Ok then....Yes I have tried.....and I was able to make a really crappy aspirator pump....for only about five times the retail cost.

.....but if you are determined.

I'll try to help.

the problem I see with your drawing, is the lack of a "venturi", a place in the pipe where the pipe goes from big to small to big again.

a crimp, if you will.

The water speeds up  in the smaller space, and makes a "low pressure

zone" that sucks in the air. in the smaller space, and makes a "low pressure

zone" that sucks in the air.

That's where you want to put the tip of the air pipe.

The low pressure zone will suck little bubbles of air out of the pipe and they will be swept away by the force of the flowing water.

Also, if your drawing is to scale, the air outlet nozzle should be alot smaller to ratio than the water pipe as it is now shown. (smaller equals more

suction equals higher flow rate!)

I wish I had paintshop, so I could draw you a picture.

Perhaps someone else could draw one?

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

axehandle

Free Radical

Posts: 1065

Registered: 30-12-2003

Location: Sweden

Member Is Offline

Mood: horny

|

|

Same principle as bystanders swept away at car races. The nearer to the bystanders, the better. And the higher the car speed the more forcibly will

the bystanders be swept away. Same with air molecules near to the water stream. You want a very high velocity water stream, i.e. thinner exit pipe

with a "rocket nozzle". Still, I wish someone could refresh Bernouille'e Law to me with a 2x4, I might be able to explain it better

then. Couldn't find any better link, only came up with the inane car-race simile, but it might hold water...

[Edited on 2004-8-30 by axehandle]

My PGP key, Fingerprint 5D96 E09E 365D 1867 2DF5 C2FE 4269 9C19 E079 CD35

\"Verbing nouns weirds the language!\"

|

|

|

janger

Harmless

Posts: 40

Registered: 20-8-2004

Member Is Offline

Mood: No Mood

|

|

Looking at the design diagram, it would almost work if the vacuum tube was made the water inlet, the water inlet made the vacuum connection, and the

water/air exit was constricted slightly.

Try it.

Dave

|

|

|

| Pages:

1

2

3

4 |