| Pages:

1

2

3

..

18 |

Xenos

Harmless

Posts: 22

Registered: 29-8-2002

Member Is Offline

Mood: No Mood

|

|

Sodium!

Ok, well my power supply came from ebay (5V @ 50amps)  so i tried some simple

electrolysis. Using carbon electrodes, as close together as possible i first tested it in a salt water solution. It bubbled rapidly, and i plan to

attempt to make and capture the Hydrogen and fill a balloon with it. I then proceeded to try KOH. I heated it on my hotplate and put the electrodes

in. Soon it began bubbling rapidly, and forming a kinda grayish mix. However, i stoped that experiment. Yesterday i tried to heat some NaOH, but my

hotplate wasnt getting hot enough, so i put a torch to the crucible and it began to bubble away. This happened for about 30 min, while the NaOH was

turning a silvery black color. ( I suspect this was the C coming off, and they were a bit smaller than before). However, my crucible got a hole in it,

so i stoped. That sat overnight, and i then wetted the mix, to find some whitish specks on the side got hot when water touched it. I think if any Na

or K formed, the water from the + electrode converted it back to OH as soon as it formed. Today i made a crucible with fire cement and put an C rod in

the center. Hopefully that will prevent anything from getting to the material. so i tried some simple

electrolysis. Using carbon electrodes, as close together as possible i first tested it in a salt water solution. It bubbled rapidly, and i plan to

attempt to make and capture the Hydrogen and fill a balloon with it. I then proceeded to try KOH. I heated it on my hotplate and put the electrodes

in. Soon it began bubbling rapidly, and forming a kinda grayish mix. However, i stoped that experiment. Yesterday i tried to heat some NaOH, but my

hotplate wasnt getting hot enough, so i put a torch to the crucible and it began to bubble away. This happened for about 30 min, while the NaOH was

turning a silvery black color. ( I suspect this was the C coming off, and they were a bit smaller than before). However, my crucible got a hole in it,

so i stoped. That sat overnight, and i then wetted the mix, to find some whitish specks on the side got hot when water touched it. I think if any Na

or K formed, the water from the + electrode converted it back to OH as soon as it formed. Today i made a crucible with fire cement and put an C rod in

the center. Hopefully that will prevent anything from getting to the material.

The ASPCA never liked Shrodinger, but they never knew he was a theroretical physicist.

|

|

|

madscientist

National Hazard

Posts: 962

Registered: 19-5-2002

Location: American Midwest

Member Is Offline

Mood: pyrophoric

|

|

I prepared some sodium metal this last Saturday myself. I placed 20g of NaOH in a ceramic crucible, and proceeded to heat it on a hotplate until it

melted. I inserted two electrodes, both graphite, and bubbling began at the anode. I left it unattended for around an hour. When I returned, the

crucible contained a greyish, silvery liquid, permeated with greyish-black lumps. I allowed it to cool, and poured in charcoal lighter fluid to

protect the sodium from oxidation. I found that the somewhat grey and faintly silvery solid was brittle when cold. It clearly contained a lot of

graphite impurity. I chipped some of it out, and saved it in a beaker containing charcoal lighter fluid. I then reheated the contents of the crucible

to about 100C; and poured as much of the liquid sodium as possible into that same beaker. Localized boiling occured for a few moments; then several

dull silvery pieces of sodium metal settled at the bottom. I allowed the crucible to cool, and rinsed it with cold water. There was several sizzling

sounds, and what was left of the heavily-corroded cathode disintegrated completely. The mass of the ceramic crucible fell from 73.5g to 72g over the

course of the experiment. The anode was not corroded to any noticeable degree. Next time, I will use a copper cathode, and will pour off the sodium

metal while it is still molten (immediately after electrolysis) into chilled xylene.

I weep at the sight of flaming acetic anhydride.

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

speculating from my armchair

In an ideal world, DuPont would deliver ingots of alkali metal to our doorsteps for production costs + 15%, or we would all have sophisticated machine

shops and expendable hunchbacks to operate the apparatus that we built. In the real world, I have never been able to confirm anybody's home production

of significant quantities of such metals. I recall reading somebody's old Usenet posts that claimed the writer had build some fairly good apparatus

and didn't have nearby neighbors, and so was able to produce kilogram-range quantities of potassium and sodium from the chlorides. Wouldn't I like to

do that.

With alkali electrolysis the main problem (apart from atmospheric isolation) is (IIRC) be protecting the metal from the products produced at the

anode, which dissolve in the molten alkali and can re-oxidize the metal. Unfortunately, this process is so old that references to its specifics are

difficult to find.

I would like to try using an equimolar mixture of NaOH and KOH, which is a eutectic melting around 200 degrees C (lower MP should significantly

increase ceramic crucible lifetime). The resulting Na/K alloy may have an unmanageably high reactivity and low melting point, though.

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

I think if you were to electrolise that when molten, firstly all the sodium would be produced because of it's higher electronegativity and lower

reactivity.

This will ofcourse have its effect on melting point, because the mixture will shift to Na + KOH.

Na/K alloys are often liquids at roomtemperature and very reactive, that is more reactive than pure sodium or potassium metal.

One shouldn't accept or resort to the mutilation of science to appease the mentally impaired.

|

|

|

trinitrotoluene

Hazard to Others

Posts: 142

Registered: 17-10-2002

Location: California

Member Is Offline

Mood: paranoid

|

|

I think what can be done to protect the K , Na alloy is do to pour a layer of mineral oil on top of the mixture and then do electrolysis.The only

problem is what kind of mineral oil has a boiling point of above around 200*C? I also consiture to do the same with Na metal.If the mineral oil can

remail a liuqid and not boil. If theres a hydrocabon that remains a liquid at the melting point of KOH then I guess it can be used to protect the

reactive metal.

TNT

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Sodium Ive done in small amounts without a blanket, and the air oxidation was amazing to watch, the metal constantly had a yellow aura around it.

Small hydrogen explosions tended to propell sodium across the room and this is something of a hazard. I used a copper cathode and a steel

anode/container, this seemed to work quite well.

Since I tried this, about 10 years ago, Ive picked up a fair amount more information from a number of sources.

The most common mistake is to overheat the hydroxide, in which the sodium is soluable. Too hot and the hydroxide/sodium produces a metaloid which

conducts electricity and electrolysis stops. Numbers from a book on sodium were, 5 degrees above the melting point of sodium hydroxide you get an 80%

yeild on a current basis, and 25 degrees above it you get nothing.

This partially explains why a lot of early references dont use gas burners to make sodium, they rely on the current itself to do the heating, and

controlling the current gives much more precision in controling the temperature of the cell.

vulture has a very good point about NaK alloys. This are much more reactive than either of them alone and burst into flames on contact with air at

room temp. The general concensus of the people Ive talked to, is that the difference in electrode potential is too small to produce only sodium from

a molten mixture of both salts. This is potentially very hazardous.

The book recommends I think 12% of carbonate in the mixture for optimum yeilds, and suggests a 50:50 mixture of sodium hydroxide with sodium sulphide

to reduce the melting point. This is aparently patented. Ive found information on hydroxide/nitrate/nitrite eutectics, but its impossible to guess

how reduction/oxidation at electrodes would affect the bulk mixture. Something that also bothers me about sulphide mixtures.

|

|

|

a_bab

Hazard to Others

Posts: 458

Registered: 15-9-2002

Member Is Offline

Mood: Angry !!!!!111111...2?!

|

|

I saw in some chemistry manual the construction of cells for Na production from NaOH, and the Na is produced under some sort of bell-shaped thing.

Actually the (-) electrode it's inside of that bell. In this way, because sodium it's lighter than NaOH it'll float over the molten NaOH, under the

bell, and it'll be protected in the same time from the air. It's verry simple.

|

|

|

menchaca

Hazard to Self

Posts: 80

Registered: 12-3-2003

Member Is Offline

Mood: No Mood

|

|

Na with Hg catode

first of all sorry for my english

Ill try to explain as well as i can

i ve never try this but i think it can work

the idea consist on a quicksilver catode

where the Na forms an amalgam. After the quicksilver takes all th Na that it can (i dont know how long must it take) just take the amalgam and heat

it until Hg boils when Hg desapear solid Na should be there you can use an alembic to recover the Hg i´ll try to send you some draws of the idea i

had, you can send it to others and they will be able to tell you if it works or it doesnt and improve it

|

|

|

It burns

Harmless

Posts: 1

Registered: 14-3-2003

Location: Aberdeen (UK)

Member Is Offline

Mood: No Mood

|

|

hot electrochemical sodium

| Quote: | Originally posted by trinitrotoluene

I think what can be done to protect the K , Na alloy is do to pour a layer of mineral oil on top of the mixture and then do electrolysis.The only

problem is what kind of mineral oil has a boiling point of above around 200*C? I also consiture to do the same with Na metal.If the mineral oil can

remail a liuqid and not boil. If theres a hydrocabon that remains a liquid at the melting point of KOH then I guess it can be used to protect the

reactive metal. |

Im new and possibly wrong but couldnt you use tar, its got a realatively high melting temperature and is a hydrocarbon (at least im pretty sure it is)

might be a pain to get the everything back out of though

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

Mencacha, the quicksilver amalgam becomes solid when the Na content goes above 0,7% and the maximum obtainable is 5% IIRC. Add to that that

you're going to need large amounts of Hg which is very expensive.

One shouldn't accept or resort to the mutilation of science to appease the mentally impaired.

|

|

|

rikkitikkitavi

Hazard to Others

Posts: 192

Registered: 17-6-2002

Member Is Offline

Mood: No Mood

|

|

When you increase the percentage of Na in Hg due to electrolysis , the emk increases and about 0,6-0,7 % Na, it will be the same as for the

H2O=> H2 + OH- reaction , thus it will not absorb any more Na by electrolysis but only decompose water.

So from 1 kg Hg(which is very expensive and hard to get ,lucky me that I have it you will recieve about 5 grams of Na.

you will recieve about 5 grams of Na.

The to evaporate this amounts of Hg I can imagine the difficulties setting up an adequate distillation arrangement.

/rickard

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

I find it interesting that you refer to mercury as being very expensive. I can order it for about $30/kg, which makes it moderately priced to my way

of thinking. That's still an outrageous price compared to what it would cost in bulk, but not so bad compared to many other laboratory chemicals.

It seems strange that chemical availability and pricing varies so much by region, when you would expect these commodities to have near-identical

prices without geographic differentiation.

|

|

|

a_bab

Hazard to Others

Posts: 458

Registered: 15-9-2002

Member Is Offline

Mood: Angry !!!!!111111...2?!

|

|

Hmmm...30 $/Kg is very cheap. Is it a regulated chemical ? In my country is banned and you can go into prison if you are caught with it. The price on

the black market it's said to be around 1000 $/kg.

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

No, the personal possession of mercury is not regulated here, though I am sure it is illegal and punishable to dispose of it improperly. That does

explain the price difference, though. Commodities can become very expensive when they are not legally available.

|

|

|

Theoretic

National Hazard

Posts: 776

Registered: 17-6-2003

Location: London, the Land of Sun, Summer and Snow

Member Is Offline

Mood: eating the souls of dust mites

|

|

Sodium!

Everyone, do yourself a favour and make do without NaOH. How? Well, just take salt with a bit of soda to make a low-melting eutectic (600 Celcius). No

corrosion - no water evolved - no trouble getting NaOH.

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

NaOH has a much lower melting point, secondly, electrode corrosion is very high at 600C and you're dealing with Cl2 vapors.

Besides that, you always give me the impression of being a smartass when posting. Maybe you should calm down a bit and read the threads first before

you post something.

|

|

|

jimwig

Hazard to Others

Posts: 215

Registered: 17-5-2003

Location: the sunny south

Member Is Offline

Mood: No Mood

|

|

industrially mercury has historically been used to produce chlorine from NaCl acting as the anode (?) for a Whorill cell.

I think it goes like this

Na Cl electrolitically decomposes to Cl as a gas and Na as an amalgum with the Hg acting as an electrode on the bottom of the cell.

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Castner Tiegel

NaOH sodium electrolysis is done with this:

The trick is the iron net between the electrodes (cathode - copper, anode - nickel) which are only 2cm apart. This is a very tight net (100/per cm*cm)

and yes it divides also the voltage of about 4V.

If interest I can post more data on this.

|

|

|

Theoretic

National Hazard

Posts: 776

Registered: 17-6-2003

Location: London, the Land of Sun, Summer and Snow

Member Is Offline

Mood: eating the souls of dust mites

|

|

Sodium

I think a graphite electrode would be resistant to chlorine, as it's hard to get chlorine to attack carbon.

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

I would say the mercury amalgane process is indiscutable for home use - the separation of the amalgane is plain to dangerous. (I don´t say this

often, yes?)

The NaCl electrolysis has in my eyes no advantages over the NaOH electrolysis. The "Castner Tiegel" shows the principle for how to setup a

electrolytic cell for the NaOH process. Not so diffficult. Materials are common and cheap.

Now I answer all the questions nobody has asked:

Pot: Iron

Cathode: Copper

Anode: Nickel

The distance between anode and cathode is only 2cm. The amperage at the cathode is about 1,6Amp/cmxcm at the anode about 1,1Amp/cmxcm. (Smaller units

call for higher current density). The voltage should be about 4V to 5V then, the current density is the more important point.

The magic part:

Between anode and cathode is a iron fabric as diaphragm which has about 100 mesh/cmxcm. This works naturally as a voltage divider. The fabric is fixed

in a way that 40% of the voltage are on anode - diaphragm and 60% are on cathode diaphragm.

The maximum temperature is 330°C, 20°C higher as the melting point of NaOH.

Suggestions: The use of steelwool between glassfibre fabric or glassfibre fabric with a steelnet embedded would do for a diaphragm. The better this

is the higher will the purity of the Na. I believe the voltage divider function being essential and that the ratio may shift to 30/70 instead 40/60

but not 50/50. The distance of diaphragm - anode/cathode IS critical.

The sodium from NaOH electrolysis is also cleaner as the one from NaCl - simple sedimentation is all whats needed. For even higher quality filtration

through an ironfabric or glassfibrefabric under inertgas or petroleum is used. (petroleum is not preferred - fire hazard). Remelting under paraffine

is another possibility.

The diaphragm as voltage divider and the bell on top - thats it. This sounds doable in a safe enough way to me and some steelwool for a improvised

diaphragm is sure for everybody available without loosing the improvised touch....

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

holla...

The thread is on sodium, so a photoreactor is perhaps not the right picture.

I apologize

<sniff>

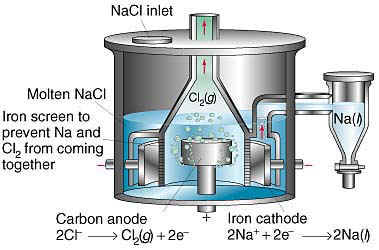

Downs NaCl Sodium Production Cell

this is on topic I guess and answers what theoretic suggested: Yes! Graphite electrodes are useable in this process! The principle is the same working

with an iron diaphragm. I would suggest to exchange anode and cathode for to be able to harvest the Na central what seems much better for a smaller

scale unit. But I would fill it with NaOH anyways - no chlorine and much lower temperatures - no question.

|

|

|

blindreeper

Unregistered

Posts: N/A

Registered: N/A

Member Is Offline

|

|

Does anyone who is good with pottery wanna try to make one of these out of ceramic? I imagine it would not be too difficult. If i had a kiln

and some clay and a wheel thingy I'd try it.

|

|

|

rikkitikkitavi

Hazard to Others

Posts: 192

Registered: 17-6-2002

Member Is Offline

Mood: No Mood

|

|

pottery usually contains SiO2 wich would be attacked by the molten NaOH. Except from precious metals like Pt, I believe that Ni is fairly resistant to

molten NaOH.

Ordinary stainless steel is corroded by lye above 60 C @ 0,1 mm/year, @ 100 C corrosion is about 3-4 mm/year so I expect molten NaOH @ 400 C would

show significant corrosion on stainless. But if it was hi-Ni content perhaps?

I can se a problem with the cathode , where Na is formed. the anode reaction would probably also be under quite reductive conditions since H2 is

evolved ?

OH- => H2O + H2 + e-

/rickard

|

|

|

kryss

Hazard to Self

Posts: 77

Registered: 11-7-2003

Location: N Ireland

Member Is Offline

Mood: No Mood

|

|

anyone ever try using a carbon fibre elctrode - should nbe shapable.

|

|

|

Organikum

resurrected

Posts: 2342

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

ehem..

cathode = copper

anode = nickel

pot = iron

diaphragm = iron net, 100mesh/cmxcm

for NaOH electrolysis.

Thats the material used in industry and as it is cheap and easy I strongly suggest to use these materials also - whats wrong with them? Every

scrapyard provides a pot of thick iron for near free, the nickel willl be the hardest to get as I believe but far from impossible.

The "Castner Tiegel" is more on the point as the more beautiful second graphic!

Also thick iron will stand the molten NaOH for a long time there is a trick: heating from the center has the effect that NaOH solidifies on the bottom

and the walls of the cell. This protects from corrosion and contamination.

So preheating by a propane burner to about 290°C and then over the melting point and holding the actual temperature of maximal 330°C (400°C is far

out) by resistance/thermoelement inside the cell.

Not bad, isn´t it?

The hydrogen formed together with the Na provides the inert atmosphere over the Na. No problem - a feature.

If you want problems here they are:

- A pain in some bodyparts is the exact fixation of the diaphragm - I suggest strongly to use wider space between anode/cathode (more as only 2cm) and

compensate by higher voltage. This provides a good part of the needed heating this way - two with one.

- OTC NaOH is dirt like shit often. Big bad surprise! Use labgrade or test before use a small sample - cleaning the cell is - yes what? A work for

vulture?

|

|

|

| Pages:

1

2

3

..

18 |