Maja

Hazard to Others

Posts: 143

Registered: 27-2-2006

Member Is Offline

Mood: No Mood

|

|

4-methoxyphenol purification

4-methoxyphenol obtained from Hydroquinone methylation with Methanol/H2SO4 and Benzoquinone is very very dirty oily crystals, those can't be simply

recrystallized or purified by other ways(vacuum might be a choice). I have tried ethyl acetate, ethanol/water/, methanol/water, isobutyl alcohol,

ispropyl, toluene, hexane, benzene and even making Phenolate. It does not form crystals! And even if crystal forms they forms very dirty and ugly....

So SOMEONE managed to get pure/nice crystals from that reaction ?!? THANK YOU.

|

|

|

flyingbanana

Harmless

Posts: 38

Registered: 1-3-2005

Member Is Offline

Mood: No Mood

|

|

I've had enough problems with that method to just give up on it. Either a) blackish/brown oily residue that refused to crystallize except at 0 C, but

would always revert to viscous goo at room temp. b) ugly brown crystals, obviously impure.

Someone said recrystallization from water works, but I tried that with no success...the brown solids would just turn into a brown oil that refused to

crystallize.

Another possibility is short path distillation, which I haven't tried.

I eventually gave up and went with 4-methoxybenzaldehyde -> 4-methoxyphenol which is a bit cleaner reaction.

|

|

|

Sergei_Eisenstein

Hazard to Others

Posts: 290

Registered: 13-12-2004

Location: Waziristan

Member Is Offline

Mood: training

|

|

Phenols and phenol ethers are often purified by bulb-to-bulb distillation. I have no experience with your synthesis method though.

damnant quod non intelligunt

|

|

|

ziqquratu

Hazard to Others

Posts: 385

Registered: 15-11-2002

Member Is Offline

Mood: No Mood

|

|

Perrin says: "Crystd from benzene, pet ether or H20, and dried under vacuum over P2O5 at room temp. Sublimes in vacuo."

Sublimation might be a reasonably simple option if recrystallisation is an issue.

|

|

|

Phosphoryloxy

Harmless

Posts: 6

Registered: 10-6-2006

Member Is Offline

Mood: No Mood

|

|

In my experience, recrystallization from petroleum ether (b.p. 40-60°C) worked well and gave small, almost white crystals. The only problem was that

the solubility in boiling pet. ether is very low and it takes a lot of solvent. using the same pet. ether repeatedly without distillation was not

problem as it dissolved almost none of the dark red impurities...

If larger amounts have to be purified this method is too much work and vac. distillation with hot water running through the condenser proved to be

more effective and gave a slightly yellow oil that crystallized on cooling.

flyingbanana: Do you have more details to the 4-methoxybenzaldehyde method? it sounds very interresting to me...

[Edited on 22-7-2006 by Phosphoryloxy]

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Short path/bulb-to-bulb distillation, then crystallization. Also try a NaHSO3 aq wash on the oil, it can pull out quinones formed as side products.

|

|

|

Maja

Hazard to Others

Posts: 143

Registered: 27-2-2006

Member Is Offline

Mood: No Mood

|

|

ETHYL ACETATE !! IS A KEY !!! You won't believe.... I have found THE WAY to purify it using ETHYL ACETATE !!! Firstly I DID NOT noticed that

p-methoxyphenol has very low melting point ... When I tried to recrystall it from ethyl acetate I just heated it to near boiling point ... And didn't

thought about low melting point... And phenol just melted and too much of it was suspended in solvent... Today I have tried to heat solvent to 40*C

and then dissolve as much as it can take ... So when I was unable to dissolve more of it, I filtered solution and put it into the freezer(-25*C,

before I let it slowly cool to room temperature) after a few hours A LOT OF HUGE , NICE crystals formed with a little reddish tint. I'm sure that I

will remove that reddish color with another recrystallization. URA !

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

I guess it's useful that you found the best solvent. Considered together with Phosphoryloxy's post it seams a petrol ether/ethyl acetate mixture would

be the best choice in regards of product recovery and solvent volume. However, I doubt anything would be more effective than vacuum distillation,

though I’m not sure it would give a clean enough product. A recrystallization will always cause great loses of the product. Make sure to report back

how much % you recovered.

I also got the same black impure product that was impossible to recrystallize from water or water/EtOH mixtures. Eventually I gave up trying.

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

Maja

Hazard to Others

Posts: 143

Registered: 27-2-2006

Member Is Offline

Mood: No Mood

|

|

Look ... I have just made a few batches.... To see actual yield on recrystallization ... 2ml for 1g product and other batch with that recrystallized

product... used 0.5gr for 1ml. Now it's just sitting in freezer. Tomorrow will post recovery rates.I can afford low boiling petroleum ether ,but it

cost A LOT OF in my country ... The price is near as much as pyridine. So I will just stick to ethyl acetate. I fully agree with you that vacuum

distillation is the best option... But now I don't have access to vacuum source....

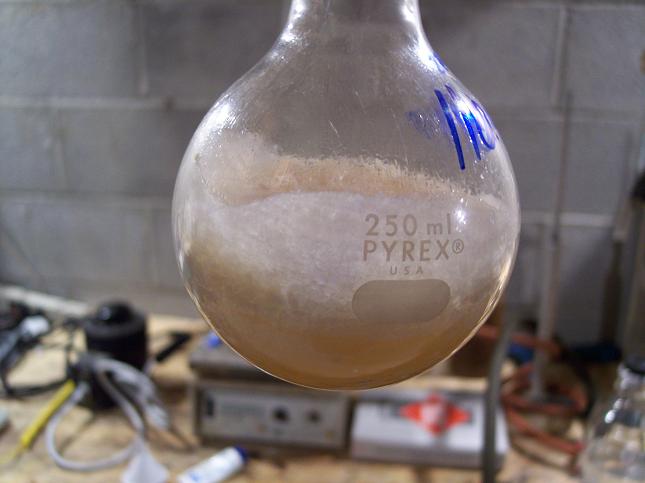

Here is the picture of once recrystallized product :

http://img108.imageshack.us/my.php?image=recrystallrz0.jpg

It is actually much cleaner than it looks like

So I will post results tomorrow ....

Just extracted new batch of 4-methoxyphenol and will try to recrystall whole batch tomorrow.

|

|

|

flyingbanana

Harmless

Posts: 38

Registered: 1-3-2005

Member Is Offline

Mood: No Mood

|

|

4-methoxybenzaldehyde -> 4-methoxyphenol

peracid oxidation, there is an article on rhodium 'phenols from benzaldehydes' they use sulfuric acid and h2o2. performic/peracetic acid can also be

used, the details are outlined in a microgram issue that deals with anise oil.

also, shulgin uses this reaction for some compounds in pihkal, I can't remember off the top of my head though. It basically just involves a long

reflux

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

Also know as the Baeyer-Villiger Oxidation

Avoiding the use of per-acids with BV:

http://aiche.confex.com/aiche/2006/preliminaryprogram/abstra...

http://pubs.acs.org/cgi-bin/abstract.cgi/joceah/2005/70/i26/...

http://www.achema.de/data/achema_/congress/1235.pdf

|

|

|

Maja

Hazard to Others

Posts: 143

Registered: 27-2-2006

Member Is Offline

Mood: No Mood

|

|

Ok, Ok .... Not very good news.... First of all SWIM wants to report about that 1g of that dirty 4-mp did not crystallized ..... If someone will try

this recrystallization, use 1ml for 1gr dirty product ! Otherwise it won't form crystals. Once recrystallized p-mp 0.5g in 1ml ethyl acetate nicely

recrystallized and formed big crystals... but YIELD was VERY LOW.... from 0.5g SWIM managed to get just 0.1g. I can blame small quantities and SWIM is

positive that he can get atleast 0.4g from 0.5g in BIGGER scale... Maybe evaporating 2x volume of solvet.

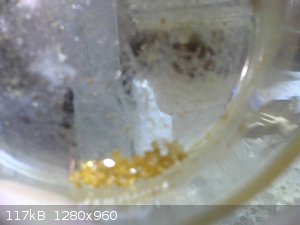

Friend of mine gave me this photo of p-mp.

Twice recrystallized :

http://img225.imageshack.us/my.php?image=2recrych1.jpg

Friend just thought that he is satisfied with once recrystallized product.Dunno about purity ,but it isn't bad as oily crystals... Thanks...

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

At least the twice recrystallized crystals look very clean. Even cleaner than reagent grade p-MeO-phenol.

| Quote: | | from 0.5g SWIM managed to get just 0.1g |

That's what I thought. Ethyl acetate is too polar and dissolves p-MeO-phenol too well for an efficient recrystallization. If you can’t get

petrolether or find it expensive (that’s weird), try using “cleaning gasoline” or “medicinal grade gasoline” or whatever it is called in

your country (it is mostly lower alkanes, just like petroleum ether). Avoid “naphta” or “white spirit” or whatever it is called where you live

(it contains higher alkanes as well and they leave a nasty smell). If you can’t get any other alternative for petroleum ether then you might try

recrystallizing from toluene/ethyl acetate (1:1, for example). It won’t help as much, but the recovery of the product should be better.

| Quote: | | I fully agree with you that vacuum distillation is the best option... But now I don't have access to vacuum source.... |

Do your best to buy or build a water jet pump. Doing organic chemistry without a vacuum pump is like building a car with stone age tools. Trust me, you will never regret it. Trust me, you will never regret it.

Damn, you can’t even properly filter anything without vacuum. And considering that all liquid compounds need distillation you get stuck pretty soon

without at least a water jet pump. Once you get it you can distill your p-MeO-phenol directly from one flask to the receiver by excluding the

condenser (it would only clog by the crystallizing product and it is completely unnecessary if you use a two neck flask for the receiver with one neck

connected to the pump). That would be a scaled up version of a bulb to bulb distillation (aka kuglrohr).

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

Maja

Hazard to Others

Posts: 143

Registered: 27-2-2006

Member Is Offline

Mood: No Mood

|

|

I said "I don't have access to vacuum source" meant STEADY and HIGH vacuum... I have even 3 aspirators.. One built myself and others is made from

glass. I'm filtering under vacuum very often, but my water-supply IS SHITTY AND tend to drop/increase in pressure and I can't afford steady vacuum

with that. I have everything I need to build vacuum station with water pump, but now I'm leaving my country for half month ... Thats all. No doubt I

will make my vacuum station  Petroleum ether COST HUGE AMOUNT OF MONEY from

supplier I DO NOT KNOW WHY. And "white spirit" is the best option I can get for the same price as ethyl acetate. There isn't such thing as "Petroleum

ether" in stores, there is just WHITE SPIRIT Petroleum ether COST HUGE AMOUNT OF MONEY from

supplier I DO NOT KNOW WHY. And "white spirit" is the best option I can get for the same price as ethyl acetate. There isn't such thing as "Petroleum

ether" in stores, there is just WHITE SPIRIT  Bad news one more time : SWIM just

extracted that phenol , distilled benzene and amount of 4-methoxyphenol was 28.4g from 30gr hydroquinone quite good, isn't it ? Friend of mine

dissolved that in 28ml ethyl acetate with heating to 40*C and cooled slowly to room temp, then he cooled it to -25*C and nothing precipitated Bad news one more time : SWIM just

extracted that phenol , distilled benzene and amount of 4-methoxyphenol was 28.4g from 30gr hydroquinone quite good, isn't it ? Friend of mine

dissolved that in 28ml ethyl acetate with heating to 40*C and cooled slowly to room temp, then he cooled it to -25*C and nothing precipitated    He tried to seed/scratch/swirl that solution and nothing helps. Any ideas why ?! What

about using atmosphere pressure for distilling phenol using air cooled condenser ?! That would work ? He tried to seed/scratch/swirl that solution and nothing helps. Any ideas why ?! What

about using atmosphere pressure for distilling phenol using air cooled condenser ?! That would work ?

|

|

|

not_important

International Hazard

Posts: 3873

Registered: 21-7-2006

Member Is Offline

Mood: No Mood

|

|

The low boiling cut, less than 75 C, of petrol works at petroleum ether. White spirt tends to have some fairly high boiling stuff in it; you should

distill commerical mixed solvents to get know boiling ranges.

The bp of 243 or so C is pretty high, you're inviting reactions you likely don't want, either of the product or of the gunk with it. As a minimum

flush the still out with CO2 or at the very least put a little lowing boiling stuff like alcohol in before starting to drive air out.

Crystalization takes patience, sometimes stuff takes days to crystallize.

|

|

|

Phosphoryloxy

Harmless

Posts: 6

Registered: 10-6-2006

Member Is Offline

Mood: No Mood

|

|

anise oil -> 4-methoxyphenol

@flyingbanana:

I know that microgram paper and it sounds very interresting, but the main problem there is the first oxidation of anethole to 4-methoxybenzaldehyde

which in the paper is done with bichromate, a very poisonous substance that is very bad for the environment. it would be great to find a substitute

for this. i found an old rhodium document about the electrooxidation of anethole involving in-situ regeneration of MnO2 with 50% yield in a nondivided

cell. Has anyone tried this? or any other oxidants? could it be possible with Trichlorocyanuric acid?

|

|

|

PainKilla

Hazard to Others

Posts: 306

Registered: 29-4-2004

Member Is Offline

Mood: No Mood

|

|

A method that I found works well is this:

Dissolve your crystals/gunk in boiling water, so you get a saturated solution. It should be dark, with no solids at the bottom (if there is a bit of

dark oil it's alright)... Then hold this at room temperature for a few hours. You will get a dark oil layer at the bottom and lighter water layer on

top of that. Place this in the freezer until the upper layer becomes lighter, and starts to freeze. Let this thaw until you can easily decant the

upper water layer from the oil. Evaporating this water give lightly tan but slightly oily fine crystals which can then be further purified by method

of choice (or maybe even used as is, I recall the ortho-form reaction can be done using impure 4-methoxyphenol in good yield). The oil that remains...

repeat the process, eventually you will be able just to dump out everything, and the oil will stay fairly together, and you can collect all the

crystals but the oil. In this fasion, there are very little losses (unless you spill  ) and the product is much cleaner. ) and the product is much cleaner.

This method is much easier, and removes the dark impurity from the crystals, which can then be further purified. These crystals also have a much more

exact melting point, and I'd imagine after a second recrystallization (probably from water) that they will be quite pure. Yields after purification

are good, ranging from 60-70% of the initial reaction.

Good luck!

Note/Edit: I'd imagine with larger amounts, it'd be ideal to perform this in a seperatory funnel, and simply remove the oil, and repeat. This should

make everything much easier...

[Edited on 6-8-2006 by PainKilla]

|

|

|

Maja

Hazard to Others

Posts: 143

Registered: 27-2-2006

Member Is Offline

Mood: No Mood

|

|

Ouh, PainKilla, I really appreciative your write-up .... Thanks a lot if that works... I will try to purify p-meophenol with water tomorrow and I

hope that works...

EDIT :

OK, I or dish Fucked up .... Look what happend :

I followed PainKilla procedure for purifying that damn phenol.... Everything went very good till I started to boil down the water ! Poured all water

extracts to PYREX dish turned on hotplate when about 100ml was left I left it without babysitting for a few minutes and then BACH !!! LOUD CRACK(I had

a chance to hear to from open window) FUCK !

http://img412.imageshack.us/my.php?image=platecs6.jpg

My methanol is running low .... Just started to mix another Hq methylation batch.... I think I will end up buying it ....

Maja

[Edited on 7-8-2006 by Maja]

|

|

|

PainKilla

Hazard to Others

Posts: 306

Registered: 29-4-2004

Member Is Offline

Mood: No Mood

|

|

Perhaps I am onto something here, perhaps not:

http://www.uni-regensburg.de/Fakultaeten/nat_Fak_IV/Organisc...

Quinhydrone:

Appearance:

Green crystalline solid.

Solubility:

Slightly soluble in cold water, soluble in hot water

Density:

1.4

First off note, the green that we see during the methylation... there it is  ... I

suspect my crystallization worked because I had just the right amount of benzoquinone/hydroquinone... thus forming the quinhydrone, which sank to the

bottom after cooling... allowing decanting of the solution. Therefore, ideally, one must perform the methylation using a fairly small amount of

benzoquinone, so you can "titrate" with additional when you recrystallize... I will test this soon but what I am saying is this: ... I

suspect my crystallization worked because I had just the right amount of benzoquinone/hydroquinone... thus forming the quinhydrone, which sank to the

bottom after cooling... allowing decanting of the solution. Therefore, ideally, one must perform the methylation using a fairly small amount of

benzoquinone, so you can "titrate" with additional when you recrystallize... I will test this soon but what I am saying is this:

Hypothesis:

We have our dirty crystals, which are probably contaminated with hydroquinone/benzoquinone/quinhydrone... now, depending on where the problem lies, we

want to form the quinhydrone so it precipitates to the bottom of solution and allows decanting. if you collected the crystals via toluene, you will

probably have mostly benzoquinone impurity... so add small amounts of hydroquinone until an oil forms... if you extracted via water, add benzoquinone

until you get the oil. Personally, I find the water method much easier, that is, neutralize with Na2CO3 solution, stoichiometrically, with just the

right amount of water to dissolve Na2SO4... adding in small portions with good stirring allows for the formation of relatively pure product which

needs much less purification than collecting via toluene (pale brown - almost tan)... The only disadvantage here is that you lose about 10% of your

product the solution... but it is worth it for the lack of a headache  . .

It is also interesting to note that I noticed this after a poorly done methylation... I dumped contents of methylation (few grams of 4meophenol, in

solution) into a flask with a few remnants of BQ, and boom, the oil forms...

This deserves further investigation, as purification can ultimately be made quite possible...

EDIT: Atmospheric (short parth) distillation works great!

[Edited on 8-8-2006 by PainKilla]

|

|

|

appetsbud

Harmless

Posts: 21

Registered: 15-8-2008

Member Is Offline

Mood: No Mood

|

|

"I know that microgram paper and it sounds very interresting, but the main problem there is the first oxidation of anethole to 4-methoxybenzaldehyde

which in the paper is done with bichromate, a very poisonous substance that is very bad for the environment. it would be great to find a substitute

for this."

i can't remember where i saw it, but i recall it being possible to oxidise to the aldehyde by using potassium permanganate and an alumina catalyst,

along with an ion exchange resin ( amberlite? ). yields were reportedly very high, >95 if i remember correctly. i'm sure you could hunt it down if

you felt that way inclined.

pez!

|

|

|

NERV

Hazard to Others

Posts: 152

Registered: 22-9-2002

Location: USA

Member Is Offline

Mood: Fluorinated

|

|

I recently did this synthesis and followed the method recommended by Klute. After the completion of the reaction with the MeOH sulfuric acid distill

off half the volume of methanol then add an equivalent amount of water and extract the mixture with DCM. Wash your extracts a couple times with some

brine to remove any acidic impurities then distill the solvent off at atmospheric pressure as soon as your solvent is gone pull a vacuum and distill

you phenol either bulb to bulb, or use an air condenser that is kept warm with a hot air gun.

The product you will collect will still be slightly dirty but re-crystallization from ethyl acetate/ heptane works great. Heptane can be had from

distilling starting fluid in large amounts, and since its one of the main fractions in pet ether it makes a great replacement (at least it did for

me). I managed a 60% yield of very pure hydroquinone mono methyl ether using this route.

Here is the thread were the details are given by Klute:

https://sciencemadness.org/talk/viewthread.php?tid=9835

Also a picture of the freshly vacuum distilled material before re-crystallization.

[Edited on 22-9-2002 by NERV]

Vir sapit qui pauca loquitur.

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Bravo!

Did you get any cristn inside the condenser when distilling? At which temp did it pass? I would suggest a recrysatllization of the distd material, as

it seems there always a little impurities passing over near the end. ReX from AcOEt/Pet ether gives beautifull, large cristals, and ables a very good

recovery. Apparently the impurities are liquid and very soluble in AcOEt/ pet ether mixture (noticed after leaving the mother liquor to evaporate).

I'm sure the distd product is pur enough for most purposes, but the reX being so easy and efficient, it's really worth the time.

thank you for sharing your results!

\"You can battle with a demon, you can embrace a demon; what the hell can you do with a fucking spiritual computer?\"

-Alice Parr

|

|

|

NERV

Hazard to Others

Posts: 152

Registered: 22-9-2002

Location: USA

Member Is Offline

Mood: Fluorinated

|

|

The product came over at 185-186'C there was really no crystallization in the condenser at all I kept a hot air gun with me during the process though

and made sure that my condenser was always warmish. I didn't use a strong enough vacuum so I think the 60% yields may be due to the high B.P. at which

my product came over at (lots of tar left in boiling flask at end of distillation). I would recommend a good rotary vane pump or at least a good

aspirator to pull the vacuum.

I did recrystallize from EtOAc/heptane, but sadly I didn't snap a picture of the recovered crystals they were very very beautiful  . .

Vir sapit qui pauca loquitur.

|

|

|

Wolfgangg

Harmless

Posts: 5

Registered: 18-2-2015

Member Is Offline

Mood: No Mood

|

|

Hey, this is my first post here so I apologize for violating any forum edicate that may exist. I've noticed a lot of people having problems purifying

crude p-methoxyphenol from the reaction of p-benzoquinone, MeOH, hydroquinone, and H2SO4, including myself. Distillation at 0.5 mm Hg failed, as the

product only seemed to want to sublime under that hard a vacuum. When a condenser was applied, dense white vapors passed through it like it was

nothing. At no point did I see liquid product.

Problems with recrystallization seem to be well documented and wide spread across many forums. I'm not really sure why, and I apologize if this info

is redundant, but xylene seems to be the ideal solvent to use. Recrystallization in xylene gave huge, clear crystals with very few loses. In my first

attempt (which I wasn't very careful with, since I had little hope that the experiment would bare fruit) 2.0 g crude product returned 1.7 g of a

clear, MUCH cleaner product, though it was tainted with a tan impurity.

However, that was with the extremely crude gunk left at the bottom of the flask after a failed distillation attempt. In my second trial, the crude

crystals attained from extraction of the reaction mixture were used and more care was taken to fully saturate the hot solvent. The recrystallization

went faster (crystals were seen growing after a few hours, rather than 12 hours), and I was able to recover ~1.9 g from 2.0 g crude product. Just be

aware that it may take 1-2 days for it all to fully crystallize, but the ease and return makes it well worth it in my opinion.

You'll be left with a clear crystalline solid that looks exactly like the beautiful pictures posted by the user "Klute" elsewhere on this forum.

Except you'll have completely bypassed the annoying vacuum distillation. Sorry for the blurry pictures, but I figured some proof was better than none.

Hopefully this helps atleast one person somewhere.

Solidified gunk from failed distillation attempt

Recrystallization of that gunk, clear but tan crystals

Crude product attained from extraction of the reaction mixture

Huge, clear crystals growing in xylene after only 4 H

|

|

|

Chemosynthesis

International Hazard

Posts: 1071

Registered: 26-9-2013

Member Is Offline

Mood: No Mood

|

|

Not that my opinion is of any more import than anyone else's, but I think your first post was excellent in every way. It does certainly appear as

though this will be useful given how much interest this chemical has had expressed in it.

Interesting how this alternative online preparation makes extractive solvent use of xylenes, but then advises re crystallization from ethyl acetate.

https://www.thevespiary.org/rhodium/Rhodium/Vespiary/talk/in...

I wonder how many people danced around this prior.

|

|

|