| Pages:

1

2

3

..

6 |

sokay

Harmless

Posts: 2

Registered: 22-5-2006

Member Is Offline

Mood: No Mood

|

|

benzyl alcohol oxidation

any good references for conversion of benzyl alcohol to benzaldehyde using cuo or sulfuric acid or things generally otc

|

|

|

guy

National Hazard

Posts: 982

Registered: 14-4-2004

Location: California, USA

Member Is Offline

Mood: Catalytic!

|

|

Use PCC in with acid catalyst. It can be used for any alcohol --> aldehyde reaction

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

Of course PCC requires anhydrous conditions or you get benzoic acid. And PCC (pyridium chlorochromate) is hardly OTC.

Perhaps sidechain chlorination with TCCA, then hydrolysis, and it will then loose water and go to benzaldehyde. Much more OTC.

|

|

|

praseodym

Hazard to Others

Posts: 137

Registered: 25-7-2005

Location: Schwarzschild Radius

Member Is Offline

Mood: crazy

|

|

How about using H2O2 for the partial oxidation of benzyl alcohol to benzaldehyde?

Benzyl alcohol, on oxidation with nitric acid, is converted into benzaldehyde as well.

Oxidation of benzyl alcohol to benzaldehyde can also be carried out using tert-butyl hydroperoxide under reflux, in the presence of

permanganate(MnO4-)-exchanged Mg-Al-hydrotalcite catalysts.

Benzyl alcohol can also be oxidised to benzaldehyde simply by using O2 with Pd-catalyst. Pd giant cluster catalyses benzyl alcohol oxidation to

benzaldehyde and inhibits its further oxidation. Al2O3 can also be added to further increase the rate of reaction.

Polymer-supported IBX esters and amides can also oxidise benzyl alcohol to benzaldehyde. More info here: http://blog.tenderbutton.com/wp-content/polymeribx4.pdf

Ceric ammonium nitrate, ammonium nitrate and sodium nitrite in trifluoroacetic acid are also effective catalysts for the quantitative oxidation of

benzyl alcohol to benzaldehyde.

Moreover, there are 2 distinct enzymes which attack benzyl alcohol, namely, xylene oxygenase and benzyl alcohol dehydrogenase; and their catalytic

activities were additive in the conversion of benzyl alcohol to benzaldehyde.

Oxidation of benzyl alcohol to benzaldehyde can also be done using a copper bipyridine complex in the presence of 2,2,6,6-

tetramethylpiperidinyl-1-oxy and base as cocatalysts.

Furthermore, benzyl alcohol can be oxidised to benzaldehyde in the presence of clayfen using a continuous isothermal reactor under microwave

irradiation. More info here: http://www.rsc.org/delivery/_ArticleLinking/DisplayArticleFo...

Alles sollte so einfach wie möglich gemacht werden aber nicht einfacher.

|

|

|

leu

Hazard to Others

Posts: 368

Registered: 13-10-2005

Member Is Offline

Mood: No Mood

|

|

An aqueous solution of sodium hypochlorite commonly known as household bleach is probably the most easily available route, it must be done precisely

as stated in US1405261 adjusting the molarity for the difference between calcium and sodium hypochlorite  Such oxidations are published in many different organic expermental laboratory course textbooks, you'll probably need

to visit a decent university library after studying the patent Such oxidations are published in many different organic expermental laboratory course textbooks, you'll probably need

to visit a decent university library after studying the patent

Chemistry is our Covalent Bond

|

|

|

Organikum

resurrected

Posts: 2337

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

Hi Lugh!

Doesnt work though in realwolrd. Gives just a mess and nobody with a brain wants to separate Bz-OH from Bz-dehyde except with bisulfite or so and then

you are an idiot for not knowing how to make it better in the first run.

[Edited on 25-5-2006 by Organikum]

|

|

|

leu

Hazard to Others

Posts: 368

Registered: 13-10-2005

Member Is Offline

Mood: No Mood

|

|

It works fine in this part of the real world, though apparently not in yours  More details as to how this happens can be found in the WD archives, search and you shall find out how it's done

More details as to how this happens can be found in the WD archives, search and you shall find out how it's done

[Edited on 25-5-2006 by leu]

[Edited on 26-5-2006 by leu]

Chemistry is our Covalent Bond

|

|

|

solo

International Hazard

Posts: 3975

Registered: 9-12-2002

Location: Estados Unidos de La Republica Mexicana

Member Is Offline

Mood: ....getting old and drowning in a sea of knowledge

|

|

OXIDATION OF BENZYL ALCOHOL AIMING AT A GREENER REACTION

Hongbing Ji a , Kohki Ebitani b , Tomoo Mizugaki b and Kiyotomi Kaneda b a

React.Kinet.Catal.Lett. Akadémiai Kiadó, Budapest Vol. 78, No. 1, 73-80, 2003

Abstract A highly efficient heterogeneous catalyst Ru-Mn-Fe-Cu-O successfully oxidized benzyl alcohol to benzaldehyde in the presence

of oxygen using toluene or water as solvent, and without solvent aiming at greener chemistry. Keywords: Benzyl alcohol, oxidation, green chemistry,

heterogeneous catalyst

Attachment: Oxydation of Benzyl alcohols.pdf (41kB)

This file has been downloaded 2775 times

It's better to die on your feet, than live on your knees....Emiliano Zapata.

|

|

|

garage chemist

chemical wizard

Posts: 1803

Registered: 16-8-2004

Location: Germany

Member Is Offline

Mood: No Mood

|

|

I had to test some benzyl alcohol for identity earlier (got some from as supplier who mislabeled two bottles, so I had to test everything).

To do this, I added some of it to a dilute solution of sodium persulfate, and heated. A powerful smell of benzaldehyde was produced quickly,

confirming its identity.

However, a precipitate of benzoic acid was also seen shortly afterwards.

|

|

|

evil_lurker

National Hazard

Posts: 767

Registered: 12-3-2005

Location: United States of Elbonia

Member Is Offline

Mood: On the wagon again.

|

|

How about the oxidation of benzyl alcohol using plain old DMSO?

One mole of benzyl alcohol is mixed with 7 moles of DMSO and heated to reflux for 14 hours. During that time a stream of air was pumped thru the

reaction mix. Seperation was achieved by diluting the reaction mix with water and extracting with ether. Yeild is 80%.

JAC vol 86, pg 298-299

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Is the by- product of that reaction dimethyl sulphide?

If so please don't do it when I'm anywhere near. (We need a "smiley" holding his nose here).

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

No shortage of these in the English-language literature.

Attachment: jacs_86_298_1964.pdf (311kB)

This file has been downloaded 2244 times

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

A long time ago I tried to oxidate BzOH with K2Cr2O7/H2SO4/H2O.

It works, but yield I obtained was 40%-50%. I think it could be higher, by very slowly adding oxidating mixture to stirring suspension BzOH/H2O. I

distilled product of reaction and there was signifant amount unreacted alcohol in benzaldehyde (product) and in remainder.

Propably there is an optimum: not oxidated alcohol - overoxidated acid (PhCOOH), so amount of oxidant will be needed higher than stoichiometric.

It is btw, not "good reference"

|

|

|

Ammar

Harmless

Posts: 8

Registered: 3-7-2006

Member Is Offline

Mood: No Mood

|

|

you can try Jones reagents in absence of water and in 2:1 ratio to your alcohol.

|

|

|

dugstar

Harmless

Posts: 1

Registered: 18-7-2006

Member Is Offline

Mood: No Mood

|

|

oxidation benzyl alcohol

Can benzyl alcohol oxidise at RT in the presence of air? Does it need a catalyst?

|

|

|

jokull

National Hazard

Posts: 506

Registered: 22-2-2006

Location: Everywhere

Member Is Offline

Mood: Ice glassed

|

|

yes dugstar

Benzyl alcohol gets oxidised at RT espontaneously, however the reaction is very slow. If you mean to oxidise BzOH in a short time then you can employ

a photocatalytic route, but this kind of synthesis has a lot of limitations although it is very selective.

|

|

|

Ammar

Harmless

Posts: 8

Registered: 3-7-2006

Member Is Offline

Mood: No Mood

|

|

Hi.Use of CrO3 with NaHSO4.H2O in 1:1:1 ratio will give you bezaldehyde by 95% yield. ( Im still using it myself,trust it)

|

|

|

cubicon

Harmless

Posts: 1

Registered: 16-8-2006

Member Is Offline

Mood: No Mood

|

|

Hi Ammar

95% yield ?

Would you be able to post a workup.Looks like one with potential.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Synthesis of Benzaldehyde from Benzyl Alcohol

Described below are my experiments in making benzaldehyde from benzyl alcohol.

Introduction and Background

I had been looking for a simple route to benzaldehyde. Fleaker supplied that route by his mention of the oxidation of benzyl alcohol with persulfate.

Garage chemist had also recommended the use of benzyl alcohol.

I was at first skeptical of this route as I did not see what would prevent the over-oxidation of benzaldehyde to benzoic acid. I also had no written

procedure to follow, just general guidelines from Fleaker and NERV.

Theory

The synthesis of benzaldehyde from benzyl alcohol is an oxidation-reduction reaction. The reaction can be broken into two half-reactions:

C6H5-CH2OH ----> C6H5-CHO + 2H+ +2e-

S2O8-- +2H+ + 2e- ----> 2HSO4- (E=2.1v)

Overall: C6H5-CH2OH + S2O8-- ----> C6H5-CHO + 2HSO4-

This reaction is highly exothermic.

1st Experiment

200mL of water was added to a 500mL RBF set up on a mantle & hot plate-stirrer. 10mL of benzyl alcohol (BnOH) was added and vigorous stirring

begun. Even with vigorous stirring not all of the BnOH dissolved.

An equivalent molar mass of Na2S2O8 (23g) was dissolved in 75 mL of water and placed in a pressure equalizing dropping funnel connected to the RBF.

Added persulfate solution to the RBF at 1 drop/sec while stirring.

Set up for steam distillation using direct steam method (not live steam). Began heating with the mantle. At one point the reactants suddenly turned

from clear to milky. Estimated temperature 60-70C. Eventually an oily yellow colored liquid began floating on the surface. Steam distillation

began with condensate coming over in regular spurts. Turned off stirrer as pot was at a regular boil. Stopped steam distillation when condensate

almost clear. Total condensate was ~90 mL with about 4-5 mL of separated product on the bottom. Aqueous pH of distillate ~5.

2nd Experiment

Encouraged by the results of experiment 1, a second was performed by doubling the reactants while keeping the water content the same. 150mL of water

was added to the RBF followed by 20mL of BnOH and vigorous stirring. Because the solubility of BnOH is only about 5g/100g water there was concern

that there would be a poor conversion due to the two-phase nature of the BnOH/water mix.

46g of Na2S2O8 was dissolved in 125mL water and placed in the dropping funnel as before. Oxidant added at 1-2 drops/sec. Turned on mantle heat.

Again when the temperature reached 60-70C there was a dramatic reaction and the pot started boiling. This could be called a runaway. Fortunately it

was all set up for steam distillation as before. Again a yellow-orangish colored oil formed and began floating on the surface. Continued the steam

distillation until the distillate ran almost clear. 135mL distillate collected with 15-20mL of product organic on the bottom of the receiver in a

separate phase.

3rd Experiment

Two things became apparent from the results of experiment 2: (1) The amounts of reactants could not be increased using the same methodology and

apparatus due to the runaway reaction occurring at 60-70C, and (2) the two phase BnOH/water reactant system had no negative affect on yield.

For the 3rd experiment the reactants were increased to 3X the size of the 1st experiment. Only this time the BnOH/water in the RBF was heated to 65C

and kept there during the slow addition of the oxidant.

75mL of water was placed in a 3-neck 500mL RBF followed by 30 mL of BnOH and vigorous stirring. A thermometer was inserted in one of the necks. 69g

of Na2S2O8 was added to 188 mL of water and placed in the dropping funnel as before. This worked out OK and the reaction temperature was kept at

65-75C by dropping in oxidant as required. When all oxidant had been added the system was set up for direct steam distillation as before.

Workup

The distillates from all three experiments were combined in a 500mL separatory funnel and the heavy organic was drained off. NaCl was added to the

water in the separatory funnel to salt out another mL or two of product. Anhydrous MgSO4 was added to the combined organic for drying.

During all handling of the BnO (crude & final) CO2 was used to backflush all containers and apparatus. Virtually no formation of benzoic acid was

noted.

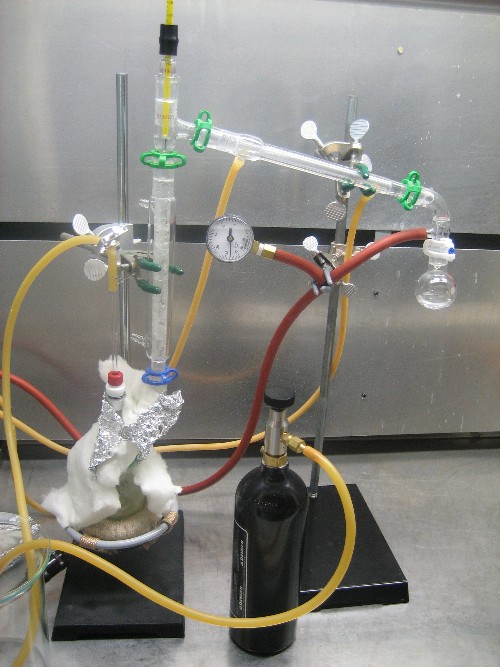

The crude dried BnO was fractionally distilled using a broken glass packed column at reduced pressure (60mmHg). Vapor temperature was 92-93C. The

bubbler needed to prevent bumping was supplied with CO2 from a crude reservoir (1000mL beaker). A photo of this setup is shown below:

Results

The combined recovery of BnO was 38mL. Based on the combined 60 mL of charged BnOH, the yield is 64.6%.

Discussion and Conclusions

The product was tested with Fehling's solution, Tollens solution, Bayer permanganate test, and formation of NaHSO3 adduct test. All were positive

except for the Fehling’s test. The Fehling’s reagents were verified as good by using fructose as reductant. It seems that the Fehling’s

reagent (Cu++) is just not a strong enough oxidant to oxidize BnO. The NaHSO3 adduct test gave a massive formation of white solids.

Of course ether extraction, and formation of the NaHSO3 adduct, could be used instead of steam distillation and fractional distillation at reduced

pressure to isolate the BnO. I’m not even sure how necessary it is to use reduced pressure for the distillation of BnO. Vogel seems ambivalent on

this.

This would be an interesting method to try on an aliphatic primary alcohol. I believe their aldehydes do give a positive Fehling’s test. Perhaps

they oxidize much easier than aromatic aldehydes. This would explain the apparent lack of over-oxidation of BnO to benzoic acid

I am very satisfied with this method of synthesis for BnO. With further work to refine the method, and with use of a larger batch size, the yield

could possibly be significantly increased.

[Edited on 23-4-2008 by Magpie]

[Edited on 23-4-2008 by Magpie]

[Edited on 23-4-2008 by Magpie]

[Edited on 23-4-2008 by Magpie]

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Very nice work Magpie, pleasure to read.

A couple of thoughts:

The persulphate obviously doesnt react below 60C (much the same as it doesnt etch Cu below that temperature) so adding it dropwise to the mixture

preheated to that temperature should help avoid run-away, and increase size of yield per batch.

I dont think the two-phase nature need be a concern with stirring- it wasnt in my hydrolysis of BzCl2, which was also two phase. In this case, since

the reaction is much more vigorous, I would think its a blessing.

Im not 100% sure there isnt some alcohol in the benzaldehyde - its more soluble in water than the latter - but I believe its solubility in the

benzaldehyde is greater still. Their bps at atmospheric are within 25C of each other (though at reduced pressure that increases). A way to check would

be to form an adduct and weigh.

Im like yourself curious that the oxidation doesnt go to benzoic acid since BzO would appear to be much easier to oxidize than BzOH judging by the

action of O2 on both. Must be peculiarity of persulphate.

Unfortunately BzOH is as hard to get here as BzO - both restricted for sale.

[Edited on 24-4-2008 by len1]

|

|

|

Klute

International Hazard

Posts: 1378

Registered: 18-10-2006

Location: France

Member Is Offline

Mood: No Mood

|

|

Very nice! I'm impressed about your resuults!

I tried this reaction several times, but using a Cu2+/Fe2+ catalyst system, with mixed results. Trilobite posted a very complete article in the

"benzylic oxidation using various oxidants" thread. See patent US 4,146,585. I obtained mixed results, most of the time there was benzoic acid present

to some extent.

Did you not use theses salts for a reason, or just didn't know about this variation?

To compensate for the poor solubility of persulfate at RT (i used ammonium persulfate), I added half of it as a conc aq solution, and the other half

as a solid. It dissolution is pretty endothermic.

I used bisulfite to seperate the aldehyde from the alcohol, but in retrospect, i think it was that efficient (benzaldehyde losses).

I'm glad to see other people working with what is, IMHO, a pretty versatil compound! And relatively cheap too.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks Len. From Len:

| Quote: |

Im not 100% sure there isnt some alcohol in the benzaldehyde - its more soluble in water than the latter - but I believe its solubility in the

benzaldehyde is greater still. Their bps at atmospheric are within 25C of each other (though at reduced pressure that increases). A way to check would

be to form an adduct and weigh.

|

I was concerned about this also and for this reason debated whether or not to go with NaHSO3 adduct isolation vs distillation. I plotted the

available BnO vapor pressure data (P vs T), and for P=60mmHg T should be 100C instead of my steady 92-93C. I then checked Gmehling's Azeotropic

Data for an azeotrope with BnOH. There is none at pressures of 30, 100, 300, and 760 mmHg. So I'm not sure what to think here.

And thank you Klute. Klute says:

| Quote: |

I tried this reaction several times, but using a Cu2+/Fe2+ catalyst system, with mixed results. Trilobite posted a very complete article in the

"benzylic oxidation using various oxidants" thread. See patent US 4,146,585. I obtained mixed results, most of the time there was benzoic acid present

to some extent.

|

I did see this patent. But Fleaker/NERV made no mention of the use of catalysts so I decided to try the simpler approach first.

|

|

|

grind

Hazard to Others

Posts: 120

Registered: 13-1-2007

Member Is Offline

Mood: No Mood

|

|

Another very easy way:

1. BnOH + HCl = BnCl

2. BnCl + Hexammin = quat. salt

3. quat. salt you can treat in 2 ways, one way leads to benzaldehyde, the other way gives benzylamine (sommolet and delepine).

|

|

|

Zinc

Hazard to Others

Posts: 472

Registered: 10-5-2006

Member Is Offline

Mood: No Mood

|

|

Very interesting. But fortunately I can easily buy benzaldehyde (around 43 $ per liter) and benzyl alcohol (around 75$ per liter).

I know it is a little OT but where could I find out how to make benzyl nitrate and information about its properties?

|

|

|

len1

National Hazard

Posts: 595

Registered: 1-3-2007

Member Is Offline

Mood: NZ 1 (goal) - Italy 1 (dive)

|

|

Its great of course all these people can buy PhCHO and PhCH3O, I cant buy either for love or money. I can get PhCOOH, and PhCH3 - thank heaven for

small mercies. Mind you if you have to spend $75/l for benzyl alcohol then making it out of $10/l toluene (the chlorine is essetially free, and the

HCl reusable) might still be worthwhile.

Magpie, in your experiment 3 you have already done whatb Ive suggested - sorry I didnt notice that before. What I dont understand is why dont we have

PhCHO + S2O8-- + H2O -> PhCOOH + 2HSO4-

given we have

PhCH3O + S2O8-- -> PhCHO + 2HSO4-

its not like theres a lack of water, and its a well known fact that aldehydes are much more prone to oxidation than the corresponding alcohols.

Normal methods for preparation of aldehydes, eg formaldehyde, acetaldehyde, rely on the volatility of the aldehyde to remove it as soon as its formed,

so no appreciable concentration builds up on the LHS of the first reaction. But that apparently is not whats happening here.

The only thing I can sugget is that the relative solubility of the alcohol/aldehyde in water is used. The reaction takes place in aqueous medium -

thats were the persulphate is. The benzaldehyde separates from this into a separate layer - and so is essentially removed from equilibrium. If one

vigorously mixes such a solution instead of letting it separate that should rapidly oxidize the benzaldehyde and send the yield well down. However if

one has an excess of the alcohol, so not all of it dissolves stirring is precisely what one has to do to promote the reaction. The result is - this

is my hypothesis, that the yield is entirely based on the solubility differential 5gms:0.5gms per 100ml H2O of benzyl alcohol/benzaldehyde. In this

case it is indeed impossible to increase the yield as its limited by the amount of water needed to dissolve the small amount of alcohol, i.e. size of

vessel is 20 times greater than max yield volume.

Whats protecting the benzaldehyde is its inability to join the aqueous phase - where the alcohol has much less such protection. As the aquesous layer

has its alcohol converted more dissolves to make up the difference - however this dissolution must be accompanied by some benzaldehyde dissolving - so

theres a limit to the efficiency of this method.

In regards to the bp - my feeling based on my experiences is not too trust thermometers in such arrangements very much, depending on the type and

experimental arrangement I have found they can read 10C too low easily. But even if theres no azeotrope, liquid with close boiling points will behave

like one, it'll be very hard to separate them. What is needed is an IR or very careful gravimetric analysis. I wish I had access to PhCH3O so I

could repeat your experiment and analyse the result.

[Edited on 25-4-2008 by len1]

|

|

|

| Pages:

1

2

3

..

6 |