| Pages:

1

..

13

14

15

16

17 |

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

A major breakthrough!

One of the biggest problems in producing nitrite by reduction of nitrate is its tendency to react with oxygen at the reaction temperature. The

solution? Remove oxygen.

I recently got an argon cylinder over the counter from a local welding supply store (Machine Mart) and decided to retry the sodium sulphide reduction

method described in Morgan, in the same manner as the molten lead method (reductant added to molten nitrate in portions), while sparging the flask

with argon and keeping oxygen out.

It only went and bloody well worked!

I'll need to reproduce and refine the method before providing a full write-up, but this is definitely a viable way to produce nitrites at a small

scale. Get in!

|

|

|

clearly_not_atara

International Hazard

Posts: 2828

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Chalk up another victory to the inert atmosphere! First eugenol demethylation, now nitrite.

Lovely choice of reducing agents we have. Sodium sulfide or lead. Any word on nickel carbonyl?

But seriously, nice work!

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

To be fair, sodium sulphide is easily obtainable from photography suppliers (it's the traditional reagent used for sepia toning), and you only need 1

mole of sulphide per 4 moles of nitrate. Plus, technical grade sodium sulphide is hydrated and is a liquid at the temperature the reaction is carried

out, so the reaction mixture is uniform, and you don't have the problem of uneven mixing that you'd get with a solid/liquid or solid/solid mixture.

The process described in Morgan was carried out in iron pans, with no mention of an inert atmosphere, which is a recipe for failure (and an awful lot

of ammonia.) The chemistry itself was sound, but the process was pretty bad.

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

I couldn't reproduce this method.

In my initial attempt, I stopped when addition of sulphide started producing small deflagrations at the surface of the molten mixture, likely due to

formation of elemental sulphur - this started happening when 60% of the sulphide had been added. However, when I crystallised out nitrite, it was only

60% pure, suggesting an incomplete reaction had taken place. So the second time, I added all of the sulphide.

On dissolving the solidified reaction mixture, it appears the nitrite had been destroyed in the reaction, most likely due to sulphide reacting with

nitrite, forming elemental sulphur and ammonia; as no ammonia vapours were evident during the reaction, it was most likely captured as ammonium

sulphate. This would explain why although a highly soluble hygroscopic substance was produced on concentrating the mixture to near-dryness under

vacuum, it did not look like either sodium nitrate or nitrite (smaller crystals), and the pH of a solution was too low for it to be either nitrite or

nitrate (about 5).

Sod the shipping costs, going forward I'm just buying it from Poland.

|

|

|

fx-991ex

Hazard to Others

Posts: 109

Registered: 20-5-2023

Member Is Offline

|

|

In the first post he do NaHSO3 + CaCl2 and then heat the resulting Ca(HSO3)2 to decompose to CaSO3 + H2SO3.

I was thinking.

Lets start with sodium metabisulfite.

Na2S2O5 + H2O = NaHSO3

Then

NaHSO3 + Ca(OH)2 = CaSO3 + NaOH + H2O

Can this be done?(i know weak base displace stronger base, not the opposite, but the low solubility of CaSO3 will drive it forward?)

or (this should definitely work)

NaHSO3 + NaOH = Na2SO3 + H2O

followed by

Na2SO3 + CaCl2 = CaSO3 + NaCl

Also about the thermal reduction of NaNO3 + CaSO3, i plan to do it in a crucible(porcelain) with bunsen burner.

Do i heat it till the nitrate/nitrite melt?, is it gonna be hard to tell when it reached completion? or theres some color change?.

[Edited on 19-6-2023 by fx-991ex]

[Edited on 19-6-2023 by fx-991ex]

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Quote: Originally posted by fx-991ex  | In the first post he do NaHSO3 + CaCl2 and then heat the resulting Ca(HSO3)2 to decompose to CaSO3 + H2SO3.

I was thinking.

Lets start with sodium metabisulfite.

Na2S2O5 + H2O = NaHSO3

Then

NaHSO3 + Ca(OH)2 = CaSO3 + NaOH + H2O

Can this be done?(i know weak base displace stronger base, not the opposite, but the low solubility of CaSO3 will drive it forward?)

or (this should definitely work)

NaHSO3 + NaOH = Na2SO3 + H2O

followed by

Na2SO3 + CaCl2 = CaSO3 + NaCl

Also about the thermal reduction of NaNO3 + CaSO3, i plan to do it in a crucible(porcelain) with bunsen burner.

Do i heat it till the nitrate/nitrite melt?, is it gonna be hard to tell when it reached completion? or theres some color change?.

[Edited on 19-6-2023 by fx-991ex]

[Edited on 19-6-2023 by fx-991ex] |

My only comment is that you will need to work with an inert atmosphere, as nitrite salts are rapidly oxidised to nitrate by oxygen in their molten

state.

Good luck!

|

|

|

fx-991ex

Hazard to Others

Posts: 109

Registered: 20-5-2023

Member Is Offline

|

|

Quote: Originally posted by Lionel Spanner  | Quote: Originally posted by fx-991ex  | In the first post he do NaHSO3 + CaCl2 and then heat the resulting Ca(HSO3)2 to decompose to CaSO3 + H2SO3.

I was thinking.

Lets start with sodium metabisulfite.

Na2S2O5 + H2O = NaHSO3

Then

NaHSO3 + Ca(OH)2 = CaSO3 + NaOH + H2O

Can this be done?(i know weak base displace stronger base, not the opposite, but the low solubility of CaSO3 will drive it forward?)

or (this should definitely work)

NaHSO3 + NaOH = Na2SO3 + H2O

followed by

Na2SO3 + CaCl2 = CaSO3 + NaCl

Also about the thermal reduction of NaNO3 + CaSO3, i plan to do it in a crucible(porcelain) with bunsen burner.

Do i heat it till the nitrate/nitrite melt?, is it gonna be hard to tell when it reached completion? or theres some color change?.

[Edited on 19-6-2023 by fx-991ex]

[Edited on 19-6-2023 by fx-991ex] |

My only comment is that you will need to work with an inert atmosphere, as nitrite salts are rapidly oxidised to nitrate by oxygen in their molten

state.

Good luck! |

Apparently it can be done without melting the mixture (230C-300C)

Heres a video where it seem to be working well: https://www.youtube.com/watch?v=5BLPoE6Y-ns

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

If you can actually get it to work, that'd be one hell of an achievement.

As I said: good luck!

|

|

|

Sir_Gawain

Hazard to Others

Posts: 494

Registered: 12-10-2022

Location: [REDACTED]

Member Is Offline

Mood: Still in 2022

|

|

Would it work better with potassium nitrate? KNO2 is 10 times more soluble than KNO3.

“Alchemy is trying to turn things yellow; chemistry is trying to avoid things turning yellow.” -Tom deP.

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Since reductive pathways to nitrite generally require high temperatures and produce poor purity products, or result in over-reduction to ammonia, it

may be worth taking a cue from the industrial synthesis, namely the reaction between nitric oxide and caustic soda, which doesn't involve any

oxidation or reduction at all.

Now nitric oxide itself is hard to come by for amateurs, but here's an idea for an indirect route: prepare nitrosyl sulphuric acid, dissolve it in

sulphuric acid, cool the solution to near 0 °C, then add it (slowly and carefully!) to an equally cold hydroxide solution, under an inert atmosphere,

to produce a mixture of nitrite and sulphate, that can easily be separated due to the large difference in solubility.

Brauer claims direct addition of water to nitrosyl sulphuric acid produces dinitrogen trioxide, a direct precursor to inorganic and organic nitrites,

but this is probably only true at temperatures well below zero.

Nitrosyl sulphuric acid is not trivial to make, as it requires sulphur dioxide to be bubbled through cold fuming nitric acid, but as a non-volatile

solid with a melting point of 70 °C it is easier to handle than other simple inorganic nitrosyl compounds, which are highly toxic gases or

low-boiling liquids.

[Edited on 2-8-2023 by Lionel Spanner]

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Here's what may be a very interesting and relevant paper, describing selective production of nitrite or nitrate by electrochemical oxidation of

ammonia with a copper electrode.

https://chemistry-europe.onlinelibrary.wiley.com/doi/epdf/10...

Unfortunately Sci-Hub hasn't indexed it, and I'm not in a position to drop the Britbongland equivalent of $49 just to download it, especially if it

turns out to be hot garbage. Would anyone who has access to the Wiley online library be able to share it? Many thanks!

|

|

|

Parakeet

Hazard to Self

Posts: 75

Registered: 22-12-2022

Location: Japan

Member Is Offline

Mood: V (V)

|

|

Here it is.

Haven't read everything yet, but the procedure looks amateur friendly.

Attachment: ChemSusChem - 2021 - Johnston.pdf (714kB)

This file has been downloaded 364 times

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Fantastic, thank you very much!

|

|

|

unionised

International Hazard

Posts: 5135

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Thanks but...

"Large-scale nitrite production (NaNO2) is achieved by bubbling gaseous N2O and NO through a solution of NaOH and Na2CO3".

Really?

|

|

|

Parakeet

Hazard to Self

Posts: 75

Registered: 22-12-2022

Location: Japan

Member Is Offline

Mood: V (V)

|

|

Quote: Originally posted by unionised  |

Thanks but...

"Large-scale nitrite production (NaNO2) is achieved by bubbling gaseous N2O and NO through a solution of NaOH and Na2CO3".

Really? |

Yeah. I've also read the third reference. It should be NO2.

|

|

|

fx-991ex

Hazard to Others

Posts: 109

Registered: 20-5-2023

Member Is Offline

|

|

In water it is, but in Alcohol the sodium nitrite salt is more soluble, and since alcohol is easier to remove thats why i went with the sodium salt

instead of the potassium one.

I did try the reaction(didnt extract with alcohol yet)

When i mixed the sulfite and nitrate it was a bit endothermic, so it seem like it process very easily.

Also the sulfite/nitrate salt quantity on the video i posted are for the anhydrous sulfite salt, the user that made the video also made another video

on how he made the sulfite salt and i think he is using the dihydrate like i did so the ratio is wrong. Probably why he has low yield(except from the

fact he has lost a lot of product from overheating the mix and a broken beaker/kept the top part).

I think this method is very promising.

For 5G of NaNO3 its 9.187G of CaSO3.

Na2S2O5+H2O→NaHSO3 NaHSO3+NaOH→Na2SO3+H2O Na2SO3+CaCl2→CaSO3+NaCl CaSO3+NaNO3→CaSO4+NaNO2 last one use heat - temp 230-300 C for 30-10 min.

[Edited on 14-8-2023 by fx-991ex]

|

|

|

Alkoholvergiftung

Hazard to Others

Posts: 198

Registered: 12-7-2018

Member Is Offline

|

|

I ve never tried this way but i think its for bigger scale lab. Production the best methode. You dont need to melt something and you can make it in

big Backers.

50 Parts Sodiumnitrate desolved in 150 Parts of Water. Add 350ml Ammonia solution with specific wight 0,96. After this give slowly 60 parts Zinc

powder to it and hold temperature between 20C and 25C.After an short time all nitrate is converted to nitrite.

Its from an patent who improved an old lab methode from Poggendorfs Analen of Physic and Chemistrie.

Concentrations and Temperatures are improtand if it isnt exactly followed the nitrate gets reduced to hydroxide.

|

|

|

Fantasma4500

International Hazard

Posts: 1682

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

Aluminium nitrite

aluminium metal doesnt react with nitric acid, and neither nitric acid vapors, but it will react with nitrate salts such as copper nitrate and iron

nitrate- however if aluminium can be kept seperate from a nitric acid / nitrate salt mixture the NO2 may react rapidly with the aluminium to form

aluminium nitrite

ideally the container is first flushed with CO2, butane maybe- as that is a very heavy gas

i did one attempt but the nitric acid/NOx fumes ate through the perforated plastic bag that was holding the shredded aluminium foil

(al foil flitter made by coffee grinding aluminium foil balls)

NO2 source was nitric acid and steel wool balls

i had a slight success proven by wettening the resulting mixture in IPAlcohol and adding dilute HCl which then formed IPNitrite, flame test faintly

showed IPNitrite but it was largely yellow, probably due to hydrogen effervescence and presence of sodium nitrate as i used Na2CO3 + HNO3 to form the

CO2 before i started the reaction, i shall attempt this further as this was a very poor attempt.

sadly it doesnt appear that aluminium carbonate exists, it decomposes into aluminium hydroxide which is difficult to filter as its a gel rather,

IPNitrite might be best way to scavenge the nitrite from this reaction

|

|

|

unionised

International Hazard

Posts: 5135

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

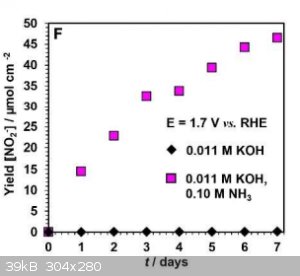

Am I reading this correctly? The yield is about 50 micro moles per square cm per week.

So, with a 10cm by 10 cm electrode you would get less than a quarter of a gram of nitrite per week.

|

|

|

Kloberth

Harmless

Posts: 38

Registered: 2-6-2023

Member Is Offline

|

|

Quote: Originally posted by Alkoholvergiftung  | I ve never tried this way but i think its for bigger scale lab. Production the best methode. You dont need to melt something and you can make it in

big Backers.

50 Parts Sodiumnitrate desolved in 150 Parts of Water. Add 350ml Ammonia solution with specific wight 0,96. After this give slowly 60 parts Zinc

powder to it and hold temperature between 20C and 25C.After an short time all nitrate is converted to nitrite.

Its from an patent who improved an old lab methode from Poggendorfs Analen of Physic and Chemistrie.

Concentrations and Temperatures are improtand if it isnt exactly followed the nitrate gets reduced to hydroxide. |

Do you have a link to this patent or pdf?

|

|

|

Alkoholvergiftung

Hazard to Others

Posts: 198

Registered: 12-7-2018

Member Is Offline

|

|

See Attachment. They are in German.

Attachment: NitritDE000000168450A_2.pdf (65kB)

This file has been downloaded 372 times

|

|

|

Alkoholvergiftung

Hazard to Others

Posts: 198

Registered: 12-7-2018

Member Is Offline

|

|

First Part.

Attachment: NitritDE000000168450A_1 (1).pdf (78kB)

This file has been downloaded 380 times

|

|

|

Lionel Spanner

Hazard to Others

Posts: 176

Registered: 14-12-2021

Location: near Barnsley, UK

Member Is Offline

|

|

Quote: Originally posted by unionised  |

Am I reading this correctly? The yield is about 50 micro moles per square cm per week.

So, with a 10cm by 10 cm electrode you would get less than a quarter of a gram of nitrite per week.

|

That's with 0.1 molar ammonia, i.e. 0.17% w/v. I suspect a more concentrated solution would result in better yields.

[Edited on 22-8-2023 by Lionel Spanner]

|

|

|

Alkoholvergiftung

Hazard to Others

Posts: 198

Registered: 12-7-2018

Member Is Offline

|

|

I ve found this crusicible methode.Englisch and later german copy.

Very finely divided metallic copper is first prepared by distillation of acetate of copper, and from this freshly prepared metallic powder, 2

equivalents, or even a slight excess, are taken to 1 equivalent of nitrate, according to the equation

2 Cu + KO, NO⁵ = 2 CuO + KO, NO³.

Persoz took 320 grm. saltpetre and 200 grm. from the copper represented in the manner indicated.

To prepare an intimate mixture, the saltpeter is first dissolved in the smallest possible quantity of hot water, and then the copper is added, which

at first is difficult to wet. When the mixture has become quite uniform, it is heated in a porcelain dish, or better yet, in a cast-iron pan, in a

sand bath, stirring constantly to prevent splashing. When the mass is completely dry, there comes a moment when, like a pyrophor, it catches fire and

glows; when the combustion is over, which lasts but a moment, the reaction has taken place; it is allowed to cool, the melt treated with water,

filtered, and the nitrate allowed to crystallize. If excess copper has been used, no nitrate is present, and crystallized nitrite is obtained at once,

which is then melted and kept in well-closed flasks, as the salt is very hygroscopic. Any undecomposed nitrate of potash present is separated out by

the first crystallization, since it is far less soluble than nitrate of potash. The copper oxide obtained as a residue during the operation can, after

proper washing, be used for organic analysis, or at least for mixing with the organic substance to be examined, since, although it is very finely

divided, it is nevertheless very dense and to a much lesser degree hygroscopic than the annealing of nitrate of copper.

It is to be remarked, however, that common copper, even in a very finely divided form, would not be fit for the foregoing purpose, as in its

application

to bring about the intended reaction the temperature would have to be raised much higher, so that caustic potash rather than nitrate of potash would

be obtained; on the other hand, when using the copper prepared from the acetate salt, the reaction occurs at as little as 200° to 250° C. (Annales

du Conservatoire des arts et métiers, t. II p. 353.)

Man bereitet sich zunächst durch Destillation von essigsaurem Kupferoxyd sehr fein zertheiltes metallisches Kupfer, und nimmt von diesem frisch

bereiteten Metallpulver 2 Aequivalente oder selbst einen geringen Ueberschuß, auf 1 Aequivalent Salpeter, entsprechend der Gleichung

2 Cu + KO, NO⁵ = 2 CuO + KO, NO³.

Persoz nahm 320 Grm. Salpeter und 200 Grm. von dem auf die angegebene Weise dargestellten Kupfer.

Zur Herstellung eines innigen Gemenges löst man den Salpeter zunächst in der möglich geringsten Menge heißen Wassers, und setzt dann das Kupfer

hinzu, welches sich anfänglich nur schwierig benetzen läßt. Ist das Gemenge recht gleichartig geworden, so erhitzt man dasselbe in einer

Porzellanschale oder besser, in einer gußeisernen Pfanne im Sandbade unter beständigem Umrühren, um Spritzen zu verhüten. Ist die Masse

vollständig getrocknet, so tritt ein Moment ein, wo sie, gleich einem Pyrophor, Feuer fängt und erglüht; ist die Verbrennung vorüber, was nur

einen Augenblick dauert, so hat die Reaction stattgefunden; man läßt erkalten, behandelt die Schmelze mit Wasser, filtrirt und läßt das

salpetrigsaure Salz krystallisiren. Hat man überschüssiges Kupfer angewendet, so ist kein Nitrat vorhanden und man erhält sogleich krystallisirtes

Nitrit, welches man dann schmilzt und in gut verschlossenen Flaschen aufbewahrt, da das Salz sehr hygroskopisch ist. Etwa vorhandenes nicht zersetztes

salpetersaures Kali wird durch die erste Krystallisation abgeschieden, da es weit weniger löslich ist als das salpetrigsaure Kali. Das bei der

Operation als Rückstand erhaltene Kupferoxyd kann nach gehörigem Auswaschen zur organischen Analyse, wenigstens zum Vermengen mit der zu

untersuchenden organischen Substanz angewendet werden, da es, obgleich sehr fein zertheilt, dennoch sehr dicht und in weit geringerem Grade

hygroskopisch ist, als das durch Glühen von salpetersaurem Kupferoxyd erhaltene.

Zu bemerken ist indessen, daß gewöhnliches Kupfer, selbst in sehr fein zertheilter Form, zu dem vorstehenden Zwecke sich nicht eignen würde, da bei

seiner Anwendung

zur Hervorrufung der beabsichtigten Reaction die Temperatur weit höher gesteigert werden müßte, so daß man eher Aetzkali als salpetrigsaures Kali

erhalten würde; bei Anwendung des aus dem essigsauren Salze dargestellten Kupfers hingegen tritt die Reaction schon bei 200 bis 250° C. ein.

(Annales du Conservatoire des arts et métiers, t. II p. 353.)

|

|

|

woelen

Super Administrator

Posts: 8082

Registered: 20-8-2005

Location: Netherlands

Member Is Offline

Mood: interested

|

|

Interesting quote. The english translation contains some small, but essential errors. Below follows the corrected translation.

Very finely divided metallic copper is first prepared by distillation of acetate of copper, and from this freshly prepared metallic powder, 2

equivalents, or even a slight excess, are taken to 1 equivalent of saltpeter, according to the equation

2 Cu + KO, NO⁵ = 2 CuO + KO, NO³.

Persoz took 320 grm. saltpeter and 200 grm. from the copper represented in the manner indicated.

To prepare an intimate mixture, the saltpeter is first dissolved in the smallest possible quantity of hot water, and then the copper is added, which

at first is difficult to wet. When the mixture has become quite uniform, it is heated in a porcelain dish, or better yet, in a cast-iron pan, in a

sand bath, stirring constantly to prevent splashing. When the mass is completely dry, there comes a moment when, like a pyrophor, it catches fire and

glows; when the combustion is over, which lasts but a moment, the reaction has taken place; it is allowed to cool, the melt treated with water,

filtered, and the nitrite allowed to crystallize. If excess copper has been used, no nitrate is present, and

crystallized nitrite is obtained at once, which is then melted and kept in well-closed flasks, as the salt is very hygroscopic. Any undecomposed

nitrate of potash present is separated out by the first crystallization, since it is far less soluble than nitrite of

potash. The copper oxide obtained as a residue during the operation can, after proper washing, be used for organic analysis, or at least for mixing

with the organic substance to be examined, since, although it is very finely divided, it is nevertheless very dense and to a much lesser degree

hygroscopic than the annealing of nitrate of copper.

It is to be remarked, however, that common copper, even in a very finely divided form, would not be fit for the foregoing purpose, as in its

application to bring about the intended reaction the temperature would have to be raised much higher, so that caustic potash rather than nitrite of potash would be obtained; on the other hand, when using the copper prepared from the acetate salt, the reaction

occurs at as little as 200° to 250° C. (Annales du Conservatoire des arts et métiers, t. II p. 353.)

This is quite an interesting thing. I did not know that copper acetate can be converted to copper metal by heating the salt. This is definitely

something to try on a small scale. Maybe this process also works with NaNO3 instead of KNO3. The resulting NaNO2 is much less hygroscopic than KNO2.

Also interesting to see that in this old writing potassium ion is considered divalent. They wrote KO,NO5 for potassium nitrate, which we now would

write as K(NO3)2. Potassium nitrite is KO,NO3, which in modern notation would be K(NO2)2. Copper(II) at that time already was regarded as a divalent

ion.

|

|

|

| Pages:

1

..

13

14

15

16

17 |