| Pages:

1

..

6

7

8

9

10

..

14 |

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

For dead over-pressed CHP and Lithex are resistant. Pressed in the vise. Output segment on cca 50 - 100 Kg. Start segment are hands pressed

on 5 - 20 Kg. During approx. 2,000 pressing operations, without incident so far.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

ManyInterests

National Hazard

Posts: 938

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by Laboratory of Liptakov  | For dead over-pressed CHP and Lithex are resistant. Pressed in the vise. Output segment on cca 50 - 100 Kg. Start segment are hands pressed

on 5 - 20 Kg. During approx. 2,000 pressing operations, without incident so far. |

That sounds good. I will need to get a way to mechanically press my CHP caps once I have some ammonium perchlorate done. I made a lot of sodium

chlorate that I need to purify of NaCl, but after that it'll all be getting it to go on sodium perchlorate synth before I make ammonium perchlorate.

Would a vice/clamp like this work? It is probably too small (only 50mm length) and I will need something bigger. But in concept would it suffice? Just

turn it until the dowel will go no farther?

edit: https://youtu.be/WeIN8JUKTYg

Would a press like that work? How would I know what the press weight is? You said you went up to 100kg. That is quite a lot of weight. So I assume CHP

is very, VERY safe to work with. I probably won't want to make that kind of weight on it. I do want to know how much weight I would put on it.

[Edited on 29-8-2022 by ManyInterests]

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

Quote: Originally posted by ManyInterests  | I will need to get a way to mechanically press my CHP caps once I have some ammonium perchlorate done.

Would a vice/clamp like this work? It is probably too small (only 50mm length) and I will need something bigger. But in concept would it suffice? Just

turn it until the dowel will go no farther?

edit: https://youtu.be/WeIN8JUKTYg

Would a press like that work? How would I know what the press weight is? You said you went up to 100kg. That is quite a lot of weight. So I assume CHP

is very, VERY safe to work with. I probably won't want to make that kind of weight on it. I do want to know how much weight I would put on it.

[Edited on 29-8-2022 by ManyInterests] |

I wouldn't bother with that press in the youtube link, but a g-clamp like you show in your post would do nicely. You just need to get one long enough

to take the length of the detonator body plus the length of the dowel used to press. G-clamps will often have their rated clamping force listed on the

suppliers website. A reasonable quality one with an opening of 100 mm should be able to apply hundreds of kgs of clamping force. Better still is a

vice. You can apply more pressure and you put some shielding in place between you and the detonator.

|

|

|

ManyInterests

National Hazard

Posts: 938

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by B(a)P  | Quote: Originally posted by ManyInterests  | I will need to get a way to mechanically press my CHP caps once I have some ammonium perchlorate done.

Would a vice/clamp like this work? It is probably too small (only 50mm length) and I will need something bigger. But in concept would it suffice? Just

turn it until the dowel will go no farther?

edit: https://youtu.be/WeIN8JUKTYg

Would a press like that work? How would I know what the press weight is? You said you went up to 100kg. That is quite a lot of weight. So I assume CHP

is very, VERY safe to work with. I probably won't want to make that kind of weight on it. I do want to know how much weight I would put on it.

[Edited on 29-8-2022 by ManyInterests] |

I wouldn't bother with that press in the youtube link, but a g-clamp like you show in your post would do nicely. You just need to get one long enough

to take the length of the detonator body plus the length of the dowel used to press. G-clamps will often have their rated clamping force listed on the

suppliers website. A reasonable quality one with an opening of 100 mm should be able to apply hundreds of kgs of clamping force. Better still is a

vice. You can apply more pressure and you put some shielding in place between you and the detonator.

|

OK that'll save me some time and cash.

I can maybe do something to provide shielding, but if it is as safe as LL said that shouldn't be a problem.

The new metal bodies I ordered are 8mm OD (so either 7mm or 6mm ID. Which is the same as a bic round stic pen)and 50mm in length. I originally thought

of getting 100mm but those are actually too long. Finding anything in between and of similar diameter proved hectic so I went with the next best

thing.

I also am getting more practice in making e-matches that are as small as possible so I can slip them in the smaller cap and still seal them with epoxy

and crimp them (since they're steel, crimping won't be hard).

I can also use empty firearm cases for this. I have plenty and of a variety of sizes. From 9mm, .45ACP, 7.62x25mm, 7.62x51mm, 7.62x57R and of course

5.56x45mm. Some other ones that would make for an excessively oversized and overpowered detonator.

I just have to clean them out thoroughly to remove any residue from burnt powder and primer material before doing so.

Edit: how much CHP do you normally use per cap? Also how big are your caps normally?

I had another question, but I forgot... later when I remember.

[Edited on 29-8-2022 by ManyInterests]

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ManyInterests  | Quote: Originally posted by B(a)P  |

OK that'll save me some time and cash.

I can maybe do something to provide shielding, but if it is as safe as LL said that shouldn't be a problem.

The new metal bodies I ordered are 8mm OD (so either 7mm or 6mm ID. Which is the same as a bic round stic pen)and 50mm in length. I originally thought

of getting 100mm but those are actually too long. Finding anything in between and of similar diameter proved hectic so I went with the next best

thing.

I also am getting more practice in making e-matches that are as small as possible so I can slip them in the smaller cap and still seal them with epoxy

and crimp them (since they're steel, crimping won't be hard).

I can also use empty firearm cases for this. I have plenty and of a variety of sizes. From 9mm, .45ACP, 7.62x25mm, 7.62x51mm, 7.62x57R and of course

5.56x45mm. Some other ones that would make for an excessively oversized and overpowered detonator.

I just have to clean them out thoroughly to remove any residue from burnt powder and primer material before doing so.

Edit: how much CHP do you normally use per cap? Also how big are your caps normally?

I had another question, but I forgot... later when I remember.

[Edited on 29-8-2022 by ManyInterests] |

Keep in mind that the cap body crushing then breaking can create a pinch point then a sudden force which could cause an accidental detonation.

I wouldn't recommend pressing CHP with any kind of setup that's not well thought out. Good shielding, eye and ear protection as well as a clear head

is advised when assembling caps. |

|

|

|

ManyInterests

National Hazard

Posts: 938

Registered: 19-5-2019

Member Is Offline

|

|

| Quote: |

Keep in mind that the cap body crushing then breaking can create a pinch point then a sudden force which could cause an accidental detonation.

I wouldn't recommend pressing CHP with any kind of setup that's not well thought out. Good shielding, eye and ear protection as well as a clear head

is advised when assembling caps |

What do you mean cap body crushing then breaking?

Also of course I will take as much precaution as I can. I don't want to lose any fingers or eyesight or hearing. But just how dangerous are we talking

about? LL said he pressed thousands of caps without issue.

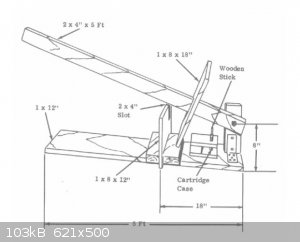

I won't even be using the full force of the clamps I plan on using. I once even thought of making an improvised press like that found in the

Improvised Munitions Handbook.

Only problem is... a device like that would be very large, and seems really excessive.

LL, do you have a picture of your setup that you use to load your caps?

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ManyInterests  | | Quote: |

Keep in mind that the cap body crushing then breaking can create a pinch point then a sudden force which could cause an accidental detonation.

I wouldn't recommend pressing CHP with any kind of setup that's not well thought out. Good shielding, eye and ear protection as well as a clear head

is advised when assembling caps |

What do you mean cap body crushing then breaking?

|

When crimping I'd recommend gloves, ear plugs and doing it while staying behind an angle (doorway, wall...)

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ManyInterests  | | Quote: |

Keep in mind that the cap body crushing then breaking can create a pinch point then a sudden force which could cause an accidental detonation.

I wouldn't recommend pressing CHP with any kind of setup that's not well thought out. Good shielding, eye and ear protection as well as a clear head

is advised when assembling caps |

What do you mean cap body crushing then breaking?

Also of course I will take as much precaution as I can. I don't want to lose any fingers or eyesight or hearing. But just how dangerous are we talking

about? LL said he pressed thousands of caps without issue.

I won't even be using the full force of the clamps I plan on using. I once even thought of making an improvised press like that found in the

Improvised Munitions Handbook.

Only problem is... a device like that would be very large, and seems really excessive.

LL, do you have a picture of your setup that you use to load your caps? |

I mean the cap body can swell out and then begin to fold over onto itself trapping some HE inside the fold, it can snap and create enough of a jolt to

detonate.

Similar to how rimfire ammunition priming works.

I was actually thinking of nickel hydrazine perchlorate when you said CHP. I believe CHP is a lot safer but I have no experience with it.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Small vise is enough. And heavy steel brick security. + Thick cloth over vise. Is not on picture. Det,,,,Dia 8/6 x 50 mm.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

MineMan

International Hazard

Posts: 1013

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Smart

|

|

|

ManyInterests

National Hazard

Posts: 938

Registered: 19-5-2019

Member Is Offline

|

|

It looks very simple and elegant. Also the size of your caps are the same size I bought (8mm OD x 50mm. ID is not stated, but I can assume it is 6mm

as well).

When I have CHP ready to make, I'll look at local hardware stores and make a setup like this. When that time comes and I active am searching for bars,

I will look over everything and bring back the photos to make sure I have a good, safe setup.

ETN + NHN blasting caps are simple enough to be made by hand. Just melt-cast the ETN, add a tiny bit on top and gently press and then a bit of NHN

with another gentle press is suffice. It'll set off the melt-cast ETN which is the workhorse of the situation.

Edit: I learned that the type of vise shown is a drill press vise, the metal bricks I think are 1-2-3 blocks. I'm not sure about the technical name

for the block. But I will find it. Either way it seems quite affordable and most everywhere.

I will need to do a little more research. when making the wirse I need to obviously put the bricks on top and something below it so that in the event

of an accidental detonation I won't damage the furniture or my floor. Another thing needed is some kind of gauge to limit the pressure put to around

70kg since many of those vises can easily go further than 100kg of pressure, which is not what is needed here.

Edit2: I forgot to ask again. How many grams of CHP do you use normally?

[Edited on 1-9-2022 by ManyInterests]

[Edited on 2-9-2022 by ManyInterests]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Basic construction is: 1) Output segment 300mg CHP on 50 - 100 Kg in the vise. 2) Next filling is about 500mg CHP, hand pressed, around

bridge wire. pressed on 5 - 10 Kg. 3) next filling is 200mg CHP (or 200mg BP) as plug. Pressed on 20 Kg. Done. For cavity 8/6 x 50 mm. Is described

above vise pictures.

[Edited on 6-9-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I use a setup much like LL, but I use a thick (7 cm) slab of wood as shielding instead of steel. It's a little more affordable, and is quite capable

of stopping potential fragments. Also, it can be bigger without being prohibitively heavy. Mine is about 30x40 cm.

|

|

|

MineMan

International Hazard

Posts: 1013

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Microtek  | | I use a setup much like LL, but I use a thick (7 cm) slab of wood as shielding instead of steel. It's a little more affordable, and is quite capable

of stopping potential fragments. Also, it can be bigger without being prohibitively heavy. Mine is about 30x40 cm. |

Microtek. Any update on the HDEM like UZP and the others you mentioned

|

|

|

Microtek

National Hazard

Posts: 872

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

It has been a while since I did any lab work (I prefer doing other things during summer), so I don't have any recent updates.

|

|

|

ManyInterests

National Hazard

Posts: 938

Registered: 19-5-2019

Member Is Offline

|

|

Quote: Originally posted by Laboratory of Liptakov  | Basic construction is: 1) Output segment 300mg CHP on 50 - 100 Kg in the vise. 2) Next filling is about 500mg CHP, hand pressed, around

bridge wire. pressed on 5 - 10 Kg. 3) next filling is 200mg CHP (or 200mg BP) as plug. Pressed on 20 Kg. Done. For cavity 8/6 x 50 mm. Is described

above vise pictures.

[Edited on 6-9-2022 by Laboratory of Liptakov] |

So 1 gram total in a 50mm cap? Impressive. Also do you use any epoxy to seal it? Or crimping?

The way how I load my blasting now is to melt cast the ETN, add an additional bit of ETN (hand pressed) and then the NHN (hand press again). I insert

an e-match on top if it and make sure there is firm contact between the match and the NHN. The e-match uses some nichrome wire in contact with a

regular safety match as an igniter. It is not enveloped in the NHN.

I do find that you putting in a bridge wire sandwiched between the CHP is interesting.

BTW, I was looking at clamps and vises. I have an interesting discovery... I managed to find access to a cartridge reloading pressing. The one where

you reload spent firearms cartridges. I can repurpose it to place the metal cavity with a wooden dowel and do the press.

There is one problem though... it is capable of much, much more than 100kg (possibly more than double). I also have no way of measuring the amount of

force your are talking about. I did find some clamps (not vises) that can work for a decent price, and their maximum pressure is 136 KG. So I know I

can easily eyeball the amount of pressure to 60 or 70KG with a little practice (not on CHP).

I cannot put the metal shields in place. Though I may need to add some heavy metal containment as a safety measure. I hope.

As for the Ammonium perchlorate synthesis... I was working with Mysteriusbhoice and I ran into severe difficulties, but as of writing this, I am

slowly drying some possible ammonium perchlorate yield It isn't 100% pure, but Mysteriusbhoice did make CHP before and said it should be pure enough

for CHP synth. My platinum anode was destroyed in the process, so this is going to be the only shot I have at this for a while.

Once my yield is fully dry (air dried) I will try to make some CHP. I should have enough for several synths.

| Quote: | | I use a setup much like LL, but I use a thick (7 cm) slab of wood as shielding instead of steel. It's a little more affordable, and is quite capable

of stopping potential fragments. Also, it can be bigger without being prohibitively heavy. Mine is about 30x40 cm. |

Wow. i will need to find something like that. I will also need to see how I can install that in position with any press I might have...

[Edited on 16-9-2022 by ManyInterests]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

ManyInterests ....You ultimately forced me produce detonator.... .... (Only

specimen without any compound) .... (Only

specimen without any compound)

For pressing, is necessary a special rod that has a hole in the middle and a groove on the side. This is used for filling the low-pressure part

around the wire and also for the final pressing of the plug. No glue is used. After pressing (approx. 30 Kg), the wire holds very firmly. I hope that

pictures are clear.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

ManyInterests

National Hazard

Posts: 938

Registered: 19-5-2019

Member Is Offline

|

|

LL, you are one of a kind! I probably don't be doing it that way. I'll load up the first amount via the press as you did, hand press the rest and then

insert the match, just like I do with my caps, and none of my caps failed to go off.

It's going to be a touch scary having that setup. Melt-casting ETN seems so much safer!

But at any rate... I think I have some decently pure Ammonium perchlorate, and it is almost fully dry, but I will dry it out for another 36 hours or

so before attempting a small CHP synth. I'll report it to you personally when I got some on hand!

Edit: i might try a new e-match design. Since I salvaged some potassium perchlorate as well, with a touch of sulfur and some glue, I can put a nice

putty on the nichrome wire that will make flare up nicely!

[Edited on 17-9-2022 by ManyInterests]

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Instead nichrome wire is possible use scourer on dish. On picture is special Wi - Fi scourer. Surface is nickel and core is steel. Works always.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

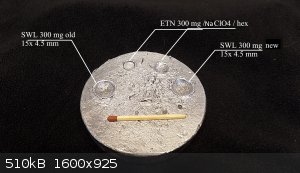

SWL confirmation

With sucessful was tested stability of Lithex, respectively SWL, which is Lithex + CuO as catalyseur, prepared from solution of Schweizer reagent.

Details of preparatio on page 4 of this thread.......( 16-2-2022 )

This 8 month old SWL was save in partially closure jar. During this time becomed moisture in. Powder looks a like dry, but water was in molecule

during a all time of storage. After drying process at 175 Celsia and evaporate water from molecule (mixture) on hot plate was prepared for filling

again. Detonation pressure is identical as for a new SWL, prepared in last days. (15x 4.5 mm crater) So there was no degradation of the energy

material during 8 months, which is goodly news. Preparation of a new batch was same as for old batch.

LiClO4 anhydride 1,6g + hexamine 0,4g was dissolved in 20g Schweizers reagent. After evaporated on hot plate at 175 Celsius, arise flammable mixture

for filling. Which is react on flame on alu foil similarly a like BP. Output segment was pressed on cca 100 Kg, others filling is pressed of hand, cca

on 10 Kg. A like always is necessary keep temperature of filling process on 40 - 50 C, against moisture. Material is very hygroscopic. Absorbs

moisture within 15 seconds unless hot or hermetically sealed in a cavity. This can be an advantage, because when spilled or improperly handled, SWL

loses its energy properties almost immediately. Which can be renewed at any time by drying at 175 C. The SWL detonation pressure is estimated at 28

GPa. (ETN 30 GPa, CHP 25 GPa)

There are 2 more side tests in the picture using ETN as the exit segment. And with the starting segment where the primary mixture was used: NaClO4 80%

+ hexamine 20%. Dissolved in Schweizer's reagent 20g and dried under the same conditions. After repeated attempts, NaClO4 appears to be an unpromising

oxidizer for primary-secondary use. There is a failure, or only a partial detonation of ETN.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

ManyInterests

National Hazard

Posts: 938

Registered: 19-5-2019

Member Is Offline

|

|

I tried to use metal scourers in the past. I didn't have the result I wanted. But maybe I wasn't using the right thing. I will try again in the

future, but I also have lots and lots of nichrome wire. I found that of all the diameters I have tested, the 0.25mm and 0.20mm are best. Going any

thinner will not have the best results. Thicker and you will need more electrical power in order to light it up. You can also test the 0.25mm bridge

while it is in the detonator/cavity for a complete circuit with a multimeter. I haven't had an accidental detonation when testing them.

Quote: Originally posted by Laboratory of Liptakov  | With sucessful was tested stability of Lithex, respectively SWL, which is Lithex + CuO as catalyseur, prepared from solution of Schweizer reagent.

Details of preparatio on page 4 of this thread.......( 16-2-2022 )

This 8 month old SWL was save in partially closure jar. During this time becomed moisture in. Powder looks a like dry, but water was in molecule

during a all time of storage. After drying process at 175 Celsia and evaporate water from molecule (mixture) on hot plate was prepared for filling

again. Detonation pressure is identical as for a new SWL, prepared in last days. (15x 4.5 mm crater) So there was no degradation of the energy

material during 8 months, which is goodly news. Preparation of a new batch was same as for old batch.

LiClO4 anhydride 1,6g + hexamine 0,4g was dissolved in 20g Schweizers reagent. After evaporated on hot plate at 175 Celsius, arise flammable mixture

for filling. Which is react on flame on alu foil similarly a like BP. Output segment was pressed on cca 100 Kg, others filling is pressed of hand, cca

on 10 Kg. A like always is necessary keep temperature of filling process on 40 - 50 C, against moisture. Material is very hygroscopic. Absorbs

moisture within 15 seconds unless hot or hermetically sealed in a cavity. This can be an advantage, because when spilled or improperly handled, SWL

loses its energy properties almost immediately. Which can be renewed at any time by drying at 175 C. The SWL detonation pressure is estimated at 28

GPa. (ETN 30 GPa, CHP 25 GPa)

There are 2 more side tests in the picture using ETN as the exit segment. And with the starting segment where the primary mixture was used: NaClO4 80%

+ hexamine 20%. Dissolved in Schweizer's reagent 20g and dried under the same conditions. After repeated attempts, NaClO4 appears to be an unpromising

oxidizer for primary-secondary use. There is a failure, or only a partial detonation of ETN.

|

The hygroscopic nature of lithex is really making me wonder if I should try to make some yet. I still have a bit of ammonium perchlorate made and I

could try to turn some of my lithium chloride into lithium perchlorate using that, but keeping them dry will be a challenge.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Lithex (LTX)

Whenever I prepare Lithex, I shake my head in disbelief as to how such a simple binary mixture can provide a brisantion close to ETN. And with the

addition of 3% aluminum, the brisantion is almost identical to ETN. White Lithex itself is difficult to ignite. And the small pile sometimes goes out

on its own.

With the addition of aluminum, the whole pile suddenly burns. With a red-purple flame, but still reluctantly. Is it an miracle and funny, that such

miserably burning material behaves in the cavity as molecular EM.

(Lithex is made by simply mixing lithium perchlorate dihydrate and hexamine in a ratio of 80:20 - details this thread)

[Edited on 16-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

CHP

Since this thread is about mixtures of hexamine and perchlorates, I am attaching a CHP test in a brass cavity. The cavity wall is only 0.4 mm of

relatively soft sheet metal, which may not be enough for a deflagration-detonation transition (DDT). However, if the CHP is prepared correctly and

from quality starting materials, reliable detonation will occur. As evidenced by the crater in the picture. However, a steel or copper cavity is

usually used for CHP. With a wall thickness of 1 mm. Output segment is usually 300 - 1000 mg CHP at density 1.5 - 1.6 g/cc. Next segment is 150 mg of

density 1.2 - 1.4g/cc. Follow starting segment from relatively fluffy CHP of density 0.8 - 1g /cc. Which is around bridge wire. His amount is usually

0.8 - 1.2 g. Last segment is the plug.

It can be for example Black powder or epoxy or else type of plug.

[Edited on 18-11-2022 by Laboratory of Liptakov]

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1409

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Successfully was tested a new design for construction of detonator.

Which saves on the substances used. The heat shrink tube contains a resistance bridge. And it is filled with Lithexal (Lithex + 3% Al bright).

Approximately 200 - 300 mg. The substance is poured into the plastic tube freely, without tamping. And secured by a slightly compressed ball of

fibrous nitrocellulose. (12.4 N +) The output segment is pressed 300 mg Lithexal at 1.77 g/cc. The transition segment is 100 mg of Lithexal by manual

pressure per 2 Kg. A CHP with the same design has also been successfully tested. The output wires are sprinkled with baking soda. And sprinkled with 4

drops of instant glue. The total weight of the substance used is only 700 mg. Compared to 1700 mg in older design types. Baking soda + glue create

very solid plug.

High pressed Lithexal 300 mg provide basically a same detonation pressure a like 300 mg

high pressed ETN. Thus crater of diameter 17 mm and depth 6.5 mm.

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Sir_Gawain

Hazard to Others

Posts: 458

Registered: 12-10-2022

Location: [REDACTED]

Member Is Offline

Mood: Stable

|

|

Be careful with super glue and baking soda. The reaction is quite exothermic and might cause the detonator to go off!

“Alchemy is trying to turn things yellow; chemistry is trying to avoid things turning yellow.” -Tom deP.

|

|

|

| Pages:

1

..

6

7

8

9

10

..

14 |