| Pages:

1

2 |

Broken Gears

Hazard to Self

Posts: 96

Registered: 7-8-2005

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

Acid neutralizing on industrial scale

I manage a process where an ethylene oxide scrubber is a part of it.

EO is washed through a 5% sulfuric acid solution. When the ethylene glycol content reaches 30%, the efficiency falls, and the emission goes up.

Disposing of the mixture is expensive. Mostly because of the corrosive properties. I don’t have a separate tank to do a neutralizing with a base;

soda lime, NaOH or maybe Na-Carbonate.

But can I do the neutralizing when the tank is drained? If I know the volume and the acid conc. I can calculate the amount of base needed, according

to whatever base is chosen. But can it be mixed by or in a mixing valve, or is that too risky?

Any ideas on how this could be managed?

|

|

|

BromicAcid

International Hazard

Posts: 3253

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

What volume are you talking about? You could do a slick setup with two metering pumps going to a inline mixing element with an inline pH probe and

quench it in a continuous flow process or a skid mounted setup. I mean, if you're saying you don't have a mixing tank and adding one is not an option

then this might be your best bet.

|

|

|

Broken Gears

Hazard to Self

Posts: 96

Registered: 7-8-2005

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

We are talking about 9000 L

No a bad idea :-) I'll do some research on that setup.

Heat could be a concern. Could it reach 100 degrees celsius resulting in pressure in the pipes?

[Edited on 12-4-2022 by Broken Gears]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Quote: Originally posted by Broken Gears  | We are talking about 9000 L

No a bad idea :-) I'll do some research on that setup.

Heat could be a concern. Could it reach 100 degrees celsius resulting in pressure in the pipes?

[Edited on 12-4-2022 by Broken Gears] |

Neutralization of h2so4 produces lots of heat

Depending on concentration,solvent,water content, solution

temperature,speed of mixing, possibility of cooling etc etc 100'c is definitely

a possibility but not a certainty.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Can't you take 10 liters or so and dump in the NaOH to see what happens?

|

|

|

Metacelsus

International Hazard

Posts: 2539

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

I would do some very careful calculations and a few smaller scale experiments before doing anything at 9000L scale!

And I wouldn't rely on this forum for chemical engineering advice.

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Using NaHCO3 for neutralization will reduce the heat production significantly, but also releases plenty of gas. Foam is the major concern, though; gas

can be vented.

Olivine - MgSiO3 - has been proposed for neutralization of waste acids; it is / can be very cheap and not too exothermic, but it produces silica

powder as a byproduct and can self-passivate under the wrong conditions:

https://www.sciencedirect.com/science/article/abs/pii/S03756...

Ordinary magnesium oxide/hydroxide might do well enough to limit ∆H, and has neither of the above concerns, though I'm not sure of the price.

Probably still cheaper -- and definitely easier to handle -- than NaOH. Not sure if it's worth trying to recover/sell MgSO4.

|

|

|

Sulaiman

International Hazard

Posts: 3721

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

maybe obvious;

if neutralizing with KOH or NaOH the heat of solution (enthalpy of dissolution) is massive,

(easier to boil water than with Az. sulphuric acid)

so use a pre-cooled solution, rather than dumping in solid base.

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Quote: Originally posted by clearly_not_atara  | Using NaHCO3 for neutralization will reduce the heat production significantly, but also releases plenty of gas. Foam is the major concern, though; gas

can be vented.

Olivine - MgSiO3 - has been proposed for neutralization of waste acids; it is / can be very cheap and not too exothermic, but it produces silica

powder as a byproduct and can self-passivate under the wrong conditions:

https://www.sciencedirect.com/science/article/abs/pii/S03756...

Ordinary magnesium oxide/hydroxide might do well enough to limit ∆H, and has neither of the above concerns, though I'm not sure of the price.

Probably still cheaper -- and definitely easier to handle -- than NaOH. Not sure if it's worth trying to recover/sell MgSO4. |

He wants to neutralize inline with a mixing valve, how would solids or gas releasing agents work there?

If heat is the problem, use colder or more dilute NaOH.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

You could, in principle, just run the effluent through a trough full of limestone chippings.

That will strip out most of the acidity and allow the CO2 to escape.

Is it possible to recover the glycol by distillation?

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

I have a 6000L tank, and my neighbor has a 9000L one, so I have an idea of how much solution this is.

How quickly must the tank be drained? In one hour, overnight, one week, etc.?

What pH range is required for the "cheaper" disposal? It is likely not exactly 7.000, but a range I would think. This would be useful to know.

One idea is to continuously pump the tank volume through a mixing valve, and then run the mixed solution through a heat exchanger before it is

circulated back to the tank. If neutralizing with NaOH (for example), mix in much less than what is stoichiometrically required for the solution flow

rate through the mixer. Continuously monitor the pH of the tank over hours/days. When it achieves your target range then you're ready for disposal.

The tank itself may need some mixing/circulation.

|

|

|

Bmoore55

Hazard to Self

Posts: 85

Registered: 23-7-2018

Location: Texas

Member Is Offline

|

|

You should strongly consider not using either NaOH or Soda Lime as you could push this too far and risk creating a strongly basic solution that can

cause stress corrosion cracking in the base metal of your tank. Sodium bicarbonate will release a lot of CO2, but the end result should be much safer

for your tank metal and it will mitigate the thermal release when mixing.

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Quote: Originally posted by Tsjerk  |

He wants to neutralize inline with a mixing valve, how would solids or gas releasing agents work there?

If heat is the problem, use colder or more dilute NaOH. |

I may not have considered the situation carefully enough.

|

|

|

Rainwater

National Hazard

Posts: 937

Registered: 22-12-2021

Member Is Offline

Mood: Break'n glass & kick'n a's

|

|

Im no expert but i like recycling in my processes. Saves money.

it sounds as if a distillation apparatus would be useful.

First the spent solution has the water removed @ 100c and returned to the start of the process, then around 150c the ethylene glycol distills out.

Next the cruid sulfuric acid can be purified or simply returned to the system.

As a result you have a useful by product to sell, less of a mess to pay disposal fees for, and less neutralizing agents to purchase.

Your basicly exchanging neutralizing reagents for distillation energy

Maybe vacuum distillation might save on the energy requirements.

There could be another method to separate these compounds.

What are your other perdicted/observed byproducts?

Edit: just did a little more research and discovered my suggestion will result in dioxane perduction as well as a lot of other byproducts

[Edited on 16-4-2022 by Rainwater]

"You can't do that" - challenge accepted

|

|

|

Texium

Administrator

Posts: 4618

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: PhD candidate!

|

|

Also, distilling 9000 liters of liquid requires a tremendous amount of energy...

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Besides the tremendous amount of energy, a 9000 liter distillation rig is huge and expensive. OP mentioned he doesn't have a vessel where he can do

the neutralization, I doubt he has the right standing by.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

I think the only way forward was suggested above: take 10 liters of solutin, get a few 20L buckets and a thermometer & try a few different

neutralization products & get some data. There's no going forward without doing this to see what works best for you and what doesn't & what

can be managed with what you got.

[Edited on 16-4-2022 by draculic acid69]

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Rainwater  | Im no expert but i like recycling in my processes. Saves money.

it sounds as if a distillation apparatus would be useful.

First the spent solution has the water removed @ 100c and returned to the start of the process, then around 150c the ethylene glycol distills out.

Next the cruid sulfuric acid can be purified or simply returned to the system.

As a result you have a useful by product to sell, less of a mess to pay disposal fees for, and less neutralizing agents to purchase.

Your basicly exchanging neutralizing reagents for distillation energy

Maybe vacuum distillation might save on the energy requirements.

There could be another method to separate these compounds.

What are your other perdicted/observed byproducts?

Edit: just did a little more research and discovered my suggestion will result in dioxane perduction as well as a lot of other byproducts

[Edited on 16-4-2022 by Rainwater] |

If you boil glycol with acid it turns into dioxane which is carcinogenic.

(Not dioxin which is more famous).

But if you neutralised it first then that's a much better approach.

Selling the glycol, together with savings on waste disposal costs might pay for the still.

Incidentally, the heat evolved is well documented.

https://en.wikipedia.org/wiki/Enthalpy_of_neutralization

[Edited on 16-4-22 by unionised]

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

I was just doing some calculations on the back of an old envelope and the solution won't get close to boiling, even if you would dump in solid NaOH.

Unless you start at ridiculously high temperatures of course.

|

|

|

Broken Gears

Hazard to Self

Posts: 96

Registered: 7-8-2005

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

Thank you all so much for all the input.

I think I have underestimated the extent of this project...

With a pH at pH 6-9 we can deliver it to a Biogas-plant free of charge, and it will be converted to district heating = helping the local community.

Another solution is to neutralize it and dump it in the industrial sewer and it would be the wastewater plants problem. It's all within the law, but

it seems backwards thinking to me.

The neutralization tank I can manage, but I think the inline model will be more favorable. Does that kind a equipment come ready-made? What would be

the process time for pumping and neutralizing 9000 L with out too much heat generated?

The current downtime is 4 hours for draining the scrubber tank, refilling with water and adding conc. H2SO4. In 6 mouths time the sterilization

process is doubled, add pressure to the scrubber system, but it give me a possibility to have accepted downtime of 24 hours.

|

|

|

Rainwater

National Hazard

Posts: 937

Registered: 22-12-2021

Member Is Offline

Mood: Break'n glass & kick'n a's

|

|

You have the potential to produce a lot of very profitable products or a lot of very toxic pollution. I hope you figure out a good method for dealing

with your byproducts.

The local market will help determine the best end products.

If you're in the farming area, neturalizeing with ammonia, then purifying the ammonia sulfate could be an option, and the pure product would be a

great fertilizer.

A city or industrial area, neturaling with aluminum, will produce aluminum sulfate, which is a common chemical used in waste water treatment. Which

seams a little arronic taking your waste water and using it to treat waste water.

Hopefully, you'll get this worked out before you produce all that waste

"You can't do that" - challenge accepted

|

|

|

Rainwater

National Hazard

Posts: 937

Registered: 22-12-2021

Member Is Offline

Mood: Break'n glass & kick'n a's

|

|

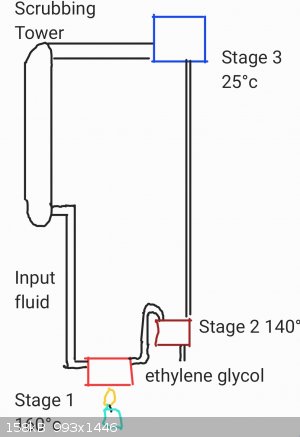

After some more research into industrial practices and making a few phone calls, calcium hydroxide is the standard neturalizeing reagent due to the

easy use of a settling tank to separate the products.

Why is the scrubbing solution being acidified? To encrease the conversion of Eo to ethylene glycol.

The separation and treatment time/cost would be greatly reduced if the acid was not present. As well as eliminating the production of several

byproducts.

A greater surface area would be required to react ethylene oxide with water at an equally efficient rate, but the problem with neturalizeing the wash

water would be eliminated.

An additional problem that arises is self solving with a properly designed production process. That is the purity of the scrubbing media. For the

greatest efficiency, the water should be free from glycol.

For example

At that point, a continuous distillation apparatus could be used to consentrate ethylene glycol and return the purified water back to the scrubbing

reactor.

The apparatus could be constructed of common items such as old car radiators and copper tubing. Which would result in high thermal loss but could

still be cost effective.

Proper heat exchangers would preheat the stage 1 solution with heat from stage 3, recycling energy and saving money

Temperature monitoring would ensure proper separation.

Further optimizing the system to a 2-stage reaction would result in less energy required and produce a less pure ethylene glycol solution but greatly

reduce initial investment cost and construction requirements.

Also, by using a continuous recycling method, and by controlling the rate of glycol production to match removal, you can create a non-stop process

that will increase overall production.

Edit:

if co2 emissions are not a consequence, conversion by acid catalyzed reactions to volatile products followed by combustion could supplement the

distillation heat source.

Properly controlled with appropriate safety measures, complete combustion of the byproducts can occure and sulfuric acid can be

recovered and recycled.

[Edited on 21-4-2022 by Rainwater]

"You can't do that" - challenge accepted

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

Well yeah, but if the OP is trying to avoid buying (or doesn't have room for)a neutralization tank it sounds like these more elaborate setups are off

the table.

Looks like simple is a big priority here.

|

|

|

Bonee

Harmless

Posts: 29

Registered: 20-12-2010

Member Is Offline

Mood: No Mood

|

|

Could try multi stage reverse osmosis or electrodialysis as well. Although the ethylene glycol may complicate things.

see patent.

https://patents.google.com/patent/US7976710B2/en

|

|

|

WGTR

National Hazard

Posts: 971

Registered: 29-9-2013

Location: Online

Member Is Offline

Mood: Outline

|

|

Quote: Originally posted by Broken Gears  | Thank you all so much for all the input.

I think I have underestimated the extent of this project...

With a pH at pH 6-9 we can deliver it to a Biogas-plant free of charge, and it will be converted to district heating = helping the local community.

Another solution is to neutralize it and dump it in the industrial sewer and it would be the wastewater plants problem. It's all within the law, but

it seems backwards thinking to me.

The neutralization tank I can manage, but I think the inline model will be more favorable. Does that kind a equipment come ready-made? What would be

the process time for pumping and neutralizing 9000 L with out too much heat generated?

The current downtime is 4 hours for draining the scrubber tank, refilling with water and adding conc. H2SO4. In 6 mouths time the sterilization

process is doubled, add pressure to the scrubber system, but it give me a possibility to have accepted downtime of 24 hours. |

Your reply is helpful and helps with understanding the scope of what you are trying to do. Yes, unfortunately this sounds like a big project, because

4 hours is very little time to empty and refill a tank of this size if we add a neutralization step. This can be done of course, but there is so

little room for error that no solution that I can offer will likely be useful, and it may take an engineer to design the process (due to the lack of

room for error).

Anyway, is the tank pumped out, or is it emptied via gravity flow? If by gravity, the simplest method that I can conceive would be to have a second,

equally-dimensioned tank, that is at the same height as the process tank. The second tank would contain pre-mixed neutralization solution (whether

this is NaOH or something else) with a calculated concentration. The two tanks are joined with a 'Y' fitting through valves at their outputs for

mixing. The output of the mixer would need to go to a small retention tank so that the pH could be constantly monitored as the tanks empty. Beyond

this I wish you success.

|

|

|

| Pages:

1

2 |