| Pages:

1

2 |

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Is there a possibility that it can it be used in a grignard to yeild

primary alcohols?

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Possibly if a catalyst is used with sufficient temp, it could form formaldehyde in situ. If the pyrolysis works well though, I'd opt for just making

formaldehyde and use it, because plastics, especially colored ones, can have additives, which could either react or need extra step for purification.

Not sure what the coloring agent is, but the black one makes your hands black when you handle it.

I wonder how much the plastic mass will foam when degenerating it with heat? I probably should fill the flask first pretty conservatively to see how

it behaves.

Also, if formaldehyde gas is lead into cold receiver(cold, as below -19C of formaldehyde bp), should it form paraformaldehyde? Possibly a flask could

be immersed in CaCl2 bath at -35C and lead a tube into it to condense it as pure form? This could be beneficial if it is intended to be stored, as

formalin takes a lot more space and is possibly not as stable.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

It sort of works.

The delrin decomposes upon heating, forming white mass that coats every surface of the apparatus. It generates very stingy, burnt-rubber like smell,

and it's completely different from formaldehyde smell. I've got a little paraformaldehyde which I know the odor.

Adding a little NaOH made the white mass slowly dissolve, and the solution gave off formaldehyde odor, so it's supposedly paraformaldehyde. ABEK

respirator does little to nothing to stop the odor.

I'm thinking how to create an apparatus that allows the recovery of it? Possibly by directing the reactor fumes with stillhead directly to a 3-neck

flask that also acts as the suckback reservoir for the final bubbling apparatus.

The bubbler seemed like it put all the bubbles straight through the water, but no odor of formaldehyde was detected, so is there a possibility it was

some other gas formed by the plastic?

It appears that the major product is paraformaldehyde which immediately sticks. MP appears to be on point too, with heat gun and IR temp meter.

I used only salt ice for the cold trap as formaldehyde BP is -19C so CaCl2 bath should be used instead. This could possibly be used to trap all

products into one vessel as paraformaldehyde.

Sorry if text is a bit messy, I'm tired AF and will look into this later with some pics I took. Please comment and ideas are very welcome.

|

|

|

enlight

Harmless

Posts: 30

Registered: 8-2-2021

Member Is Offline

Mood: dephlogisticated

|

|

Could you just wash your apparatus with water and filter, then add methanol? Seems like your paraformaldehyde just never made it to the bubbler.

Perhaps you can charge your apparatus (a three-neck flask) with a stream of air to force the paraformaldehyde into your trap. The loss of material

then depends on the surface area of your apparatus.

I believe the Delrin you're looking for is the white homopolymer, as I'm not sure what the black Delrin consists of. Find a supplier that is willing

to supply a material test report.

I would opt for turning Delrin rod in a lathe to increase its surface area (acetal plastic makes large stringers from what I remember). Otherwise, buy

large 1mm thick sheet and break it into smaller pieces.

Also consider using a warm water bath around your trap to increase solubility.

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

The sublimate was very sparsely soluble to water, and only adding a little NaOH made it dissolve by time. The water was cold, though. I had better

luck with stronger NaOH and hot water when I washed the glassware after.

Does formaldehyde dissolve better in hot than cold water? I used cold water in the trap. I weighed the water initially to 630g and final weight was

660g, this including few grams of NaOH, and some losses when using the water to wash all the parts that I was able to. The bubbles did little to

absorb though, I've bubbled all kinds of gases like NH3 to water, formic acid, HCl gas to all kinds of things etc and the bubbles just disappear at

once. These came through like nothing.

I was using black POM plastic turnings which were left from me after turning some clamps in lathe and mill. By tightly packing, I was able to fill

200g of turnings into 1L rbf. If these were not so cheap, I'd opt for purchasing 10mm rods and cutting them to short prills with wire cutters as they

would allow a significant weight charge over turnings which are very lightweight, a small bucket was filled by those 200g of turnings. Afaik all

polyacetal are the same, they might have some minor additives and that might explain the stingy smell which came through ABEK like nothing. The very

distinctive formaldehyde odor, which I've associated with corpses, morgues and rotten stuff even I'm not aware what those smell actually, was present

at times when handling it, especially when wet. The mere white stuff was of little odor.

I was first thinking of using my chromatography reservoir as the sublimate vessel to be placed upon the pyrolysis flask, but the issue is that the

polywhatever-white stuff doesn't seem to stick at any specific place, no matter if it's warm or cold, it just melts and evaporates with heat gun, and

it eventually covers the whole apparatus in uniformly thick layer, and no more seems to sublime on that same spot. It will eventually clog any small

ways, like the distillate takeoff adapter tube which I used to connect it to the cold trap flask. It didn't condense anymore of the white stuff, even

when the temp was -20C.

I was expecting that it would steadily sublime to the spots that are cold, and stop there, and I would collect a lot of it in that flask, but nope, it

just went through it like everything else.

I would like to develop a working apparatus to extract (para)formaldehyde in useful quantities from delrin, so any ideas for input are willingly

appreciated and tested if deemed potential.

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I would argue that it kinda doesn't considering a yield of virtually nil. Max solubility in water is 37% @1.09, that should be more than soluble

enough for a simple bubble trap.

First suggestion would be a liquid medium. Low thermal contact means high temperatures and low heat flux, not exactly ideal conditions.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

I may have missed a detail. Did you add an acid catalyst to promote decomposition?

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

Thermal decomposition only.

The patents referring to acids also include elevated pressures up to 10bar.

|

|

|

unionised

International Hazard

Posts: 5128

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

I worked in a lab looking at measuring formaldehyde in air.

One option was to draw the air through a filter coated with dinitrophenylhydrazine and an acid catalyst.

We had problems with filter holders made from acetal.

So I'm pretty sure that, even at room temperature, phosphoric acid attacks acetal.

At elevated temperatures I'm sure it would be even better. Obviously the use of higher pressures lets you raise the temperature of an aqueous acid

further. But it also actually impedes the reaction.

It would be interesting to do a repeat experiment but to rinse the shavings with, say, 5%, phosphoric acid first

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

I'll give phosphoric acid a try. Should sulfuric acid work also? Compatibility charts give them all a severe effect at all concentrations, so I

suppose so.

[Edited on 1-3-2021 by Fyndium]

|

|

|

Fyndium

International Hazard

Posts: 1192

Registered: 12-7-2020

Location: Not in USA

Member Is Offline

|

|

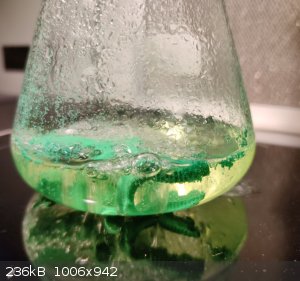

Did not got phosphoric acid, but sulfuric acid so I thought to give it a try. I put a keck clip as a sacrifice and added sulfuric acid. 1% at boiling

did pretty much nothing, and gradually adding more neither, so I poured a good one, and likely the concentration rose to 30%-ish. Now the plastic

creates constant flow of bubbles, and formaldehyde odor is clearly noted.

The green gunk appears to be the coloring agent for the plastic, left from decomposition. During the process, bubbles were formed on the plastic in

rapid manner, looking like boiling stones, but the liquid was not boiling itself.

As I don't want to waste anymore of my high € per kg keck clips, I'll wait till I get back to my workshop to do an actual test run now that I have

proof of concept and I will rerun it with delrin turnings and bubble it through a water trap. I weight the flask prior and after, and same for the

water trap to see how much gas was dissolved. Formaldehyde gas absorbs into cold water as usual, but paraformaldehyde dissolves better in hot water,

just for the record as earlier was suggested to place the trap in warm bath.

I have lots of conc sulfuric acid so I'll likely use it, but I also want to test out phosphoric acid, because it is much easier available. It seems

that very dilute solutions decompose the plastic slowly, although keck has very little surface area compared to turnings, and applying concentrated

hot acid can cause too rapid decomposition, blasting the gas through the trap, so I'll start with dilute acid and add more if the reaction appears too

slow. As the acid's supposed to act as catalyst and only little traces are left within the liquid, the mother liquor should be able to be reused

multiple times after the depolymerization is complete, and temporarily cooling down and refilling the reactor should allow for quick generation of

useful quantities of formaldehyde.

[Edited on 4-3-2021 by Fyndium]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Delfin is what bic lighters are made of so this provides a never-ending source of plastic that can be recycled into a saleable product.the h2so4

method sounds best if all that is required is a reflux

|

|

|

| Pages:

1

2 |