| Pages:

1

2

3 |

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

First nickel nitrate synthesis... did I do it right?

While I have asked questions about Nickel Nitrate hexahydrate synthesis. Today I finally worked up the guts to do it. My first attempt ended in a

runaway almost immediately. I will put all the details of what I did.

I first put in 20 grams of nickel metal (cut into tiny pieces). The metal was 99.96% pure. The next thing I did was add 6ml of 35% hydrogen peroxide.

I saw no reaction. I then poured 30 ml of 70% nitric acid (which had cleared up from all NO2 pollution BEAUTFULLY! It was clear as water) and I added

the acid to the flask.

I used a 100ml boiling flask, and the result was a very violent reaction of a massive cloud of fumes and acid spilling out. Thankfully my spidey

senses warned me immediately of the danger and I put the flask down very quickly and ran back. I did all this in my balcony and sealed the door. No

fumes entered my place.

Cleaning the mess was hectic, but nothing bicarbonate water couldn't do...

At any rate, I collected what nickel metal pieces I could (there is still more that I will sweep up later). I cleaned the flask up and put another 20

grams of metal, added the acid first (I will need to make more nitric acid soon). Then I put the flask into position to insert it into my reflux

column (which I had coolant flowing through already) and put in, drop wise, 2.5 ml of hydrogen peroxide. I had another ultra violent reaction, but I

managed to put it into the column quickly so no spillage happened. But I saw the column go red with the NO2 fumes, but I could not smell any.

I let it boil in a water bath for 2.5 hours, and then I took it out of the water bath and let it boil for 15 minutes, turned off the heat (my heating

mantle's heat settings are useless if I have no way of inserting the thermometer into the solution) and then boiled it again for another 15 minutes

before turning off the heat and ending the experiment.

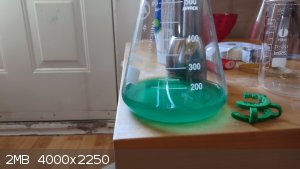

It's cooling now and I will let it cool outside an ice bath for a few more hours. I posted pictures of my result. Do I have nickel nitrate? Do I need

to filter this? There is still some unreacted nickel metal that I can salvage for later.

If I cannot get the hexahydrate from it, can I still use this solution as is for NHN/Nickel Hydrazine Nitrate synthesis?

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

I think I did it! After several hours of drying and cooling at room temperature this is what happened (pictured below).

I would call this a success. Albeit I'll need to remove the unreacted nickel metal at the bottom and find a way to scoop out all the nickel nitrate.

|

|

|

Syn the Sizer

National Hazard

Posts: 600

Registered: 12-11-2019

Location: Canada

Member Is Offline

|

|

Yah, just filter it, reduce the volume a bit and crystallize it should be good.

I like the colour of nickel nitrate

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

By reduce the volume a bit, you mean boil it down some more? Also when filtering, how do I remove any unwanted stuff? Nickel nitrate is super soluble

in water.

Edit: Also yes, Nickel nitrate is a colorful thing. NHN is also beautiful in how purple it is.

I just need to master freebasing hydrazine... or making a distillation of azeotropic hydrazine. I think after my experiences with distillation the 2nd

option sounds much easier.

[Edited on 11-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

You shouldn’t have much in the way of contaminants (given you had pure nickel metal) so you could boil to obtain a wet solid mixture/slurry to

filter with gravity or with a vacuum pump, or you could instead desiccate the solid mix to dryness if there are only a insignificant amount of

contaminates.

Hydrazine distillation is quite complex since it must be performed in an inert environment to prevent oxidation of the hydrazine, freebasing isn’t

as horrific, it's a little difficult since it generates lots of hydrazine fumes and heat but it only takes half an hour or so

|

|

|

Bedlasky

International Hazard

Posts: 1241

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

What do you mean by unwanted stuff? You have just nickel nitrate in solution. Unreacted nickel can be removed by magnet (put magnet to the bottom of

flask (from outside ofcourse) and pour solution in to the beaker. Nickel will be atracted to the magnet, so it will stay in the flask).

I think that distilling hydrazine is unnecessary and dangerous. Nickel hydrazine nitrate is very sensitive explosive, so be very careful with that

stuff.

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

| Quote: | | What do you mean by unwanted stuff? You have just nickel nitrate in solution. Unreacted nickel can be removed by magnet (put magnet to the bottom of

flask (from outside ofcourse) and pour solution in to the beaker. Nickel will be atracted to the magnet, so it will stay in the flask).

|

You can't see it from the photos, but there is some unreacted nickel metal in the bottom of the flask. Or maybe it's gone and has reacted while I

wasn't looking. If that is the case, that is good.

In the case of making hydrazine hydrate... OK I'll just freebase it. I will cover the container that I will freebase it in to prevent as much of the

fumes from coming out as possible, and do it outside.

| Quote: | | Nickel hydrazine nitrate is very sensitive explosive, so be very careful with that stuff. |

This is not true. While all explosives must be treated with the utmost respect, NHN is famously friction and impact insensitive. This is why I was so

obsessed with wanting to make some. I did see a video where someone made a batch that did go off with solid hammer blow. But in all others I've seen

people pound the living hell out of it and scrape it with little reaction. This is not to say I will be playing football with the stuff. Quite to the

contrary. But it's currently the safest primary known.

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

On the sensitivity, it's going to go off if you hit it with a hammer most times (I use a honking 2kg sledge hammer just for context), it's definitely

safer than a majority of primaries that i've worked with, treat it similarly to ETN (it's slightly more sensitive than ETN and is especially more

friction sensitive), so "very sensitive" is a stretch, but it's always important to be vigilant and careful. it is definitely less sensitive than most

primarys when it comes to heat sensitivity as it can be deflagrated in 0.5g+ "piles" without detonation (at least as far as I have noted) however that

all changes in confinement where it has a very low DDT. (It's also not the "safest primary" but it's definitely one of the safest, and potentially the

safest when complicated/expensive energetics are excluded)

[Edited on 11-12-2021 by fredsci93]

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

I've worked with the ETN that I made. I tried several (tiny) bits and tried to get them to go off with a regular hammer. I pounded that stuff HARD and

it didn't go off at all. This is what convinced me that hand pressing it into a plastic detonator (made from a ballpoint pen body). I plan on putting

in the ETN, giving it a slow but solid press with a wooden dowel, add the NHN, press again, then the black powder/nitrocellulose as an ignition

mixture before inserting my electric match and sealing the whole thing with hot glue

My electric match is made of an actual pair of cardboard matches that I wrap with nichrome wire (I experimented with various thicknesses. From 0.25mm

to 0.08mm I honestly think the 0.25mm might be better than the others. But I wanted to test 0.2mm to see if that one maintains firmness while also not

needing as much current to set off). Since the match head already technically has the pyrogen, I wonder if I need black powder or nitrocellulose at

all in the end.

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

For my det caps I use a centrifuge tube with 500mg melt cast ETN at the Bottom, 200mg ETN in the middle and 200mg NHN on top. Nichrome thickness

isn’t crucial for me, I use a little lead battery or a little lithium cell both capable of +35A so just about any nichrome is fine, and even thin

copper wire or steel wire. Steel wire is actually my wire of choice since if you get galvanised steel wire it bursts into flames when you run current

through it which makes it very effective.

You probably need gunpowder to set it off, I use permangnate/sulfur/silicone downstream of the e-fuse to set off the NHN since the e-fuse alone is not

great at setting off the NHN.

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

I tested my gunpowder out (I made with the wet method, but it wasn't 100% successful) I need a jet of flame to get it to go off, but my electric

matches did manage to make it go off as well. I think .3 grams of black gunpowder that surrounds the e-match should be sufficient.

How do you melt cast ETN? I heard of melt casting, but I have no idea how to do it. What I planned on doing was following the Improvised Munitions

Guide on making detonators. Their guideline is 1 gram of secondary (they used picric acid and RDX. Others have used PETN with similar amounts. They

made no mention of ETN as these guides were written decades ago before ETN was a viable option) and .5 to .75 grams of primary. The closest I could

find to NHN in terms of powder was DDNP, which they specified that 0.5 grams was necessary.

I never built a blasting cap before. I did make a nitrocellulose filled cap as well as chlorate/sugar mixture, both went off well (albeit I put them

in a saw-dust filled 5 gallon bucket, so I did not see the explosion), I realize that a true blasting cap like this would be significantly more

powerful.

I don't have any lithium cells, but I do have lots of alkaline batteries and battery packs. I made my own 12 volt battery pack with C cells and a 15

volt with D cells. These will set off any e-match. The current they provide might not match an equivalent lithium cell, but they will still fire up

any wire.

Speaking of which, I learned a lot about wires for e-matches. I had no idea you could use galvanised steel! That stuff is everywhere where I live. But

I'm basically stuck with nichrome as I have a lifetime supply of that. I need to use what I got right now and not spend more money.

One other thing about hydrazine to nickel nitrate mixture. What are the ideal proportions? Like how many grams of nickel nitrate in solution to

hydrazine? WessonSmith's video (he used commercially purchased hydrazine monohydrate though) used around 60 grams of nickel nitrate (far more than I

am willing to use!) with 700ml of water with dextrine added and around 8ml of hydrazine monohydrate.

Chemplayer's video on freebasing hydrazine was crystal clear. I will probably make a surplus if I need to. but is a surplus of hydrazine OK, or do I

need to saturate it with nickel nitrate in order to get some NHN?

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

OK so I attempted to freebase some hydrazine... but I am pretty sure something was off. It is possible that my hydrazine sulfate was far too

contaminated with sodium sulfate. I added around 30 grams of sodium hydroxide gradually to 40 grams of hydrazine sulfate, with 110ml of ethanol added.

I mixed them for about 20 minutes and let them sit in an ice bath (covered with plastic wrap) for almost an hour now and the liquid is milky white

with no clear liquid out there. I added more ethanol and the ethanol solution is still very milky white.

Was my hydrazine sulfate a dude or what?

|

|

|

Bedlasky

International Hazard

Posts: 1241

Registered: 15-4-2019

Location: Period 5, group 6

Member Is Offline

Mood: Volatile

|

|

Sodium sulfate is insoluble in ethanol.

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

First off, One can melt cast ETN by submerging the ETN in a boing water bath, I put 500mg ETN in the centrifuge tube and lowered that into the boiling

water (not actively being heated, just water from my kettle put in a beaker) after 30s the centrifuge tube was taken out and cooled to yield the melt

cast ETN.

My detonators are meant for setting off secondarys and plastic explosives, the power from ~900mg powerful explosives is sufficient for setting off

secondarys and plastic explosives (plastic ETN and Plastic RDX/keto-RDX) however you would probably need a larger amount of explosives to set off a

tertiary like ANFO.

The galvanised wire I'm talking about is the threaded/rope stuff they use in bike breaks and stuff like that.

The best proportions are near molar 3:1 hydrazine to nickel nitrate hexahydrate (BY MOL), with a slight excess of hydrazine (5% max), for hydrazine

sulphate the mass ratio works out to 1.34:1 hydrazine sulphate to nickel nitrate hexahydrate (BY WEIGHT) and for hydrazine hydrate (80%) it works out

to ~0.64:1 hydrazine hydrate to nickel nitrate hexahydrate (BY WEIGHT)

For your hydrazine freebasing you used 0.307mol hydrazine sulphate and 0.750mol sodium hydroxide, which means you used an excess of sodium hydroxide,

this is undesirable since sodium hydroxide dissolves in ethanol, I would recommend reacting this solution with 12.6g sodium bicarbonate (0.15mol) over

an hour or so (you might want to use an excess) to convert any sodium hydroxide to insoluble sodium carbonate otherwise the sodium hydroxide will

react with the NHN and make useless nickel hydroxides.

After that filter it through a coffee filter and you should be golden, unless the hydrazine sulphate is just fucked.

|

|

|

Fantasma4500

International Hazard

Posts: 1681

Registered: 12-12-2012

Location: Dysrope (aka europe)

Member Is Offline

Mood: dangerously practical

|

|

there was a man back in the time of r0guesci who purified his ETN by melt-casting

he lived in alaska

one day he just stopped posting

nobody knew exactly where he lived

its hard to tell how much is too much action for molten ETN, but one thing is for sure its very powerful stuff, ive seen just half a gramme of it turn

a half liter soda can into fine shreds

and maybe 50 milligrammes of it snapping a hot knife in half when pressed against it

so in that you would be dealing with molten ETN, which some friction or pressing

would be nice if someone would set up some experiments for liquid ETN, with some powerful blast shields and remote controlling for friction/shock

sensitivity

now to stick to the topic, i always flush chemical compounds with solvents that the salt isnt soluble in, to pull out all the water, because when you

try to dry something using heat, the solubility increases and you end up with awful chunks (which you can easily crush with a round-bottomed jar,

using circular motions- ive found) but flushing it with acetone or similar low boiling/high vapor pressure solvent greatly reduces the time you spend

on dealing with it and gives a better final product

sadly it appears nickel nitrate is soluble in EtOH and i cant find anything on ethanol

ether maybe? you can dump some gasoline in a distillation flask and contract some very low boiling stuff, it seemed a decent portion was at all the

way down to 40*C, this should be great for flushing the nickel nitrate.

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

Good stuff.

This is the liquid nickel nitrate (using distilled water with some dextrin added).

I wasted a lot of it in the failed NHN synthesis. So I will need to make more today. How does it look though?

EDIT: There was a LOT of unused nickel metal in my flask. The next time I will use an excess of nitric acid (I don't got much left. So I need to make

a touch more... if my current nickel nitrate solution is insufficient), and just boil it to completely destroy all remains of nitric acid in it. This

stuff has zero nitric left as the nickel nitrate was rock solid. Thankfully it was quite water soluble and I was able to rinse it out almost

immediately.

[Edited on 12-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

it looks a little more turquoise that one would expect, probably has some nickel hydroxide, what's the pH?

This is my nickel nitrate dissolved in water

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

I think it might be too dark... I might need to dilute it more. I am making another batch to use up all remaining nitric acid I have. (I am reusing

the unreacted nickel metal from the last synthesis. Seems like you can get a LOT of nickel nitrate from a bit of nickel metal!).

The pH appears to be slighly acidic. I think it is 4 on the pH scale, but I could be mistaken. Here is the picture.

If it is too acidic, what can I do to resolve that issue? More water or what?

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

the pH looks alright, you could remove the cloudiness with a filtration which would improve the colour, it doesn’t look to concentrated to me, do

you have any idea how much nickel is dissolved?

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

I didn't write it down, but I believe around 8 grams or so were fully reacted. The other bits have some tarnish on them, so I assume they were

partially reacted, but not fully.

I am running another synthesis. I added 8 grams of the previously used nickel metal to 14 ml of nitric acid. I also added around 4ml of slighly

diluted hydrogen peroxide (I put in 2.5ml of my 35% and added another 1.5 ml of water. It still reacted quite violently, but I was expecting it and

well prepared for it).

I'm glad that at least the pH is good. You did tell me that the pH is important when it comes to NHN synthesis...

All I need now is to make some good hydrazine sulfate. I hope my next batch will be the last I will need to make.

Edit: Hydrazine question: I realize the answer might probably be no but... I am guessing that after making the hydrazine after adding the hydroxide,

bleach, and urea/gelatin and heating for 5 minutes at 85C is not good enough, but can it be used immediately after the addition of hydrochloric acid

and sulfuric acid?

[Edited on 12-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by ManyInterests  |

Edit: Hydrazine question: I realize the answer might probably be no but... I am guessing that after making the hydrazine after adding the hydroxide,

bleach, and urea/gelatin and heating for 5 minutes at 85C is not good enough, but can it be used immediately after the addition of hydrochloric acid

and sulfuric acid?

[Edited on 12-12-2021 by ManyInterests] |

Heating at 85C for ~5mins or when the amount of bubbling is very low is the norm for a hydrazine sulphate synth and works well, any longer and you

will start to lose yield.

You should let the solution cool fully before neutralising with sulphuric and hydrochloric since otherwise the solution will overheat and there may

also be some effect on the amount of hydrazine that forms.

Also for the freebasing you need to use 40g hydrazine sulphate to 24.5g sodium hydroxide, it's important to use a very slight excess of hydrazine salt

as if any sodium hydroxide is left in the ethanol it will screw over the reaction, if the hydrazine sulphate is impure then I recommend passing the

ethanolic hydrazine solution over sodium bicarbonate to remove any sodium hydroxide (if the hydrazine sulphate was only 90% then 2.5g of sodium

hydroxide will not be able to react and will simply dissolve into the ethanol).

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

That's good. One thing I need to mention is that once I add the gelatine/urea solution and start heating (I cover it completely and I am always

stirring with the stir bar) is that it takes quite a while to get to 85C.

Do I start the timer for 5 minutes as soon as it hits near 85C or do I stop once it gets there? I think this is where I am losing out. I did let it

cool down completely in an ice bath (still covered with plenty of plastic wrap) until it is around 15C or so before adding the acids, wherein the

temperature goes up to around 30C. then I let it cool down to 15/13C before immediately vacuum filtering. I don't see that much sulfate percipitate,

but when I start filtering it shows up immediately.

I'm trying to find out where I am going wrong with this. Am I adding the acid too fast or what?

Edit: I am guessing that mixing the sodium hydroxide with the hydrazine sulfate first before adding any ethanol is a must. I used 95% denatured

ethanol, and I chilled it in the fridge, is this correct?

[Edited on 12-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

Your synth technique sounds fine, probably something weird making it fail.

As for the freebasing you should add sodium hydroxide to the hydrazine sulphate in ethanol slowly, if you add the two dry then add ethanol you will

get more hydrazine fumes and it will be more dangerous. (95% ethanol works fine)

|

|

|

ManyInterests

National Hazard

Posts: 934

Registered: 19-5-2019

Member Is Offline

|

|

That sounds good.

You know what? I'll try to freebase the remaining 20 grams of hydrazine sulfate that I have. Who knows? Maybe it might work. Nothing ventured nothing

gained.

I'm done with my second nickel nitrate synthesis. I've decided that after my reactio nis done. I heat the flask until complete dryness. That way no

more acids remain and I don't have to worry about drying the stuff on the frit. I can just hydrate it from the flask straight and add it to my supply.

I.Just.Want.One.NHN.Synthesis!

Edit: wow. I had no idea you could get that much nickel nitrate from such small amounts of nickel metal. I guess the purity really did make a major

difference!

[Edited on 13-12-2021 by ManyInterests]

|

|

|

fredsci93

Hazard to Self

Posts: 84

Registered: 29-12-2017

Member Is Offline

Mood: No Mood

|

|

yea, 20g scale is good and would make ~10g NHN, add 12.2g sodium hydroxide to 20g hydrazine sulphate in ~50ml ethanol and let react for a half hour

with stirring and cooling, then filter through a coffee filter, wash the solids well with ethanol. The filtrate should be good but if you have any

suspicions about the purity of the hydrazine sulphate then you can pass it over some sodium bicarbonate.

|

|

|

| Pages:

1

2

3 |