kick_ass

Harmless

Posts: 3

Registered: 25-1-2021

Member Is Offline

|

|

Diameter to length shape of explosive punching effectiveness

Hello hello

I'v been playing with the boom boom stick over a year

Started with TATP, then NC

As progressed newer questions arose and wanted to see what is actually the shape of the explosion, so at 1st tested what happens to metal tubes from

within till critical failure, then external placement onto tubes to see half shape of the explosion indentation, then when i got some way of

measurment, started to test what amount of det cap fully initiates secondary charge NC.

Then wanted to calculate the force been apllied onto target plate and found 2 physics collision equations, but they both greatly depend on time of

collision as work× time = force

In car collisions they use 1/5 of a second as force is all transferred, but in explosives the speeds are much higher than 27.7 m/s.

What is understandable is that the faster the charge goes poof, the more energy is released onto the target.

Example For readers like me, if i make a 150gr density 1gr cubic ml 20mm×200mm tube charge and blow it in a room or some closed place, the energy

will be released lets say in 0.0002 seconds

If i make a 150gr 30mm×100mm charge it will release same energy in 0.0001 seconds, twice faster, which will create higher pressure and more damage to

what ever contains the explosion.

The current question is, when the shape of a charge is cylindrical, i set a det cap at 1 side then the most punch is at the other end of the charge in

the direction of wave front, the shape is sort of mushroom like, and most damage is at the farthest end.

What is the length of a charge in relation to diameter most effective we should make if the goal is to get most of the punch at 1 end of the

cylindrical charge ?

What i mean is this, lets say i do a 30mm diameter charge 1 meter long, i know for a fact that the farthest 50cm of explosion will have no effect on

the other end of the charge, because the crazy prsssures of 200-350kbar are usually very very close to the explosive it self, if i have a tube charge

30mm×30mm and place metal plates at a distance starting from 0mm, 10mm, 20mm-50mm the force that can damage critically 0mm plate fades pretty fast

till the 50mm plate.

is there any knowledge or some equation for effective diameter to length shape of charge ?

A friend told me he uses for length of charge a rule of thumb 2-3 diameters, if a charge

Diameter is 50mm the length is 100-150mm

So at what length in relation to diameter there is no more point making the charge longer?

Like if a make a 10mm×10mm will get a lesser punch on 2mm metal plate

10mm×20mm better punch indentation

10mm×30mm even better as more material

10mm×50mm punch through

10mm×100mm punch through cant see difference

10mm×150m no different than 10mm×50mm

That means its pointless adding extra 100mm.

I didint find the lower limit because its not easy testing in my area.

The question is coming from collision equation, as the best most effective punch should be in the fastest release of energy, which is most compact in

shape maybe a sphere?

But the dynamics of wavefront releases most energy at 1 end of the charge and not an equal spread, and because of that you would not try to punch

through metal plate with a spherical charge, best is cylindrical.

This is only tube flat end shape charge question, not about shape charges with concave shape or copper lining.

Just looking for not wasting charge on extra length that will not have any effect on punching harder.

If question not understandable i will add pics

Thanks

[Edited on 25-8-2021 by kick_ass]

[Edited on 25-8-2021 by kick_ass]

[Edited on 25-8-2021 by kick_ass]

[Edited on 25-8-2021 by kick_ass]

[Edited on 25-8-2021 by kick_ass]

|

|

|

kick_ass

Harmless

Posts: 3

Registered: 25-1-2021

Member Is Offline

|

|

Diameter to length ratio of explosive, punching effectiveness

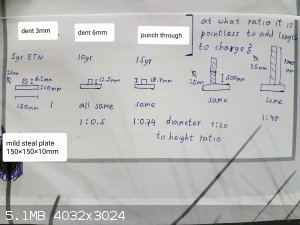

I will add a pic that might help with the question.

Also the impact equation, where i wrote time×work=force is not what i meant, the impact equation is actually the shorter the time the stronger the

impact released.

In pic is an example of mild steal plate 10mm thick 150×150mm vs 5gr of ETN, 10gr, 15gr in a 25mm soft shell.

I was testing what size det cap is enough to fully initiate molten ETN.

Then wondered if there is a rule of thumb to go around instead of testing in increments of 5gr or 6.18mm additional length in charge when extra length

becomes pointless.

As i said earlyer, if the charge is 10mm diameter, i probably wont need 50cm long charge to punch a hole in 5mm steal plate, 5cm is enought, on the

other hand if a plate is 20mm thick than as long as the charge is 10mm in diameter, 50cm long charge would not punch through 20mm plate nor even 1

meter charge will, so there is probably some aproximate ideal diameter to length ratio for best result.

So instead of wasting 1 meter of charge, if the ideal ratio axists i can make a charge bigger in diameter and shorter and then test the ideal ratio vs

20mm plate till the correct diameter works, instead of making hundreds of tests of combinations 15mm diameter and 10mm-200m lengths

Then 16mm and 10-200mm lengths

And so on till it punches through.

[Edited on 27-8-2021 by kick_ass]

|

|

|

MineMan

International Hazard

Posts: 1014

Registered: 29-3-2015

Member Is Offline

Mood: No Mood

|

|

This is really cool. And original I think too, even tho this is prolly published somewhere, I haven’t seen it in any recent texts, or actually any

texts.

Great work.

|

|

|

Etanol

Hazard to Others

Posts: 195

Registered: 27-2-2012

Member Is Offline

Mood: No Mood

|

|

Excellent remark. I also conducted similar experiences to find the best ratio height:diameter of detonator and received a value of 2.5 - 3.

|

|

|

|