Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Derivatising p-dichlorobenzene through its nitro compound

Mono-nitration of p-dichlorobenzene

While there are numerous threads on Science Madness dealing with the chemistry of p-dichlorobenzene only one is really practical and contains useful

data: (http://www.sciencemadness.org/talk/viewthread.php?tid=14000&...)

The remainder are mostly of the type that looks at nigh-on impossible conversions, at least for the amateur, of p-dichlorobenzene into such compounds

as phenol or chlorobenzene. This thread is dedicated to the actual derivatisation of p-dichlorobenzene through nitration.

My motivation for posting these details is the fact that I have recently posted a preparation3) for which 2,5-dichloro-nitrobenzene is a

precursor and only afterwards realised that no amateur-friendly, detailed procedure has appeared for the mono-nitration of p-dichlorobenzene in spite

of the fact that the availability of this material has made it the subject of much discussion. I acquired my 2.5 kg bucket of p-dichlorobenzene eons

ago when it was still deemed acceptable to “splash it around” in urinals, garden shed, cloths storage cupboards etc.

There are several published preparations of 2,5-dichloro-nitrobenzene from p-dichlorobenzene, the best are probably those found in Cain1)

and Fierz-Bavid2) but both of these use fuming nitric acid in conjunction with

concentrated sulphuric acid. Given the problems for an amateur in obtaining or preparing high-test nitric acid I experimented with nitration using

ordinary 68-70% nitric acid and sodium nitrate as the nitrating agents. While ordinary concentrated nitric acid was found to be perfectly adequate for

this purpose I have concentrated, in this article, on the use of sodium nitrate in order to conserve nitric acid. I have carried out the nitration of

p-dichlorobenzene many times with both nitric acid and sodium nitrate and the procedure given below is getting close to optimal for sodium nitrate. It

is surely possible to replace the sodium nitrate with ammonium or potassium nitrate but it may require some experimentation to determine the amount of

sulphuric acid needed for the reasons discussed below.

When replacing fuming (98% or greater) nitric acid with 68-70% acid it is necessary to reduce the water activity by adding more sulphuric acid,

roughly 2 moles of extra conc. sulphuric acid per mole of 70% nitric acid used. When using sodium nitrate (and therefore other anhydrous nitrate

salts) the issue is not added water but the rheology of the final acid-nitro compound-metal salt slurry that is important. In other words the slurry

must remain stirrable to the end but because of the heterogeneous nitration conditions the right viscosity is important as a viscous slurry helps the

stirrer break up the immiscible organic phase into a very fine suspension towards the end which helps to maintain nitration which essentially occurs

at the surface of the droplets.

Temperature too is important. Fierz-David recommends 30-35°C for nitration in concentrated sulphuric acid-fuming nitric acid mixture and I found that

35-40°C is suitable for ordinary nitric acid-concentrated sulphuric acid mixtures. For sodium nitrate-sulphuric acid nitration mixtures the optimum

temperature is about 40-43°C. Particularly towards the end when the slurry becomes thick and at lower temperatures the nitration mixture becomes

almost unstirrable. At higher temperatures nitration is rapid and the viscosity of the mixture lower making stirring easier but the yield is lower.

For instance at 100-110°C the reaction is over in 45 minutes but the yield is only about 55-60% and much material is rendered water soluble,

presumably through competing sulphonation but other complex products are also formed as the solution become deep orange when made alkaline.

Nitration with sodium nitrate is distinctly exothermic but the reaction temperature is easily controlled through the rate of addition until the end

when gentle external heating is required to maintain the temperature and therefore stirrability. One further issue is stirring, a powerful overhead

stirrer is essential; a magnetic stirrer is simply not able to stir such a viscous mixture and is not capable of generating the fine dispersion

necessary to achieve complete nitration.

Experimental

66.68g of commercial p-dichlorobenzene were added to 200ml of concentrated sulphuric acid in a 600ml tall-form beaker sat on a hot plate and

equipped with an overhead stirrer unit. A PTFE propeller type stirrer was used. The stirrer was switched on and allowed to run unit the

dichlorobenzene had formed an even dispersion in the acid. The hot plate was used to warm the mixture to about 25° and then switched off.

Fig. 1 p-Dichlorobenzene being stirred into sulphuric acid and the overall set-up of the stirrer, thermometer etc part way through nitration

With the stirrer running as fast as possible without causing splashes the addition of 41.95g of fine powdered sodium nitrate was commenced. The

nitrate salt can be added a little faster at first but care must be taken to ensure that there is not an excessive build-up of unreacted nitrate as

this can lead to an excessive temperature rise. When the temperature reaches about 38-40° the rate of sodium nitrate addition is moderated to just

maintain the temperature in the range 40-43°.

Fig. 2 The final reaction mixture (left) and the reaction mixture poured into ice and water (right)

After about ¼ of the nitrate salt has been added then organic phase become entirely liquid and forms a dispersion of fine droplets in the acid. After

the addition of about ⅔ to ¾ of the salt the product suddenly forms coarse semi-solid, curd-like masses within the sulphuric acid but as the

nitrate addition continues the crude nitro compound forms a fine dispersion again. Once all of the nitrate salts has been added (about 2½ hours)

vigorous stirring was continued for a further 2 hours. During this period it is necessary to apply a little heat to maintain the temperature at

38-40° as the exothermic nitration is now largely complete.

Once the nitration was complete the thick slurry was poured into 1l of cold water containing 200-300g of ice and the mixture stirred until the product

solidified into pale yellow granules. The mixture was left to stand to cool to room temperature (12°C) and then filtered through a sintered glass

frit (medium coarse) and washed with copious cold water. The crude product was washed into a 500ml beaker with about 300ml of water and 5g of

anhydrous sodium carbonate added.

Fig 3. The melt-washed and granulated crude product (left) and the dried crude product (right)

The mixture was warmed on a hotplate until the nitro product melted and then stirred gently until CO2 evolution ceased. The molten compound was washed

by decanting (note 1) with hot water until the washings were neutral. Finely 200ml of ice cold water were added and the beaker stirred manually until

the product solidified into pale creamy yellow granules. These were filtered off, washed again and air dried for several days on a large watch glass.

The yield was 87.13g which is practically quantitative; however, if the product is fused in a shallow ceramic bowl small amounts of water usually

separate.

The crude product can be purified by either heating in a shallow bowl on a steam bath to remove the water an also some of the unreacted

dichlorobenzene and the stirred until it solidifies; this method is adequate if the product is to be reduced to the amine the yield is then 97-98%. A

better product was obtained by recrystallizing the crude product from 200ml of iso-propanol (about 2.1ml per g; note 2) which give about an 85% yield

of almost white, free flowing crystalline powder. Distilling of most of the solvent from the filtrate allows the recovery of most of the remaining,

though less pure dichloro-nitrobenzene.

Note 1. The washing always carry away a little of the product that clings to the surface of the water. The washings should be saved in large beaker

and allowed to cool. The solidified product can then be recovered by filtration; it can amount to as much as a gram of product.

Note 2. Sometime the solution in isopropanol is cloudy. If this is the case it is better to add further isopropanol to about 2.5ml per g, add a little

decolourising charcoal, heat almost to boiling and filter hot through a pre-heated 7 or 9cm Buchner funnel with very gentle suction (otherwise the

filtrate boils!). The recovery is somewhat lower (about 80%) but again the filtrate can be distilled or evaporated down to about 50ml and cooled, the

less pure product can be recrystallized again to obtain pure or added to the next batch.

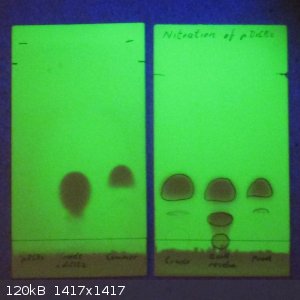

TLC failed to reveal any other spots with the recrystallized compound but with the crude product a faint spot above the product spot is probably

unreacted p-dichlorobenzene. There was no evidence of dinitration products.

1) Cain; 1919; The Manufacture of Intermediate Products for Dyes; 2nd Edition

2) Fierz-David and Blangey; 1949; Fundamental Processes of Dye Chemistry, 5th Edition

3) http://www.sciencemadness.org/talk/viewthread.php?tid=156594

|

|

|

AvBaeyer

National Hazard

Posts: 651

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

I am happy to be the first to say that this is a very nice piece of work. Well done. It is nice to see a procedure for nitration which uses a nitrate

salt instead of nitric acid.

AvB

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Thanks AvBaeyer, I will probably post a slightly amended version to the prepub section. I would like to include the TLC results and Mp data.

Interestingly I have just been running more TLCs of the recrystallised and crude product along with some standards including the starting material,

p-dichlorobenzene. It appears that the faint cresent I had previously assumed was residual starting is not. In fact p-dichlorobenzene doesn't seem to

produce a spot at all even with high loading. I can't reproduce the spots I got before although I was not using the same solvent; I am currently using

Pet. ether boiling range 100-120C were as before I used 60-80C Pet. ether and ethyl acetate 8:1. The nature of the lower spot is uncertain, it may be

dinitro compounds after all but I would have expected two cresents if so.

The right hand TLC shows lanes L1 to L3 from the left: the crude washed nitration product (L1), the filtrate from the second crop of crystals from the

recrystallisation (L2) and L3 the product from the 1st crop of recrystallised product. The Left hand TLC has for comparison L1 starting material

p-diClBz (no spot visible, L2 crude product (as in L1 in left hand TLC), L3 commercial 2,5-dichloronitrobenzene aquired from an Ebay supplier long

ago.

The interesting one is L2 on the left hand TLC the residue from the second crop of crystals during recrystallisation, there is clearly a considerable

accumulation of an impurity. I have evaporated this fraction to dryness and will investigate further.

By the way do you know if you can chromatograph charge-transfer complexes such as those of aromatic compounds and for example; picric acid,

3,5-dinitrobenzamide and 2,4,7-Trinitro-9-fluorenone? Do you thing I could use one of these to visuallize the p-dichlorobenzene?

|

|

|

Justin Blaise

Hazard to Self

Posts: 82

Registered: 5-10-2011

Location: Parts Unknown

Member Is Offline

Mood: No Mood

|

|

Nice prep! And it's nice to see some characterization by TLC too. I would suggest using more diluted material to spot your plate with and to make your

eluent a little more polar (maybe 6:1 H:E) for better resolution.

Why don't you think the lower spot is the dinitro compound? That seems like a reasonable guess to me. Maybe you can crystallize the mononitro compound

out further and concentrate that impurity and get a melting point.

|

|

|

AvBaeyer

National Hazard

Posts: 651

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

I am quite surprised that you cannot visualize p-dichlorobenzene. The compound is very volatile as you probably know. Did you use any heat to dry your

tlc plates? Did you let them air dry for any length of time? In either case, the p-dichlorobenzene may have volatilized. You can test this as follows.

Spot the p-dichlorobenzene sample on your plate but look at it under uv before you run it. You should see a spot at the origin unless it truly does

not quench the plate fluorescence. If you see a spot, run the plate and look at it under the uv after removal from the solvent tank and before any

drying. As a rule, I always look at my tlc plates under uv before I develop them to ensure adequate spotting or note an overload.

As for the minor impurity spot, it may be some sort of phenolic compound. These types of products are often minor contaminants in nitration reactions.

Try your recrystallization from ethanol or methanol and water. The more polar compound should stay behind.

AvB

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Justin Blaise  | Nice prep! And it's nice to see some characterization by TLC too. I would suggest using more diluted material to spot your plate with and to make your

eluent a little more polar (maybe 6:1 H:E) for better resolution.

Why don't you think the lower spot is the dinitro compound? That seems like a reasonable guess to me. Maybe you can crystallize the mononitro compound

out further and concentrate that impurity and get a melting point. |

Thanks for the comments Justin. I ran the first TLCs on on earlier batch and I didn't get the faint lower cresent, so the comments were not made about

material in the photo'ed experiment. The TLCs photographed were made after I had posted the notes above but they were made on the material from this

preparation. The faint lower cresent was not present on the earlier batch TLC.

Thanks also AvBaeyer, I try your suggestions and also try using more dilute solutions made from the solid products so I can better control the amount

in solution. I just let the solvent evaporate at RT from the TLCs but I often let them stand for an hour or so before I scan them. When I examine them

I usually draw the spots on the plate with a soft pencil as I have noticed before that they often disappear over time! That was the motive behind my

question regarding less volatile derivatives.

I have just received some micro pipette tips for my gilson pipette so I should now be able to produce more accurate spots (25 micronL I think). When I

tried the nitration at higher temperatures, certainly anything over 80C the formation of nitrophenolic compounds is clear from the deep orange red

colour of the sodium carbonate wash. At less than 45C though the yield of such material appears negligable.

I have recently been reviewing the preparation of the dinitro compound and the last paper on the subject (Page & Heasman; JChemSoc, 1923,

pp3247-3255; Nitration of p-dichlorobenzene) showns that the best yield of the dinitro compound is obtained under quite modest conditions: less

concentrated acid and similar reaction times though higher temperatures than I used above!! So I am going to give it a go. Also Hollander &

Haeften (1920) outline the preparation of the 2,5-dinitro-1,4-dichlorobenzene preparation via the mono amino-2,5-dichloroaniline -> acetylation

-> nitration to 4-nitro-2,5-dichloroaniline -> final product via the diazonium nitrate but were short on details. This looks doable too.

[Edited on 30-11-2020 by Boffis]

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@AvBaeyer. I have just done a little experiment with p-dichlorobenzene and bromobenzene on a TLC plate. When first spottedthey are clearly visible but

by the time the TLC has finished development, say about 10mins, the spot is already much weeker. Bromobenzene had disappeared withing 30mins and

p-dichlorobenzene was only just discernable. The TLC illustrated in the photo above are now almost blank too, only the lower central spot on the right

hand plate is still clearly visible. I have learned to draw on the spots with a soft pencil as soon as they have been done or photographed for just

this reason.

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Extremely cool to see this old talking point finally become reality. But is an amination in the cards?

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@clearly_not_atara, yes over the next few days I am going to try a both reduction to 2,5-dichloroaniline and dinitration of the mononitro compound. I

have just be doing some experiments with nitration mixtures that are homogeneous. I though I had been successful with a mixture of 55ml of conc.

sulphuric acid, 13.6g of NaNO3 and 12ml of 70% nitric acid. I mixed the reagents; they become warm (perhaps 30-35 C) and after 10 minutes stirring I

had a nice clear homogeneous solution. I left it to cool to room temperature and still a nice clear liquid. I poured it into a dropping funnel and it

instantly froze, half in the flask and half in the funnel connected by an icicle of solid stuff followed by a lot of unrepeatable vocabulary!

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Nice to hear that others are also improving their vocabulary at times.  I can

imagine that supercooled nitration mix in the funnel stuck in. Yuck. I can

imagine that supercooled nitration mix in the funnel stuck in. Yuck.

A few days ago I came across an article in which I found an interesting step: apparently 1,4-dichlorobenzene can be acylated too and would yield

2,5-dichloro-acetophenone. The conditions seemed relatively tame (maybe ZnCl2/Ac2O, but I'm not sure) and the yield was decent too. This step -if

worked- could open a whole new area of possibilities in further derivatization.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Pumukli, you don't happen to have that reference do you? The only comparable reaction I have seen referred to is benzoylation under fairly drastic

condition posted by Nicodem in the thread I linked above.

I have managed to melt my rouge nitrating mixture with a methylated spirit lamp. On standing in a beaker it crystallised again into long prisms but

there didn't seem to be much liquid left so god only knows what is happening. I thought if it was bisulphate I may be able to filter it off with a

glass frit funnel and just use the liquid portion but there doesn't seem to be very much of it!

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Well I ran an attempt to reduce 20g of dichlorinitrobenzene to 2,5-dichlloroaniline yesterday. The reduction seems to have worked well and I got a

very dark brown oil that smells similar to dimethylaniline, a very pungent and slightly unpleasant aromatic smell. It dissolves rapidly and almost

completely in hot 10M H2SO4. Its strong smell made me think that it is fairly volatile for a compound that boils at 246 C so I tried steam distilling

it. This worked but is very slow and I am now looking for other means, maybe vacuum distillation. The procedure is mentioned in many texts but details

are seriously lacking. Most simply state something along the lines of "reduced with iron in the same manner as nitrobenzene" with no details of the

work up which turned out to be the tricky bit.

I carried out the reduction as follows. In a 400ml tall-form beaker I placed a stir-bar that almost spanned the beaker, I added 60ml of water and 5ml

of 36% HCl heated almost to boiling and then added 32g of fine iron powder to the vigorously stirred solution. The iron reacted vigorous initially but

as soon as I started adding the nitro-1,4-dichlorobenzene powder the reaction appeared to subside (less frothing) and the aqueous phase which had

started to turn green became black. The nitro compound was added in small portions over about 15minute and then the beaker was covered and simmered

for about 45minute more. The final product was a black soup that resembled crude oil. Having fished out the stir-bar and rinsed of most of the

attached solid I diluted the residue with about 30ml of water and vacuum filtered it. The cake was stirred up with 20ml of dichloromethane and vacuum

drained, this was done three times. The filtrate separated cleanly and the heavy dark brown oil separated.

The dichloromethane was distilled off and the residue steam distilled for and hour but only about 2ml passed over and the cooling water had to be

drained periodically to allow the aniline to melt and run into the receiver. The heavy brown oil in the distillation flask was allowed to cool and it

soon solidified. The water was poured off and replaced with 40ml of 15% hydrochloric acid and heated. The amine did not dissolve but turned into light

brown voluminous granules that I have yet to investigate but I am hoping is the hydrochloride.

Given the product's melting point (about 45 C) it may be tricky to distill even with an air condenser so I might also try recrystallisation from

various solvents. Any suggestions?

[Edited on 20-1-2021 by Boffis]

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

How the steam distilled product looked like?

As for solvents, maybe (m)ethanol or acetic acid (perhaps mixed with water) could be used for the hydrochloride.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Pumukli, the steam distilled product is comes over as a pale yellow liquid that solidifies into a very pale yellow crystalline solid. I have found

that the salt are not stable, this morning the granular brown hydrochloride had turned into a furry mass covered in delicate colourless needles of

what appear to be the free base. When the hydrochloride is placed in water the pH drops to about 1 so I suspect that the salt hydrolyses very strongly

to free base and hydrochloric acid until equilibrium is reached.

I am going to try steam distillation again but this time with an external steam source so that I can run it for longer. Attempts t recrystallise it

directly from the crude brown product have not been particularly successful yet, they don't remove the colour.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Success, I steam distilled part of the original brown crud, about 9.3g, using an external steam generator. I collected about 300-350ml of distillate

plus 400g of ice that I added to the receiver because the aniline is rather volatile. The product was filtered off and now is drying in the

desiccator.

An interesting feature was that over night the crude brown granular free base had acquired a crust all over of velvety needles of colourless

2,5-dichloroaniline giving some indication of just how volatile this compound is. I have also found a couple of papers that describe the chemistry

this compound in some detail but not its preparation so am still winging it  . .

I did find a chinese patent on the reduction of the 2,5-dichloronitrobenzene to the corresponding amine with hydrazine hydrate using ferric chloride

and a phase transfer catalyst. I have a google-translate of it but its a bit patchy and I can't see what the PTC is that they have actually used. I

have to say I am a bit skeptical because other aromatics with reactive halogens adjacent to a nitro group form hydrazines and then

N-hydroxybenzotriazole. So I will have to try it out.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Glad that steam distillation worked.

Carefull with this compound if it is so volatile. At least 4-chloro- and 3,4-dichloro-aniline is carcinogene as I heard. (This is what prevents me

from exploiting a leftover bottle of Afalon (withdrawn herbicide in the EU) by hydrolysis and purification. It would yield 3,4-dichloro-aniline. On

second thought, I don't even need this aniline for anything.)

|

|

|

Fery

International Hazard

Posts: 1026

Registered: 27-8-2019

Location: Czechoslovakia

Member Is Offline

|

|

Boffis, here in CZ everyone can buy cheap OTC sodium dithionite Na2S2O4.

https://fichema.cz/384-dithionicitan-sodny-hydrosulfid-sodny

I've already bought more than half a kilo of it, for reduction of -NO2 to -NH2 - everytime when buying from this supplier and I see it in the eshop:

cool, still in the stock, let's add it into the cart.

When I was small boy we used to buy it in small sachets in drugstores under name "Odbarvovac" = decolorizer, it was used to decolorize cloths. We did

some devil things with it but I can't remember exactly the second drugstore substance we mixed it with.

I did reduction of nitrobenzene to aniline decades ago using HCl + Fe.

Could you tell me please which way is more advantageous by your opinion Fe+HCl or Na2S2O4?

Pumukli - Afalon contains linuron, it is androgen receptor antagonist, so the negative impact is not only to male reproductive system, but also bone

strength and a lot of other things, these receptors are everywhere...

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

I found this interesting paper in German about the chemistry of 2,5-dichloroaniline that covers many potential "down the line" derivatives as well as

details of its diazotisation, sulphonation, further nitration and coupling of the diazotised amine etc. I thought others may find it interesting and

useful so I have translated it.

Attachment: Derivatives of 2,5-dichloroaniline Berichte Noelting & Kopp 1905 English.pdf (237kB)

This file has been downloaded 384 times

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Hi Fery, do you have any idea of the stoichiometry of the dithionite reduction of nitro compounds? Another thing that worries me about sodium

dithionite is the tendency of the o-chloro atom to undergo replacement by sulphur containing species as I have described elsewhere.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

The further nitration of 2-nitro-1,4-dichlorobenzene

This procedure is taken from a paper by Page and Heasman (1) in which they describe both the mono-nitration of p-dichlorobenzene and then the further

nitration of the mono-nitro compound to a mixture of dinitro derivatives. They also describe the separation of the various isomers and claim (in

contrast to some other researchers) that their nitration product consists mainly of 2,3-dinitro and 2,6-dinitro-1,4-dichlorobenzenes and that

2,5-dinitro-1,4-dichlorobenzene, if present is so to only a small extent. I haven’t yet attempted to carry out the separation in the manor described

by Page and Heasman but it is my intention to do so eventually.

In this first attempt at dinitration I chose to use my trusty sodium nitrate /sulphuric acid nitrating mixture and adjust the ration of reactants to

reflect Page and Heasman’s composition. In doing so, I have departed from the original procedure which used 90% nitric acid. I endeavoured to get as

close as possible to their nitration conditions but I found the ratio of nitric acid to substrate unmanageable when using sodium nitrate and would

have had to add a great deal more sulphuric acid to achieve a stirrable mixture. However, in the text of Page and Heasman’s paper they state that

the molar ratio of nitric acid to substrate should be at least 2.5:1 but in their final experimental description they use almost 7:1 which seems

wasteful. I eventually settled for about 3:1 since the water content of my nitrating mixture was lower than theirs, an advantage of using an alkali

nitrate instead of 90% nitric acid.

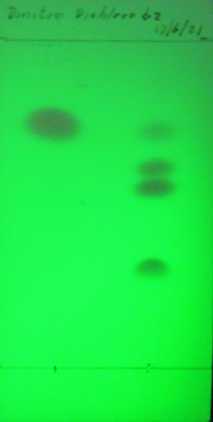

Page and Heasman used the crude product directly for the separation of isomers but I carried out TLC on my material first and found 4 spots (fig. 1

right-hand lane). The highest spot is clearly unreacted starting material and so I decided to recrystallize the material from iso-propanol first in an

attempt to remove it. The remaining spots are all behind the starting material and are presumed to be the three possible dinitro isomers. The lowest

spot appears to be more soluble in iso-propanol and it seems to accumulate in the recrystallization liquor, the right hand lane in fig. 2 (Both

photographs in figure 2 are of the same plate, the left one is a little out of focus but the right one has had the spots marked with a pencil). It

will be interesting to see how the isomers distribute during Page and Heasman’s separation technique.

Fig. 1 Left TLC shows the starting compound (left L) against the crude product Fig. 2 Right TLC show the starting material against the recrystallised

product (Centre L) and the residual filtrate (right L)

Experimental detail

22g of dried and finely ground sodium nitrate were added to 70ml of 96-98% concentrated sulphuric acid in a 400ml tall-form beaker. The beaker stood

on a hotplate and was equipped with an overhead stirrer. The mixture was stirred vigorously to disperse the sodium nitrate and then the suspension was

warmed to 60°C. Once at this temperature 19.2g of finely ground 2-nitro-1,4-dichlorobenzene was added in small portion over about 10 minutes. There

was almost no discernible exotherm. The temperature was then raised to 80-85° over about 15 minutes and then held at this level for 50 minutes. The

temperature was then raised to 110-120° over about 20 minutes and then maintained at this level for an hour and a quarter.

The mixture was allowed to cool to about 70°C and 18ml of water added, this caused the temperature to rise rapidly to 90°. The reaction mixture was

allowed to cool to room temperature but as stirred slowly to granulate the product as it solidified. When cold the suspension was filtered through a

glass frit, the nitrating mixture separated and the solids washed with copious water to remove the sodium sulphate from the organic solids. The nitro

compound was washed into a small beaker, 100ml of water added and the beaker heated until the solids melted. The molten nitro compound was stirrer

with the water and allowed to settle, the water decanted off and replaced with fresh water and the process repeated. The decanted water was preserved,

cooled and the small amount of solids filtered off and added back to the nitro compound. After the last washing the organic phase and some residual

water was heat to a higher temperature and the whole lot drawn through a small preheated Hirsh funnel, poured into a hemispherical bowl and allowed to

solidify (note 1).

The solid “biscuit” was easily removed from the bowl and mopped dry between filter papers then placed in a dry bowl and melted at about 80-90°

until all of the water droplets had disappeared, the pale yellow oil then being allowed to solidify once more. The final cream coloured biscuit of

mixed nitro compounds weighed 17.74g which is about 75% of theory. A further 0.70g (about 3%) of crude material was recovered from the washings and by

scraping the beaker side when cold. A TLC of the crude material was run again the starting material (figure 1 above). This revealed a little residual

starting mono-nitro compound and three product spots.

The crude material was recrystallized from iso-propanol, 2ml per g are required. Other alcohols were tried but appear to offer no significant

advantage but could be substituted if more readily available. The crude material was dissolved into 35ml of iso-propanol to give a clear pale yellow

solution that did not require filtering. On cooling the solution appeared to solidify into a mass of tiny spheres but liquefied on stirring. The

slurry was filtered when cold, the cake pressed down and then washed with about 15ml of cold iso-propanol. The dried cake weighed 14.00g (59% of

theory).

The filtrate was evaporated down to about 30ml and used to recrystallize the 0.70g of beaker “scrapings” to give a further 1.39g (about 6%); this

material was not chromatographed and will be added to the next batch of nitration product.

Note 1: Filtering the molten nitro compound helps remove entrained alkali salts which are sparingly soluble in alcohol and iso-propanol and would make

it necessary to filter the solution during recrystallization but this is very difficult with such concentrated solution. When filtering the molten

nitro compound boiling water can be used to prevent the compound solidifying during filtering.

Conclusion

Overall the procedure was fairly successful and worked much as expected based on Page and Heasman’s paper. While I have not proved, it does appear,

that at least a little 2,5-dinitro-1,4-dichlorobenzene is formed and that this is the lowest spot on the TLC. While Page and Heasman report that it is

difficult to separate the 2,3 and 2,6-dinitro-1,4-dichlorobenzenes by recrystallization from alcohol it does appear from my work that at least one of

the three isomers, probably the 2,5-dinitro isomer, can be selectively extracted from the crude product ethanol or iso-propanol.

The high molar ratio of nitric acid to nitro-1,4-dichlorobenzene for dinitration given by Page and Heasman in their experimental section is

unnecessary and wasteful. A 3:1 ratio is quite adequate when using sodium nitrate, the small amount of unreacted starting material is easily removed

by recrystallization from iso-propanol.

The dinitro compound tends to cling to glassware, stirrers etc. when molten and is difficult to scrape off due to its hardness. Mechanical losses are

therefore significant but a larger scale preparation may reduce the proportion of these losses. A significant amount of yellow, water soluble,

material is produced and lost during washing.

1) Page & Heasman; J. Chem. Soc., 1923, pp3247-3255; Nitration of p-dichlorobenzene

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by Boffis  | | Another thing that worries me about sodium dithionite is the tendency of the o-chloro atom to undergo replacement by sulphur containing species as I

have described elsewhere. |

IDK about o-X, but m- seems fine...BTW it's been said that dithionite only works on nitro phenols/benzoic acids/anilines (edit: and azo cpds.,

obviously), but I'm quite sure it reduces nitrotoluene quantitatively in minutes if not seconds under the right conditions...maybe to

tolidine or other unexpected amine, didn't look too deeply into that.

[Edited on 19-6-2021 by S.C. Wack]

|

|

|