Petn1933

Hazard to Others

Posts: 106

Registered: 16-9-2019

Member Is Offline

|

|

3v cap

After trying several strands of wire such as steelwool, thin copper wire, 0.1mm nichrome , I came to the conclusion that the safest and least

expensive way to make an electric detonator. Use tungsten inside 3-volt bulbs.

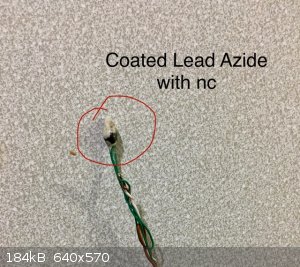

I gently break the lamp glass. Then I soak the tungsten filament in a mixture of nitrocellulose and acetone. After the tungsten filament is coated

with nitrocellulose, I place it in lead azide. And I do this two more times. After a few minutes and when the mixture has hardened, I cover it all

with a thin layer of glue.

That's it.

It will explode even without using a high voltage source and with a 1.5 volt battery.

It should be noted that this method is not innovative and is used by many of you who are currently reading. I just used a 3 volt bulb instead of the

other wires.

Thank.

|

|

|

aromaticfanatic

Hazard to Others

Posts: 173

Registered: 10-9-2019

Member Is Offline

|

|

I've tried this before but couldn't solder any wire to the leads. I opted to use thin solid copper wire that had the wire crimped onto strands of

steel wool rolled into a kinda thin wire. Works really well so far.

Another issue I had was that the filament extraction was only 50% successful for me as there was a glass bead holding the leads together and when I

would heat shock the glass, there was a bottom piece remaining that needed pliers to break. 50% of the time I would break that bead of glass holding

everything together and it caused everything to fall out.

Another reason I think my steel wool setup was superior to the light bulb was that I was able to bend the little wire holding the steel wool wire in a

way that allowed for compressing my primary very hard without the filament breaking. The way my light bulb filament was set up it would break and if I

tried to bend it, the filament often fell off or became even more sensitive. I had one idea in mind for how I could try and compress the primary a

little better with the light bulb but I never got to it.

|

|

|

Petn1933

Hazard to Others

Posts: 106

Registered: 16-9-2019

Member Is Offline

|

|

Quote: Originally posted by aromaticfanatic  | I've tried this before but couldn't solder any wire to the leads. I opted to use thin solid copper wire that had the wire crimped onto strands of

steel wool rolled into a kinda thin wire. Works really well so far.

Another issue I had was that the filament extraction was only 50% successful for me as there was a glass bead holding the leads together and when I

would heat shock the glass, there was a bottom piece remaining that needed pliers to break. 50% of the time I would break that bead of glass holding

everything together and it caused everything to fall out.

Another reason I think my steel wool setup was superior to the light bulb was that I was able to bend the little wire holding the steel wool wire in a

way that allowed for compressing my primary very hard without the filament breaking. The way my light bulb filament was set up it would break and if I

tried to bend it, the filament often fell off or became even more sensitive. I had one idea in mind for how I could try and compress the primary a

little better with the light bulb but I never got to it. |

Yes, breaking a lamp is somewhat sensitive. I use special pliers without damaging the filament of the lamp. Of course, breaking the lamp with heat

does not require much heat. A cold and heating is enough

[Edited on 29-11-2020 by Petn1933]

|

|

|

aromaticfanatic

Hazard to Others

Posts: 173

Registered: 10-9-2019

Member Is Offline

|

|

Yea I find blowtorching it to the point of melting is the best way to do it. It weakens the little bulb at the bottom and it also makes the glass

practically fall off of the filament piece.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

You can buy tungsten wire.

A glass cutter is about $5 and will make that job a lot easier.

Score the base of the glass part of the bulb and wet the score mark and heat the base and it will pop right off.

I have never had a problem with kanthal wire which is easier to find on amazon.

Neither one can be soldered with regular solder.

You can however twist them with copper wire and use solder as a physical restraint to keep the wires together.

Model rocket igniters and also be used to set off a larger primary charge.

|

|

|

macckone

Dispenser of practical lab wisdom

Posts: 2168

Registered: 1-3-2013

Location: Over a mile high

Member Is Offline

Mood: Electrical

|

|

PS. it is christmas season again.

Christmas mini light bulbs are 3.5v and have nice leads and the filament is toward the center and it is a long bulb.

A glass cutter will allow you to take off the end and pour in the primary of your choice.

or cut the base and give you a nice set of leads.

https://www.amazon.com/Clear-Replacement-Christmas-Light-Bul...

and glass cutter

https://www.homedepot.com/p/Husky-5-in-Glass-Cutter-8501H/10...

|

|

|

itsallgoodjames

Hazard to Others

Posts: 276

Registered: 31-8-2020

Location: America Lite

Member Is Offline

|

|

I've had decent luck cutting off the little bump thing on the top of the bulb with wire cutters and pouring the primary in that way, no need for a

glass cutter. You can then seal it with nitrocellulose dissolved in acetone. The acetone evaporates and the nitrocellulose forms a plug to prevent

your explosives from spilling out. With less temperature sensitive primarys, you can (and I can't stress this enough) VERY CAREFULLY seal it with a

little dab of hot glue, though I would advise against it. Heat around explosives, especially primaries seems like a bad idea.

Nuclear physics is neat. It's a shame it's so regulated...

Now that I think about it, that's probably a good thing. Still annoying though.

|

|

|

aromaticfanatic

Hazard to Others

Posts: 173

Registered: 10-9-2019

Member Is Offline

|

|

Quote: Originally posted by itsallgoodjames  | | I've had decent luck cutting off the little bump thing on the top of the bulb with wire cutters and pouring the primary in that way, no need for a

glass cutter. You can then seal it with nitrocellulose dissolved in acetone. The acetone evaporates and the nitrocellulose forms a plug to prevent

your explosives from spilling out. With less temperature sensitive primarys, you can (and I can't stress this enough) VERY CAREFULLY seal it with a

little dab of hot glue, though I would advise against it. Heat around explosives, especially primaries seems like a bad idea. |

I used to hot glue detonators. I had an inert powder like flour on top of my primary. It helped to press it too. However, I made some changes to have

better safety and I found epoxy putty works really well as a replacement. No high heat and it doesn't react with flour, tissue paper, cotton, and I

think most primaries.

|

|

|

itsallgoodjames

Hazard to Others

Posts: 276

Registered: 31-8-2020

Location: America Lite

Member Is Offline

|

|

I'll have to try using the epoxy resin to seal it at some point. Sounds like a great idea. Out of curiosity, does the plug of epoxy tend to stay

mostly intact? I've found that hot glue tends to do that, but I imagine resin is more brittle, so it might not.

Edit- I should clarify that I meant after detonation of the primary alone, without a secondary

[Edited on 29-11-2020 by itsallgoodjames]

Nuclear physics is neat. It's a shame it's so regulated...

Now that I think about it, that's probably a good thing. Still annoying though.

|

|

|