B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

Q: Making sodium cyanide from sodium cyanate and sodium metal

Hey there, I've read in the wiki that it's possible to convert sodium cyanate to sodium cyanide by mixing it with magnesium turnings and igniting the

mixture.

I also read that the yield is quite low due to exposure to oxygen in the air. I happened to have much more sodium metal then magnesium metal.

Is it possible to prepare sodium cyanide by reacting powdered sodium cyanate(made by the rxn of urea and NaOH) with molten sodium metal in a medium of

hot mineral oil(to reduce exposure to air)? Or do you think it is unlikely to succeed?

Much thanks as always,

stay safe, B.D.E

[Edited on 20-3-2020 by B.D.E]

|

|

|

Vosoryx

Hazard to Others

Posts: 282

Registered: 18-6-2017

Location: British Columbia, Canada

Member Is Offline

Mood: Serial Apple Enjoyer

|

|

If you include carbon in your urea/naoh mixture you'll get cyanide. Not sure about the stoichiometry though, nurdrage did a video on it but it's long

since deleted.

"Open your mind son, before someone opens it for you." - Dr. Walter Bishop

|

|

|

anti

Harmless

Posts: 32

Registered: 17-2-2020

Member Is Offline

Mood: Mood: Mood:

|

|

If you included carbon in your Alkali/Urea melt, about 8.3 Alkali: carbon, you would guarantee complete reduction of any cyanate that forms.

I must warn you: YOU will die if you mess up , tho I don't know how you could reach the lethal dose by (for example) touching the solution.

Be careful if working around acids, the vapour in the air, wear gloves, etc.

Signature:

HTML is On

BB Code is On

|

|

|

mackolol

Hazard to Others

Posts: 459

Registered: 26-10-2017

Member Is Offline

Mood: Funky

|

|

The better way to make cyanide is to create HCN by acting with acid on ferrocyanide solution. Then bubbling the HCN gas to NaOH solution.

But the method is very dangerous, HCN gas has very weak smell and there is high chance that you won't smell it at all. You must be extremely careful

working outside with proper gasmask as it can kill you or cause big health problems.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Why would you use sodium (costly,rare, hard to get,,overkill for this rxn) when you can use cheap ass common off the shelf carbon?

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Not to mention how are you going to purify the nacn after the rxn? You'll end up with sodium hydroxide in your product whereas any excess carbon will

be easily filtered out

|

|

|

B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

Quote: Originally posted by Vosoryx  | | If you include carbon in your urea/naoh mixture you'll get cyanide. Not sure about the stoichiometry though, nurdrage did a video on it but it's long

since deleted. |

Quote: Originally posted by anti  | If you included carbon in your Alkali/Urea melt, about 8.3 Alkali: carbon, you would guarantee complete reduction of any cyanate that forms.

I must warn you: YOU will die if you mess up , tho I don't know how you could reach the lethal dose by (for example) touching the solution.

Be careful if working around acids, the vapour in the air, wear gloves, etc. |

Oh, I didn't known that. Thanks for the info. BTW, NurdRage's video was reuploaded to YouTube.

Quote: Originally posted by mackolol  | The way to make cyanide is to create HCN by acting with acid on ferrocyanide solution. Then bubbling the HCN gas to NaOH solution.

But the method is very dangerous, HCN gas has very weak smell and there is high chance that you won't smell it at all. You must be extremely careful

working outside with proper gasmask as it can kill you or cause big health problems. |

lt's good to know, but unfortunately I don't have any ferrocyanide on hand. Also, it's preferable by me to avoid dealing with HCN gas. My fumehood

ain't bad, but LClowest of 107ppm for a human sounds horrifying to me.

Well first - I didn't know you can simply use carbon

Second, at least for me, sodium metal is quite cheap and obtainable(given, not as much as coal). In addition because sodium is a stronger reducing

agent, it might work in relatively modest temperatures of 200-230C, instead of much higher temperatures required for most other methods. I'm still not

sure if I have the means for reaching the 450C needed for the coal-cyanate reaction :S

Quote: Originally posted by draculic acid69  | | Not to mention how are you going to purify the nacn after the rxn? You'll end up with sodium hydroxide in your product whereas any excess carbon will

be easily filtered out |

Please current me if I wrong, but it is from my understanding that the coal reduction method requires an excess of NaOH(to avoid potentially making

HCN gas). So at least from this aspect there isn't much of a difference.

Thanks everyone!

[Edited on 21-3-2020 by B.D.E]

|

|

|

chornedsnorkack

National Hazard

Posts: 564

Registered: 16-2-2012

Member Is Offline

Mood: No Mood

|

|

Heating organics with metallic sodium with intent of producing cyanides is standard Lassaigne test.

Gaseous HCN is not a problem because Lassaigne test normally produces excess of NaOH on workup, so cyanides stay in solution.

It might be a bigger problem if your Lassaigne test discovers phosphine - it does not stay in solution.

|

|

|

rockyit98

Hazard to Others

Posts: 283

Registered: 12-4-2019

Location: The Known Universe

Member Is Offline

Mood: no mood is a good mood

|

|

i think it much easier to heat sodium with persian blue and dissolve the mix in NaOH solution and using a magnet to remove metallic iron from it.

"A mind is a terrible thing to lose"-Meisner

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Quote: Originally posted by B.D.E  | Hey there, I've read in the wiki that it's possible to convert sodium cyanate to sodium cyanide by mixing it with magnesium turnings and igniting the

mixture.

I also read that the yield is quite low due to exposure to oxygen in the air. I happened to have much more sodium metal then magnesium metal.

Is it possible to prepare sodium cyanide by reacting powdered sodium cyanate(made by the rxn of urea and NaOH) with molten sodium metal in a medium of

hot mineral oil(to reduce exposure to air)? Or do you think it is unlikely to succeed?

Much thanks as always,

stay safe, B.D.E

[Edited on 20-3-2020 by B.D.E] |

Are u 100% sure magnesium won't form the MgCN salt or get too hot for the CN to survive and not break down?

[Edited on 24-3-2020 by draculic acid69]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Second, at least for me, sodium metal is quite cheap and obtainable(given, not as much as coal). In addition because sodium is a stronger reducing

agent, it might work in relatively modest temperatures of 200-230C, instead of much higher temperatures required for most other methods. I'm still not

sure if I have the means for reaching the 450C needed for the coal-cyanate reaction :S

It's been done in a tin can on a BBQ or a gas stove.

Please current me if I wrong, but it is from my understanding that the coal reduction method requires an excess of NaOH(to avoid potentially making

HCN gas). So at least from this aspect there isn't much of a difference.

theres no hydrogen in sodium cyanate to form hcn with and there shouldn't be any naoh in there either and if there was it would mean hcn could not

form at all.

Sodium cyanate+carbon from a homebrew/petshop in a tin can(supermarket)

on a gas stove (hardware store) will work for making cyanide.keep a lid on it and don't let it absorb co2 or moisture from the air.

[Edited on 24-3-2020 by draculic acid69]

|

|

|

B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

Quote: Originally posted by chornedsnorkack  | Heating organics with metallic sodium with intent of producing cyanides is standard Lassaigne test.

Gaseous HCN is not a problem because Lassaigne test normally produces excess of NaOH on workup, so cyanides stay in solution.

It might be a bigger problem if your Lassaigne test discovers phosphine - it does not stay in solution.[/rquote][/rquote]

[Edited on 24-3-2020 by draculic acid69] |

Wow, I really enjoyed reading about the Lassaigne test

But in the end I've decided to use carbon instead.

Quote: Originally posted by rockyit98  | i think it much easier to heat sodium with persian blue and dissolve the mix in NaOH solution and using a magnet to remove metallic iron from it.

|

I don't have any prussian blue. You can see my "backback" in my signature for everything I currently

own(almost).

Quote: Originally posted by draculic acid69  |

Are u 100% sure magnesium won't form the MgCN salt or get too hot for the CN to survive and not break down?

[Edited on 24-3-2020 by draculic acid69] |

I'm not quite sure about it. But I am aware that the yield is quite poor(~10% according to the wiki). This is why I aimed for a different method.

Quote: Originally posted by draculic acid69  |

Second, at least for me, sodium metal is quite cheap and obtainable(given, not as much as coal). In addition because sodium is a stronger reducing

agent, it might work in relatively modest temperatures of 200-230C, instead of much higher temperatures required for most other methods. I'm still not

sure if I have the means for reaching the 450C needed for the coal-cyanate reaction :S

It's been done in a tin can on a BBQ or a gas stove.

Please current me if I wrong, but it is from my understanding that the coal reduction method requires an excess of NaOH(to avoid potentially making

HCN gas). So at least from this aspect there isn't much of a difference.

theres no hydrogen in sodium cyanate to form hcn with and there shouldn't be any naoh in there either and if there was it would mean hcn could not

form at all.

Sodium cyanate+carbon from a homebrew/petshop in a tin can(supermarket)

on a gas stove (hardware store) will work for making cyanide.keep a lid on it and don't let it absorb co2 or moisture from the air.

[Edited on 24-3-2020 by draculic acid69] |

You're right. Thank for taking the time to current me and write some instruction

I actually already tried the rxn twice since my latest post.

First try was done with 1:1:1 ratio for all reagents, with the lid off and heated(with charcoal) for only ~1 hour. I tested it by reacting with

Fe(II)/Fe(III) mixture to get prussian blue and it worked(though I'm not sure about the purity and yield).

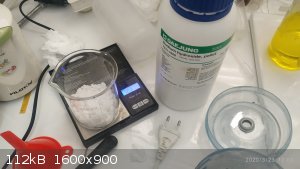

here is the crude product from the first try:

My second try was yesterday with 1:1.5:1.25 ratio of urea:carbon:NaOH accordingly. In retrospect I probably should have used equiv amount of NaOH.

The lid was off only for the first hour of the reaction, to allow the NH3 gas to escape. I guess it's OK due to the excess of carbon which should

"re-reduce" any newly formed NaOCN(from the oxidation of NaCN by the air). The can was heated for a total of about 8 hours, with a maximum temperature

read of 750oC(outside of the can).

Here are some pictures from my second try(if anyone is interested):

I'm now extracting the product with methanol.

---

Thanks for all the help and tips, feel free to share more if you have any

[Edited on 25-3-2020 by B.D.E]

|

|

|

rockyit98

Hazard to Others

Posts: 283

Registered: 12-4-2019

Location: The Known Universe

Member Is Offline

Mood: no mood is a good mood

|

|

when with carbon 2NaCNO + C +2NaOH -------> 2NaCN + Na2CO3+H2O

after cooled down, reacting the mix with ammonium carbonate will give mix of NaCN and NaHCO3 (Na2CO3+(NH4)2CO3 ------>2NaHCO3+2NH3) cooling the

said mix will precipitate out NaHCO3 like in the solvay process.

"A mind is a terrible thing to lose"-Meisner

|

|

|

clearly_not_atara

International Hazard

Posts: 2800

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

| Quote: | | reacting the mix with ammonium carbonate will give mix of NaCN and NaHCO3 (Na2CO3+(NH4)2CO3 ------>2NaHCO3+2NH3) cooling the said mix will

precipitate out NaHCO3 like in the solvay process. |

Don't acidify mixtures of cyanide without a fume hood. Which, based on your photos, you don't have. Do not attempt to perform this reaction. It can

release hydrogen cyanide gas. rockyit98: do not post dangerous procedures without the appropriate knowledge.

Instead, you can recrystallize the NaCN from MeOH, which dissolves sodium cyanide but not the carbonate. Maximum solubility of NaCN in MeOH is 7.8%

w/w at 25 C.

[Edited on 25-3-2020 by clearly_not_atara]

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by rockyit98  | | i think it much easier to heat sodium with persian blue and dissolve the mix in NaOH solution and using a magnet to remove metallic iron from it.

|

Wrong part of the world:

Prussia, not Persia

The spirit of adventure was upon me. Having nitric acid and copper, I had only to learn what the words 'act upon' meant. - Ira Remsen

|

|

|

B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

Okay, so I've made some arguably interesting development.

First of all, The purification was kind of a mess. To make a long story short I now have 2 solutions:

1. NaCN/Na2CO3 in mehtanol(which is a bit orange for some reason)

2. NaCN/NaOH in distilled water(clear-ish)

The surprising thing(at least IMO) is that the aqueous solution ppt some huge crystals:

I recovered the crystals from the solution, dissolved a sample in dH2O and added some Fe2+/Fe3+ ions to the solution.

Immediately when adding the ions, a deep blue ppt was formed(suspected to be prussian blue).

I did a quick google search and found this: https://patents.google.com/patent/US4083935A/en

I'm yet to have read it thoroughly(it's also quite messy), but it seems to provide some in dept details about recovering NaCN from an aqueous NaOH

solution. Keep in mind you do get some sodium formate as a side product, but with some planning ahead, this contamination should supposedly be minor.

Overall it might be a better way to recover a near pure product from those type of reactions(i.e. one pot preparations of NaCN from coal, NaOH and a

nitrogen containing compounds).

|

|

|

B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

Some more crystals after cooling the solution:

Final yield isn't great(55% based on urea, assuming 100% purity). I guess it is most likely due to leftover NaCN in the raw product, which shifteted

overnight from coal black to a white covered coal(however it was too contaminate to recover, so I took it out of the trash into a beaker, poured some

H2O2 over it and thrown it again(probably should've done it in the first place).

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Quote: Originally posted by rockyit98  | when with carbon 2NaCNO + C +2NaOH -------> 2NaCN + Na2CO3+H2O

after cooled down, reacting the mix with ammonium carbonate will give mix of NaCN and NaHCO3 (Na2CO3+(NH4)2CO3 ------>2NaHCO3+2NH3) cooling the

said mix will precipitate out NaHCO3 like in the solvay process. |

Which is why you don't add the carbon until you have already purified your cyanate.

You can't just go straight to cyanide from urea.urea +naoh->cyanate and after purification and drying then onto cyanide.not before.

|

|

|

B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

[NEVERMIND]

[Edited on 28-3-2020 by B.D.E]

|

|

|

PirateDocBrown

National Hazard

Posts: 570

Registered: 27-11-2016

Location: Minnesota

Member Is Offline

Mood: No Mood

|

|

Prussian Blue (Fe7(CN)18) can be easily gotten in the States, as laundry bluing.

Very old school for laundry, but still available in WalMart, in 8 ounce bottles of Mrs Stewarts.

Just dry to an anhydrous solid, then heat with phosphoric acid. You get iron phosphate residue and HCN gas. distill with very cold coolant to condense

the gas, (liquid HCN boils around room temperature, 20C or so) into anhydrous EtOH saturated with dry KOH. you can then crash out crystals of pure KCN

by evaporation.

Needless to say, use very good ventilation, gaseous HCN can kill you fast. and double glove, with extra other PPE. Liquid HCN can kill you via skin

absorption.

Also, use an oversize reaction vessel, as this reaction tends to bump vigorously.

[Edited on 3/28/20 by PirateDocBrown]

Phlogiston manufacturer/supplier.

For all your phlogiston needs.

|

|

|

PirateDocBrown

National Hazard

Posts: 570

Registered: 27-11-2016

Location: Minnesota

Member Is Offline

Mood: No Mood

|

|

If you want to go the thermal reduction route, I'd get a metal crucible, (I use stainless culinary ramekins) charge with a mix of powdered carbon, KOH

and cyanuric acid (swimming pool chlorine stabilizer), and heat strongly.

I've done it before with just a propane torch, but got poor yields, though the soluble product did test positive for CN ion. Should I do this in the

future, I'd repurpose my lead casting melter into a molten lead bath. Protect the reaction from too much ambient oxygen with aluminum foil.

Crush the mass into powder, dissolve out the product with anhydrous MeOH, and filter out the residue. crash out crystals as usual.

Cyanuric is much less stinky than urea.

[Edited on 3/28/20 by PirateDocBrown]

Phlogiston manufacturer/supplier.

For all your phlogiston needs.

|

|

|

PirateDocBrown

National Hazard

Posts: 570

Registered: 27-11-2016

Location: Minnesota

Member Is Offline

Mood: No Mood

|

|

B.D.E, what are you using to heat your crucible to red heat like that?

And where are you, that you can get metal sodium, but not laundry bluing?

Phlogiston manufacturer/supplier.

For all your phlogiston needs.

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Quote: Originally posted by PirateDocBrown  | If you want to go the thermal reduction route, I'd get a metal crucible, (I use stainless culinary ramekins) charge with a mix of powdered carbon, KOH

and cyanuric acid (swimming pool chlorine stabilizer), and heat strongly.

I've done it before with just a propane torch, but got poor yields, though the soluble product did test positive for CN ion. Should I do this in the

future, I'd repurpose my lead casting melter into a molten lead bath. Protect the reaction from too much ambient oxygen with aluminum foil.

Crush the mass into powder, dissolve out the product with anhydrous MeOH, and filter out the residue. crash out crystals as usual.

Cyanuric is much less stinky than urea.

[Edited on 3/28/20 by PirateDocBrown] |

I've used cyanuric acid and if I was to do this again I'd go urea.

Cyanuric acid doesn't melt like urea will and I believe this is a source of

low yeilds. It still let's off massive amounts of smoke which is rich in

ammonium carbonate and the whole reaction really needs to be left open

to the atmosphere to evaporate and absolutely can't be done inside.

u also need to make sure no one thinks all that smoke is from fire as

the amount of smoke is a lot.it also needs to be heated for at least 6hrs at

max on a hotplate.the ammonium carbonate will clog a tube so putting a

flat ss or cardboard plate over the heating vessel which is removed and scraped clean is the only way to recover the nh3co2 byproduct.im also a strong

believer in doing the carbon reduction separately to the forming rxn.i think it would cause lower yeilds.

|

|

|

Keras

National Hazard

Posts: 938

Registered: 20-8-2018

Location: (48, 2)

Member Is Offline

|

|

I never synthesised sodium cyanide yet, but when I do it, I'll surely adopt ChemPlayer's method of reducing potassium ferrocyanide (II) with sodium

metal. Seems much less risky than the carbon way. I do have all the ingredients at hand, so I'm going the safe route (if there is any).

[Edited on 30-3-2020 by Keras]

|

|

|

B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

Quote: Originally posted by PirateDocBrown  | B.D.E, what are you using to heat your crucible to red heat like that?

And where are you, that you can get metal sodium, but not laundry bluing? |

The crucible was heated by charcoal, but it is not really red-hot, that's just a camera "glitch". The charcoals were glowing red hot, and I guess that

the camera adjusted the color balance or something.

I live in Israel. But it's not like sodium is being sold on the farmers market or something. I just happened to have found a local supplier who's

willing to sell me

---

Just a final update, the large crystals were indeed Na2CO3 covered with some NaCN. The smaller crystals were also mostly Na2CO3 but with much more

NaCN(compared to the bigger ones).

Luckily I saved to mother solution(i.e the solution from which the crystals ppt), and added some acetone to crush everything out. Whatever crushed out

should contain a much larger portion of NaCN(as I already removed a lot of the Na2CO3 via crystallization in water).

I saved everything I've made in 3 different containers(large crystals, small crystals, crushed-out powder), and I will probably purify it in the

future via the methanol "method".

Thanks for all of the help and suggestions. I definitely know a lot more about making NaCN compared to before opening this thread. That's pretty

awesome

[Edited on 3-4-2020 by B.D.E]

|

|

|