Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

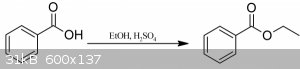

Ethyl benzoate synthesis

Synthesis of ethyl benzoate

-two different routes-

Foreword:

I've been lurking, even posting this and that on the forum during the last few years. I enjoyed thoroughly the great articles in the Prepublication

section and dreamt about posting my own results one day. Besides the dreams I gathered equipment and chemicals and with some unexpected freetime I

could finally start my experiments.

The start was not without hickups. I made silly mistakes that only a beginner can make but these mistakes were very useful: I bet I won't do such

things in the future. :-) Fortunately they were far from to be dangerous but were annoying to the last bit.

Anyway, finally I managed to prepare a new and useful compound for my lab in a substantial quantity and good quality.

Reaction:

Properties of reagents:

Benzoic acid Ethanol Sulfuric acid Chloroform Ethyl benzoate

M (g/mol)

122.12 46 98 119.4 150.17

Bp (C)

249.2 78.3 61.2 213 C

Density (g/cm3)

1.27 0.789 1.84 1.49 1.05

Description:

Method „A” , direct esterification:

Into a 1 litre flask I measured 227.6g (1.64 mole) crude benzoic acid. (I made this benzoic acid from sodium benzoate and hydrochloric acid a few days

before this ester synthesis. I made my first silly mistake during this preparation: I forgot to thoroughly wash off any remaining NaCl from the

product. I just sucked it as dry as I could on the Buchner funnel. I realized that I probably SHOULD HAVE washed it as well with water but I thought

„what problem can a bit of inert NaCl cause in this benzoic acid?” and omitted the washing. I assumed it may contain up to 10% NaCl contamination

and calculated equivalent masses accordingly. In retrospect I wish I washed the acid thoroughly. It could have saved me much grief in the long run.)

I added 510 g (11 mole) denatured ethanol and 20-22 ml concentrated sulfuric acid into the above flask. Put 5 small boiling stones into the mixture in

the flask and started boiling it gently.

I already started the heating when I realized that the previously assumed inertness of NaCl is not really true when sulfuric acid comes in the

picture. :-) I realized it might outgass some HCl via the top of the reflux condenser. I have no fume hood, I did this synthesis on the top of my lab

bench. I did not want to risk any HCl fumes in the air so I turned off the heat and went to the nearest hardware store to buy 2m plastic tube with

appropriate diameter to fit onto the exit stud of the condenser. (It has no ground glass joint at the top.) I attached a glass funnel on the other end

of the tube and submerged it slightly (just touching the surface) in a bucket of cold water.

After this interruption I turned on the heat again.

As the mixture approached its boiling point the not so small ammount of undissolved NaCl started to cause severe bumping. So much about the

assumptions on what can be tolerated in a crude benzoic acid as „inert contaminant” and what not!

I refluxed it for 5 and a half hours. After 2 hours of refluxing the mixture became more translucent than it was before. After cooling it down I

filtered the contents of the flask via a small wad of cotton wool into another 1l flask. The filtrate was a syroupy liquid with a strong, mint-like

odour and a faint yellow color. I changed the reflux condenser to a distilling one, added about 10 ml cc. sulfuric acid to the mixture and started

slowly heating it up again. I distilled off some ethanol and with that I washed the NaCl on the filter and put the washing back into the distilling

flask.

Continued the distillation and after 300 ml came off, the mixture became turbid in the flask.

At that point I let it cool to room temperature. Upon cooling the mixture spontaneously separated into two layers: a lower, whitish, milky looking one

(water plus salt plus acid layer) and an upper, faint yellow, organic one.

I poured the content of the flask into a 1l extracting funnel and added 300 ml brine to further facilitate the separation. This salt water wash really

helped the separation.

Then I went a bit overboard and added approximately 25 ml diethyl-ether to the previously separated brine layer in the hope that it would help to

extract the last drops of ester. Well, it was unnecessary, because it did not really do anything useful just made the organic layer more dangerous

(flammable) to distill. By the way, I could only recover just a few millilitres of organic (ether) layer this time. Either I should have used more

ether to be useful or just omit this step altogether.

I washed the organic phase with NaHCO3 solution to about pH 6 and then finally with tap water. Then I used anhydrous Na2SO4 (about 6-8 g) as drying

agent.

(And made my silly mistake number 2: I thought”Hmm, one drying agent is good. Perhaps two is even better! Why not use CaCl2 also? CaCl2 would not

only remove water but -as everyone knows- would remove the excess of ethanol as well! What a bright idea!”

Needless to say it was not. I tossed in a small spatula CaCl2 and as it started to dissolve in the water everything became white as fine CaSO4

precipitate formed... Arrghh!

It cost me more than a hour time and several milliliters organic phase went down the drain untill I could get rid of this fine gypsum precipitate.

Lesson learned!)

After 2 to 3 days on Na2SO4 the organic phase became crystal clear and wine yellow. Yield at this point: 216g.

Method „B”, azeotropic esterification:

Before this second attempt I decided it would be wise to determine the real purity of the crude benzoic acid.

To do this I dissolved 1,021 g NaOH in 250,0 milliliter distilled water, pipetted out 20 ml into a 50 ml flask and measured about 185 mg finely

powdered crude benzoic acid into this flask. Agitated the flask carefully to speed up the dissolution of the acid and when finished I dropped 1 drop

of 0.5% phenolphtalein solution into the flask. Then titrated back the excess of NaOH with my previously made 0.1N HCl (f: 0.978). Then I titrated the

NaOH solution against the 0.1N HCl as well.

I made 5 repetitions of the above benzoic acid titration and to make a long story short they made a pretty good match. The final calculation showed

82% purity. Another indication of the importance to wash thoroughly on the filter when making the acid!

I measured 300 g crude acid (2 mole, 82% purity) into a 1 liter narrow neck Erlenmeyer (with cap) and poured in approx. 400 ml denatured ethanol

(previously distilled from NaOH) into the flask. Then on a water bath I dissolved the benzoic acid with gentle heating and filtered the solution on a

preheated percelain Buchner funnel and filter paper to get a clear solution.

(We arrived at silly mistake number 3 here: I used Sulaiman's favorite mini diafragm vacuum pump from Ebay as vacuum source for the filtration. By the

way it is a good pump but not under the circumstances I used it. My mistake was I used a 500 milliliter suction flask to collect the solution. It was

almost enough but in the end I had to realize it wasn't. The suction flask filled up quickly with warm alcoholic benzoic acid solution and the pump

started to suck it back via the vacuum hose and pump it out immediately through its exhaust port as fine mist. Rest assured, this alcoholic acid fog

is not what you want to breathe in, even if it is „just” benzoic acid and not something more agressive one! :-) Another lesson learned again.)

After filtration (and cleaning up the benzoic acid droplets from the bench, glassware, floor, etc) I poured the solution into a 1 liter flask and

distilled off some alcohol as the final volume (when cooled) was about 350 ml. (Approximately 50 ml alcohol was removed.)

I gave 20 milliliter 37% battery acid to this solution as catalyst. The azeotropic distillation should remove all (most) water from the system, so in

theory one could get away with dilute acid too. We will see.

I put an empty Soxhlet extractor on the flask, filled it up with chloroform (required 190 milliliters to overflow), then put a reflux condenser on top

of the Soxhlet. I have only a ½ mole (10 milliliters) water trap (Dean-Stark) for high density solvents so I thought a Soxhlet could be used instead

with such solvents as well. It turned out to be true!

I started heating up the system (in a sand bath on electric hot plate). To prevent chloroform vapours from escape I had to use ice water cooling. Ice

was really necessary! Reflux started, chloroform slowly dripped into the flask from the extractor, another layer formed on the top of the chloroform.

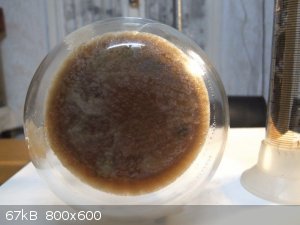

When only 30 milliliters or so pure chloroform remained in the Soxhlet the refluxed upper layer started to get hazy quickly. In ten minutes it became

milky white. I took some pictures. Then, before I had the time to put the camera back into its safe storage again, the whole contents of the Soxhlet

flushed into the flask! It was the first time I used such an equipment and I was baffled – still is. I think this unexpected flush was caused by the

open lab door and the cold air draft.quickly cooling the overflow tube of the extractor, causing the trapped air bubble to shrink and stop functioning

as an „air gap”, building up a continuous liquid body and flushing it possible.

Anyway, this „flush back” turned out to be the real deal! The reflux condenser quickly refilled the whole extractor body (I wrapped the overflow

tube in a cloth by this time) and loo and behold: there was two layers of liquid in the Soxhlet again.

A lower, chloroform rich layer and a water layer above. According to Wikipedia the lower layer is 95.8% chloroform, 3.7% ethanol and 0.5% water while

the upper layer is 1.0% chloroform, 18.2% ethanol and 80.8% water.

I started to measure how „quickly” widens the upper layer. The speed was not too great, but was constant, about 3 mm/hour for hours to come! Later

I determined that 1mm height in my extractor tube corresponds to 1.67 milliliter volume. Unfortunately the Soxhlet is not designed to be a Dean-Stark

and although it can be used it is not optimized for this kind of operation. Problem is the placement of the overlow tube. Functioning as an extractor

you want an overflow tube as high as possible because it gives the maximum usable extractor volume. For a Dean-Stark function it is not optimal! There

is a relatively big difference of densities between the upper and lower layers (0.976 vs. 1.441). It means as more and more water is extracted the

upper surface of the upper =water rich) layer starts to climb upwards and eventually reaches the height of the vapour inlet tube and starts flowing

back into the reaction flask. At this point the water removal effectively stops because the same ammount of water flows back via the vapour tube as

was extracted as vapour. For optimal Dean-Stark capability the overflow tube should be placed lower, sacrificing precious extractor volume for Soxhlet

functionality.

To make this short: I stopped the reflux at 3:00 AM one day, because the upper surface was very close to the back flow point. In the morning I

siphoned off 44 ml water rich upper layer, then continued refluxing. The extraction speed fell to 1 mm/hour after a few more hours and in late

afternoon I stopped the heating. It was still removing water but to be honest I became tired of this reaction and wanted to see the results. :-)

Next morning I disassembled the equipment, siphoned off the upper layer from the chloroform, and saved the chloroform layer – it may be used in

another synth. The combined water layer was 106 milliliters. At the bottom of the reaction flask there remained a few millimeters of watery layer, I

estimated that another 4-5 hours boiling should have been required to completely remove the water from the flask. In the flask there was a clear,

faint yellow, fairly refractive liquid. On the top of this liquid there was a thin (2mm) distinct layer with same colour. The volume of the liquid was

approximately 330 ml.

Poured the liquid into a 1 l extraction funnel and washed first with approximately the same volume of cold tap water, then with dilute NaHCO3

solution, then with water again. At this point the crude organic layer was 402 g.

Then followed the removal of remaining azeotrope by distillation. In theory it would also remove the remaining water as well. This distillation took a

while and the temperature fluctuated a bit from 55 C (azetrope distills around here), then some around 72 C. When I called it finished (temperature

rose well above 78 C, the boiling point of ethanol and the temperature of the flask were much higher, I estimated it around 150 C.) I stopped the

distillation. I let it cool for a while and measured the remaining weight of the contents of the flask. It was 273.7g crystal clear yellow liquid.

When it was cooled I poured in the dried crude end-product of „method „A””. The weight of this crude ester was 216.4 g. It surely contained

some diethylether as well, but not much.

Started the final distillation. I collected some forerun (around 10 milliliters), then the temperature quickly rose to 90 C, and the sounds from the

distilling flask started to sound a bit frightening. You know, the type of explosive boiling when there is a much higher temp liquid in a pan (e.g.

hot oil) and you drop water droplets (wet potato chips, wet meat) into this. By this time the temperature of the pure ester in the flask were much

higher than the temperature of the last refluxing drops of ethanol/water which dripped back into the flask from the condenser. It made that

frightening sound.

I changed the collecting flask at this point to a 500 ml flat bottom one. It was just the right time to do this because the temperature of the vapours

quickly ran from 90 C to 180 C in a matter of five seconds or so! I stopped the aquarium pump which recirculated cold water in the condenser so far

and quickly drained the cold water from the condenser. I replaced water cooling with air cooling (aqarium air pump pumped cold air into the condenser

now on). At about 200 C started dripping the end product, within a few seconds the temperature rose to 210 C. By this time the frightening explosive

boiling stopped and the pure ester distilled nicely. The air cooling became inadequate, the pump could not deliver enough air to safely condense all

the hot vapours so I wrapped a layer of wet tissue paper around the condenser and kept it wet with cold water until the end of distillation. With this

auxiliary cooling the condenser worked fine.

In the end the temperature started to climb up a bit and at 215 C I stopped distillation. Stopped the heating and detached the collector flask when

dripping of the ester ceased.

What I got is 463.6 g absolutely water clear highly refractive liquid. Its smell was overpowering, sweetish and minty. Some of you are probably

familiar with this.

I thought I finished the synth at this point but nooo! :-) My last silly mistake just bite me!

The smell of the product was not so „bright” as I thought it should have been. It had some sort of „after smell” if there is such a thing. I

quickly realized why.

By the time the distilling flask cooled down there was a few milliliters high boiling fraction in the flask. Actually I expected much less of such

remnants than I could see in the flask. And that brownish liquid quickly solidified into a mass of lighter coloured needles.

Yes, there was a substantial ammount of unreacted and unremoved benzoic acid in the flask! This caused the final temperature rise (bp. of benzoic acid

is 243 C) and the bad smell. So there I was again, at the washing stage!

I made a dilute solution of NaOH in cold water (around 0.1 M) and washed the distilled product first with this then with tap water and this time

checked the pH with pH paper until it was neutral!

I forgot this checking of the washing of the crude ester because I assumed „if it stopped releasing CO2 during NaHCO3 washing then all is well”.

Well, it was not. It stopped releasing the CO2 because all the NaHCO3 was neutralized but there still was a substantial ammount of unreacted benzoic

acid left dissolved in the ester. The final tap water washing could not help, because the solubility of benzoic acid in water is much lower than in a

range of other (organic) solvents! Yet another lesson learned! :-)

Then I slowly decanted the organic layer from the water, put some Na2SO4 into it and let it dry overnight. It became clear within hours. Next morning

I distilled it again, and finally I got 451.5 g now nicely smelling water clear ester. Which is the official end-product of this never-ending

synthesis nightmare for me. :-)

Now my lab is smelling like a parfumery and surely will take time until I get rid of this odour.

[Edited on 12-3-2018 by Pumukli]

|

|

|

ninhydric1

Hazard to Others

Posts: 345

Registered: 21-4-2017

Location: Western US

Member Is Offline

Mood: Bleached

|

|

Wow, beautiful writeup; I've been planning to write one but never have time to, regardless of all the experiments I have performed. I'm in the same

boat as you  . .

What are planning to use this ester for, by the way?

The philosophy of one century is the common sense of the next.

|

|

|

Akhil jain

Hazard to Self

Posts: 83

Registered: 19-2-2018

Member Is Offline

Mood: No Mood

|

|

It's smell is like printers ink toner . I am right?

I made this ester just to observe it's smell on an experimental basis

|

|

|

happyfooddance

National Hazard

Posts: 530

Registered: 9-11-2017

Location: Los Angeles, Ca.

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Akhil jain  | It's smell is like printers ink toner . I am right?

I made this ester just to observe it's smell on an experimental basis |

I would say no. It smells like nauseatingly strong fake cherry smell. Methyl benzoate smells similar; it seems slightly more nauseating IMO. But smell

is subjective, so...

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Online

Mood: No Mood

|

|

Hi Pumukli, Looking at your azeotropic esterification method I was wondering if you could use benzene as the entrainer instead of chloroform? My

thinking is that I have a Dean and Stark receiver with a drain stopcock on the bottom so its more convenient is the water sinks and the entrainer

floats on top and eventually overflows back into the flask. Since benzene azeotropic distillation is used to dry ethanol then I could probably use 95%

ethanol and just put up with the removal of the contained water first. This would simplify the whole process.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

If you have a Dean-Stark then benzene probably can be used. Actually the recipes I found used either chloroform or carbon-tetrachloride, both solvents

having higher density than water. I think the reason is in the used glassware though. In a different apparatus solvents lighter than water may be used

too!

I didn't bothered because I had more chloroform than benzene (or toluene) and it seemed to be the less expensive route.

I used 37% battery acid and at first I thought it won't work but after the water was removed and the acid became concentrated there was no problem.

Please write at least a few words if you try this method with light solvent because I'm curious of the results!

[Edited on 22-11-2019 by Pumukli]

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Online

Mood: No Mood

|

|

OK Pumukli, experiment under way! 60 oxalic acid dihydrate, 100ml 95% ethanol and 30ml benzene.

Well 2 hours in and 40ml of water removed so we should be close to completion. Does anyone know how much alcohol comes over with the water benzene

mixture? What I am getting at is the theoretical amount of water from this reaction with the quantities above is about 40g so about 40ml but how much

alcohol is there in the aqueous phase?

Nearly 4hrs in now and over 80ml of aqueous phase collect!! The contents of the flask are still completely clear so esterification must be taking

place.

[Edited on 22-11-2019 by Boffis]

[Edited on 22-11-2019 by Boffis]

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Online

Mood: No Mood

|

|

Well, this morning the flasked had cooled and to my amazement only a tiny amount of unreacted oxalic acid crystallised out. As this preparation isn't

particularly relevant to a thread on ethyl benzoate I am going to move future posts to the organics section until I carry out an ester preparation

that is relevant. I do intend to try the benzoic acid esterification by this technique next.

|

|

|

UC235

National Hazard

Posts: 565

Registered: 28-12-2014

Member Is Offline

Mood: No Mood

|

|

Did you find some other references to using azeotropic distillation for this prep? I know I used it in that youtube video for methyl benzoate from

forever ago and probably set a number of people off doing something similar, but I don't think my yield was any better than a straight reflux with a

large excess of alcohol.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Online

Mood: No Mood

|

|

Hi UC235, no I simply used the benzene azeotropic method for dehydrating 95% ethanol and added some oxalic acid. I didn't add any acid catalyst

because I wasn't sure how stable oxalic acid would be to prolonged boiling with sulphuric acid say.

I currently have a batch of ethyl benzoate running using the same basic method but I added 5ml of conc sulphuric acid to it. Curiously after 2hr of

reflux the oxalate ester run had alredy produced more then 20ml of aqueous phase but the benzoate run has not produced a single drop yet after about

1.5 hrs. To be fair there is a lot less water in the benzoate system because the acid is anhydrous and the acid will tend to sequestrate some water

too.

One question I have is why are the light entrainers usually aromatic compounds (benzene or toluene) why not petroleum spirit or cyclohexane? Is it to

do with the miscibility with the aqueous alcohol that distills off?

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Nice synth, couldn’t help but laugh at the HCl incident , it is a mistake I have made a few times too.

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|