namnguyenvn2904

Harmless

Posts: 8

Registered: 27-7-2019

Member Is Offline

|

|

Matter about DIY magnetic stirrer

When making a DIY magnetic stirrer with hot plate, i fear the heat from heating element can destroy magnet´s strength

( my magnet can bear max 80°C ) so i have to rise the working surface higher which means that stirring effeciency can decrease. So i wonder the best

way to place 2 magnets on the surface of the fan so that the magnetic force that two magnetic put into stirring bar is the strongest. I would be happy

if any guys did that device can answer my question. Here is my example of 2 magnet position, is it the best way?

[Edited on 27-07-2019 by namnguyenvn2904]

|

|

|

Sulaiman

International Hazard

Posts: 3789

Registered: 8-2-2015

Member Is Offline

|

|

Neodymium magnets are best kept cool, ferrite, AlNiCo or samarium cobalt would be a better choice

Is the hotplate surface and heating element non-magnetic ?

If there is a significant thickness of steel/iron then the magnetic field will be severely attenuated

Even a non-magnetic material such as austenitic stainless steel (A2, A4, 304, 316 etc), aluminium, copper etc. can cause a significant extra load on

the motor due to eddy current (Lenz) forces

If all of the above is ok then;

you could make an 'insulating' layer by having forced airflow through a pair of Al foil sheets between the heat source and your magnet(s)

Alternatively you can have a single layer of Al foil and air blasting past the magnet(s)

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

namnguyenvn2904

Harmless

Posts: 8

Registered: 27-7-2019

Member Is Offline

|

|

My hot plate is made of stainless steel 304 so it is nearly non magnetic. My heating element is made of tungsten which is coated by 2 Ceramic/Al2O3

layer so it is not magnetic and safe too.

Also if i set the height between working and magnet about 3 cm. Its effeciency is incredibly good, but due to the fact that i place the heating

element above a 1.5cm thick ceramic mould for safety reason, stirring is not consistent, the height between is about 7cm. so if i can stick heating

element into working surface, the matter can be removed. DO YOU HAVE ANY IDEA TO STICK THE HEATING ELEMENT INTO SUS304 PLATE. The MAX temperature

heating can get is about 500 C

any glues, heat-resistence tape

|

|

|

rockyit98

Hazard to Others

Posts: 283

Registered: 12-4-2019

Location: The Known Universe

Member Is Offline

Mood: no mood is a good mood

|

|

ferrite magnets can work up to 230C I recommend ones from old DC fan motor from car or bike dynamo they are meant to handle hot environment .it can be

find in a repair shop or junk shop.

magnets from speakers can,t work.

do not try Neodymium magnets or PC fan as a motor. use one from old hair dryer they are DC moters 12v to 20v!

|

|

|

namnguyenvn2904

Harmless

Posts: 8

Registered: 27-7-2019

Member Is Offline

|

|

I am finding SmCo magnet on ebay and they say it can bear max 350 C. Is it true?

|

|

|

wg48temp9

National Hazard

Posts: 788

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by namnguyenvn2904  | When making a DIY magnetic stirrer with hot plate, i fear the heat from heating element can destroy magnet´s strength

( my magnet can bear max 80°C ) so i have to rise the working surface higher which means that stirring effeciency can decrease. So i wonder the best

way to place 2 magnets on the surface of the fan so that the magnetic force that two magnetic put into stirring bar is the strongest. I would be happy

if any guys did that device can answer my question. Here is my example of 2 magnet position, is it the best way?

[Edited on 27-07-2019 by namnguyenvn2904] |

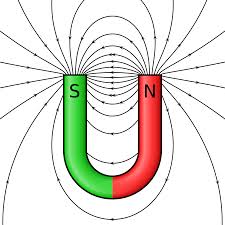

Consider the magnetic field lines of the horseshoe magnet shown blelow.

First the two magnets should be mounted on a steel bar as that will almost double the strength of the field above the magnets.

Second the distance between magnets should be between 0.5 to 1 times the height of the of the stir bar above the pole faces of the magnets. As the

magnets are separated the field above them first increases and then decreases as the separation increases. I estimate maximum is between 0.5 to 1 as

above.

The length of the stir bar should added to the separation distance as determined above.

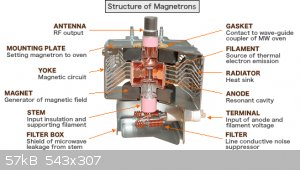

Loudspeaker magnets can be used but you will need two small ones or cut the larger ones in half. The ring magnets from the magnetrons of microwave

ovens can also be used if you cut them in half or use two for a giant stirrer LOL Note the magnets must be mounted with opposite poles facing up.

Thats why you need to cut the ring magnets in half .

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

Sulaiman

International Hazard

Posts: 3789

Registered: 8-2-2015

Member Is Offline

|

|

random information

Based on a few experiments that I did when designing a magnetic stirrer for my diy heating mantle :

(not implemented as I now use diy overhead stirring with the mantle)

The underside of the heating basket/element was padded with about 20mm glass fibre wool with a large (2 or 3 litre from memory) Pyrex bowl holding the

wool in place.

The Pyrex bowl was to allow magnetic fields to pass through,

and to 'catch' any liquids if the boiling pot breaks.

(I've not had a boiling pot break - yet)

I tried some different magnet shapes and sizes;

A 45x30x30 mm AlNiCo 'horseshoe' magnet with central 5mm hole

- good magnetic range and stirbar self-centering

- one of my favourite magnets for various experiments as it is fairly easy to fully re-magnetise,

but quite heavy, and too cute (and expensive) to use in my magnetic stirrer.

100mm long AlNiCo bar magnet(s) (very difficult to fully re-magnetise)

- the length allows a longer range between magnet and stirbar

- the magnets were too long, the self-centering effect was weak and the stirbar easily became unstable.

Two 23mm dia x 20mm tall N52 magnets,

each with a 6mm diameter central axial hole,

mounted on a rotating steel bar with 50mm separation of central mounting holes,

- excellent long range magnetic field

- good self-centering of stirbar

- not implemented due to concerns about magnet overheating

(I may re-visit this configuration)

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

namnguyenvn2904

Harmless

Posts: 8

Registered: 27-7-2019

Member Is Offline

|

|

Is there any material possible to create sheild to protect magnetic from high heat ( heat tranmission through air can reach over 100C. The best

optimal height between working surface and magnet i can measure is about 2.75 cm

So 2 questions need to be solved

1. How to stick ceramic heating element into working surface. Can solve that = reducing the height because no need for thick ceramic protective mould.

If you guy have feasible product on ebay,aliexpress, ...please share me the link

2. Using SmCo magnet possible? Its max temp can bear is 350°C. Otherwise is there any possible to protect the magnet from heat?

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Why in the name of hell is this in comp. models and techniques?

You could make a shield, although it would be much more ghetto then just getting the right kind of magnet. Search up the bread like mixture

“starlight”

Also, this project is sounding more and more like a good way to get yourself electrocuted or burn down your house. Invest in an actual hotplate

stirrer or make an overhead one.

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

namnguyenvn2904

Harmless

Posts: 8

Registered: 27-7-2019

Member Is Offline

|

|

My heating element is absolutely safe enough. OMG, i find a new idea

1. Stick the heating element into working plate by a silicone glue which can stand 700°C

2. Make another smaller plate to cover heating layer. Then my magnet is protected from terrible heat 500°C. if necessary i can place air flow fan to

cool the magnet. Then i can adjust the most optimal height about 2cm.

Do you guy think it is good enough?

[Edited on 27-07-2019 by namnguyenvn2904]

|

|

|

thanhbaphai

Harmless

Posts: 1

Registered: 14-8-2019

Member Is Offline

|

|

this question is very nice

|

|

|

wg48temp9

National Hazard

Posts: 788

Registered: 30-12-2018

Location: not so United Kingdom

Member Is Offline

|

|

Quote: Originally posted by namnguyenvn2904  | My heating element is absolutely safe enough. OMG, i find a new idea

1. Stick the heating element into working plate by a silicone glue which can stand 700°C

|

I don't think there is any silicone glues that can withstand 500C or 700C.

You would have to use a ceramic cement though that is probably going to crack due to differential expansion. Bolting a plate over the elements to

hold them would probably be best and easily implemented.

I am wg48 but not on my usual pc hence the temp handle.

Thank goodness for Fleming and the fungi.

Old codger' lives matters, wear a mask and help save them.

Be aware of demagoguery, keep your frontal lobes fully engaged.

I don't know who invented mRNA vaccines but they should get a fancy medal and I hope they made a shed load of money from it.

|

|

|

aromaticfanatic

Hazard to Others

Posts: 173

Registered: 10-9-2019

Member Is Offline

|

|

I have used neodymium magnets up to 100C just fine. Stir bars with a chemical resistant coating are cheap though.

|

|

|

aromaticfanatic

Hazard to Others

Posts: 173

Registered: 10-9-2019

Member Is Offline

|

|

Came to update that my stir bar that I had bought a while ago has ceased to function (lost magnetism) after being subjected to a 200C distillation. So

definitely don't take magnets up to 200C.

|

|

|