| Pages:

1

..

5

6

7

8 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Hey Tim , If that sim software is so good ,

then why didn't it flag that particular transistor ?

I caught it because I was curious about the

specs on the P channel device and looked it up .

Anyway it does simplfiy things considerably if

you can find complementary devices . I am scrounging

parts to build , and keeping it cheap

Seeing there are a lot of surplus high voltage N channel Mosfets available for cheap , I focused on them .

There are also some high voltage NPN transistors

available for cheap , but the beta really stinks for

the high voltage bipolars , so N channel Mosfets rule

in the performance versus cost scenario .

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

It depends on whether the breakdown characteristics are in the model for the fet. A sim is only as good as its models. The point is, it gets you in

the ballpark really fast. I just picked those fets at random  , because I

couldn't be arsed looking up the specs. , because I

couldn't be arsed looking up the specs.

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

A Dirt-Cheap, High Current Power Supply

Here's yet another use for that pensioned-off AT computer that's gathering dust in the corner.

Got an old PC gathering dust somewhere? It mightn't be much good these days but it's power supply could be... especially if you want a high current

bench supply! This article tells you how to modify one - at very little cost!

Website:

http://www.siliconchip.com.au

A Dirt-Cheap, High Current Power Supply:

http://www.siliconchip.com.au/cms/A_30705/article.html

And for the printed version:

http://www.siliconchip.com.au/cms/A_30705/printArticle.html

Remark:

Apparently you can only access a limited amount of articles in full. Then you are requested to pay for the full article.

This is just to good to miss out on, so here you have the Rapidshare link to the full article:

Power Supply.rar (548 KB)

http://rapidshare.de/files/13312579/Power_Supply.rar.html

[Edited on 15-2-2006 by Lambda]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

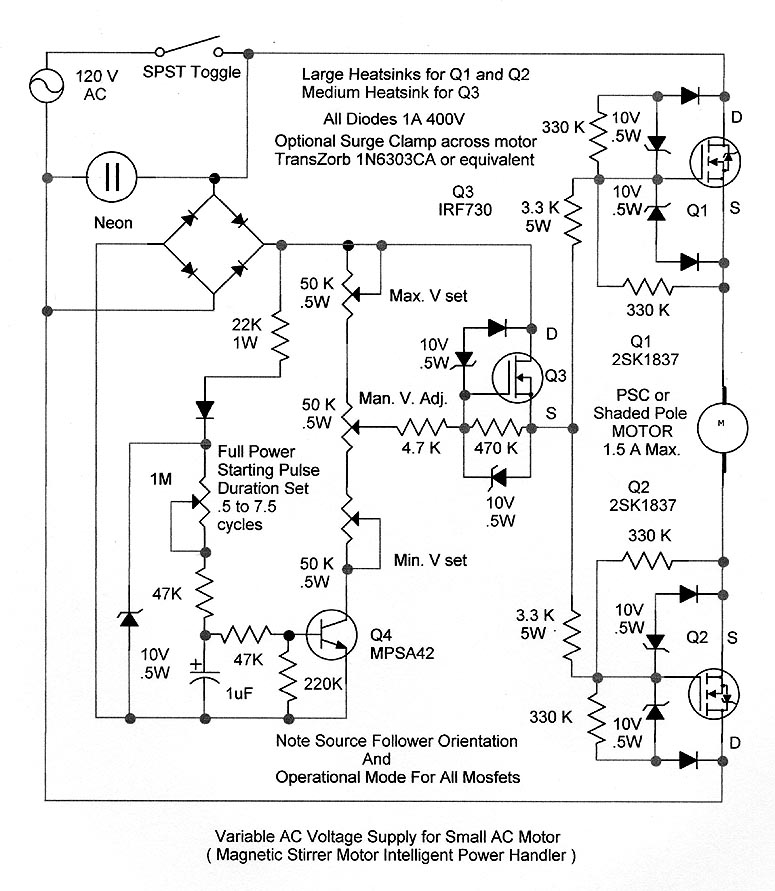

Further revision of my earlier circuit idea has brought

this design process to a point where I think the device

is ready to build , after I do a final check of my calculations

to try to find any errors or see if any values may be adjusted

to any advantage in refining what I have now .

I have added the circuit which provides a full voltage

startup pulse , adjustable upwards to a defined

burst quantity of full voltage cycles , so that when the stirrer

is switched on at a minimal speed setting , the starting

torque is greatly increased to give a clean breakaway

of the rotor into rotation , in an adjustable way that

should prevent any overshooting of the set speed .

This power control circuit combined with the PSC motor setup

having a squirrel cage fan and eddy current loading on

the lower endshaft , as I have described earlier in the thread

will result in what I believe will be a magnetic stirrer

drive scheme having superior performance and durability ,

well beyond the performance of the top of the line products

which are supplied by the major manufacturers . And if this

belief proves to be true by the performance of the prototype

which I am building , then this is state of the art in the making

( and that wouldn't be a first at this forum either )

The original attachment here has been replaced with

a corrected schematic which deletes a capacitor filter across

the power switch , for reason that it could cause a problem .

See the posts below for more about this .

[Edited on 16-2-2006 by Rosco Bodine]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I'm just going to sit down, watch this thread and laugh when it lets out smoke.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There you go with the negative vibes ,

trying to jinx my brainchild with self-doubt

I'm scrounging parts together and I'll give an honest

accounting of how it works or doesn't work .....

the unvarnished truth , such as the case may be .

Honest , if it burns it will be my first smoker and

I've put together a few things over the years .

You younger folks were making fun of my arcwire crossings

on hand drawn schematics that went out of fashion

in the 1950's . I can't read the copyright dates in

the books I learned this stuff from because I forgot how

to read Roman numerals ! So you are probably right

in hinting I needed to catch up to the times . It took

me a good two hours to learn how to use the ECAD

software to draw " respectable " schematics .

So there now .....I'm a modern , even though I still

miss riding the DC3's and DC4's and Constellations

when they were in regular airline service ! I am a

pre " jet age " sliderule operator dragged kicking

and screaming into the age of the inkjet published

virtual drawing with a schematic tucked in my pocket

that I see no reason shouldn't work like I think it

will .

So if you see a glaring fault , please elaborate .

Do you think the trickle current through the 26.5K reactance

of the .01uF cap across the open switch will trickle charge the

RC timing circuit for the startup pulse , defeating it ?

If so the cap can be omitted , it was sort of a last minute idea

I really hadn't thought about very much .

I'll probably leave it off just to eliminate that potential gremlin . Probably it is better to put a varister across the motor to clamp any spike ,

and just leave the open switch open . Yeah , I think the varister makes more sense .....

so I'll change that detail .

Thanks for the suggestion  Why didn't I think of that Why didn't I think of that

Earlier in the thread TransZorb was mentioned by densest .

Across the motor leads is probably the way to go here if

there is an appropriate voltage rating TransZorb for the task , and I'll defintely lose the cap on the switch because its a potential problem .

Update:

The attached schematic in my last post above has been updated with a corrected schematic deleting the anti-arcing capacitor which I had thoughtlessly

placed across the switch without thinking it through . A suitable value TranZorb is

recommended as an option for putting across the motor ,

but it may not be necessary . The power stage for this

device is hopefully rugged enough not to be vulnerable to

the transients associated with a small motor load . I tried

to make the vulnerable part of the Mosfets , the gates ,

as bulletproof as I could , knowing that the toggle switch

and full power setting or hot startup pulsing feature ,

would be used at times to jog the drive in on-off fashion ,

occasionally being used this way to shake a stirbar free which may be caught in a dense mass of crystals .

There are a few final changes which I am still making

in the circuit before I consider this a completed design .

So in no way consider the attached schematic above as being

a finished work . There are some revisions which

I will be posting with an updated schematic when the calculations are completed and the edits made for

the values of components I will use .

[Edited on 17-2-2006 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

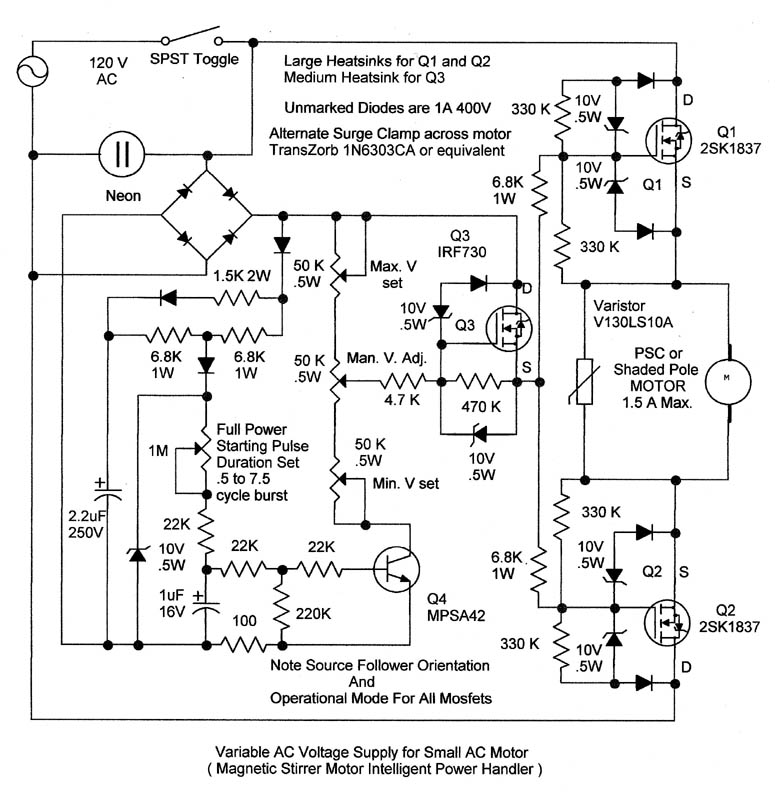

The attached schematic now shows the above mentioned

component revisions / additions . It is now closer to completion . In terms of arrangement of components

I believe the circuit is complete . However the values

for the components are not fully analyzed and checked .

So there may be some changes yet made , in the way of

further tuning and calibrating the system . I am mainly looking at optimizing the RC time constants for the startup pulse controller stage since that

is the last section added .

For you fellows who were following the circuit evolution

take a look at the timing circuit which biases Q4 .

The idea here is that on initial powerup Q4 is off and

allows the entire divider string of the control pots to

float to the potential of the positive rail , applying full

voltage reference to the gate of Q3 and followed from there

to the Output Mosfets Q1 and Q2 . While this is occuring

the capacitor in the zener regulated 10V charging path

is rising from 0 Volts towards the 1 Volt or so needed

to cause Q4 to switch , which takes the end of the divider

string for the control pots to ground , and makes their

settings effective on specifying V ref . to Q3 . The time

required for the capacitor to charge to the switching voltage

of Q4 will determine how many cycles of full power will

be delivered to the load . The larger 2.2 uF capacitor which

charges much more quickly to the full voltage of the bridge ,

acts as a virtual battery , which supplies power continuously to the 10V regulated timing circuit between cycles , so that

once Q4 has switched on , it stays switched on through the zero cross and into the next cycle , and the timer controlling

Q4 does not reset , until power to the bridge itself is interrupted and both caps bleed down .

[Edited on 17-2-2006 by Rosco Bodine]

|

|

|

densest

Hazard to Others

Posts: 359

Registered: 1-10-2005

Location: in the lehr

Member Is Offline

Mood: slowly warming to strain point

|

|

www.bestlabdeals.com/DATAPLATE_DIGITAL_PROGRAMMA_p/bmmp174.h...

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

@densest

That's a bum link . Anyway it doesn't matter what sort

of digital crutch you strap onto hardware to make up

for poor mechanicals . And on the well designed

equipment having well matched components dedicated

to the intended use , a purely analog and open loop

system is entirely sufficient . BTW I have something

like ten thousand dollars worth of commercially made

stirrers including top of the line Thermolyne and Electromantle , Fisher , and Corning , including some

brand new this years model stuff and a few pieces

that go back to 35 years ago . And for lab grade

instruments ......NONE of it is what it ought to be

in the magnets , the motors , or the speed controls ,

including the digital model . I know from studying the

equipment by tearing it down to its nuts and bolts and

cleaning and reassembling it , that I can design and build something way better quality and I mean to prove that .

I am still working on finalizing the design I have been

developing , but I don't know there isn't an easier way .

There could be . Did you look at that zener in the schematic

you posted , the one that was upside down ? Because I didn't really edit the circuit and study it through afterwards . But it seemed like a variation

on my original idea to use a bridge rectifier DC load to series regulate AC , and you had found a way to make that idea work , after I dumped that

idea and moved in the direction which brought me here to

the circuit I have now . So maybe I'm using two power

Mosfets when only one would do . I'll go back and take another look at it when I get this current design squared away since I have high confidence it

will work well . It's

always good to have more than one way of doing the same thing .

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by 12AX7

I'm just going to sit down, watch this thread and laugh when it lets out smoke.

Tim |

Hey Tim ,

Screw the SPICE simulation for this simple circuit !  ..... .....

The conceptual and mathematical analysis and a discerning schematic reading is sufficient to say " this will work , so build the damn thing "

........ and that's from the old school , " Old Spice " sliderule jockey , SPICE illiterate

as I am . If I'm wrong , then I'll have to eat my share of humble pie when you fellows nail my ass to the wall

here with well deserved ridicule ......later ,

* if * the prototype burns . ( But it won't ) I'm not

worried about a design after the point where I can visualize

the intended result as a mathematical certainty ,

the predictions are over and it's time for proof .

I'm a great believer in perf board , legwire bending ,

and soldered connection " simulations " which run the way

you " figured " when you plug the damn thing in and throw the switch !

I look at this dedicated circuit which I have designed for a niche application , and without any personal bias from ego

afflicting me with any modesty either .......

my most objective opinion would be that obviously it was a genius who designed this little work of art

And the design is damn good too , absolutely beautiful .

If she was a girl , she would be one tough bitch ,

a little top heavy maybe ....but hey I like a girl who

sports a substantial package and puts out a little heat

So for all you jokers heckling and naysaying ,

I keep looking at this thing and looking for the fault ,

trying to spot the defect and I honestly don't see a damn thing wrong with it . In my opinion it will work and it will

work as intended .....so if you see something there in

that last schematic , which just doesn't add up or looks

wrong .....hey speak up and point it out to me ,

because the simulation I have been running on this thing

in my head keeps saying it absolutely will work in the

way it was designed and intended .

I still say this thing is a work of art , a beastie from

Planet Analog as it may be .....analog is not bad ,

when analog suits the application perfectly well ,

why complicate things going digital , and lose the

stepless smoothness you have with " hydraulic logic " ?

Have you ever flown a turboprop with a constant rpm

variable pitch propellor ? Smooth as silk , and no

digital logic involved . Similar regulation concept there

as what I am about here ......there is feedback and

governing , regulation inherent in the system as

" hardware logic " so the power feed just has to

feed power , and the mechanicals automatically

do what they are supposed to do with that power

they are getting .

And for those diehards who would insist on

adding digital rpm sensing and closed loop " servo locked "

operation .....well think about the advantage

there is about a system which already has a

great deal of inherent regulation , and how much

smoother and responsive it will be to amplified feedback

since the error correction required will be so much smaller

than for a system which fully relies on active external

regulation to maintain a set speed .

It's like the situation of a cruise control on an automobile

with a 2 liter engine approaching a grade , versus the

cruise control on an automobile with a 5 liter engine

approaching the same grade , the cruise control on

the car with the larger engine is going to have less

math to do and less error to correct to maintain the

speed of the system under the changing load .

No matter how good the cruise control , when

you are a passenger riding through hilly terrain ,

the vehicle with the larger engine is going to by

its nature provide the smoother ride .

That certainty is at the heart of my purpose of

using a specially configured drive motor in a

10 inch square stirplate which is a several times

" larger " motor in terms of its actual performance

than those deficient motors typically selected by

the commercial manufacturers , while it actually

uses no more electrical power than the junk they

are using instead .

What I am doing here is like the difference between

a " mini " and a Cadillac autobahn edition in terms of

inherent " reserve power " , available torque , ect .

I'm way too old to " go back to school " if I didn't learn

what I needed to know , to know this circuit will work

when I was in school thirty plus years ago .....

So I'm just going to build this thing and throw the switch

and see what happens

I should be taking bets on this thing so I could pick up

the extra money ......because if I had to charge for this

circuit design instead of making it a freebie here for

all my nerdie online counterpart friends .....it would be costing somebody about 200K for the R&D work carried

through to successful prototype for proof of concept .

I need a gold laminated pocket protector for this one ,

and a ball cap with gold embroidery which reads ,

" Captain Nerd "  , and a silkscreened tie-dyed polo , and a silkscreened tie-dyed polo

shirt , with a pocket of course , carrying the logo

" Nerds Rule "  . Then I would be a completed work . Then I would be a completed work

with my thick glasses  However , I do have tortoise shell However , I do have tortoise shell

eyeglasses frames instead of the ebony black , since I am a

" sport model " nerd

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

| Quote: | Originally posted by Rosco Bodine

| Quote: | Originally posted by 12AX7

I'm just going to sit down, watch this thread and laugh when it lets out smoke.

|

Screw the SPICE simulation for this simple circuit !  ... ...

|

What SPICE?

| Quote: | ...

The conceptual and mathematical analysis and a discerning schematic reading is sufficient . . . |

As a matter of fact I have been doing exactly this. I have never bothered to simulate any circuit. The last time I tried I found the software almost

impossible to use. I know there are freeware versions better than the one I had, but nonetheless, I could care less when I have paper and pen in hand

and an intuition to sharpen. People tend to put too much trust in simulations, and a lot of people get really ugly errors when using it from scratch.

It takes as much knowledge either way to design a circuit since you have to expect things.

Anyway. Clearly, we come to different conclusions, so one of us must be wrong. Statistically, note that I have a few people on my side...

Oh and BTW, I hope your neon light has an internal resistor.

Tim

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

About the dropping resistor for the neon , I never

saw a 120V rated panel indicator where they weren't

built in , with the dropping resistor already inside

the threaded housing . Sometimes I have used a meter on one at the rated 120 voltage to see what is the actual current draw for 120 , and learn what

the bulb itself is dropping , to calculate the added resistance if I put the same indicator across a 240 line or other voltage .

You wouldn't be nitpicking there , no.....

and yes I wondered for about two seconds

if I shouldn't show the dropping resistor for the panel lamp .....but you know I figured anybody skilled enough to

read the schematic already knows about neons , just

like that would be a fair assumption about the person

who wrote the schematic too , who is usually the same

one who designed the device .

The truth is I don't need the simulation for a sim I can run

in my head and see fine . I can read my own schematic

like I can read a shopping list for the grocery store ,

or the radio shack ......as the case may be , and I don't see any problem in this one so far as component function

and arrangement , all the signal paths and everything

flies the way it should ....if there's anything off it will

be fixed by a different capacitor or resistor value ,

and the ones I have now may be just fine .

So you have been looking at it with the old mental signal tracer , just like I have been doing , but you are seeing a problem somewhere.... so where

exactly do you see the snag ? I may be slow sometimes , but I'm not totally braindead so if you point me at the defect , I'll see it .

Where is it ?

About the SPICE , that was specifically regarding Twospoons virtual model earlier , and I suppose misdirected frustration ,

since at least you do tell me where you see a problem , even if it isn't a problem  .....instead of saying just that my computer is smarter than your computer and my computer says it won't work ....just because it says so

.....but giving no further details .....instead of saying just that my computer is smarter than your computer and my computer says it won't work ....just because it says so

.....but giving no further details

[Edited on 19-2-2006 by Rosco Bodine]

|

|

|

IrC

International Hazard

Posts: 2710

Registered: 7-3-2005

Location: Eureka

Member Is Offline

Mood: Discovering

|

|

The standard dropping resistor for neon bulbs is 150K to 180K 1/4 watt for 117VAC, but 1/2 watt would be better from a design standpoint. I think the

size is why they use 1/4 watt instead. For 240 VAC 300K to 320K would be fine.

[Edited on 19-2-2006 by IrC]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

You know the really best looking panel lamps which

I have ever seen are made up custom jobs which

mount a high output narrow angle LED at a precise

distance behind a round fresnel lens where the

beam sort of " pops " in front like it was a virtual source

hanging in space a few mm in front of the surface !

I've never seen 'em sold , but I've made up a few of

them as a sort of " makers mark " indicators on custom equipment I have built .

After looking at the RC timing network and the signal level

which is available for switching Q4 , I don't think the NPN

is nearly as good a choice of switch as would be another

Mosfet . The base of the NPN is just trying to drink from

too small a stream of current there going to the timing capacitor and it will have marginal base current available

when the timing adjustment pot is set to provide the longest

duration startup pulse . The simple fix is just to put a Mosfet there to be Q4 and that's exactly what I'm going

to do to fix this .

Another possibility is putting a 555 there to do the timing ,

and get positive and predictable switching , whether the NPN or the Mosfet gets to be driven by the 555 . I like

555's , they are really versatile and perfect for scenarios like this one , so that's what is my inclination . Looks like this one

just won't be staying chip free , but a 555 is pretty basic .

[Edited on 19-2-2006 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

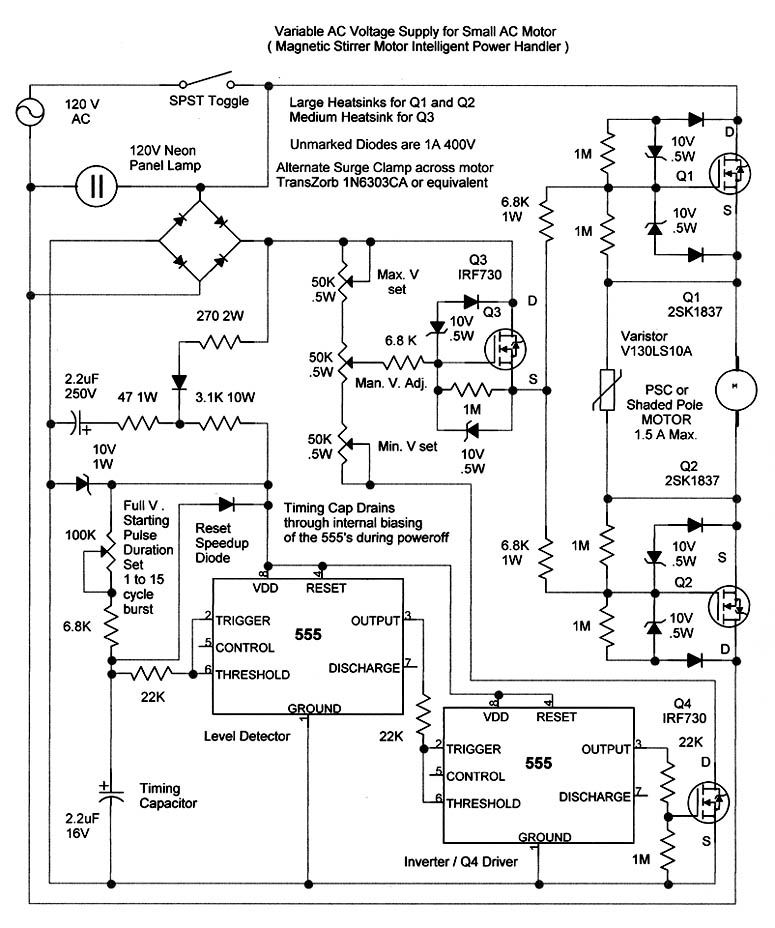

On the 19th day of clicking keys and calculations ,

I think I just nailed it .

I was trying to get the job done using no chips

if possible , but every thing I looked at was

just inferior to using 555's for the timing ,

so now that problem is hopefully solved the simplest

way . Wish every time I run into needing a

non-inverted output I didn't have to scratch build

a timer using an op-amp , or use a dual 555 .

Anybody else like to see a 10 pin package evolution

version of the of the 555's , with dual outputs ,

inverting and non-inverting so you could use

which output you need .....or both ?

I believe I have this thing supplied in a way that

it will initialize and power up logic stable , in under

2 milliseconds , perhaps 3 at the most , with sufficent

reserve in the high voltage " virtual battery " capacitor

to maintain the 555's operation and the timing status

until steady state operation matures with the first complete

cycle . If I did my math right , no decimals out of place ,

it should work fine with the values I have assigned .

Anyway see if this revision looks better ,

because I do believe this one nails it .

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

Personally, I would go for an all Transistor/MOSFET approach seeing you put so much emphasis on rigidness and reliability. There are many Mono-stable

and Bi-stable Mulivibrator designs out there that use only 2 or 3 Transistors and Polystyrene or Mica Caps with very precise timing. If you however

insist on using Chips, why not go for the all in one Chip approach. There is a whole array of pre-designed Motor Control Chips, just waiting for this

job. But then you will be deviating from your previous design Philosophy, and Unique approach. Hell, you can even "Match" Transistors for minimal

temperature drift and precise timing applications. Keep it as simple as possible, then the least can go wrong. You have now just introduced more than

30 Transistors into you design. Unless you use MIL spec. 555's, you will be introducing temperature and reliability boundaries.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There used to be a dual CMOS version of the 555 ,

maybe LM7556 .....IIRC , but I haven't seen any being dumped as cheap surplus , or I would have used those

and not have to dump so many watts in the transformerless

power supply in the drop from 170 Volts to 10 Volts for

the timers .

I tried to tie into that supply in a way that wouldn't make the ripple worse than it is bound to be , figuring the 555's are stable enough to ride the

waves that get across the zener .

There's a lot of difference between 1/3 and 2/3 of the rails ,

so the huge hysteresis there should keep the logic state

latched , even with a crude and noisy supply like I have

improvised to keep from buying a 3 dollar transformer

But there's too much delay in the power up of a separate

DC supply , so I couldn't use that approach anyway . The

duration of the startup event is so short , and begins occurring at the instant power is applied , so unless the

mains to the motor were delayed until the logic stage was

powered up and the chips initialized , a conventional power

supply could not be used .

I looked at all the motor controller chips before beginning

this effort , since none of the motor chips have the capabilities of doing this from a purely hardware level .

You have to program an EEPROM to essentially be a BIOS

for your motor control system , and even then there's things

you can't do with the turn of a pot , that I can do here .

I have used 555's before in motor controls which are associated with refrigeration compressors , to sense

power interruptions as a " missing pulse detector " which

monitors the 60 Hz , and if the compressor is running when

any interruption occurs , the 555 assumes a compressor stall

before the event , and times the compressor out for two minutes , before allowing it to cycle again and see if the

current it is getting is within specs . So I don't see any

problem with using 555's in a motor control circuit , since

there already are numerous commercial devices which use the 555's in motor controls and they have no problems .

Edit above : LM7556 was the number for the dual CMOS

version of the 555 .

Anyway if it bothers you to think of a chip going into a

control system like this ......just try to think of a 555 as

a transistor with a few extra pins and a college education ,

a transistor array that will do what you wish a transistor

would do , but can't do that concert singing solo

[Edited on 20-2-2006 by Rosco Bodine]

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

OK, wants you are spinning it's apparently impossible to deviate you off course. The 556 is indeed the dual version of the 555 and can be purchased

via CONRAD Electronics International Mail Service for 1.51 Euro.

Conrad Electronics International Home:

http://www1.int.conrad.com

Search:

Electronics/& Metering --> Components ---> Active Components ---> IC's ---> IC's - Linear ---> Timer IC's ---> ICM 7556 IPD

In Audio Amplifiers it's fairly common to use power up delay circuitry which only turns on the final stage after the whole System has charged up

sufficiently, so nothing new here.

You can also use a Transformer with a primary of 110/220 volts input and a 110 Volts and 6-12 Volts secondary output. Now we are talking

International, with only one flip of a "Shift Switch" on the back side of the Magnetic Stirrer (50/60 Hz included).

I have uploaded ~100MB of Books and Motor Control Circuitry Designs to Madhatter's FTP services.

I cant Sing, so you will have to go on a Solo Tour by yourself.

[Edited on 20-2-2006 by Lambda]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

| Quote: | Originally posted by Lambda

In Audio Amplifiers it's fairly common to use power up delay circuitry which only turns on the final stage after the whole System has charged up

sufficiently, so nothing new here. |

Yeah that's a nice feature in high power audio amps

having the filtered relays to eliminate speaker pops

that would appear during switching transients .

Of course it would be possible to get more elaborate

and go that route , but you couldn't hide the fraction of a second perceptible switching delay which would appear

at the toggle to the user , and the effect would be

" strange " to someone who doesn't know why they

have to stand there growing older by a hundred milliseconds

just bored and waiting for the stirrer to finally decide to

start turning  A fast gun or a son of a gun could clear A fast gun or a son of a gun could clear

a room full of trouble and be reloading in half that time

| Quote: |

You can also use a Transformer with a primary of 110/220 volts input and a 110 Volts and 6-12 Volts secondary output. Now we are talking

International, with only one flip of a "Shift Switch" on the back side of the Magnetic Stirrer (50/60 Hz included). |

Hey this circuit is Euro adaptable , just double the Ohm and Watts value for the the 3 power resistors below the bridge to allow for the increased

voltage , use a higher voltage capacitor . Also double the Ohm value or double the Watt rating of the 6.8K gate resistors for the output Mosfets , and

use 1 Watt pots on the main adjustments , and a higher voltage varistor for the higher voltage motor .......that's it .

| Quote: |

I have uploaded ~100MB of Books and Motor Control Circuitry Designs to Madhatter's FTP services. |

Yeah thanks for those . I have enough reading there to keep me busy for years

| Quote: |

I cant Sing, so you will have to go on a Solo Tour by yourself.

|

On some of the " industrial control " applications I like to

keep control circuits purely hardware logic where possible

and stick with linear chips . Everybody remembers the

" millenium bug " worries and what programmables might

be affected ......so there's no point in making basic control

circuits more complex than they need to be , just make

'em smart enough to do the job .....and too dumb to argue

It's the chauvinism of satisfied chip masters everywhere ,

enjoying the waltz of the flowers with satisfaction that these

obedient little minions know their place

[Edited on 20-2-2006 by Rosco Bodine]

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

OH man, ... Rosco !, ... you are just too bad, ... just too bad man.

How do I deal with this spinning wheel without cutting myself on those fine threads.

So now, ... you want to go IC, ... how about going PIC ? (don't read "Dick").

Eric's PIC Page:

http://www.brouhaha.com/~eric/pic/

Articles:

http://www.rentron.com/Myke3.htm

I have many Motor Control designs using PIC's, so just call the shots, and I will Shoot. You can tell (Program) this monkey to do anything, and if the

climb doesn't suit you, then just reprogram. You can preset a variety of programs, all to chose from, depending on what is desired. Maybe you want

your Hotplate to rise in temperature at 8 Degrees per 7 Minutes up to 73 Degrees, and gradually want the Stirrer to decline in speed from 600 rpm to

300 rpm during this period etc.

Now, I hope you won't get grey hairs over this one, ... will you. You can also start off by taking a few of mine, that will give you a "Head

Start".

Rosco !, ... you are just too bad, ... just too bad man.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

LOL , I don't want an RS232 interface on my damn soldering iron

I want pure hardware logic all the way on this thing .

There was a news item today about a 62 year old

great grandmother having a baby .....

and I couldn't help thinking ,

" I wonder who's the lucky father ? " ....

I should be safe on that count , but there's always

the off chance of being the guilty party , you know

how these things go  with paternity tests and all with paternity tests and all

|

|

|

Lambda

National Hazard

Posts: 566

Registered: 15-4-2005

Location: Netherlands

Member Is Offline

Mood: Euforic Online

|

|

Now, ... this is very nice of you, thank you for congratulating me on my new born baby.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

My wife chuckled at the news and said later we

will probably hear that the woman was arrested

after it was learned the father was age sixteen ,

one of a procession of frequent visitors who

" came for milk and cookies " from the " nice old lady "

So how is it that a woman of her age becomes pregnant ,

well it must be like playing the piano , it just takes

practice .....practice ....practice , until you get there

The news did say she already had TWELVE children ,

so it would seem she has had plenty of practice

Anyway , not to get totally off-topic here ......there are

available TTL input points provided now with the circuit at its present evolution , the gate of Q4 being the most obvious

point where modulation from a feedback signal could be

applied to " servo-lock " a set speed which is tachometer

regulated . Any sort of programmed time and speed profile

which may be wished could be input to the gate of Q4 .

And there are other ways in which the circuit could be

accessorized with extended functions , but would not

be crippled with any of those options " NOT enabled " .

I wanted a circuit which would give good performance

inherently , good enough stand alone for just about anything , but also could be adapted to enhanced functions with later " add ons " , like

servo-locked tachometer based speed control or timed period sequenced speed profiles .

I would make those functions switched options on a

separate controller stage , a separate functional " block "

from the power stage I have shown here . Those options

and their schematic would be on page 2 , not yet written ,

and connected to page 1 by 3 or 4 wires if you follow my

meaning .

[Edited on 21-2-2006 by Rosco Bodine]

|

|

|

Twospoons

International Hazard

Posts: 1327

Registered: 26-7-2004

Location: Middle Earth

Member Is Offline

Mood: A trace of hope...

|

|

I preferred your turn on delay with just the cap and transistor (or you could use a fet).

And in defence of SPICE: its just a another tool in my design arsenal. Like any tool it has its place and its limitations.

Do you use a calculator, or do you work out square roots in your head? (I estimate in my head, then use a calculator - if there's a big discrepancy I

do it again!)

[Edited on 21-2-2006 by Twospoons]

Helicopter: "helico" -> spiral, "pter" -> with wings

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There's a need for biasing a transistor which will

be used as a switch so that it has positive feedback

to the gate , so when it begins to switch it will make

a positive transition just like a relay , and hold that state

at a lower signal level than was required to transition in the first place , behaving a corresponding way when making the reverse transition . This

can be done using discrete components , on one transistor but better by using a complementary pair to create a bistable sort of

flip flop which toggles abrubtly to on or off and latches

there until a new transition signal level signal forces

a change of state . This is such a common task that

to save labor and the cost of using discrete components that chips like operational amplifiers and " timers " have been developed optimized for the

task . The label

of " timer " is actually a misnomer for the 555 type chip

since that timer function is only one of the applications

where it is defined in function by what external components are selected . I more usually use it as

a switching device having defined level transition

states at 1/3 and 2/3 of the supply rails , a signal

comparator which drives a flip flop controlled output .

It is a logic device arrangement of a very basic but useful form , a sort of rudimentary analog to digital converter . This takes all the uncertainty

out of the switching of

a single transistor which can fail to switch properly

under slowly changing or noisy signal conditions .

No chance of that happening with a flip flop , it has a binary output only , logic 0 or logic 1 state ......

fully off or fully on , and nothing in between .

I do use a calculator . The first scientific calculator I owned

was in about 1974 and it was a Texas Instruments Scientific with 1/2" Blue LED readout . It took four penlight batteries

to operate it , and IIRC in todays dollars it would have cost

over a thousand dollars at the time . But I often do the

familiar calculations in my head because I know the answer

in shorter time than it would take to key in the problem and

hit the equal key

[Edited on 21-2-2006 by Rosco Bodine]

|

|

|

| Pages:

1

..

5

6

7

8 |

|