| Pages:

1

2

3 |

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Failed nitro-aldol reaction. Possible cause and fix?

Having finally made about 40 mL of nitroethane, I couldn't resist the temptation to try the Henry reaction (using benzaldehyde as an aldehyde), even

though the reagents might not have been absolutely dry and pure. I just wanted to know whether it works at least partially.

I've set up a reflux apparatus with Dean-Stark trap. I've used the following reagents:

- 80 mL toluene (reagent grade)

- 40 mL benzaldehyde (unknown purity, however washed, dried and freshly distilled under vacuum)

- 30 mL nitroethane (unknown purity)

- 10 mL n-butylamine (freshly opened bottle)

I've basically followed the Rhodium's writeup on Erowid to the letter.

Unfortunately, I was not sure about my nitroethane quality. I distilled it several times using oil bath as a heat source, but most of the oily liquid

came over at oil bath temperature exceeding 150 °C. I don't know what other compound could be there at such high b.p. besides nitroethane, so I've

let everything come over assuming the purity will be somewhere in the 70-90% range.

As for the benzaldehyde, I dried it using anhydrous magnesium sulfate, filtered and vacuum distilled at 100 mbar using a cow adapter to collect

fractions. Unfortunately, even after 15% of the volume coming over, the final distillate still contained some visible cloudy droplets that cleared

after a while (water?).

Anyway. I mixed the reagents and added n-butylamine catalyst at the end, which turned the mixture yellow-orange immediately as expected.

I refluxed the mixture for 7 hours, collecting about 4 mL of water in the trap (I should have got something like 7 mL indicating the reaction was not

completed as expected - no more water was collected even after additional 2 hours of refluxing, so I stopped it).

I removed half of the solvent (toluene) using rotavap leaving about 70 mL of liquid. Unfortunately, the desired nitro-compound product

(1-phenyl-2-nitropropene) have not appeared even after scraping. I thus removed more toluene, leaving only about 50 mL in the flask. This means all

the toluene was probably removed and the remaining liquid is mostly the unreacted benzaldehyde. The solution became reddish-brown and much thicker,

smelling strongly of benzaldehyde. No crystallization or precipitation happened even after leaving the mixture in a freezer for several hours (-18

°C).

I tried removing more solvent, but none came over even at 100 mbar and water bath temperature of 92 °C. This made me suspicous. Maybe my nitroethane

was very impure and there was excess of benzaldehyde left behind. Benzaldehyde has much higher b.p. than toluene and would not come over at the said

conditions which also makes sense.

I am thinking about adding cold methanol to the mixture to crash out any possible product, then recrystallize it from methanol.

Of course, my error was being too eager to try this classic reaction before making sure my reagents are pure. Unfortunately, nitroethane is very hard

to obtain for an amateur and I already tried three different route to make it. After months of preparations and (failed) trials, I was really

impatient to try the nitro-aldol reaction. Last trial of making nitroethane was the classic Victor-Meyer substitution reaction of iodoethane and

silver nitrite in diethyl ether. The yield of nitroethane was very poor even after prolonged reaction time and strong mechanical stirring (less than

10 mL distilling at 112-116 °C when starting with 90 g of AgNO2).

My suspicion is that either reagents or solvent were not completely dry, driving the reaction towards different product than the dehydrated one.

I am now thinking on how to proceed in saving the little product made and what are the possible causes of failure.

|

|

|

karlos³

International Hazard

Posts: 1520

Registered: 10-1-2011

Location: yes!

Member Is Offline

Mood: oxazolidinic 8)

|

|

I made the same mistake the first time.

It seems to contain some polymeric crap judging by the colour, probably enough to hinder it from solidifying.

Also, don't use toluene for the preparation... use ethanol(not dry), that works much better and the product crystallises also a whole lot easier out.

Would first remove the toluene completely, then add some H2O to the oily liquid nitroalkene and separate that oil, wash it with more H2O, then take it

up in a few times as much EtOH(96% denat. works well enough) and then cool it down.

That should do the trick, then it is even likely it will take only a day or less.

In my opinion, you should never reflux this reaction at all, only the hot waterbath until it is at most orange coloured.

Also, the removal of water isn't as important as some writeups make it look like, there is really no need for the dean-stark trap in practice, it is

useful only if you like to use fancy glassware

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

It can easily been done in toluene, but I only did it with ammonium acetate. I got it to crystallize by dumping the cooled down reaction in ice water

(or maybe dumping ice water in the reaction mixture.. shouldn't matter I guess). Also your amount of amine sounds a bit high, but I never tried

butylamine

I also just did it using simple reflux for an hour or two. I can remember it would give about 60% yield

Toluene reaction dumped in water definitely needs recrystallization, but crystallization was immediate (causing it to enclose the polymeric crap).

Ethanol is lovely to recrystallize, I used old samples of this stuff for display purposes by dissolving them in hot ethanol, letting it crystallize

into lovely yellow needles is a tube and then poor of the remaining solution in order to get a nice tube filled with nice yellow needles.

I think I did about 1:1.1 molar ratio benzaldehyde : nitroethane and 0.1 molar ratio ammonium acetate. No water was removed, and the ammonium acetate

wasn't fully dry.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Quote: Originally posted by nimgoldman  | | Last trial of making nitroethane was the classic Victor-Meyer substitution reaction of iodoethane and silver nitrite in diethyl ether. The yield of

nitroethane was very poor even after prolonged reaction time and strong mechanical stirring (less than 10 mL distilling at 112-116 °C when starting

with 90 g of AgNO2) |

V Meyer (1874) did not use ether. The directions (Systematic Organic Chemistry or Lassar-Cohn's Laboratory Manual of Organic Chemistry) do not call

for stirring because of the exothermic gas generating reaction. OTOH the only other author using EtX and nitrite is Ray and Neogi's comparison using

mercurous nitrite, which works not as well as silver.

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Thanks for the help. I will try that. Fortunately, I have plenty of 96% and 99% ethanol at hand.

Yes I planned to use ethanol as the reaction solvent at first, but I really wanted to test my Dean-Stark trap and efficiency of a short reflux coil

condenser.

Quote: Originally posted by S.C. Wack  | Quote: Originally posted by nimgoldman  | | Last trial of making nitroethane was the classic Victor-Meyer substitution reaction of iodoethane and silver nitrite in diethyl ether. The yield of

nitroethane was very poor even after prolonged reaction time and strong mechanical stirring (less than 10 mL distilling at 112-116 °C when starting

with 90 g of AgNO2) |

V Meyer (1874) did not use ether. The directions (Systematic Organic Chemistry or Lassar-Cohn's Laboratory Manual of Organic Chemistry) do not call

for stirring because of the exothermic gas generating reaction. |

Do you think making a slurry of EtX and AgNO2 is enough for the reaction to happen? I think a large excess of EtX must then be used to cover the

nitrite salt as otherwise the AgNO2 will suck it up locally and most of it won't react. Some say both components have to be dissolved, at least

partially, to react.

I though the EtX is dissolved in ether and dropped onto nitrite suspension in ether to slow down the exothermic reaction and stirring is for the

reagents to come together.

Don't you think hot spots and thus rapid evaporation of reactants will more likely happened if EtX is just dropped over the nitrite?

What solvent did Victor Meyer used then, if any?

I would try that if the reagents weren't so expensive. It also takes time to prepare them correctly (just drying silver nitrite takes over a week, not

to mention recycling the silver) so I like to try only tested methods... ChemPlayer showed the reaction works very well with ether though I was not

able to reproduce the result. There are some high bioiling side products in the nitroethane.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

With all the silver and iodine, if someone is going to give advice it should be sodium ethylsulfate or bromopropionic acid, and reading...SOC (1937)

and LMOC (1895) were good books and in their way still are, so you should download them or perhaps read somewhere like archive.org. SOC as one of my

scans is at my site and many other places. LMOC is from google books (where I downloaded it from) and it too has floated around.

The reaction is known in solvents, with other halides and nitrites, and people do try to pretend so and so process extends to nitrothane, but I have

little faith in many things. I wonder why the literature as originally written makes everything but nitro(m)ethane and makes no claim that their new

method might make them. I also wonder if the nitroethane compilation page in the Rhodium archive has ever actually helped anyone make nitroethane.

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Quote: Originally posted by S.C. Wack  | | The reaction is known in solvents, with other halides and nitrites, and people do try to pretend so and so process extends to nitrothane, but I have

little faith in many things. I wonder why the literature as originally written makes everything but nitro(m)ethane and makes no claim that their new

method might make them. I also wonder if the nitroethane compilation page in the Rhodium archive has ever actually helped anyone make nitroethane.

|

Well the reaction works. ChemPlayer has reproduced it with 57% yield,. Full Metal Alchemist had success with the sodium ethyl sulfate method, though purity and yield was not determined.

Sure I will study more. I tried three methods from Rhodium's page but none produced any reasonable yield of nitroethane (few drops actually). The only

method that worked was the ethyl iodide + silver nitrite in ether which I originally found on PrepChem.com.

I would try the 2-bromopropionic method, but so far I invested so much time into learning the chemistry of silver and reagent preparations, that I

don't want to give up the promising and already somewhat working method.

|

|

|

chemplayer...

Legendary

Posts: 191

Registered: 25-4-2016

Location: Away from the secret island

Member Is Offline

Mood: No Mood

|

|

Can't remember where we read it but apparently the ether solvent for the Victor-Meyer reaction is essential for a good yield. The reaction is also

exothermic so you do really need to do this in a closed flask with magnetic stirring and an efficient cooled reflux condenser.

The first time we experimented with it on a very small scale (not shown on the video) we added the silver nitrite to the ethyl iodide ether solution,

and put this in a sealed flask in the freezer. About 5 minutes later... BANG!

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

BTW the chloropropionic acid works too but the bromo is easier to make without alanine so I think of that first.

Quote: Originally posted by nimgoldman  | | The only method that worked was the ethyl iodide + silver nitrite in ether which I originally found on PrepChem.com. |

Trumpism spreads to chemistry...the only nitroethane page at prepchem is copy/paste from SOC, where there is no ether, also none in reports of 71-90%

yields of nitromethane...PS the LMOC version is true to Meyer's larger scale description and is a translation; SOC is an adaptation that may have been

performed as written by someone else.

Good luck producing anything resembling an essential for good yield quote from a real chemist taking real care (not something made up and posted on

Rhodium, ending in "The yield is about 83% of theory" BS) or any comparison of with and without ether by the same hands, anyone. Sounds like an idea

for a video

[Edited on 17-2-2019 by S.C. Wack]

|

|

|

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Ummm. Stick the tip of a glass stirring rod into the solution. Remove and allow to air dry.

Crystalline haze should form on rod.

Use rod to stir the cooled solution. It should crystallize.

If it doesn't, you screwed up somewhere.

Not to worry. The path to success, is well-paved with failure.

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Okay I will try seeding the solution with a crystal. Good idea!

Quote: Originally posted by S.C. Wack  | Trumpism spreads to chemistry...the only nitroethane page at prepchem is copy/paste from SOC, where there is no ether, also none in reports of 71-90%

yields of nitromethane...PS the LMOC version is true to Meyer's larger scale description and is a translation; SOC is an adaptation that may have been

performed as written by someone else.

Good luck producing anything resembling an essential for good yield quote from a real chemist taking real care (not something made up and posted on

Rhodium, ending in "The yield is about 83% of theory" BS) or any comparison of with and without ether by the same hands, anyone. Sounds like an idea

for a video

|

I am sorry. I used multiple sources and they got mixed up. I checked and realized indeed the SOC have not mentioned ether. Indeed I will try that

approach too, not using an solvent.

I tried and compared several methods now and making notes about results from each. It's funny that I often discover the actual working method after

trying everything else and the one working is the very last one... kind of like Murphy's Law.

I will try the sodium ethyl sulfate approach and then possibly the bromo-propionic acid approach. I can source propionic acid from a chem supplier,

but this route requies making bromine and I have to wait till having more spare time to prepare it.

Sonce I am not an academic and not used to browsing journals and articles, I can only work with what I found on via internet searches... I do my best

even though I know I will never be a "real chemist" unfortunately, I just do what I love...

|

|

|

strychnineissweet

Harmless

Posts: 3

Registered: 22-2-2019

Member Is Offline

|

|

I have performed this reaction every which way you can concieve of, what you are doing is probably the worst yielding and most complicated.

Do the reaction neat. Do not use a solvent. Mix your 40mL benzaldehyde with 40mL nitroethane in a flask. Carefully add 7mL of your amine (I used

piperidine because it's what I had on hand). DO NOT reflux the mixture!!!!! This is where you are polymerizing everything and ruining your reaction.

Heat it in the flask just until it starts to bubble, and remove from heat and submerge in cool water for a few moments. Place back on heat until it

barely starts to bubble, and return to the cool water. Perform this action a total of three times. Be sure you are swirling the mixture in the flask

throughout the procedure. After the third hot/cold cycle, place reaction flask into a freezer and leave it there for about an hour. You will have

long, needly beautiful crystals. Most of your reaction mixture will solidify, you will only have a little bit of liquid left. Filter the crystals and

recrystallize with IPA.

The color you are to avoid is orange. The reaction should be piss yellow. Any orange is indicitave of polymerization, and means you have heated too

much. If you start to see any orange develop, or the yellow starts to get darker, STOP. Place into freezer and harvest what is in the reaction - you

can attempt to rework the remaining liquid, but chances are you won't get anything out of it.

I have performed this reaction easily 30 times - if I can be of any assistance I will do anything I can to answer questions and be helpful.

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Evaporating the mixture is not an option as it haven't evaporated at all even after heating - then it all eventually vaporized in dark smoke when

heated up too much. I think it's mostly benzaldehyde so the b.p. is too high and air-drying runs the risk of benzoic acid formation.

I am not sure why, but the product eventually crystallized out of solution anyway. I just moved the beaker several times between fume hood and a

freezer, doing few test-tube experiments, and it suddenly crystallized.

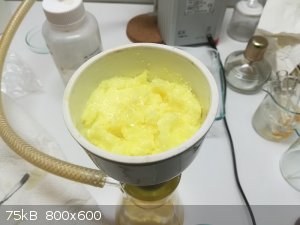

I filtered the product and washed with cold MeOH. It indeed looks like phenyl-2-nitropropene:

One of my test tube experiment was successful in precipitating phenyl-2-nitropropene (probably). I simply added some methanol to decrease solubility

of the said compound:

Therefore I added methanol to the filtrate and got a second crop of crystals:

I will recrystallize everything from MeOH since I have serious doubts about purity. The yield about 1/4th of the expected, but I am glad the method

even works!

Well this is the method I've seen many people do so I assumed it should work. I also wanted to test my Dean-Stark trap, among other reasons. I was not

concerned about yield at that point, I just wanted to see if it even works, focusing on improvements later.

My favourite method uses absolute ethanol as a solvent and water scavenger.

How could this work? The product is solid so how is it that your reaction mixture does not solidify, preventing stirring?

I understand that the solvent is there for the reagents to react completely, keeping everything in solution, and to allow removal of water.

How is your product dehydrated in the reaction? The nitroaldol reaction intermediate has to be dehydtrated. The reaction is condensation reaction,

producing water, which I guess should be removed from the mixture to yield the desired produce phenyl-2-nitropropene. In the

toluene-Dean-Stark-approach, the dehydration is achieved by distilling off the water (because of lower b.p. than toluene). Another methods use

absolute ethanol to "soak up" the water as it has high water affinity.

Thanks for your help offer!

I am planning reducing the product using Urushibara nickel (since it is not very toxic compared to mercury and not dangerous like LAH) - I will then

try to confirm the resulting product (the corresponding amine) using TLC and reagents from DanceSafe to confirm the product.

[Edited on 23-2-2019 by nimgoldman]

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

That is P2NP! Those needles are indistinguishable.

[Edited on 23-2-2019 by Tsjerk]

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

Yes I am happy for the success. It means the benzaldehyde extraction from kernels of Prunus spp. and the nitroethane synthesis were both successful.

|

|

|

morganbw

National Hazard

Posts: 561

Registered: 23-11-2014

Member Is Offline

Mood: No Mood

|

|

Perhaps not failed after all.

Be safe.

|

|

|

Chemi Pharma

Hazard to Others

Posts: 350

Registered: 5-5-2016

Location: Latin America

Member Is Offline

Mood: Quarantined

|

|

Quote: Originally posted by nimgoldman  | I am planning reducing the product using Urushibara nickel (since it is not very toxic compared to mercury and not dangerous like LAH) - I will then

try to confirm the resulting product (the corresponding amine) using TLC and reagents from DanceSafe to confirm the product.

[Edited on 23-2-2019 by nimgoldman] |

Really? Urushibara nickel? Why don't you try something less outdated, easier and high yielding like nickel boride? Here's your recipe:

Attachment: amphetamine synthesis from phenylnitropropene - NaBH4 + NICL2.doc.doc (189kB)

This file has been downloaded 679 times

[Edited on 26-2-2019 by Chemi Pharma]

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Quote: Originally posted by Chemi Pharma  |

Really? Urushibara nickel? Why don't you try something less outdated, easier and high yielding like nickel boride? Here's your recipe:

[Edited on 26-2-2019 by Chemi Pharma] |

I wanted to suggest the same, but was sort of hoping for someone to get the Urushibara nickel to work... Just for scientific sake. But I wouldn't be

the one to try to get the Urushibara nickel thing to work.

[Edited on 26-2-2019 by Tsjerk]

|

|

|

strychnineissweet

Harmless

Posts: 3

Registered: 22-2-2019

Member Is Offline

|

|

Quote: Originally posted by nimgoldman  | Evaporating the mixture is not an option as it haven't evaporated at all even after heating - then it all eventually vaporized in dark smoke when

heated up too much. I think it's mostly benzaldehyde so the b.p. is too high and air-drying runs the risk of benzoic acid formation.

I am not sure why, but the product eventually crystallized out of solution anyway. I just moved the beaker several times between fume hood and a

freezer, doing few test-tube experiments, and it suddenly crystallized.

I filtered the product and washed with cold MeOH. It indeed looks like phenyl-2-nitropropene:

https://imgur.com/9wiK16y

One of my test tube experiment was successful in precipitating phenyl-2-nitropropene (probably). I simply added some methanol to decrease solubility

of the said compound:

https://imgur.com/FDnpxTm

Therefore I added methanol to the filtrate and got a second crop of crystals:

https://imgur.com/eMeqEa2

I will recrystallize everything from MeOH since I have serious doubts about purity. The yield about 1/4th of the expected, but I am glad the method

even works!

Well this is the method I've seen many people do so I assumed it should work. I also wanted to test my Dean-Stark trap, among other reasons. I was not

concerned about yield at that point, I just wanted to see if it even works, focusing on improvements later.

My favourite method uses absolute ethanol as a solvent and water scavenger.

How could this work? The product is solid so how is it that your reaction mixture does not solidify, preventing stirring?

I understand that the solvent is there for the reagents to react completely, keeping everything in solution, and to allow removal of water.

How is your product dehydrated in the reaction? The nitroaldol reaction intermediate has to be dehydtrated. The reaction is condensation reaction,

producing water, which I guess should be removed from the mixture to yield the desired produce phenyl-2-nitropropene. In the

toluene-Dean-Stark-approach, the dehydration is achieved by distilling off the water (because of lower b.p. than toluene). Another methods use

absolute ethanol to "soak up" the water as it has high water affinity.

Thanks for your help offer!

I am planning reducing the product using Urushibara nickel (since it is not very toxic compared to mercury and not dangerous like LAH) - I will then

try to confirm the resulting product (the corresponding amine) using TLC and reagents from DanceSafe to confirm the product.

[Edited on 23-2-2019 by nimgoldman] |

I'm not sure what you mean by how is it dehydrated.....the dehydration isn't solvent dependent. The majority of your reaction mixture will solidify,

but only upon final cooling. You will be left with some orange-red liquid, but the lions share will solidify. This is the best yielding reaction

method that I personally have found.

I don't have any thoughts as to Urushibara Nickel, but I can say that the NaBH4 + NiCl2 doesn't work. I lost many hours and lots of starting material

trying to get it to - don't waste your time with that one. Your best bet really honestly is using Hg/Al. You can deal with the waste Hg by treating

it with sulfur and turning it into cinnabar - a naturally occurring ore. Hg/Al is also going to be your best yielding, just shy of LAH.

Also, do future-you a favor and save a seed crystal of your nitropropene to help your future reactions crystallize. That is beyond all other methods

the best and easiest way to induce crystallization.

Your product is most certainly P2NP, you should be happy with those crystals - they look good. I always used IPA to recrystallize, but I don't see

why MeOH wouldn't work just as well. Any other questions I can answer please ask - I love helping other chemists work through places I've been

before!

|

|

|

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

Hunh?

You intend to reduce the product to an amine?

Not legal, where I live.

But, not to worry.

Generally speaking, that reduction always fails.

LiAlH4 works. Electrolytic Reduction sort of works, if you have the right gear; though most set-ups fail. And, I have read papers, possibly

legitimate papers, suggesting some success with high pressure hydrogenation.

If the guys say Hg/Al works, to reduce Nitropropenyl benzenes to amines, it might be worth a try.

Past experience, on legal substrates, has shown me that NaBH4/NiCl2, CoCl2/NaBH4, and Pt/H2, are not effective at achieving the complete reduction of

Nitropropenyl benzenes to amines.

Also, a most effective method of producing Nitropropenyl benzenes, is just mixing yer ingredients with a minimal amount of absolute ethanol, and

letting the mixture sit for a week to 10 days at 100-120 F (absent air and light). Then let the mixture cool, and leave it undisturbed while it

solidifies into a solid block of large crystals. Rinse and use.

[Edited on 26-2-2019 by zed]

|

|

|

karlos³

International Hazard

Posts: 1520

Registered: 10-1-2011

Location: yes!

Member Is Offline

Mood: oxazolidinic 8)

|

|

Use NaBH4/CuCl2, it happens to become the new standard among a group of clandestine chemists, putting the Al/Hg to rest for now.

|

|

|

Chemi Pharma

Hazard to Others

Posts: 350

Registered: 5-5-2016

Location: Latin America

Member Is Offline

Mood: Quarantined

|

|

Quote: Originally posted by strychnineissweet  | I'm not sure what you mean by how is it dehydrated.....the dehydration isn't solvent dependent. The majority of your reaction mixture will solidify,

but only upon final cooling. You will be left with some orange-red liquid, but the lions share will solidify. This is the best yielding reaction

method that I personally have found.

I don't have any thoughts as to Urushibara Nickel, but I can say that the NaBH4 + NiCl2 doesn't work. I lost many hours and lots of starting material

trying to get it to - don't waste your time with that one. Your best bet really honestly is using Hg/Al. You can deal with the waste Hg by treating

it with sulfur and turning it into cinnabar - a naturally occurring ore. Hg/Al is also going to be your best yielding, just shy of LAH.

Also, do future-you a favor and save a seed crystal of your nitropropene to help your future reactions crystallize. That is beyond all other methods

the best and easiest way to induce crystallization.

Your product is most certainly P2NP, you should be happy with those crystals - they look good. I always used IPA to recrystallize, but I don't see

why MeOH wouldn't work just as well. Any other questions I can answer please ask - I love helping other chemists work through places I've been

before! |

I Agree with almost everything you wrote. You seems have a lot of experience in this process. I did many and many experiences in this way years ago in

the University lab, just with scientific purposes of course, just to know if I was able to produce amphetamine salts.

At those times the studies with borohydrides and transition metal couples were at the beggining and was hard to find reliable references and

experimental sections inside the researchs I barely get found at the web.

However I got found some articles talking about nickel boride and it's reductive power. I have experimented the P2NP reduction with NABH4 and NICl2

the same way the recipe I brought attached in my last comment and I got amphetamine. The smell of the amine is unmistakable but the yield sucks and I

had some troubles with the work up.

First of all, every time I stripped of the methanol and add an acid, I got a red dark resin that ruins down all the reaction. Cause this I change the

method from A-->B-->A to B-->A-->B. Researching a lot I discovered this dark red resin is some kind of nickel organic complex. Other thing

to know it's not to use HCl in the work up followed or by Dicloromethane, cause amphetamine chloridrate is somewhat soluble in DCM. Use dilute

sulfuric acid and work with the amphetamine sulphate.

I want to know from you about your negative experience reducing P2NP with NABH4 and NiCl2. Could we change some words about this? I'm quite interested

in your personal experience.

Quote: Originally posted by karlos³  | | Use NaBH4/CuCl2, it happens to become the new standard among a group of clandestine chemists, putting the Al/Hg to rest for now.

|

Karlos, could you give me more information about this method using copper boride instead nickel boride? I have read an article I donloaded here in the

Forum talking about substituted nitrostyrene reduction to dopamine, but it's too much generical. Do you have any papers talking about NABH4/CuCl2 or

CUSO4? I'm very interested on it.

|

|

|

Chemi Pharma

Hazard to Others

Posts: 350

Registered: 5-5-2016

Location: Latin America

Member Is Offline

Mood: Quarantined

|

|

Hi fellows,

Talking about P2NP reduction, I want to know your oppinion about a method that employs HCl and Zn in isopropyl alcohol at 0-5ºC. I have a very good

paper where the researchers did a very good job reducing nitrostyrenes with high yield. P2NP is just an alfa methyl nitrostyrene. I think this method

worth a try to reduce P2NP and I'm intending to try this in my lab soon.

And before somebody say I'm talking about an illegal substance, here where I live only methamphetamine and derivatives are forbidden. Amphetamine

salts can be legally prescribed by doctors in manipulated formulas, to treat morbid obesity and ADHD.

Read the attached article and give your comments, ok?

Attachment: Nitrostyrenes to amines with Zn & HCl II.pdf (265kB)

This file has been downloaded 1540 times

[Edited on 27-2-2019 by Chemi Pharma]

|

|

|

Corrosive Joeseph

National Hazard

Posts: 915

Registered: 17-5-2015

Location: The Other Place

Member Is Offline

Mood: Cyclic

|

|

The reduction of 1-phenyl-2-nitropropene in one step has been the bane of many a researcher for over 100 years now.

Al-Hg works, and quite well from what what I read........... But some people seem to have no luck with it and others just downright despise

it.......... One outstanding quality is how cheap it is.

Ritter's Urushibara (with aluminum foil) was unrepeatable and subsequent experimenters reported 0-30% yield.

Antibody hit 50% on the 3,4,5-trimethoxy variant - https://www.erowid.org/archive/rhodium/chemistry/tmp2np-red....

The French patent with aluminum grains and anhydrous nickel chloride made from members of the cabbage family (yes, I know) states a 65% return of

1-phenyl 2-aminopropane

https://patents.google.com/patent/US9149796B2/en

The Leminger (zinc and aqueous HCl acid) does not work [EDIT] - for the nitropropene

https://the-hive.archive.erowid.org/forum/showflat.pl?Cat=&a...

https://tinyurl.com/ydyr6mza

But Nicodem seemed to think it would with anhydrous conditions

https://the-hive.archive.erowid.org/forum/showflat.pl?Cat=&a...

This has been a subject of debate elsewhere on the internet and is currently untested.

It is very doubtful that NaBH4-CuSO4 will do the business, and there is no NaBH4-CuCl2 paper because this reaction was discovered by the amateur

community, and it is actually here already. Hiding in plain sight.

https://www.sciencemadness.org/whisper/viewthread.php?tid=80...

In other news, the reduction of the 1-phenyl-2-nitropropene with iron and HCl and it's subsequent hydrolysis to the ketone in 77% yields using the

method of Hass and Susie https://chemistry.mdma.ch/hiveboard/palladium/pdf/US2233823....

followed by reductive amination with zinc, nickel acetate and aqueous NH3 has finally been proven, hitting a whopping 84% with the last one. Based on

Scr0t's cyclohexylamine synthesis. Also found here.

Gentlemen.......... start your engines.............

/CJ

[Edited on 28-2-2019 by Corrosive Joeseph]

Being well adjusted to a sick society is no measure of one's mental health

|

|

|

Chemi Pharma

Hazard to Others

Posts: 350

Registered: 5-5-2016

Location: Latin America

Member Is Offline

Mood: Quarantined

|

|

Thank you @/CJ, you are my favorite librarian and historian here on this Forum!

Quote: Originally posted by Corrosive Joeseph  | | followed by reductive amination with zinc, nickel acetate and aqueous NH3 has finally been proven, hitting a whopping 84% with the last one. Based on

Scr0t's cyclohexylamine synthesis. Also found here. |

@/CJ, where's the reference? I think you forgot to add the link, I guess!

[Edited on 27-2-2019 by Chemi Pharma]

|

|

|

| Pages:

1

2

3 |