| Pages:

1

2

3 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I recently attempted to make diethyl sulfate (DES) by sparging ethene into con H2SO4 held at 97°C. The gas was sparging profusely into the acid using

a fritted tube. Sparging continued until the ethene was gone, about 4 hrs. Much char was produced and no hint of DES.

An article in the Canadian Journal of Chemical Engineering, 1991) indicates that the pressure in the vessel must be between 20-30 bar. My

sparging was done at ~6" of acid hydrostatic pressure.

Since I can make ethene efficiently I wanted to make this method work. But I would have to buy a pump capable of 20-30 bar plus make a pressure

vessel, etc, so I will abandon this approach for now.

I have great hopes for a method that first makes ethyl hydrogen sulfate. I will try this next.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

The simplest method for making DES seems reaction of EtOH and H2SO4, without any additives. It must work, but (from available literature) reaction

has to meet some important conditions.

The yield sholud be somewhere between 20% and 40%, at least I think so. I am going to try this, but currently I have no time for experiments, even

such simple ones

Слава Україні !

Героям слава !

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Magpie,

I came across the following article a few minutes ago:

On the production of the sulphates of the alcohol-radicals from the nitrites by the action of sulphurous acid

Ernest T. Chapman, J. Chem. Soc., 1870, 23, 415

DOI: 10.1039/JS8702300415

It suggests that ethylnitrite and SO2 or its concentrated solution in water yield DES.

The article is an ancient one, a bit confusing with its old nomenclature and such but seems interesting.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

kmno4: I have use this method with yields of 0-14.4%.

Pumulki: Thanks for the procedure. I may try it eventually. My next try will be using the procedure in patent GB 581,115. It is extremely simple

and promises good yields.

[Edited on 7-1-2019 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

| Quote: | | kmno4: I have use this method with yields of 0-8%. |

"This method" means nothing. Your method may not be my method.Besides, cited patent exploits reaction of H2SO4 and EtOH without any additional

substance (but stream of air and heating). So, you did not try every method

Слава Україні !

Героям слава !

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

The method I am referring to is in the first post of this thread.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

lordcookies24

Hazard to Self

Posts: 78

Registered: 2-1-2019

Location: pluto

Member Is Offline

Mood: curious

|

|

Impressive as always

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Magpie, I fished out this one:

"Solution of Ethylen in Sulphuric Acid

By Buttlerow and Gorgainow (Deut. Chem. Ges. Ber., VI, 196).

Strong sulphuric acid at 160-170 C perfectly absorbs ethylene. In Berthelot's well known experiment the absorbtion may be due to the heat developed by

friction."

Source: Organic chemistry

J. Chem. Soc., 1873, 26, 743

DOI: 10.1039/JS8732600743

It is just the abstract, but that Berichte article may be worth a look up. Also, the once well-known Berthelot method may be referenced in that

article, who knows?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I tried sparging ethylene into con sulfuric acid but at 100°C. The patent I listed above said the reactor pressure must be 20-30 bar. My pressure

was atmospheric.

I will look for that reference the next time I am at the library.

I don't think that making diethyl sulfate can be all that easy. Usually if it is easy it is given in Vogel.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

I tried to save you a journey to the library and downloaded that Berichte article - because all issuses of this journal can be searched online. :-)

Unfortunately the referenced article is just a "correspondence from St. Petersburg" - which is just an abstract in German. As I can tell it does not

say a word more than the cited English version, except that "strong sulphuric acid" is "concentrated".

No reference to the original (russian) article nor to the mentioned Berthelot's method of absorbtion. :-(

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Still no time for experiments .... but not for some little literature.

Here is very interesting article, with many important things for interested in Et2SO4 preparations.

Attachment: estr.pdf (99kB)

This file has been downloaded 925 times

Слава Україні !

Героям слава !

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

My preliminary experiment with 98% EtOH and 96% H2SO4 gave 0% of Et2SO4. It seems that H2O is very harmful for this esterification and must be

removed. Added Na2SO4 extracts practically H2SO4 only, added heptane as extractant, it extracts nothing.

I have just ordered some "H2O remover" to test some concept, we will see.....

Слава Україні !

Героям слава !

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Preparation of Neutral Ethyl Sulphate. By A. Villiers (Compt. rend., 90, 1291—1292).—This ether can be prepared by distilling in a vacuum a

mixture of sulphuric acid and alcohol. 200 grams of absolute alcohol distilled very slowly in this manner with twice their volume of concentrated

sulphuric acid, yielded from 25 to 30 grams of the neutral ether; the end of the operation is indicated by the frothing of the contents of the retort,

and by an increase of the internal pressure. The distillate separates into two layers, the lower of which consists of the pure ether. There is no

advantage in using fuming sulphuric acid, or in substituting ordinary ether for alcohol. The boiling point of ethyl sulphate under a pressure of 45

mm. is 120.5°, which falls regularly 2.5° as the pressure diminishes 5 mm. It solidifies at about —24.5°, and when treated with warm baryta-water

it gives the theoretical quantity of barium ethyl sulphate and alcohol.

JCS 38, 797 (1880)

[Edited on 15-3-2019 by S.C. Wack]

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Yes, I have seen the article from Comptes Rendus, I think I have seen most of articles about preparation of Et2SO4

My goal is not to use vacuum and/or oleum, the ethyl precursor must be EtOH, the yiel must be better than 50% counting on EtOH. I thought about

Na2S2O7 (prepared from Na2S2O8, checked), but after calculations I decided not to do this (expected problems with work-up).

Unfortunately Et2SO4 is sensitive to water or H2SO4, they both cause its decomposition....

As I said, I am waiting for "H2O remover" which is able to remove water even in fair acidic conditions (up to 80% H2SO4) and not consuming too much

H2SO4 by the way. However, I have never seen this substance to be reported for this purpose, maybe it simply does not work

But it is cheap and worth trying.

Слава Україні !

Героям слава !

|

|

|

SWIM

National Hazard

Posts: 970

Registered: 3-9-2017

Member Is Offline

|

|

Boron trioxide?

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

No, it is not B2O3. Firstly, I would expect borate esters formation in the mixture. Secondly, glassy B2O3 is terribly hard. Not so long time ago, I

prepared some B2O3 (from H3BO3) for another project (triphenyl borate).

To my surprise, I was not able to powder it in my porcelain mortar, ha. It scratches glass, so it would damage my equipment, especially under magnetic

stirring. Fortunately, for this purpose partly dehydrated H3BO3 (~HBO2) was equally good.

Слава Україні !

Героям слава !

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

I have got this "H2O remover", but in the meantime I came across the patent US3047604 in my collection of papers. I read it years ago and I thought it

is classical bullshit patent. However, it is mentioned elsewhere in this forum as giving good results for MeHSO4 formation.

I tried procedure from the patent and to my surprise Na2SO4 removes water from EtOH-H2SO4 mixture rather complelety. It does work, but somehow it

still amazes me. It looks like formed EtHSO4 has "hydrophobic" properities and is not hygroscopic at all. Further experiments are in progress, EtHSO4

is merely a halfway point

[Edited on 11-4-2019 by kmno4]

Слава Україні !

Героям слава !

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

At last some good news in this frustrating thread! :-)

Keep up the tiresome work KMnO4!

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Just for interested in same EtHSO4.

I performed many runs on 15g of EtOH+34g of H2SO4(97%) scale and result are reproducible. Reaction of these substances is not very fast and takes ~2

hours to establish equilibrium (~60% of EtHSO4 is formed). Next, 6,5-7 g of powdered Na2SO4 is added with continuous stirring, the stirring is

continued at r.t. for ~ 6 hours or more*.

The mixture is then placed in a cold place (5-15 C) for a few hours, without stirring, to maximalize stability of Na2SO4 hydrates (but this chilling

is optional). It is then vacuum filtered, 38(+/- 1)g of amber liquid is obtained after longer time of filtration**.

It is more or less pure EtHSO4, one titration gave 94% its content (assuming it contains EtHSO4 and H2SO4 only). It has weak, not specific odour,

there is no EtOH or Et2O scent, it resembles for me chlorobenzene odour, hah. There were no volatile products detected during these operations, the

output weights were equal to input ones. Unfortunately, decomposition of EtHSO4 to Et2SO4 (by Na2SO4 also) is really very frustrating: it seems that

also Et2SO4 is decomposed by Na2SO4 (at 50-55 C water bath)  . More details

later.... . More details

later....

* all oparations performed in closed bottles

** because of high viscosity of the product and large amouts of filtered solids, there are large machanical losses of the liquid, about 2-3 g is

always held in filtrate cake - it was impossible to me to recover more liquid

[Edited on 16-4-2019 by kmno4]

Слава Україні !

Героям слава !

|

|

|

kmno4

International Hazard

Posts: 1503

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

The latest news are not good.

I decided to repeat more closely analysis of the products from Na2SO4 dehydration step. It is because of odd results of further experiments. As

usually, it was checked with 15 g of EtOH + 34 g of 97% H2SO4.

1) the liquid remaining after filtering contains slightly more than 20% of H2SO4 (by BaSO4 precipitation)

2) very large amount of NaOH is needed to neutralize a sample of filter cake (0,50 g of NaOH per 1,13 g of wet precipitate)

The most important conclusion - Na2SO4 dehydrates nothing (or almost nothing) and it is converted into NaHSO4 or similar acid salt under these

experimental condition. The cited patent is just complete rubbish, as 95% of other old patents.

I had to use about 150 g of benzene dehydrated EtOH (and corresponding amount of H2SO4) to come to this simple conclusion..... It could be deduced

from a single experiment, but lazyness and "fitting" weights pushed me on this wishful thinking path.... how stupid of me

Слава Україні !

Героям слава !

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I was taught that the products of the reaction between ethanol and sulfuric acid depend on the temperature: (1) at 0°C the products are ethyl

sulfuric acid, diethyl sulfate, and water, (2) at 140°C the products are diethyl ether and water, and (3) at 170°C the products are ethylene and

water. Therefore, one would not want the temperature to reach 140°C if trying to produce diethyl sulfate.

After carefully rereading the procedure of Lynn and Shoemaker I discovered a major error on my part. It is the oil bath that is to be kept at

155-165°C, not the reactants. So I decided to give this procedure another try. I ended up making 3 successive runs over a 3 day period.

1st run. Here I kept the bath temperature at 165°C and tried to get the reactant drip at 120-130 d/min per procedure. I used a p-e

funnel stopcock to set the drip rate and could never get it right. Mostly it was way too low. Also my pressure was about 50mmHg instead of the

desired 25mmHg. After all the reactants were in I did not see 2 phases in the receiver and once again was very discouraged. But remembering that the

procedure said that it takes about 1.5 hours, I continued the heating. Slowly some heavy product began dripping into the receiver, so I continued

until this stopped, a total of about 1.5 hrs. There was about 5ml of this heavy product below the ethanol in the receiver. This gave me hope and I

decided to make another run the next day.

2nd run. My goal for this run was to scrupulously follow the procedure of Lynn & Shoemaker. I replaced the water aspirator with

a vacuum pump. This gave me a little less than 25mmHg pressure. Reasoning that the large headspace of the 1000mL pot might be condensing some of the

Et2SO4 before it could reach the condenser I insulated all the glassware up to the condenser with al foil. I kept the bath at 160°C. This run also

produced product at what seemed like a better rate. I let the condensate accumulate on top of that for the 1st run. Further encouraged I decided to

make a 3rd run.

3rd run. This was done as the 2nd run except I was determined to increase the drip rate to the 120-130d/min. This run was the best

as product began accumulating right away and was quite visible as drops falling to the bottom of the receiver through the supernatant ethanol.

However, I still did not achieve the control of the drip rate that I wanted.

Combined Product. Today the combined product was neutralized and washed per the procedure. The resulting weight of Et2SO4 was 25.3g.

Lynn & Shoemaker claim 32.6g for each run.

Future Run.At some point I will make another run when I figure out how to control the drip rate. Using just a capillary tube and a

pinch clamp may work as the system vacuum will draw the feed into the pot. Also I would try using a 500mL pot to make it easier to carry the Et2SO4

vapor to the condenser. Its normal bp is 209°C. At 25mmHg pressure it is likely about 100°C.

Photos. I have 3 photos which I will post when they show up in my e-mail.

[Edited on 8-5-2019 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

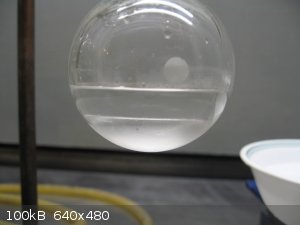

I made another Et2SO4 run today. The only change I made was to use 19/22 glassware instead of 24/40. The pot was big enough (500mL) but the

condenser was too short, ie, much vapor was sucked into the vacuum pump. Ethanol, I presume. Attached is a picture of the 100mL receiver. The

Et2SO4 is the bottom layer.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Congrats Magpie!

It seems that you really produced something.

Now comes the testing/characterization part to see if you made "the stuff"! If you could ethylate something (e.g a phenol) it would be ta-da!

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you. I have plans to identify this and eventually make phenetole as you have suggested.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here are the results of refractive index determinations:

3- run composite of 8-5-19 above: 1.397@25°C

6-9-18 batch of 11.4g: 1.398@25°C

correction to 20°C would be +0.002

literature value @20°C: 1.400

[Edited on 19-5-2019 by Magpie]

[Edited on 19-5-2019 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

| Pages:

1

2

3 |