| Pages:

1

2 |

Murexide

Hazard to Self

Posts: 51

Registered: 1-12-2018

Member Is Offline

|

|

Ammonia Generation

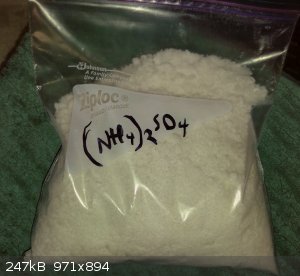

Ammonia for amateur chemistry is normally generated from one of three techniques, one of which is combining an ammonium salt with sodium hydroxide. In

this case I chose to use ammonium sulfate due to its availability.

Generation was calculated on a 0.5 molar scale with respect to ammonia, using an vacuum flask, stoppered and a tube connected to an inverted funnel

(funnel + beaker trap), which contained 50mL of water. The concentration desired was 10M.

Ammonium sulfate - 33g used

Sodium Hydroxide - 22g used (10% moisture content)

Neither reagent was ground due to the hazardness of grinding sodium hydroxide (dust). The setup is as shown

First the hydroxide was poured in, followed by the ammonium sulfate, 5mL of water and then the flask was stoppered and gas evolution immediately

occurred. Unfortunately, the bubbling ceased within 1 minute. The mixture was the heated (to around 80C) on a hot plate (as shown) and bubbling

continued.

After around half an hour the generation once again ceased. The specific gravity was tested and it was around 0.98-1.00, very close to the density of

water and within the error margin of my measuring cylinder/scale.

Through a quick titrimetric analysis with 0.1M HCl and methyl orange indicator, product was determined to be of only 0.8-0.9M.

Similar generators seen on Doug’s lab or Nile Red have achieved 10-15M ammonia in short periods of time, so it is unclear why the ammonia generator

here is of such low concentration. Note that neither reagent was dissolved in water prior to reaction to prevent significant ammonia dissolution.

Edit:

Significant refluxing of water within the flask occurred so the temperature of the mixture should not have been a limiting factor

[Edited on 2-12-2018 by Murexide]

|

|

|

Murexide

Hazard to Self

Posts: 51

Registered: 1-12-2018

Member Is Offline

|

|

Ammonia explosion

About an hour ago I attempted to duplicate the experiment with aqueous ammonium sulfate as well as double stoichiometry to increase ammonia production

and thereby the resultant concentration of the solution.

Unfortunately, as I added the 120mL ammonium sulfate solution to the 44g sodium hydroxide in the flask, foaming built up and I placed the stopper over

the flask, hoping to channel the ammonia gas into the beaker trap (in hindsight, stoppering anything where pressure is building is always a terrible

idea, however instincts to prevent overfoaming gave way).

I am not sure why, but what happened next was the pressure built up enough within one second (despite the side arm tube) for the stopper to fly out,

sending the solution mixture flying (luckily it was likely mostly ammonium sulfate solution as the hydroxide was in solid pellet form on the bottom of

the flask). It is unclear whether any of the solution was actually released in my direction, but the fumes of ammonia were very strong. Within 10

seconds I was able to start rinsing myself for around 30 minutes. There do not appear to be any burns and everything appears normal. I am particularly

lucky in that at the time both gloves and goggles were worn and the flask chosen was a vaccuum filtration flask so it did not explode (even though

adjacent beakers had due to the violence of the stopper ejecting), as well as that the synthesis was performed outside.

In light of this event, it is clear that more safety precautions were required. Quite obviously the placement of the stopper caused the explosion,

however the reason for the sudden build up in the first case is unclear (other experimenters have used similar setups and experienced no such

foaming). Perhaps an improvised glove box (storage box) and/or face masks would be appropriate for handling anything that is sealed and can build up

enough pressure to explode, such as future ammonia syntheses.

|

|

|

j_sum1

Administrator

Posts: 6334

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

My experience with NH3 is that it can be a bit fickle to work with.

Temperature effects, sudden suck-back variable rate of production and absorption all come into play.

My advice is never be in a rush. Make any changes to your system slowly. Your basic setup seems fine. Although it is always a good idea to put an

empty flask in line between your generator and the absorption setup. A bit of volume is good for pressure fluctuations and also gives extra protection

against suckback.

Keep notes. Once you find a configuration that works with your system geometry, you will want to duplicate it.

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

| Quote: | | [quote ]My experience with NH3 is that it can be a bit fickle to work with. |

I didn't see a stirbar in the receiver...?

Since NH3 lowers the density as it dissolves, it dissolves at the water-surface only, quickly saturating it and preventing further

absorption so that active stirring is essential...

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Per one of my recent threads where I needed pure ammonia water:

"... I claim my ammonia water was likely pure NH3 (aq) as I prepared it by placing distilled water (DW) in a large mouth vessel together in a

container (which was twice the volume of the DW) loaded with yellow colored household ammonia rich in surfactants, etc. I carefully placed a plug

(prepared by wrapping layers of Al foil around my finger) full of NaCl into the household ammonia and sealed the entire chamber. As NH3 has much

reduced solubility in seawater, I expected with time the DW would amass a good amount of the liberated ammonia from the now salt rich household

ammonia. A day latter, I opened the vessel, I was surprised to see the amount of bubbling/attack performed on the Al plug! "

The latter Al attack added H2 gas to increase pressure in the vessel. To reduce stress in the system, even more ammonia may be forced into the DW.

Note, if you have already created ammonium sulfate, you can try adding it to the vessel with the impure household ammonia and the aluminum plug with

salt. As the formed aluminum hydroxide is amphoteric it may (Al(OH)3 can be a difficult salt to work with) actually react with the ammonium sulfate

to produce aluminum sulfate and further liberate ammonia.

[Edited on 2-12-2018 by AJKOER]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

I usually use and addition funnel, I make a saturated sulfate solution and this goes in the flask and is heated to 90c.

The addition funnel is loaded with the saturated hydroxide solution, this is usually boiling temp due to the dissolution of the hydroxide.

Then I adjust for a slow but steady drip then adjust for a suitable gas rate.

I wish I just did that yesterday as I had an explosion like you did due to using the same methodology as you, I had to use my SCBA to turn the vent

fan on, and from there it evolved to a total cluster ----k.

Emergency shower, broken glass wear and a royal hell of a clean up.

I am making purified ammonium sulfate from my fertilizer grade material.

Fun lab tip: When you make a reagent, try to plan to be able to use the side products! Nitric acid it is worth the trouble to find ammonium nitrate,

then react the waste material in the flask till basic from ammonia gas, and you now have a great quantity of ammonium sulphate for an ammonia

generator

Plus side is ordered a 500ml soxhlet extractor with the replacement glass wear.

|

|

|

Tsjerk

International Hazard

Posts: 3032

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Very nice first and second post, clear and readable. Do you have a way to slowly add a solution of NaOH to your solution of ammonium sulfate? This

would be an intermediate of your two experiments, which I think would be more controllable.

You can ignore AJOEKER, as your practises already far surpass his.

|

|

|

mayko

International Hazard

Posts: 1218

Registered: 17-1-2013

Location: Carrboro, NC

Member Is Offline

Mood: anomalous (Euclid class)

|

|

"Luck favors the prepared"

al-khemie is not a terrorist organization

"Chemicals, chemicals... I need chemicals!" - George Hayduke

"Wubbalubba dub-dub!" - Rick Sanchez

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Tsjerk  | Very nice first and second post, clear and readable. Do you have a way to slowly add a solution of NaOH to your solution of ammonium sulfate? This

would be an intermediate of your two experiments, which I think would be more controllable.

You can ignore AJOEKER, as your practises already far surpass his. |

I too think your post are nice, clear and readable !

Great work!!

-----------------------------------------------------------

My path is really recommended for a simple hands-off approach with low demand on reagents and producing acceptable yields, with some interesting and

advanced chemistry, at least with respect to the aqueous ammonia/Aluminum foil/NaCl part.

Also, no use of hot NaOH, no use of MgSO4 (as a route to (NH4)2SO4), or exciting report(s) of ammonia explosion, injuries and such.

With respect to possible refinements on my employed path detailed above, I am thinking of adding some mechanical agitation to increase NH3 dissolution

rate.

Also, on the theoretical side, some recent readings suggest the rate of ammonia/NaCl attack of Aluminum is proportional to concentration of NaCl, so

my placing a relatively large amount NaCl surrounding by Al foil, into the household ammonia, appears to have accelerated the attack on Aluminum

metal. More interesting to me was the authors described path of how chloride (and the base ammonia) proceeded to dissolve the Aluminum, to quote from

‘Study of Aluminum Corrosion in Chloride and Nitrate Media and its Inhibition by Nitrite’ by S. N. Afzal, et al, published in Journal of Nepal

Chemical Society, 2007, Vol 22, available at http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.429... :

"Foley et al [6] investigated that in chloride solution the high energy aluminum metal ionizes rapidly to the Al3+ ion, which also hydrolyses rapidly.

These two species react further to form a reasonable stable basic aluminum chloride that is transformed slowly to Al(OH)3 "

My take on the described reaction scheme of how chloride and ammonia attack Aluminum metal is as follows:

Al = Al3+ + 3 e-

Al3+ + 6 H2O = [Al(H2O)6]3+ (aq) (see p. 4 at http://www.umich.edu/~chem125/W08/E5W08lab1key.pdf )

[Al(H2O)6]3+ (aq) + H2O = [Al(H2O)5(OH)]2+ (aq) + H+ (aq) (see relatedly https://www.chemguide.co.uk/inorganic/complexions/acidity.ht...)

NH3 + H2O = NH4+ (aq) + OH- (aq) (the OH- presence drives the above reaction to the right)

[Al(H2O)5(OH)]2+ (aq) + 2 Cl- (aq) = [Al(H2O)5(OH)]Cl2 (somewhat stable)

[Al(H2O)5(OH)]Cl2 + 2 H2O = Al(OH)3 (s) + 2 HCl (aq) + 5 H2O (slow reaction)

[Edited on 3-12-2018 by AJKOER]

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Joker, please don't pollute this thread with your aluminum/salt/magic nonsense. The OP's experiment has nothing to do with it.

==============================

Excellent first post, Murexide. You described your setup thoroughly, tried a few experiments before asking questions here, and even included pictures!

I agree that stirring in the receiver flask should help. Placing the receiver in an ice bath is good too; ammonia dissolving in water produces a

surprising amount of heat. There may be more to it than that, though; seems like a pretty large discrepancy in concentration.

Another option for an ammonia generator is to mix the two solids and slowly drip water into that. This way you minimize the amount of water in the

reaction flask, which in my experience is a pretty significant source of "loss." (in that it takes away from the ammonia dissolving in the receiver,

which is where you want it to go.)

That's actually pretty similar to how you did yours, now that I read it a second time. If you have an addition funnel, though, the drip rate can be

controlled and slowed down enough to avoid sudden surges of gas like you experienced.

|

|

|

nimgoldman

Hazard to Others

Posts: 303

Registered: 11-6-2018

Member Is Offline

|

|

To improve gas absorbtion, you want the inlet tube to go to the bottom of the solution. Note that ammonia is lighter than water and will from a layer

instead of uniformly dissolving. Stirring will promote dissolution.

Cooling the receiver flask will improve solubility of ammonia too.

I would definitely add a suckback trap even though it might lower your yield a bit.

|

|

|

Murexide

Hazard to Self

Posts: 51

Registered: 1-12-2018

Member Is Offline

|

|

Thanks for all the input. Modifications to the receiving flask seem fairly straightforward - cooling the flask and magnetic stirring (although that

would necessitate the purchase of a second magnetic stirrer). The funnel should offer sufficient suckback protection.

However, the generation of the ammonia appears to be a bit more problematic. It seems like there is no way possible other than dripping in a solution,

as addition all at once with solutions leads to uncontrollable rates of reaction, while addition of water to mixture fails to generate sufficient

ammonia.

So it seems like the usage of ground glass is required for safe and constant generation, as I do not wish to experience any more explosions,

especially of hydroxide mixtures. A two necked RBF with pressure equalising addition funnel, as well as gas adapter (one of two gas outlets wrapped

with duct tape) leading to the above receiving flask (original tube) with a solution dripped into a flask filled with solid sounds like the optimal

approach.

However, ground glass is obviously costly and there importation from China is undesirable due to customs risk. The gas adapter should not have

problems passing through customs. However I am unsure of the risks that purchasing two necked RBFs and PE addition funnels pose. Laboy glass seems to

offer a decent range of glassware, however I cannot ascertain its location and it appears to be China. In that case, the eBay sellers would be clearly

the superior option.

|

|

|

j_sum1

Administrator

Posts: 6334

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Where are you located? Most of us do not have too much of a problem purchasing glassware from China. Laboy has a good reputation. Deschem,

Nanshinglass and reacware also.

If I were you, I would do a bit more experimentation with the equipment you currently have while you wait for your ground glass. You can only learn.

A stirrer can be made easily from a cellphone charger, a computer fan and a couple of neodymium magnets hot-glued to the fan blades. I have a couple

of these. The most expensive item then is the stir bar.

One method is to perform the reaction with just dry reagents. It will take time and you will have low yield but it works. You can heat the reaction

flask if you wish but you do lose a lot of control over the reaction rate. I would use a water bath and slowly heat.

Another option is to reduce the scale of the reaction. Again this will affect the yield. But scaling back often makes the unmanageable manageable.

Anyway, I don't think you have much to lose by giving it another try.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

my set up

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

In my experience, everyone lies on customs declarations forms anyway. Every chemical/glassware package I've gotten from another country is labelled as

"T-shirts" or something. So I think the risk of a customs flag is minimal. But I understand the concern.

j_sum, you can do this reaction with just the mixed dry ingredients? I thought a bit of water was required to get it going. Solid/solid reactions are

notoriously difficult.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Quote: Originally posted by MrHomeScientist  | In my experience, everyone lies on customs declarations forms anyway. Every chemical/glassware package I've gotten from another country is labelled as

"T-shirts" or something. So I think the risk of a customs flag is minimal. But I understand the concern.

j_sum, you can do this reaction with just the mixed dry ingredients? I thought a bit of water was required to get it going. Solid/solid reactions are

notoriously difficult. |

Yep, it's called dry distillation. The yields can be fairly good. This works with many amine salts. Anyway, it's rarely truly dry as NaOH always picks

up a little H2O. Often it's the method of choice to prepare low MW amines from their salts given that extraction of these amines, even from salt

water, is terribly inefficient.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Murexide

Hazard to Self

Posts: 51

Registered: 1-12-2018

Member Is Offline

|

|

Ground glass arrived with no problems (I hope)! Setup is pretty much the same as Xeon, except I don’t have a gg stopper for the top addition funnel

so I’ll have to substitute with some tape and paper. Saturated ammonium sulfate solution is in the addition funnel to be dropped onto solid

hydroxide (I don’t feel comfortable with very concentrated hydroxide solutions). Then heating is commenced after full addition and bubbling ceases.

I’ll work on a 6/10 molar scale based on ammonia (39.6g ammonium sulfate, 27g sodium hydroxide) to dissolve in 50 mL water, so that should produce a

max concentration of 12M or 20.4%. In practice, if I get above 14% that is sufficient for my purposes.

Once I try this out soon I’ll report on how the yields with the gg equipment compare.

|

|

|

Abromination

Hazard to Others

Posts: 432

Registered: 10-7-2018

Location: Alaska

Member Is Offline

Mood: 1,4 tar

|

|

Quote: Originally posted by Murexide  | Ground glass arrived with no problems (I hope)! Setup is pretty much the same as Xeon, except I don’t have a gg stopper for the top addition funnel

so I’ll have to substitute with some tape and paper. Saturated ammonium sulfate solution is in the addition funnel to be dropped onto solid

hydroxide (I don’t feel comfortable with very concentrated hydroxide solutions). Then heating is commenced after full addition and bubbling ceases.

I’ll work on a 6/10 molar scale based on ammonia (39.6g ammonium sulfate, 27g sodium hydroxide) to dissolve in 50 mL water, so that should produce a

max concentration of 12M or 20.4%. In practice, if I get above 14% that is sufficient for my purposes.

Once I try this out soon I’ll report on how the yields with the gg equipment compare. |

Very professional, although several notes:

1. Since you do not have a ground glass stopper, if your addition funnel is pressure equalizing, I would suggest putting the hose adapter to the suck

back trap on top of the PE funnel and to place the PE funnel directly onto your reaction flask.

2. I would also suggest adding around a 5 percent excess of sodium hydroxide as it is hydroscopic, meaning that when you weigh it out the water weight

will slightly throw off your calculations.

3. I would dissolve both your NaOH and ammonium sulfate to allow for a more efficient production of ammonia.

Just the insight of an amateur ;)

[Edited on 28-12-18 by Abromination]

List of materials made by ScienceMadness.org users:

https://docs.google.com/spreadsheets/d/1nmJ8uq-h4IkXPxD5svnT...

--------------------------------

Elements Collected: H, Li, B, C, N, O, Mg, Al, Si, P, S, Fe, Ni, Cu, Zn, Ag, I, Au, Pb, Bi, Am

Last Acquired: B

Next: Na

-------------- |

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Abromination  | Quote: Originally posted by Murexide  | Ground glass arrived with no problems (I hope)! Setup is pretty much the same as Xeon, except I don’t have a gg stopper for the top addition funnel

so I’ll have to substitute with some tape and paper. Saturated ammonium sulfate solution is in the addition funnel to be dropped onto solid

hydroxide (I don’t feel comfortable with very concentrated hydroxide solutions). Then heating is commenced after full addition and bubbling ceases.

I’ll work on a 6/10 molar scale based on ammonia (39.6g ammonium sulfate, 27g sodium hydroxide) to dissolve in 50 mL water, so that should produce a

max concentration of 12M or 20.4%. In practice, if I get above 14% that is sufficient for my purposes.

Once I try this out soon I’ll report on how the yields with the gg equipment compare. |

Very professional, although several notes:

1. Since you do not have a ground glass stopper, if your addition funnel is pressure equalizing, I would suggest putting the hose adapter to the suck

back trap on top of the PE funnel and to place the PE funnel directly onto your reaction flask.

2. I would also suggest adding around a 5 percent excess of sodium hydroxide as it is hydroscopic, meaning that when you weigh it out the water weight

will slightly throw off your calculations.

3. I would dissolve both your NaOH and ammonium sulfate to allow for a more efficient production of ammonia.

Just the insight of an amateur

[Edited on 28-12-18 by Abromination] |

I've started to use this method.

I dissolve the Ammonium sulfate in cheap ammonia solution (Why not get more bang for the watt  ) )

then dissolve the hydroxide and slowly mix the solutions then heat, much better then dealing with the funnel, and the time lag is preferable to the

added cleaning of glass wear

|

|

|

beerwiz

Hazard to Others

Posts: 130

Registered: 6-2-2014

Member Is Offline

Mood: No Mood

|

|

When I need to gas some liquid with ammonia I do this:

Fill a 500ml beaker with 28% ammonia, fill another 500ml beaker with my desired solvent whether it be water, ethanol, methanol, etc. Then put both

beakers in a 1 gallon zip lock bag and seal. 24 hours later the target solution has 14-15% ammonia in it because the ammonia gas migrated over.

This works with HCl gas too the same way.

I no longer HCl gas things, lets say I need to HCl gas a solution. I make an HCl solution with the solvent of choice beforehand like the above ammonia

solution. Then I drop it into my target solution and the HCl salts precipitate out.

[Edited on 28-12-2018 by beerwiz]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Some pic's of why I been generating so much Ammonia!

I ordered some rather nasty fertilizer grade Ammonium Sulphate, So to clean it up I been direct gassing the left overs of my last Nitric acid

generation, I used Ammonium Nitrate to make it.

So gas the reaction mixture till it reads basic then boil off the water till dry = A lot of (NH4)2SO4 !

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

I was told by someone who regularly makes ammonia gas that the big red plastic fuel cans are the best and safest ( most forgiving was the exact

phrasing) thing to use for ammonia generation.the nh3 salt is poured in and is shaken so as to spread it evenly over the bottom followed by twice the

weight of NaOH and a shotglass of H2O and immediately the cap is screwed back on.the cap has a nipple and tube attached of course.nh4cl reacts

smoother than sulfate or nitrate.dont leave it unattended bcoz it goes from positive to negative quickly so suckback is to be watched out for. the

amount of H2O given is for a kilo of nh4cl so adjust accordingly for smaller size rxns.33g size rxns can probably be done best in a 2l coke bottle.i

think 1ml of water added to the dry ingredients for a 33g batch would be enough to kick it off.

[Edited on 29-12-2018 by draculic acid69]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Murexide: another thing I can add is that you will have better luck bubbling formed gas thru a thin tall cylinder rather than a wide flat beaker and

just putting the hose into the water rather than the upside down funnel seems to work better for me.doing this rxns in glass also seems dangerous and

unnecessary compared to using plastic.ie coke bottles .also using solutions of either chemical and adding all at once will lead to an exothermic

reaction followed by dramatic and then catastrophic rise in pressure of a caustic gas.not what you want.using that much water to generate the gas even

by dropping it into the flask slowly will also hold onto a lot of ammonia that will require heating to release requireing cooling of the now hot gas

your trying to condense.not what you want.

[Edited on 29-12-2018 by draculic acid69]

[Edited on 29-12-2018 by draculic acid69]

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by draculic acid69  | Murexide: another thing I can add is that you will have better luck bubbling formed gas thru a thin tall cylinder rather than a wide flat beaker and

just putting the hose into the water rather than the upside down funnel seems to work better for me.doing this rxns in glass also seems dangerous and

unnecessary compared to using plastic.ie coke bottles .also using solutions of either chemical and adding all at once will lead to an exothermic

reaction followed by dramatic and then catastrophic rise in pressure of a caustic gas.not what you want.using that much water to generate the gas even

by dropping it into the flask slowly will also hold onto a lot of ammonia that will require heating to release requireing cooling of the now hot gas

your trying to condense.not what you want.

[Edited on 29-12-2018 by draculic acid69]

[Edited on 29-12-2018 by draculic acid69] |

This sounds like some serious slum level cookery methodology!

Just use proper equipment and procedure and there is 0 risk, unlike cooks we know how to do it properly and for the most part proper glass wear.

|

|

|

happyfooddance

National Hazard

Posts: 530

Registered: 9-11-2017

Location: Los Angeles, Ca.

Member Is Offline

Mood: No Mood

|

|

A balloon somewhere on a glass set-up is great. Call it slum-level or whatever, but there is a great benefit to having a non-rigid gas generating

set-up.

|

|

|

| Pages:

1

2 |