| Pages:

1

..

18

19

20

21

22

..

25 |

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Yeah nice process ... thanks Rosco for that gem of a finding.

Very smart to work on unsensitive amino aromatic hard to diazotize and to use heat to make the substitution faster... such deactivated aromatic ring

diazoniums resist wel to heating... this is the case of trinitroanilin... the electronegativity of the NO2 into the aromatic ring is comparable to the

N into the tetrazole heteroaromatic ring...

Addition could also be made via gravity and capillarity fall through a fabric ribon coming from a reservoir and flowing near the surface or just below

the surface onto the wall of the beaker via the ribbon...

So no drops and no big increase of reactant concentration, laminar flow agitation, no shock from falling drop...pretty reproductible and no need of

electronic or pump...

[Edited on 3-10-2017 by PHILOU Zrealone]

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

This particular synthesis for NaNT is a good example of how an exacting method can be very important in its details and small changes in method used

can produce surprisingly large changes in the result. Chemical reactions that are sensitive to exacting process conditions required for process

optimization are not unusual. This appears to be one of those fickle reactions where the optimum reaction condition is a fairly narrow window. There

are many other examples of optimized chemical processes for manufacture of various materials where the process patented is a better way to skin the

cat.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Quote: Originally posted by nitro-genes  | Could only find some info on the diammonium, sodium, potassium and silver salt of 5-nitraminotetrazole, so I decided to make about 100 mg's of a

copper(II) salt of NATZ by reaction of diammonium 5-nitraminotetrazolate and copper(II) sulfate, which precipitates a light green amorphous

precipitate. Not sure if this would be Cu(II)(NATZ) or Cu(II)(NATZ)2, probably the former. It only crackles when touched by flame, but when heated

over a flame it first turns brownish/black then detonates with great brisance at around 300 deg C. Also tried to make the Cu(I) salt by reduction with

ascorbic, but just got some mustard yellow coloured gel-like crud that wouldn't filter, perhaps the Cu(I) salt is too soluble or too fine a

precipitate.

It seems Cu(II)(NATZ) doesn't need too much to make DDT, has a Cu(II)(NATZ)(NTZ) complex ever been made? The nickel(II) salt of 5-nitraminotetrazole

also seems very soluble, still would like to try if NATZ may form some more water insoluble and more flame sensitive complexes with nickel(II) nitrate

and hydrazine. Are any of these already known?

[Edited on 9-8-2017 by nitro-genes] |

It would be interesting to see if a nickel - potassium double salt would form. Gmelin has reported a double salt for the styphnate.

http://www.sciencemadness.org/talk/viewthread.php?tid=11105&...

Attachment: pages from Hand_book_of_chemistry 1857.pdf (392kB)

http://www.sciencemadness.org/talk/files.php?pid=162501&...

Ethylenediamine nitrotetrazolate would probably be worth a look too. See US4552598 attached in an earlier post

http://www.sciencemadness.org/talk/viewthread.php?tid=8144&a...

Ethylenediamine nitrotetrazolate may form an interesting binary or double salt with Ethyleneditetrazylazide which was mentioned on page 1 of this

thread

http://www.sciencemadness.org/talk/viewthread.php?tid=8144&a...

[Edited on 10/3/2017 by Rosco Bodine]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

A potassium double salt was also something I tried, though only in combination with Cu(II). Tried by slow addition of a strong copper sulfate solution

to a near saturated solution of potassium NATZ in water and by cooling of a hot solution of both. Either way, the product seemed a mix of Cu(NATZ)

hydrate (light green) and the potassium salt. The potassium salt washes out easily, so I'm quite sure it is a simple mix. NATZ being a diacid, the

formation of these complexes can be difficult and highly depended on pH, though I doubt any more flame sensitive energetic complexes of NATZ have

remained undiscovered. Something maybe worth mentioning is that instead of ether, NATZ can also be extracted using the more OTC solvents MEK and

ethylacetate (from the diammonium salt after acidification with HCl).

That batch process for the nitrotetrazole synthesis would be really useful for small scale synthesis, give that no dangerous side products are formed

such as azidotetrazole or something. Seeing it is absent from the patents, could HCl-NaCl-nitrite be a viable route to chlorotetrazole formation?

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

The double styphnate of nickel and potassium also involves a dibasic acid (styphnic acid) so it caught my notice as a possibility likewise for

nitraminotetrazole.

There was a patent US5516377 of interest attached to an earlier post

http://www.sciencemadness.org/talk/viewthread.php?tid=8144&a...

It is possible you could get complexation of copper, nickel, or cobalt, probably zinc and silver also, by adding the respective nitrate to an

ammoniacal solution of diammonium nitraminotetrazole.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Here is a related recent patent US9718791

Attachment: US9718791 Facile method for preparation of sodium 5-nitrotetrazolate using a flow system.pdf (686kB)

This file has been downloaded 899 times

A related developmental history patent is US7253288

Attachment: US7253288 Process for preparing substituted tetrazoles from aminotetrazole.pdf (900kB)

This file has been downloaded 879 times

[Edited on 10/5/2017 by Rosco Bodine]

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Was wondering if anyone has more information on Guanylazide Picrate? (VOD, lead expansion,sand test,ect) All I have found is this : http://www.sciencemadness.org/talk/files.php?pid=131275&... and a small paragraph in Federoff ‘s encyclopaedia I did expect to find a bit

more info since there was a patent which would suggest that some tests were done.

Anyway I used this patent as a rough guide to synthesise some myself. Firstly I diazotised Aminoguanidine Bicarbonate as per a synthesis for 5-ATZ

but instead of using base and heat to complete it I instead neutralised it with a hot sodium picrate solution. This formed an immediate precipitation

of a bright yellow micro crystalline substance which I believe is the product. This was filtered off on a Büchner funnel, rinsed several times with

ice cold water and set aside to dry. In a burn test it caught fire very easily and burnt much faster than picric acid alone with the trademark yellow

smoke and carbon left behind. It is very insensitive and much like picric acid it needs to be wrapped in foil and belted very hard to get any visible

result.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

It seems guanylazide picrate is only mentioned few times in literature indeed, couldn't find anything either. Nice video on DBX-1 btw!

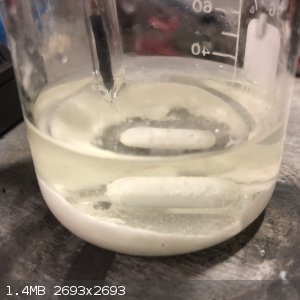

Tried the batch 5-NTZ production process from US9598380 today, the reaction went exactly as mentioned in the patent, no hard to filter, sticky,

explosive CUNTZ, copper oxides or m(i/a)cro explosions during the additions, hooray!

I did downscale the reaction to 0.5 grams of 5-AT monohydrate instead of 1 gram, keeping the reaction volumes similar (Don't have <20 ml beakers)

so not sure if this affected the end product somewhat. Still wonder how this reaction can supposedly produce such good yields, as I would have guessed

the pH during the early additions would be too high to form the diazonium precursor in the first place and OH- or even water would be competing with

nitrite.

Reaction:

1.18 grams of sodium nitrite in 10 ml distilled water were added to a 20 ml beaker, temperature was kept at 65 deg C. using a waterbath. To another 20

ml beaker, 0.73 grams of 98% sulfuric was added to 5 ml of water. Then 0.5 grams of 5-AT*H2O was dissolved in the dilute sulfuric and put next to the

other beaker in the waterbath. The 5-AT/SA solution was added in the smallest increments possible, using a pipette, over the course of 45 minutes. The

effervescence was only slight and proceeded steadily. There was a very noticable decline in effervescence with the addition of the last few drops of

the 5-AT solution. After the effervescence had mostly stopped (another 5-10 minutes of stirring), the beaker was removed from the waterbath and

allowed to cool down. As indicated in the patent, the reaction mixture had attained a very slight yellow colour and total volume (due to evaporation)

was around 10 ml, end pH was between 2 and 2.5.

Sodium bicarbonate was added to bring the pH up to around 7, then a slight excess of calcium nitrate added and the calcium sulfate filtered off. The

solution attained a noticeably darker yellow colour upon neutralization. A few mg's of silver nitrate in disitilled water was used to precipitate some

silver 5-NTZ, which precipitated as a slightly beige coloured product. I was unable to remove the beige colour by washing with water as the silver

salt of 5-NTZ should be completely white. It does behave very flame sensitive, detonates in microscopic amounts, blackens at around 240 deg C and

explodes only when dropped on a hotplate >300 deg C, so probably reasonably pure silver salt of 5-NTZ. Yields were not determined due to small

scale.

[Edited on 25-11-2017 by nitro-genes]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

No more sloppy wet CUNT for you guys except maybe on special occasions

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

NeonPulse, I like your electric furnace seen in the sulfuric acid distillation video. Some interesting looking videos.

Hello Rosco, good to see you on here. Glad to see you still find chemistry sexy.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Quote: Originally posted by nitro-genes  | Could only find some info on the diammonium, sodium, potassium and silver salt of 5-nitraminotetrazole, so I decided to make about 100 mg's of a

copper(II) salt of NATZ by reaction of diammonium 5-nitraminotetrazolate and copper(II) sulfate, which precipitates a light green amorphous

precipitate. Not sure if this would be Cu(II)(NATZ) or Cu(II)(NATZ)2, probably the former. It only crackles when touched by flame, but when heated

over a flame it first turns brownish/black then detonates with great brisance at around 300 deg C. Also tried to make the Cu(I) salt by reduction with

ascorbic, but just got some mustard yellow coloured gel-like crud that wouldn't filter, perhaps the Cu(I) salt is too soluble or too fine a

precipitate.

It seems Cu(II)(NATZ) doesn't need too much to make DDT, has a Cu(II)(NATZ)(NTZ) complex ever been made? The nickel(II) salt of 5-nitraminotetrazole

also seems very soluble, still would like to try if NATZ may form some more water insoluble and more flame sensitive complexes with nickel(II) nitrate

and hydrazine. Are any of these already known?

[Edited on 9-8-2017 by nitro-genes] |

Working from the diammonium 5-nitraminotetrazolate precursor you may be getting ammonia complexation in situ for the reacting Cu or Ni or Ag salts and

this may be a partial complexation in absence of sufficient ammonia.

The nickel(II) NATZ salt being very soluble is interesting as a potential opportunity for that solubility to be upset by complexation with hydrazine

and to form a Nickel tris-Hydrazine NATZ analogue of NiNHN. Also suggested is the possibility of a double salt with the NiNHN analogue where a mixed

solution of nickel nitrate and nickel NTZ is treated gradually with hydrazine to coprecipitate a possible double salt of NiHN and NiNTZ. I think the

NTZ compound has more promise than the NATZ compound for such a coprecipitation scheme if the solubility of NiNTZ is good also, but could react with

hydrazine to form a low solubility complex.

A nickel hydrazine azide is also reported so it provides another possibility as a candidate in a double or multiple complex salt scheme where a

coprecipitation may occur. Such schemes have the potential of enhancing the properties of NiHN.

Ethylene diamine has interest as a complexation agent as well as interest in double salt formation due to reported ability to undergo a half

neutralization by one acid reacting with one of its amines and completion of neutralization by a second different acid reacting with the second amine.

Glycine is known to complex metals and might have interest particularly for the Cu salts or potential double salts. Methylamine is another candidate

for potential Cu complexation schemes.

It is impossible to really predict what sort of solubility driven interactions may lead to formation of what complexes that may occur for resulting

materials that could be complexed and or multiple salts having synergistic properties. This is an area of pure research and experimentation for

compounds that may be possible but are undiscovered or unreported.

The half neutralization scheme for ethylene diamine being completely neutralized by a second different acid, may likewise be possible for basic salts

of one acid which are half neutralized by formation by first one acid and then converted to neutral complex salts by a second acid.

Regarding the silver salts, excess ammonia may dissolve and allow for purification by reprecipitation on neutralizing the ammoniacal solution of the

silver salt.

[Edited on 11/26/2017 by Rosco Bodine]

|

|

|

Tdep

National Hazard

Posts: 519

Registered: 31-1-2013

Location: Laser broken since Feb 2020 lol

Member Is Offline

Mood: PhD is done! It isn't good but it's over lol

|

|

I also tried the batch 5-NTZ production process from US9598380 yesterday, but on a 0.75g 5-ATZ scale. I made the silver salt, and it iss good, very

similar to silver fulminate really, but what really blows me away is just the power of this reaction mix.

Ok, so the pH for me ended up at around 9... I might not have scaled the nitric exactly correctly (it was a weird concentration in the patent). But

here's a video showing....

Firstly: The raw reaction mix. It's very hard to dry, but when I stick it in the freezer, the whole lot turns into a sticky mass of crystals. The

water boils off, and everything detonates violently.

Next, what I did was try to recrystallise from acetone. When a lot didn't dissolve, it turned more into an extraction. The yellow solid left behind

(i'd say like 90% of the mass of the reaction mix?) after the acetone extraction is not energetic. When put over a flame, it simply evaporates away,

calmly, not even burning like 5-ATZ does. The acetone used to extract the mix though.....

The next two clips are me heating (or accidentally setting fire to) the acetone solutions. The acetone boils/burns off before the solid explodes, but

when it does, it's phenomenal. Look how it shreds that aluminium foil......!

So... is this the sodium salt of nitrotetrazole? I mean it has to be, because the pH of the mix is basic, but gee, it goes hard. The sodium salt seems

to outperform the silver salt almost... whats up with that?

VIDEO: https://youtu.be/j3ulrXukg6o

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Ooops, just noticed I got the ratios of sulfuric and nitrite wrong for the batch 5-NTZ proces... Shouldn't be doing this stuff late at night (or at all Shouldn't be doing this stuff late at night (or at all ) )

The potassium salt might be interesting as well, it doesn't form hydrates like the sodium salt. Read somewhere that the main reason it is unsuitable

as a primary is it's "low" decomposition temperature of 195 deg C, although couldn find any sensitivity data.

Some interesting paper about DBX-1

Attachment: Development of a Lean Process to the Lead-Free Primary Explosive DBX-1 (929kB)

This file has been downloaded 803 times

[Edited on 3-12-2017 by nitro-genes]

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

Had a go at making mercuric Nitrotetrazolate according to the synthesis depicted in this document: http://www.dtic.mil/dtic/tr/fulltext/u2/a036086.pdf

I did it at 1/10th the scale - making large amounts of such a powerful primary makes me nervous. Followed the synthesis to a T including preparing the

Mercury nitrate solution from HgO. The Solutions of HgNO3 and Sodium Nitrotetrazolate were mixed at 75c as directed and were left at a slow stir

speed until 30c. Shortly after mixing not much seemed to be happening but at about 55-50c there was a gradual precipitation of the product in a

microcrystalline snow in The beaker. Once it got to about 30c which was also the temp in my lab I left the solution for a few mins before gravity

filtering and rinsing several times with ice water and finally with a small portion of Dichloromethane.

Now I must say that I was very impressed by this stuff. It flashes off with a dull thump like its fulminate cousin but a bit faster, with a white

orange flash. when confined in foil I had perhaps a few Mg in a bit of foil and held it over my alcohol burner and the report was loud. It actually

shocked me. The foil was atomised shiny glitter and my ears were ringing. I don’t recall the DBX-1 being quite as powerful. It’s also not super

impact sensitive or friction sensitive but enough to be useful as a primer. Obviously a drawback is that it contains mercury. The little squares of

foil that I lit it on showed the signs of amalgam formation in the way of the tiny fibers that formed when mercury is in contact with Aluminium.

[Edited on 4-12-2017 by NeonPulse]

|

|

|

snooby

Hazard to Self

Posts: 88

Registered: 24-5-2013

Member Is Offline

Mood: No Mood

|

|

When I made the raw NaNTZ mix, and I put aceton in the mix to extraxt the pure NaNTZ from the crude crystal mix I end up with unknown amount of NaNTZ

dissolved in the aceton.

To use the pure NaNTZ to make BNCP I need to know how much NaNTZ I have made. So, I need to evaporate the acetone and wheigh the NaNTZ. This part i

really dont like, because of the power and sensitivity of pure NaNTZ. Just 0.5 gram CAN turn u deaf.

To avoid contact with the stuff, I wheigh the empty can, then let the aceton evaporate, and wheigh the can again. Then I just put the right amount of

distilled water over it to get a useable solution of nantz in water.

I would like to know, how do you guys handle crude and pure NaNTZ?

Is there a reason to be so scared of it?

[Edited on 30-11-2018 by snooby]

|

|

|

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

NaNTZ crystallizes from water as a dihydrate which is quite insensitive. It requires pretty strong blows with a hammer to go off.

Acetone on the other hand may or may not give you the dihydrate so I would be very careful, the anhydrous salt is very sensitive!

|

|

|

snooby

Hazard to Self

Posts: 88

Registered: 24-5-2013

Member Is Offline

Mood: No Mood

|

|

That is excactly what concerns me. The aceton step is very important to remove impurities from the NANTZ mixture. I did the whole process 5 times with

about 3 grams of raw NaNTZ and never had problems. Still I dont feel very comfortable with it. Are there any guys that did NaNTZ purification?

Edit: I remember following thing. When i had the pure nantz in the aceton dissolved, i poured distilled water in this mixture. Then I would heat the

liquid untill no acetone smell was obtained anymore. I then simple let the water evaporate. Quite time consuming however

[Edited on 3-12-2018 by snooby]

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

No experience with recrystallization from acetone, though recrystallizing NANTZ from hot methylethylketone (MEK) definitely resulted in a hydrate

(melted and boiled first when heated, only then exploded). Even though this was tested at small scale first, I still added a few drops of water to the

MEK for the main batch as a psychological reassurance.  Wondered if MEK would

not be an even better solvent for NaNTZ recrystallization, since it is more hydrophobic than acetone and has a higher boiling point, so maybe less

likely to crystallize an anhydrate and better recovery efficiency? Wondered if MEK would

not be an even better solvent for NaNTZ recrystallization, since it is more hydrophobic than acetone and has a higher boiling point, so maybe less

likely to crystallize an anhydrate and better recovery efficiency?

Thinking some more about the patented batch process...what would be the most prominent impurities? I've noticed that a dark yellow impurity is formed

along with the colourless NANTZ. The yellow impurity darkens in colour when basified further, so my guess would be that this would be mostly

5,5'-diazoaminotetrazole or 5,5' azotetrazole? Maybe the reaction is so fast that upon adding the 5-ATZ/Acid solution to the nitrite solution, the

mixing efficiency becomes limiting in how much self-coupling takes place? The same thing applies for the reaction of hydrazine and nitrous acid to

from hydrazoic. Apart from really strong mixing, would further dilution of the 5-ATZ/Acid solution not be more beneficial?

Also noticed that insufficiently purified NANTZ, immediately produces a fine green haze when cupric salts are added. IIRC, the solubility of the

cupric salt of 5-NTZ is much higher than those of unreacted 5-ATZ, 5,5'-diazoaminotetrazole or 5,5' azotetrazole. Wonder if a first NANTZ enrichment

step using cupric salts woudl be feasible. Don't know the exact solubility of all the cupric salts though, or if they even are all known...

[Edited on 3-12-2018 by nitro-genes]

|

|

|

Hex

Harmless

Posts: 3

Registered: 19-6-2003

Location: Republic of Scotland

Member Is Offline

Mood: No Mood

|

|

Been a long time (12 years maybe?!) since I last posted on here, still some familiar names from back in the day though...PHILOU, Roscoe, hello! I'm

still working in energetics and rediscovered the forum searching for anything new on DBX-1...some of the skills and improvisations in this thread are

really impressive!

A couple of things that I don't think have come up in the previous 20 pages, apologies if I missed them on scanning through.

1) The "acid copper salt" actually turns out to have about 4% sodium in it (when using sodium hydroxide to neutralise, obviously). It's defied

recrystallisation so I don't think anyone's got an X-ray structure yet.

2) If your "DBX-1" is brown and a nightmare to collect in a filter, it's probably not DBX-1. No-one is 100% sure what the brown, "gel-like"

intermediate is that forms on ascorbate reduction of NaNT/Cu(II), but it's very difficult to convert to DBX-1 without having DBX-1 crystals to seed

the reaction with...chicken and egg. Apparently the transition from gel to DBX-1 is quite obvious visually when it happensand the product is visibly

crystalline and reddish, unlike the brown sludge. I had a few goes (without seed) and isolated the products...they were all energetic and flame

sensitive, but the DSC peak exotherm varied across a range of around 80C depending on the batch.

I've got some nice NaNT.2H2O in hand, made by an adaption of the Fronabarger filter reactor method for making NaNT solution, but as I was going for

purity I evaporated it, Sohxleted the solids and recrystallised by slow evaporation from acetone (some of the rhombic crystals are 40x40mm plates!)

and have slight yellowish tinge, I'm going to try the Cu(I) method next, it seems to be less seed dependent...looking back over the thread I see

Neon's tried this method and it's no surprise that his product looks much more like DBX-1 - nice job!!

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

It seems very difficult to get good DBX-1 crystals. The "gel" is a weird thing indeed... I remember trying some alternative synthesis schemes using

the cupric/ascorbic method, and in one instance (using much lower temperatures during the synthesis), the entire solution became like a solid gelatin

pudding. What I found really strange is that boiling this gelatin mass in some instances still refused to produce DBX-1.  The gel doesn't form from the CuCl synthesis indeed, though even then the product

seems a mix of well formed crystals and almost amorphous stuff. Could be the simultaneous presence of cupric and cuprous results in this gel (The

cupric may allow more ligand binding, forming almost a polymer) and/or could relate to the ascorbic, though both would seem easy enough to exclude.

Alternatively, the DBX-1 forms as very small crystals, and the formation of DBX-1 crystals from this colloid depends on a poorly understood

self-assembly process maybe? The gel doesn't form from the CuCl synthesis indeed, though even then the product

seems a mix of well formed crystals and almost amorphous stuff. Could be the simultaneous presence of cupric and cuprous results in this gel (The

cupric may allow more ligand binding, forming almost a polymer) and/or could relate to the ascorbic, though both would seem easy enough to exclude.

Alternatively, the DBX-1 forms as very small crystals, and the formation of DBX-1 crystals from this colloid depends on a poorly understood

self-assembly process maybe?

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

There is a strange gel formation that can also occur for lead styphnate. So it may be a clue what is occurring there has a physical chemistry

parallel. It seems like the gel could be exploited, perhaps as a method of formation for double salts which might be gotten by mixing one gelled

system with another gelled system where the two could interact and form a product from the gel precursors.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Interesting idea, using these gels to produce double salts... Strange phenomena

these gels, noticed there was a paper posted on SMDB about the lead styphnate jelly, from what I read it seems to be controlled by pH mostly, so maybe

is determined by how coordinated water interacts with the Pb2+ and styphnate to produce some hydroxide containing complex, though cannot picture how

this would look like. Strange phenomena

these gels, noticed there was a paper posted on SMDB about the lead styphnate jelly, from what I read it seems to be controlled by pH mostly, so maybe

is determined by how coordinated water interacts with the Pb2+ and styphnate to produce some hydroxide containing complex, though cannot picture how

this would look like.

Can DBX-1 be produced at slighty lower pH? What happens if ascorbic acid is used instead of sodium ascorbate?

[Edited on 13-12-2018 by nitro-genes]

|

|

|

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

I have used ascorbic acid instead of sodium ascorbate! It worked perfectly; the DBX-1 was reddish and settled quickly on the bottom.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Seriously? Nice!!! Any microscopy pictures?  Does the DBX-1 produced dissolve

in HCl as a clear solution, no copper particle residual? Is it actually soluble in HCl? Does the DBX-1 produced dissolve

in HCl as a clear solution, no copper particle residual? Is it actually soluble in HCl?

5-NTZ is a very strong acid, coincidentally about as strong as picric ( ) at a

pKa of 0.8, so after performing the picric reductions using cupric/ascorbic I was contemplating before if a pH of about 2 would interfere with the

formation/complexation of 5-NTZ to the cuprous salt indeed. Performing the entire reaction in dilute acetic might be even more beneficial. Similarly,

the picramic and styphnamic complex of Cu(I) is only displaced at very low pH and high concentrations of competing ligands such as Cl- or NO3- (but

not sulfuric), so was wondering if the same would apply for DBX-1 indeed. The reduction of picric/styphnic might be interesting for the production of

DBX-1 as well, as it is sort of an optimized procedure for the steady production of Cu(I). ) at a

pKa of 0.8, so after performing the picric reductions using cupric/ascorbic I was contemplating before if a pH of about 2 would interfere with the

formation/complexation of 5-NTZ to the cuprous salt indeed. Performing the entire reaction in dilute acetic might be even more beneficial. Similarly,

the picramic and styphnamic complex of Cu(I) is only displaced at very low pH and high concentrations of competing ligands such as Cl- or NO3- (but

not sulfuric), so was wondering if the same would apply for DBX-1 indeed. The reduction of picric/styphnic might be interesting for the production of

DBX-1 as well, as it is sort of an optimized procedure for the steady production of Cu(I).

One of the important differences would be the question how hard that Cu(I) is "gripping" the 5-NTZ? Is there some measure or definition for that?

Reading IIRC that DBX-1 is easily hydrolysed by water, my first guess was that it was a rather weak interaction. Silver azide is another surprising

example, forming almost a completely ligand coordinated polymer that precipitates even from very acidic solutions, despite the azide ion being a

rather weak base.

[Edited on 14-12-2018 by nitro-genes]

|

|

|

snooby

Hazard to Self

Posts: 88

Registered: 24-5-2013

Member Is Offline

Mood: No Mood

|

|

Anyone with a decent dbx1 synth? The one with ascorbic acid gave me brown chunks wich where not usable as a primary. I hope someone can post another

synthesis or some advise about that.

Also a question: when purifying crude NaNTZ crystals I do an extraction with aceton. Since I dont want to evaporate the acetone (to exclude forming of

anhydrous nantz) I mix the aceton with demi water. Then I let the aceton evaporate on a hot water bath, so only water remains. Is this a good thought?

|

|

|

| Pages:

1

..

18

19

20

21

22

..

25 |