| Pages:

1

2 |

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

The nitrated intermediate is still damp after 12 hours in a desiccator so I proceeded with the final hydrolysis step.

REAGENTS

* 30% w/w ammonia solution

1,1-DIAMINO-2,2-DINITROETHENE (FOX-7)

The damp nitrated intermediate from step 2 was added to 50ml distilled water in a 250ml conical flask and the suspension set on stir.

30% ammonia solution was added dropwise while maintaining the temperature between 20-30 degrees C.

With each addition, a gold colour was noticed where the ammonia solution contacted the suspension. A small exotherm with frothing was noticed about

halfway through and the temperature jumped to 31 degrees C momentarily but quickly cooled back down.

The pH was monitored with test strips and addition was stopped at approximately pH 9. Fine canary yellow crystals of 1,1-diamino-2,2-dinitroethene

were now suspended in the solution.

The solution was stirred for 2 hours and then filtered before washing with water a few times. The yield is nearly dry and reads 4.5 grams on the

scale which is half of what is claimed on the paper even when taking into account a half sized batch. Paper mentions 19.66g final yield which means I

should have around 9.5g.

I attribute this to not getting a full yield of 2-methoxy-2-methyl-4,5-imidazolidinedione and then losing a lot of the nitrated intermediate when

trying to filter again (did I mention it is shit to filter . Also not having

the intermediate dried properly may have had an effect. . Also not having

the intermediate dried properly may have had an effect.

I have another last batch of 2-methoxy-2-methyl-4,5-imidazolidinedione which I can process and try and get some more for testing purposes.

The disadvantage with this synthesis is definitely the large amount of solvent and exotic reagents needed, and the three steps for a small amount of

product returned. Even if you get a decent yield from the half sized batch, it would only be just over 9 grams.

[Edited on 6-9-2018 by greenlight]

[Edited on 6-9-2018 by greenlight]

[Edited on 6-9-2018 by greenlight]

[Edited on 6-9-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

HNA lost password

Harmless

Posts: 1

Registered: 6-9-2018

Member Is Offline

|

|

wow... Good work! I'm truly amazed. Who'd have thought that such a simple molecule would need such complex precursors. In any case, congratulations!

Probably a silly question, but I know that DDNP is made by converting one of the nitro groups of TNP into a primary amine, and then turning that into

a diazo group. Could you theoretically do the same thing with the NH2 groups on FOX-7, to make it into (di) diazo dinitroethene? If so, would it make

it more powerful, more sensitive, or both? If it's even possible, I know the oxygen balance would be even at least.

|

|

|

Tdep

National Hazard

Posts: 519

Registered: 31-1-2013

Location: Laser broken since Feb 2020 lol

Member Is Offline

Mood: PhD is done! It isn't good but it's over lol

|

|

Is that the colour it is meant to be? I like the idea of FOX-7 but I have a personal bias against yellow compounds

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@HNA, thanks. I am sure if (di) diazodinitroethene was possible it would have been attempted by someone by now. I am guessing that it would lose its

favorable stable properties though by chucking those diazo groups on if it is possible but I doubt that.

@Tdep, Yes that is the colour its meant to be, I asked myself the same question. From high density energy materials:

"FOX-7 exists as a canary-yellow solid and may be recrystallized from various solvents"

It is the kind of picric acid colour that makes you not want it to contact anything in your lab but I have found it doesn't stain anything at all

except the filter paper and easily washes off instruments and skin. It is a well behaved yellow

Be good, otherwise be good at it

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

I must say congrats! Fox-7 in an amateur lab is no small feat! Even with the lower yield are you going to recrystallise it? Some photos of nice pretty

crystals would be cool to see.

Pretty inspired to attempt this myself at some point. Seeing as now you have proven it possible in amateur settings. Would be interesting to see the

results of testing and comparisons to PETN or ETN.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thanks NP

I am not sure if I will recrystallise it yet. Apparently it can be done with DMSO or 0.5, HCl but it has limited solubility in the dilute HCl.

I think for testing purposes, I could press it in a aluminium tube with an initiating charge of lead azide on top and detonate it against a steel

plate. I would also make a second charge of PETN pressed the same in the same type of tube to compare it with.

Be good, otherwise be good at it

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

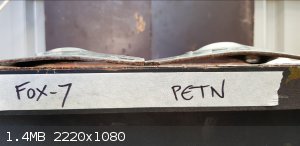

PETN vs FOX-7

I decided to test the FOX-7 against a known energetic and using NP's idea I used PETN.

I took 3.5 g of each explosive and pressed them hand tight in a bench vice into 12mm diameter aluminium tubes. Unfortuneately I don't have a device

for measuring the amount of pressure put into loading each one. They were both as tight as I could get with my hand.

300mg lead azide was then packed carefully on top of each secondary to absolutely ensure initiation. Finally a small amount of Black powder and a

piece of visco before sealing them.

The charges were taped onto small matching 3.4mm thick steel plates I had laying around as shown below:

Full detonations were observed on both plates. The results are quite interesting as the PETN created a deeper dent of 9mm depth while the FOX-7

produced only a 7mm deep indent.

I held the plates level and filled the dents with water multiple times, measuring the amount held and averaged the results and the PETN plate

lost....wait what the fuck!?? No it didn't, the FOX-7 plate holds just as much and slightly more water (43.25ml) than the PETN witness plate

(43.10ml). The FOX-7 dent is wider though.

The PETN charge threw the plate nearly twice as far as the FOX-7 did as well.

My conclusion is that the PETN is more brisant than the FOX-7 and creates a deeper dent and projects the plate farther but the FOX-7 still has nearly

equal power as the dent is much similar and does indeed hold more water.

The PETN definitely does have more brisance and shattering power though and it is known to perform better than some explosives in smaller charges.

All that work to find th

The FOX-7 takes the win in the stability insensitivity and heat resistance (due to the amine groups) though and that seems the current trend nowadays

in energetics; but damn that stuff is a costly time consuming fucker to make

[Edited on 2-10-2018 by greenlight]

[Edited on 2-10-2018 by greenlight]

[file]71021[/file] [file]71019[/file]

[Edited on 2-10-2018 by greenlight]

[Edited on 2-10-2018 by greenlight]

[Edited on 2-10-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

I also have these two photos of the plates that show the two dents are extremely similar in shape and size:

I have been trying to explain why the PETN dent is deeper slightly though. Both explosives have similar negative oxygen balances. PETN is -10.21 and

FOX-7 slightly more negative at 21.6% exactly the same as RDX. Not enough to really make a difference there.

When I calculate the moles of gas produced upon detonation though the results are more interesting.

PETN (C5H8N4O12) produces 14 mol gas whether you favor CO or CO2 in the products.

FOX-7 (C2H4N4O4) produces only 6 mol of gas upon detonation.

If you work out how much gas is evolved per gram of explosive you get these numbers:

PETN = 0.992L has per gram

FOX-7 = 0.908L gas per gram

I think the excess 0.084L of gas produced exerts slightly more pressure on the surroundings (thin steel plate) and causes the PETN to get the higher

result in the plate dent test.

I think the FOX-7 would work well in shaped charges, especially EFP's, as from experience PETN seems to have an easy to cross upper limit where it

starts to rip the liner into pieces instead of form a slug. Ideally, you could use more FOX-7 explosive to get a high velocity on the slug before you

reached this limit. This is just my opinion I do not know how much truth would be in this.

I really need more FOX-7 to conduct different tests but damn it's expensive to make at home

[Edited on 5-10-2018 by greenlight]

[Edited on 5-10-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

I would guess that they seem similar in power because they're at similar density, but if you were to bring them close to their max density the FOX-7

would be all around more powerful.

Even though FOX-7 has a higher max density compared to PETN that doesn't necessarily mean it reaches a higher density when pressed with equal force, a

lot of that comes down to crystal size I think.

In any case this is an awesome thread!

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@OneEyedPyro, you are probably correct about the performance results. I am sure the FOX-7 would slightly outperform the PETN if pressed to its

maximum density and I was surprised when I got similar effects on the plates.

I need a gauge so I can record the pressures they are pressed to and work out the densities for future tests.

Be good, otherwise be good at it

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

@greenlight.. You could use an arbor press with a torque wrench for pressing, this would give you a pretty good measurement of pressure with some

calculations and you could achieve pressures far beyond hand pressing thus reaching much higher densities and give a better idea of the potential

power of different explosives.

For no more than $150 shipped you could have an adequate setup, you'd just have to figure out how to attach a square drive bit to accept the torque

wrench (I welded mine on).

You could use flat bottomed tubes of known/consistent volume and measure how deeply the charge is pressed into the tubes along with the overall weight

to calculate density very accurately.

During pressing you'd also need an outer tube of great strength which will perfectly fit around the tube you intend to use for the charge because the

inner tube might otherwise swell or crush under pressure.

Obviously, you'd want very thick shielding around the press and wear PPE in the case of an accidental detonation because the outer tube creates some

very serious shrapnel concerns!

These are just my proposed methods but it's food for thought.

[Edited on 10-10-2018 by OneEyedPyro]

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

@OneEyedPyro, ..I have seen arbor presses before and I have one on my list of things to get as I was going to use it to press AP and whistle rockets

too.

Your idea of measuring the volume of the tubes is good. I use a similar technique when getting a density value for plastic explosives by pressing a

small amount in a syringe and calculating density from the ml and grams.

What does attaching the torque wrench to the arbor press do. I have seen modified arbor presses like that on pyrotechnic sites. Does it enable me to

know how much pressure I am applying.

The secondaries are quite low risk to press (PETN borderline out of them all) but I do use shielding just in case.

Pressing primaries into caps is the task that always gets me on edge though

Be good, otherwise be good at it

|

|

|

OneEyedPyro

Hazard to Others

Posts: 280

Registered: 7-10-2015

Member Is Offline

Mood: No Mood

|

|

@greenlight... The torque wrench mostly just allows you to control pressure exerted for the sake of consistency.

You could use it to figure out pressure but you'd have to know the gear ratio of the press and calculate how much torque equates to a given PSI with

a specific size pressing bit, but it would probably be easier to use a gauge made for that.

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thanks for the info OneEyedPyro, I have put an arbor press on my list of things to buy.

Be good, otherwise be good at it

|

|

|

Herr Haber

International Hazard

Posts: 1236

Registered: 29-1-2016

Member Is Offline

Mood: No Mood

|

|

I would be most greatful if someone could give me a few keywords to google for arbor press tools.

All I can find are tools to remove balls from ball bearings (those are ok for pressing)

What if... I want to use a conical tool to make a tube wider ? Or narrower ? Or just indent the edge of my material, or create a small depression etc.

?

Damn, there must be tools out there and there must be a name to call them by !!!

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Swedging tool = tube expanding : These can be lathed if you have access to one

https://www.google.com/search?num=100&newwindow=1&cl...

you can make a press with a hydraulic jack and some channel stock

[Edited on 16-10-2018 by XeonTheMGPony]

|

|

|

| Pages:

1

2 |