| Pages:

1

2

3

4

5 |

greenlight

National Hazard

Posts: 753

Registered: 3-11-2014

Member Is Online

Mood: Energetic

|

|

I did use a small amount of 98% sulfuric acid in the fractional distillation, I just forgot to mention it haha. I used 60ml H2SO4 for every 500ml of

antifreeze in the first distillation and about 16-17ml in the fractional distillation to hydrolyse impurities.

I am not sure sure if the week wait would actually affect the dioxane yield but maybe next time try it the other way and see if it makes a difference.

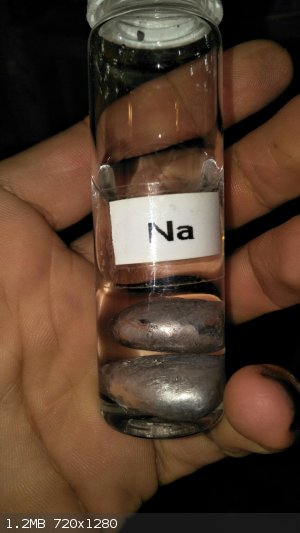

Also I have re-weighed the sodium yield and it is only 6 grams. Something wrong with my scale and it is fines simce I replaced the batteries. Still

a decent yield though I think..

It is very exciting to see blobs of molten Na as the solvent level gets low. I plan to run the reaction quite a few more times as I need something

like 50g elemental sodium.

I wonder if the reaction can be scaled up?

[Edited on 9-4-2018 by greenlight]

Be good, otherwise be good at it

|

|

|

MöbiusMan

Harmless

Posts: 14

Registered: 13-7-2018

Location: Australia

Member Is Offline

Mood: studious

|

|

Synthesising 1,4 Dioxane

Ok, I finally did it.

I somewhat followed NurdRage’s video and Dough's but have come up with a better one.

First distill your antifreeze and collect the pure ethylene glycol; it boils at about 200ºC so i used an air condenser with a wet towel placed over

it as water jacket condensers may crack due to thermal stress. Once you finish distilling the ethylene glycol, you will see a bunch of salt and

corrosion inhibitors left in the flask and can wash them out with water.

You also want to distill your sulfuric acid if you are using drain cleaner; Use pieces of terracotta pot as boiling chips, they will react at first

and colour the acid red but then stop reacting and make perfect boiling chips, NO BUMPING AT ALL. Once that was distilled, depending on the brand you

may have some junk left in the flask.

Now put however much ethylene glycol you have in a large jointed flask. You want to have a lot of headspace in you flask as it will foam up a lot (I

used a 2L flask for 500ml of ethylene glycol). Then add 7% of the volume of ethylene glycol of your 98% sulfuric acid. Set up a fractional

distillation with a vigreux column or others and heat up your mixture; use strong stirring. Collect everything that comes over and continue heating

the reaction flask. Towards the end of the distillation the reaction flask will turn a dark brown and eventually a tarry black. It is important to

keep strong stirring all the way through to stop the foaming. It is at this point most people's yield goes out the window because they stop too early

due to the foam. This is why we use the oversize flask. Continue heating until the foam is super thick and fills the flask. You need good ventilation

as a lot of vapours form and are toxic. Turn off heating before it all overflows and save your distillate from the oncoming foam if necessary.

I collected about 400 - 450ml of crude distillate from 500ml of ethylene glycol. To this distillate I add 5% of the distillates volume in 98% sulfuric

acid. Set up another fractional distillation. Heat the flask and you will collect a bunch of impurities which boil at about 40 - 50ºC. When the still

head reaches 86ºC change out the receiving flask and collect your dioxane. The temperature should then sit at 87.7ºC for a while and the rate of

distillation will greatly increase. Continue collecting until 93ºC at which point the distillation is over.

With this purified dioxane, add NaCl with strong stirring and intermittently stop stirring and wait a minute. If no by-phase has formed continue

adding NaCl. Continue doing this until you have a nice by-phase with a little extra pile of salt at the bottom. I left mine to stir for an hour on

strong stirring.Then pour the mixture into a separatory funnel. Allow the layers to separate and drain away the lower aqueous layer. Collect your

upper dioxane layer in another flask.

To this dioxane add some NaOH using the same method mentioned before (stirring then waiting for a by-phase to form). This time, make sure there is a

decent amount excess NaOH sitting at the bottom. Stir this for another couple of hours. It will turn an orange colour and you may have solid bits of

polymerised impurities. If you do it right the lower layer should form a semisolid thick gel layer. Add the mixture to a clean separatory funnel and

allow the layers to settle. Drain away the lower orange/red layer, and collect the upper dioxane layer.

Using sodium magnesium aggregate further dry the dioxane with stirring overnight; make sure to not seal it as pressure may build up. Then distill the

dioxane using a simple distillation and collect whatever boils at 100-103ºC. If there wasn't much water you may be able to create sodium spheres as

you distill it but most of the time you won’t get much at all. The second time you distill the dioxane with sodium magnesium aggregate you will get

alot more sodium as the dioxane is now completely dry.

Its amazing how much you can write when you enjoy what you write about.

If you have any questions write them in below.

Good Luck and Happy Carcinogening!

[Edited on 15-7-2018 by MöbiusMan]

If chemistry was easy it would be called biology.

|

|

|

j_sum1

Administrator

Posts: 6333

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Thanks MM.

I have been doing the same thing the past couple of days. Again following Nurdrage pretty explicitly.

Batch 1 was about 300mL of antifreeze in a 500mL RBF using 40mL of sulfuric acid. I managed to have it foam over twice and so it got triple

distilled. Then 10mL of Sulfuric acid added to the distillate and fractional distillation. Product looked clean and clear at this stage. This was

followed by stirring with NaOH for several hours. I got some dark waxy-looking lumps appear quite quickly and two liquid layers. The organic layer was

still very amber in colour so I responded with a large amount of additional sodium hydroxide. The result was an orange sludge of polymer gunk and a

much smaller amount of discoloured dioxane. I filtered and have a measly 50mL that will still need distilling to purify.

Batch 2 was 250mL usung 60g of sodium bisulfate. Distillation was a bit slower but not unreasonably so. Distillate came over with a yellow tinge

before foaming occurred so the process was halted. Volume yield seems ok at this point but I have not cleaned it up yet. Tarry mess with solidified

NaHSO4 looked a real mess to clean at first. But adding some NaOH and a bit of water and leaving it over night loosened it up nicely. Washing it out

left a lovely sparkling flask.

I will try the NaCl salting out. That might be a step in the right direction following my hydroxide mess.

If, as you say, the sodium synthesis needs very dry dioxane, it might be better to distil over NaOH rather than just stir and decant.

I will be doing a few runs over the next couple of weeks so I can play with the parameters a little.

[Edited on 15-7-2018 by j_sum1]

|

|

|

MöbiusMan

Harmless

Posts: 14

Registered: 13-7-2018

Location: Australia

Member Is Offline

Mood: studious

|

|

Yes, the NaCl salting will remove most of the water so you save on sodium hydroxide and it forms less wastage in the gelatinous stuff. What yield of

distillate did you get on the first distillate because I found a lot of the distillate comes over when the foaming gets intense. This could be a one

of the reasons people get such a low yield for this synthesis. Having a massive flask to allow the foam to build was the way i handled it.

If chemistry was easy it would be called biology.

|

|

|

j_sum1

Administrator

Posts: 6333

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

I did not measure reagents accurately so don't know the yield.

I am limited to a 500mL rbf for heating. There was quite a bit of liquid there when it began foaming. Hard to estimate volume of a foam but I would

reckon equivalent of 80-100 mL of reagent from a ~300mL charge.

Maybe one of the secrets is not to be too ambitious with batch size since it will be lost anyway.

Or maybe it is worth putting an addition funnel into the process.

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

I'm going to give the iron sulfate method a go, I just made some from 23grams of iron turnings, it is now a nice pale green crystal structure filling

the bottom of the beaker, need to dry this to anhydrous state

Attachment: 1,4-Dioxane msds.pdf (456kB)

This file has been downloaded 575 times

Attachment: Dioxane excerpt from Elderfield's Heterocyclic Compounds volume 6.pdf (3.1MB)

This file has been downloaded 632 times

|

|

|

j_sum1

Administrator

Posts: 6333

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Thanks for that Xeon. I haven't read the whole thing but it is fascinating thus far. Separation of Li from other group I salts. Whodathunkit?

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by j_sum1  | | Thanks for that Xeon. I haven't read the whole thing but it is fascinating thus far. Separation of Li from other group I salts. Whodathunkit?

|

http://www.sciencemadness.org/talk/viewthread.php?tid=65311

Credit belongs to this thread! We should have a Dioxane sticky

As I suspect a great many threads will be popping up!

I'll add some pictures of my iron sulfate and eventually dioxane work up to one of these threads, probably the larger one.

I plan to use my addition funnel (250ml) and a 500ml 3 necked flask to try and do a continuous flow system

Just a tip to you guys, Seafoam containers will be ideally suited to storing Dioxane as they are a stamped aluminium seamless bottle with a fairly

good sealing cap on them, and around here at least you find them around the roads due to ignorant people littering, so keep an eye out!

I use them to store my used alcohol for drying, I then dry/distill and use it in my alcohol burner.

[Edited on 15-7-2018 by XeonTheMGPony]

|

|

|

MöbiusMan

Harmless

Posts: 14

Registered: 13-7-2018

Location: Australia

Member Is Offline

Mood: studious

|

|

I got up early this morning at 5:30 and went up to the lab to check on things and found that my distance has frozen. Guess that's expected seen as it

was 3 degrees C. Well that gives me some confidence that I actually have dioxane. Bloody climate change its nearly sub zero in Sydney! Grrrrr

If chemistry was easy it would be called biology.

|

|

|

Vosoryx

Hazard to Others

Posts: 282

Registered: 18-6-2017

Location: British Columbia, Canada

Member Is Offline

Mood: Serial Apple Enjoyer

|

|

I used is 11 Celsius melting point to crystalize it before I used it in my sodium synthesis, just by heating the flask it was in and then placing it

in a closed thermos in the fridge. At the end there was a tiny bit of water that I couldn't even pour off - I had to put a cool paper towel on it to

remove the water.

It wasn't needed though, the Na/MgO would have removed it. I just wanted a crystal because it was my science fair project and I wanted it to look cool

on the poster board. Of course, it didn't even produce a crystal, just solidified inside the flask in the thermos.

"Open your mind son, before someone opens it for you." - Dr. Walter Bishop

|

|

|

MöbiusMan

Harmless

Posts: 14

Registered: 13-7-2018

Location: Australia

Member Is Offline

Mood: studious

|

|

This raises the question if it is possible to purify dioxane by recrystallisation

If chemistry was easy it would be called biology.

|

|

|

Vosoryx

Hazard to Others

Posts: 282

Registered: 18-6-2017

Location: British Columbia, Canada

Member Is Offline

Mood: Serial Apple Enjoyer

|

|

Experiments will have to be done.

I'll add it to my growing list of things to do.

"Open your mind son, before someone opens it for you." - Dr. Walter Bishop

|

|

|

MöbiusMan

Harmless

Posts: 14

Registered: 13-7-2018

Location: Australia

Member Is Offline

Mood: studious

|

|

Wohooooo

I have sodium. The dioxane i made must be good because this is what i got. I didn't have any isopropyl on hand to coaless the sodium and found that

adding a few drops of the dioxane worked out and I ended up with a nice chunk of sodium. It even has those crystallisation lines that NurdRage talked

about in his vid. Yieeewwww

If chemistry was easy it would be called biology.

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Nice work MobiusMan!

|

|

|

MöbiusMan

Harmless

Posts: 14

Registered: 13-7-2018

Location: Australia

Member Is Offline

Mood: studious

|

|

Heheheheh I've been back in the lab. I'm addicted to the joy you get when you see those silver beauties forming.

If chemistry was easy it would be called biology.

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

I filled a 1000 ml round bottom flask, set up for simple distillation, with 350 ml of purified ethylene glycol. I then added 35 ml 93% w/w H2SO4 in

one portion. Heating and stirring were applied. Distillate came over at 120 C, tapering down to 105 C at the end, where foaming became too intense to

continue. I haven't proceeded with the rest of the reaction so I'm not sure of yield just yet.

Videos on YouTube show distillations between 90-100 C when the H2SO4 is added to the ethylene glycol. Why is this -- why are my still head

temperatures so high? Ethylene glycol boils at 197 C so it can't be unreacted ethylene glycol coming over.

[Edited on 5-23-2020 by monolithic]

[Edited on 5-23-2020 by monolithic]

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Quote: Originally posted by j_sum1  | I did not measure reagents accurately so don't know the yield.

I am limited to a 500mL rbf for heating. There was quite a bit of liquid there when it began foaming. Hard to estimate volume of a foam but I would

reckon equivalent of 80-100 mL of reagent from a ~300mL charge.

Maybe one of the secrets is not to be too ambitious with batch size since it will be lost anyway.

Or maybe it is worth putting an addition funnel into the process. |

Do u mean as a bulb between the neck of the flask and the distillation head?

|

|

|

draculic acid69

International Hazard

Posts: 1371

Registered: 2-8-2018

Member Is Offline

|

|

Also just found this:https://m.youtube.com/watch?v=0OhWEDtIQ2M

|

|

|

monolithic

Hazard to Others

Posts: 436

Registered: 5-3-2018

Member Is Offline

Mood: No Mood

|

|

As a follow up to my last post, I tried fractionally distilling the ethylene glycol + H2SO4. This brought the distillation temperature down a bit but

it was still fairly high. In total,

350 ml ethylene glycol + 35 ml 93% H2SO4, stirred 20 mins, simply distilled to yield 349 g crude distillate.

Added 35 ml 93% H2SO4 to distillate, stirred 20 mins, fractionally distilled to collect 87 - 95 C fraction total mass 205 g.

350 ml ethylene glycol + 35 ml 93% H2SO4, stirred 20 mins, fractionally distilled to yield 360 g crude distillate.

Added 35 ml 93% H2SO4 to distillate, stirred 20 mins, fractionally distilled to collect 87 - 95 C fraction total mass 211 g.

Combined both fractions, 416 g with total volume ~400 ml, and added 70 g KOH. Stirred between 1.0 and 1.5 hours.

Physical appearance: some black sludgy solids, lighter clear aqueous layer on bottom, dirty brown-red organic layer on top.

Discarded bottom aqueous layer, ~100 ml, as well as polymerized sludge.

Added another 25 g KOH, stirred for 1.5 hours. Majority of KOH did not dissolve as water was absent.

Physical appearance: undissolved KOH had some sludge on it, no aqueous layer, organic layer deeper brown-red color.

Gravity filtered solution and fractionally distilled to collect fraction 97.5 C - 102.7 C, crystal clear in appearance.

Total yield 272 g with a measured density of 1.02 g/ml @ 25 C (lit. 1.034 g/ml @ 25 C.)

Stored in an amber glass bottle with ~0.05 g BHT (~200 ppm) over 27 g activated 4A sieves (~10% w/w.)

Cleanup of the black sludge from the ethylene glycol + H2SO4 distillation was kind of shitty. Lots of acetone swirling and the stir bar had to be

scraped clean with a razor blade.

[Edited on 5-24-2020 by monolithic]

|

|

|

TLutman

Harmless

Posts: 26

Registered: 13-10-2019

Member Is Offline

|

|

Dioxane didn’t end well

I was going through NurdRage vids and decided to do the dioxane from antifreeze synthesis . I used Traveller concentrated ethylene glycol antifreeze.

Using a 1000ml erlenmeyer, I used 300ml of antifreeze and 40ml Liquid Fire drain cleaner. Initial distillation brought a yellowish distillate first,

followed with an overlapping clear distillate. The two were immisible, with the yellow layer staying up top.

Soon, there was perhaps 15ml of the yellow layer on top, with the clear more viscous liquid punching through like a lava lamp. This took a bit

longer than planned, so I ended up shutting down heat when there wasn’t much left but tar ( no foam at all). I debated using a separatory funnel and

getting rid of the yellow layer, but ultimately went to bed. After work the next day, much of the yellow was gone. I proceeded with another 10ml

H₂SO₄ and fractional distillation. Small amount came over under 83C, changed flasks and 120ish ml of clear liquid from 83 to 103C was collected.

Put 40g NaOH in with stirring. It soon just turned black with clumps of dirty NaOH on the perimeter. There was no clear anything after stirring all

night.

That brings me to now. I’m not sure what went south, or why. I was thinking on distilling again to see where it leads me.

Any thoughts?

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

| Quote: | | This took a bit longer than planned, so I ended up shutting down heat when there wasn’t much left but tar |

Don't do this. You distill all sorts of crap into the product. Anything condensing higher than 101 C is crap.

But are you sure that your antifreeze was pure ethylene glycol? The only other product I can think of is 2-methyldioxolane, which has a high water

solubility; dioxane is miscible. Paraldehyde shouldn't come over until 124 C. Acetaldehyde does not form easily in these conditions, anyway. The

presence of immiscible distillate suggests another organic component.

Some antifreeze may contain a mixture of ethylene and propylene glycols. If there were propylene glycol in your antifreeze, you could have obtained

propanal and 2-ethyldioxolane. These are much less hydrophilic. Ethanol can be present and may form diethyl ether.

There are a lot of variants of Traveller antifreeze. I was unable to find one claiming to be pure or diluted ethylene glycol with no other organic

components. What kind did you use?

It may be possible to flocculate out the tarry components with alum salts.

Alternatively, since the dioxane-water azeotrope boils at 87 C, you might collect the fraction boiling between 85-95 C and discard anything else. That

could be cleaner.

Or both!

[Edited on 22-4-2021 by clearly_not_atara]

|

|

|

TLutman

Harmless

Posts: 26

Registered: 13-10-2019

Member Is Offline

|

|

Label calls ethylene glycol, diethylene glycol, water, mixed corrosion inhibitors.

As for the high temp on initial distill, I shut down at 105, which was the steady temp for the majority of time. The flask wasn’t tar, but was

noticeably more viscous. After cooling, it’s more syrup, with a bit of liquid in it.

I distilled again, getting roughly 90ml, all coming over at 95c. I shut off heat when temp started dropping. Boiling flash is black with NaOH visible.

Not sure if it’s thick yet, I just turned it off.

|

|

|

TLutman

Harmless

Posts: 26

Registered: 13-10-2019

Member Is Offline

|

|

I have the dioxane stirring now with NaOH. It’s looking good so far, with only some clumping of the hydroxide but no other visible reactions.

I’m sure that I will be doing this again in the near future, just trying to learn from my mistakes.

|

|

|

clearly_not_atara

International Hazard

Posts: 2799

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Sounds like it worked out.

The other components in Liquid Fire are also corrosion inhibitors. I wonder what the hell is going on with all of these corrosion inhibitors?

|

|

|

XeonTheMGPony

International Hazard

Posts: 1640

Registered: 5-1-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by clearly_not_atara  | Sounds like it worked out.

The other components in Liquid Fire are also corrosion inhibitors. I wonder what the hell is going on with all of these corrosion inhibitors?

|

left in the tar usually, I distill my ethylene glycol first, and all the salts are left in the distillation flask.

|

|

|

| Pages:

1

2

3

4

5 |