kuro96inlaila

Hazard to Self

Posts: 96

Registered: 21-6-2010

Location: Malaysia

Member Is Offline

Mood: Quietly thinking

|

|

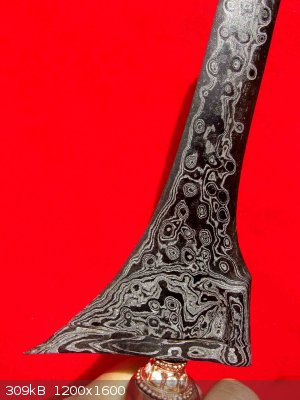

Pattern welded metal and etching

Okay before we start on the discussion I'd have to make clear I don't have any pattern welded metal on hands, so I'd not be able to test any of the

reaction on it.

In malay culture, the pattern of keris dagger is made by folding soften steel, nickel, iron, or such metals (the exact metal is not clear because

normally local call it by traditional name).

Some of the traditional practice to make the pattern more prominent, or making it lustre even more is to brush it with concoction of crushed realgar

mixed with lime juice. I'm guessing it's some etching process going on. CRC handbook on metal etchant did mention realgar etching recipe. do you guys

know how realgar might play part in this process? other candidate might be As2O3 instead of realgar or orpiment, arsenic

sulfide.

another thing came to mind is that, in these sort of pattern work, wouldn't some more reactive metal in the mix act as sacrificial metal to the less

reactive one? wouldn't it facilitate the rusting of the reactive layer?

|

|

|

Melgar

Anti-Spam Agent

Posts: 2004

Registered: 23-2-2010

Location: Connecticut

Member Is Offline

Mood: Estrified

|

|

I know some stuff about this. The patterns have more to do with the crystalline structure of the steel than anything. And that alternates between

ferrite, austenite, pearlite, and martensite, I think. Plus, working it changes the shape of the grains, sort of like how they make polarized

filters.

Really, the main reasons they'd use that stuff is because that was more readily available than other acids like hydrochloric acid and phosphoric acid.

But those are the acids I'd use, if your goal is to make the patterns more visible. They're still visible before "developing" the patterns with acid

though, it's just that they're quite a bit fainter. But you'd definitely be able to see them at the right angle.

The first step in the process of learning something is admitting that you don't know it already.

I'm givin' the spam shields max power at full warp, but they just dinna have the power! We're gonna have to evacuate to new forum software!

|

|

|

Sulaiman

International Hazard

Posts: 3721

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

The most valued Keris in S.E.Asia are those made from besi tahi bintang - meteorite metal.

(literally 'star-shit metal')

Lime juice is a common etchant and there is a lot of ritual processes involved in the manufacture.

..........

trivia:

My mother-in-law had such a keris that she always carried in her handbag,

even on international flights after 9/11 !

She said it is 'protected', and as I have accompanied her on international flights through all airport security - I'm inclined to believe her.

To-date I've not been able to take away the keris to examine it carefully as a distant brother-in-law now keeps it, along with a sword-type kris.

My wife's great-grandfather was a silat teacher from Indonesia, silat involves mysticism.

I wore a traditional Malay costume for our wedding - which includes a kris.

[Edited on 24-3-2018 by Sulaiman]

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Vosoryx

Hazard to Others

Posts: 282

Registered: 18-6-2017

Location: British Columbia, Canada

Member Is Offline

Mood: Serial Apple Enjoyer

|

|

AFAIK, (and this is my secondary hobby) the pattern is due to variations in the types of steel. In general, the less carbon, the lighter the shade of

the etch. On edges where the carbon gets oxidized out of the metal, it's lighter.

I use a solution of FeCl3 to etch, though it is heavily diluted.

Interestingly, i'm actually editing a video on this subject for my youtube channel right now...

"Open your mind son, before someone opens it for you." - Dr. Walter Bishop

|

|

|

kuro96inlaila

Hazard to Self

Posts: 96

Registered: 21-6-2010

Location: Malaysia

Member Is Offline

Mood: Quietly thinking

|

|

Quote: Originally posted by Melgar  | I know some stuff about this. The patterns have more to do with the crystalline structure of the steel than anything. And that alternates between

ferrite, austenite, pearlite, and martensite, I think. Plus, working it changes the shape of the grains, sort of like how they make polarized

filters.

Really, the main reasons they'd use that stuff is because that was more readily available than other acids like hydrochloric acid and phosphoric acid.

But those are the acids I'd use, if your goal is to make the patterns more visible. They're still visible before "developing" the patterns with acid

though, it's just that they're quite a bit fainter. But you'd definitely be able to see them at the right angle. |

ahhh I see so the pattern is a result of different crystal structure rather than drastically different composition being layered side by side.

yep the availability of classic traditional acidic substance is main reason they're use, other than being economically cheap. Since they do the job,

local didn't really tried to replace it with stronger more effective substance like standard acid.

Quote: Originally posted by Sulaiman  | The most valued Keris in S.E.Asia are those made from besi tahi bintang - meteorite metal.

(literally 'star-shit metal')

Lime juice is a common etchant and there is a lot of ritual processes involved in the manufacture.

..........

trivia:

My mother-in-law had such a keris that she always carried in her handbag,

even on international flights after 9/11 !

She said it is 'protected', and as I have accompanied her on international flights through all airport security - I'm inclined to believe her.

To-date I've not been able to take away the keris to examine it carefully as a distant brother-in-law now keeps it, along with a sword-type kris.

My wife's great-grandfather was a silat teacher from Indonesia, silat involves mysticism.

I wore a traditional Malay costume for our wedding - which includes a kris.

[Edited on 24-3-2018 by Sulaiman] |

yeah we do call meteorite "star poop" here hahahaa  always a common thing to

ask parents do star even poop like is it really a poop omg just imagine the childhood confusion. always a common thing to

ask parents do star even poop like is it really a poop omg just imagine the childhood confusion.

ohh that's interesting, what occurrence make you inclined to believe her? they didn't detect the keris at airport or?

Quote: Originally posted by Vosoryx  | AFAIK, (and this is my secondary hobby) the pattern is due to variations in the types of steel. In general, the less carbon, the lighter the shade of

the etch. On edges where the carbon gets oxidized out of the metal, it's lighter.

I use a solution of FeCl3 to etch, though it is heavily diluted.

Interestingly, i'm actually editing a video on this subject for my youtube channel right now... |

Carbon get oxidized out of the metal, this happen during the weld phase or can it happen overtime on normal temperature? Seem like

reverse-carburization at first hmmhmm

I wonder what mechanism it acts on for iron chloride to etch the metal. simple lewis acid I guess bc I remember reading iron chloride recipe can be

used on non-iron metal. I could be wrong tho, my knowledge is really rusty bhahaha

I get the idea of using arsenic/arsenous acid for etching, but to use arsenic sulfide in form of realgar and orpiment doesn't seem to help the etching

process theoretically. I mean, I cannot think of how they play the role here.

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

You can do both. Meteorites are often high in nickel, anywhere from 5-65% afaik.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

|