sipuli

Harmless

Posts: 4

Registered: 7-11-2017

Member Is Offline

Mood: No Mood

|

|

Working with old TNT

Disclaimer: i know that working with old military explosives is questionable at best.

---

Hello, long time HE hobbyist and lurker here. Just recently i came up with a problem that has not been discussed in great detail before.

I have acquired some soviet 200 gram TNT blocks from World War II. As far as i know they have been exposed to elements for decades. I already cleaned

them and dried in room temperature for several months.

I was little bit suspicious about the composition since i know the fact that at least end war explosive products may be far from pure TNT.

The material melts around expected 80-ish Celsius and when open flame is applied to molten material it burns with yellow to red flame and produces

large amount of black soot. Also hammering it furiously does nothing as expected. So I think I do have safe product here.

Since some of blocks are damaged (crushed) i would love to make my own small TNT castings out of them (does TNT have critical diameter?)

Im looking for TNT casting methods and other information related to this project. Plan is to use ETN based homemade blasting cap/booster combo to make

sure the TNT is set off properly. Old military initiators from same place and conditions are too damn scary to even handle.

And there is no way in hell im going to perform the initial melt indoors. I have a workshop in rural area and plan is to use modified electric stove

(PID control to control the water bath temperature) and 50 meter extension cord.

[Edited on 7-11-2017 by sipuli]

What could possibly go wrong

|

|

|

LearnedAmateur

National Hazard

Posts: 513

Registered: 30-3-2017

Location: Somewhere in the UK

Member Is Offline

Mood: Free Radical

|

|

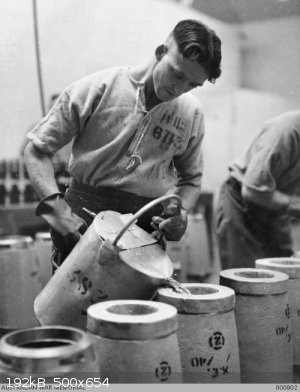

When they used to make TNT based bombs to be dropped from aircraft, manufacturers literally just poured in the molten TNT into the casings and left to

solidify, this was even done for the Grand Slam bomb which contained a whopping 4 tonnes of TNT/RDX/aluminium powder. As for the detonating cap, you

could place a steel rod in the TNT when it's cool enough to be mouldable then remove when solidified; a wooden dowel may also work but I don't know if

it'll react with the TNT or not.

In chemistry, sometimes the solution is the problem.

It’s been a while, but I’m not dead! Updated 7/1/2020. Shout out to Aga, we got along well.

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

If you cast TNT and allow for natural cooling you will end up with a concave surface due to strong contraction of TNT from the liquid state to the

solidified state.

To avoid this, you will have to cool it from the bottom (bottom-up) that way the concavity will be less... you will have to put a little excess molten

TNT after solidification on top to get a full loading.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

greenlight

National Hazard

Posts: 737

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Nice pic learned amateur.

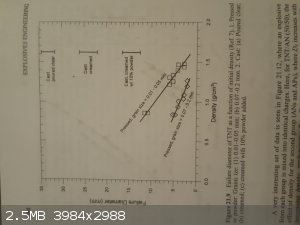

Here is a graph showing critical diameter for TNT from explosives engineering.

Maybe might be of some help. Seems for pure poured TNT, failure diameter is around 30-35 mm.

Much lower for the pressed grains though probably because there are more spaces in it (more porous than the melt cast).

[Edited on 7-11-2017 by greenlight]

Be good, otherwise be good at it

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Quote: Originally posted by PHILOU Zrealone  | | you will have to cool it from the bottom (bottom-up) that way the concavity will be less... you will have to put a little excess molten TNT after

solidification on top to get a full loading. |

Another method used is to top fill a case through a paper funnel, leaving excess melted TNT in the funnel above the desired fill height. As the lower

levels are chilled, solidify and shrink, this additional still molten material flows downwards and prevents cavitation.

Ideally, just a bit more than exactly what will be needed to accommodate shrinkage is left in the funnel, then the slight excess is removed along with

the funnel after solidification and shrinkage are finished.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Quote: Originally posted by Bert  | | Another method used is to top fill a case through a paper funnel, leaving excess melted TNT in the funnel above the desired fill height. As the lower

levels are chilled, solidify and shrink, this additional still molten material flows downwards and prevents cavitation. |

Precisely the same method used in metal casting, as metals also shrink on cooling.

The 'Sprue' into which the molten metal enters the mould is reasonably tall, creating Bert's 'paper funnel' for exactly the same reason.

|

|

|

sipuli

Harmless

Posts: 4

Registered: 7-11-2017

Member Is Offline

Mood: No Mood

|

|

Very interesting read, thank you guys.

The melt and cast will happen next weekend

What could possibly go wrong

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

That's pretty cool and slightly scary - though you've obviously proved fairly well the safety of the block's present composition. Any pictures of the

initial blocks?

|

|

|

Vosoryx

Hazard to Others

Posts: 282

Registered: 18-6-2017

Location: British Columbia, Canada

Member Is Offline

Mood: Serial Apple Enjoyer

|

|

I don't know ANYTHING about the casting of TNT, but I do know quite a lot about casting metals. (My other hobby being metalwork, such as casting,

machining, blacksmithing, etc)

The method Bert mentioned of overfilling using sprue's and allowing the shrinking metal to fill the space is used all the time. That way you also get

a bit of material left over.

If you do decide to use that method to fill the casings up, it might be beneficial to use a large sprue or preheat whatever funnel you plan to use.

That way the material won't "freeze" on the way in - a problem that has plagued me when casting bronze.

In light of this, I might not use paper unless you can make the opening a fairly large size.

Or, perhaps i'm very wrong because most metals have a much higher thermal conductivity that TNT. I don't know enough, just wanted to add my thoughts.

Good luck.

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Quote: Originally posted by greenlight  | Nice pic learned amateur.

Here is a graph showing critical diameter for TNT from explosives engineering.

Maybe might be of some help. Seems for pure poured TNT, failure diameter is around 30-35 mm.

Much lower for the pressed grains though probably because there are more spaces in it (more porous than the melt cast).

[Edited on 7-11-2017 by greenlight] |

The intergrain spaces induce hotspots when the detonation wave passes through... thus the all batch is sensitized... hence the smaller critical

diameter.

Stangely in your very instructive diagram the cast, cast creamed and cast creamed with 10% powder are all at the same density...

==> I would have expected a visible slope with density into the sequency: cast > cast creamed > cast creamed+10% powder.

Funny to observe that all 3 curves will merge arround d= 1,6 with a critical diameter < 5 mm

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Quote: Originally posted by Bert  | Quote: Originally posted by PHILOU Zrealone  | | you will have to cool it from the bottom (bottom-up) that way the concavity will be less... you will have to put a little excess molten TNT after

solidification on top to get a full loading. |

Another method used is to top fill a case through a paper funnel, leaving excess melted TNT in the funnel above the desired fill height. As the lower

levels are chilled, solidify and shrink, this additional still molten material flows downwards and prevents cavitation.

Ideally, just a bit more than exactly what will be needed to accommodate shrinkage is left in the funnel, then the slight excess is removed along with

the funnel after solidification and shrinkage are finished. |

Nice method... didn't knew it ...

Thanks Bert for the information.

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Fulmen

International Hazard

Posts: 1716

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

It's worth mentioning that initiation sensitivity also changes (cast being harder to set of), so there are several good reasons for pressing rather

than casting.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

cagce88

Harmless

Posts: 3

Registered: 11-10-2016

Member Is Offline

Mood: No Mood

|

|

Soy Lecithin or a little bit of beeswax will help avoid cast defects. add at like .5 percent.

|

|

|