| Pages:

1

..

22

23

24

25

26 |

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

I'm certainly interested in your results.

You don't seem to have a lot of oxygen in your system though: maybe about 0.008 mol of O2? Or am I missing something?

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Where is the excess air (N2) vented?

Did you wind the kanthal or did you buy/salvage it as a coil?

Do you have a reference for this method or is it your invention?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Jimmymajesty

Hazard to Others

Posts: 153

Registered: 9-7-2009

Member Is Offline

Mood: No Mood

|

|

blogfast you are right, the O2 concentration in the reactor is very low. 10ml of air to 3-5 drop of toluene, but this is exactly hat you want, too

much O2 and the CHO goes to COOH or even CO2 & H2O

Magpie, of course it was salvaged, it is from an old air heater, the kanthal wire is so old that I tried to wind out the other one and it broke in

many points so I just left this one as it was.

Actually I did not find any ref for continuous recycling lab procedure, all the patents around describing yield based on one pass due to high

conversion rates, also note that every patent describes net oxidizing air+toluene mixtures, so in my case benzoic acid formation should not be

significant, still... copper can facilitate in its formation even in net reducing mixtures because its too strong catalyst if you only want aldehyde.

Molybdenum trioxide would be much better, or tungsten.

So I have many ideas if this experiment fails.

1, Decrease the toluene flow and ramp up temps in the current design

2, Increase toluene flow and ramp down temp... you never know ) )

3, oxidation with heated copper filament

4, oxidation with heated tungsten filament

5, oxidation with heated molybdene filament

The N2 exhaust point is at the end of the condensor, you can see it in the first picture, it is the highest point of the setup.

[Edited on 30-1-2016 by Jimmymajesty]

|

|

|

Jimmymajesty

Hazard to Others

Posts: 153

Registered: 9-7-2009

Member Is Offline

Mood: No Mood

|

|

After the run, I let everyting cool, then take out 5ml yellow toluene, shook with 25ml water, then I let it settle and smelled the watery phase to

find out there is hardly any benzaldehyde in it, as a result I bypassed "Idea 1 and 2".

I did a run today by "idea 3" but with a vertical reactor design.

After 1hr I sampled it and the presence of benzaldehyde was evident.

So I am gona run the vertical reactor for a whole weekend sometime.

Damn I wish I had more time for chemistry...

|

|

|

Jimmymajesty

Hazard to Others

Posts: 153

Registered: 9-7-2009

Member Is Offline

Mood: No Mood

|

|

Hi,

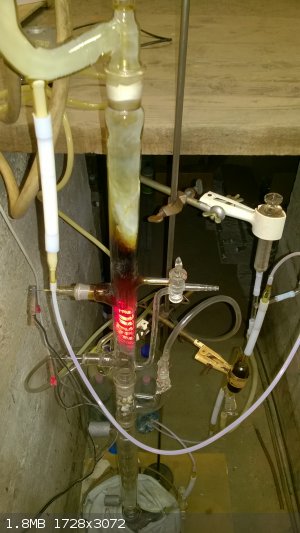

I gave it a decent try today. The toluene vapors went through a column which provided some degree of separation. Air inlet connection, then raschig

packing to help air mix into the toluene vapor, then kanthal wire wound around a mica sheet and copper oxide pellets (see pic). After the reaction all

condensable liquid went back into the flask. This was basically the setup used at my first attempt but an improved version.

I added 50ml water to the toluene to increase the vapor pressure of the benzaldehyde after the reaction zone. I gradually adjusted the voltage on the

kanthal to intitiate self pyrolysis of toluene, then decreased it a lil bit and adjusted the air inlet to be ~2ml/sec.

I sampled the condensed liquids from time to time shook it with water then smelled the watery phase. I went from the above condition till the kanthal

was orange (~5sampling) to find out there was not any benzaldehyde in the condensate.

Now I am kinda puzzled since this means that a simple ethanol => acetladehyde setup with brute force produces more benzaldehyde than the current

one...?! I do not really know how to improve from here. I will sample the watery phase in the flask when it cools, but I am skeptic that it will

contain any benzaldehyde.

|

|

|

Jimmymajesty

Hazard to Others

Posts: 153

Registered: 9-7-2009

Member Is Offline

Mood: No Mood

|

|

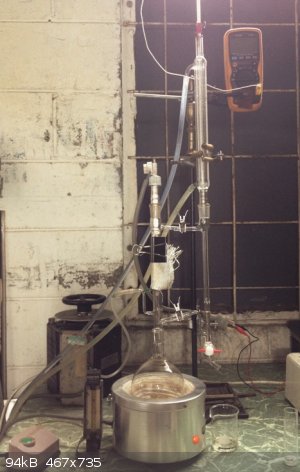

So... I also tried out copper plated kanthal wire and manganin as the heating element. Chunks of diesel catalytic converter and copper sponge as the

catalyst. Countless air and wattage settings but not a single molecule of benzaldehyde, during the 12hours torturing the initially yellow toluene

turned into a somewhat viscous black crap, so I managed to find a new way to turn half a litre toluene to useless crap.

I took a picture to show how hard I kicked the toluene molecules in the ass, there is black tar coming down as condensate (bottom-right side small

black bulb). This run was with diesel catalyst chunks, the condenser filled up with uncodensable myst which I believe was benzoic acid, still no

benzaldehyde...

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Benzaldehyde is sensitive to auto-oxydation into benzoic acid

Also you may request this document in document request section:

THE PYROLYSIS OF BENZALDEHYDE AND OF BENZYL BENZOATE

Charles D. Hurd, C. W. Bennett

J. Am. Chem. Soc., 1929, 51 (4), pp 1197–1201

DOI: 10.1021/ja01379a030

Publication Date: April 1929

First page

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

Quote: Originally posted by Jimmymajesty  | | Magpie, is hiring a glassblower really such big a deal? In every town there are at least two, they always complaining not to have enough work so the

one I usually go to quite happy when he sees me. |

It can be. I'm in a depressed part of the us and a lot of glassblowers have gone under. To make matters worse the local U is a private rich kids

school and they don't repair any glassware and don't have very creative chemists. The guy I have to use is 60 miles away and spends a lot of his time

on ebay.

The other guy does quartz for the med school and charges too much for simple mods and repairs.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

Jimmymajesty

Hazard to Others

Posts: 153

Registered: 9-7-2009

Member Is Offline

Mood: No Mood

|

|

I have other ideas that I want to try out like, oxidizing the toluene with NO2 I just have to take a break when handling these aromatics, gas mask or

not I just can not avoid getting some when handling it... also when I try to identify the product my only instrument is my nose and my gf smelled

something gasoline-ish in my breath when I spent the whole day in my lab... my fume hood sucks like a hooker since it can only accomodate a test tube

confortably, so most of my time goes with silver recovery from relays and such benigh things.

As for the glassblower mine just diagnosed with cancer so I do not really know who to turn to if he can not work anymore... so I feel your situation.

I always use the local flea market search engines with the words "lab, labware, lab instrument, flask, chemistry, chemical, etc. from week to week

there is a hit and usually the seller do not know what they are selling so the glass comes fairly cheap I bought this on the weekend for 4USD do not

know what to do with it but it sure looks lovely isnt it?

|

|

|

lolohydrat

Harmless

Posts: 2

Registered: 29-2-2016

Member Is Offline

Mood: No Mood

|

|

Which metal can you use instead of lead?

|

|

|

Chemetix

Hazard to Others

Posts: 375

Registered: 23-9-2016

Location: Oztrayleeyah

Member Is Offline

Mood: Wavering between lucidity and madness

|

|

Air oxidiser

I have wanted a way to make p tolualdehyde fairly easily, this post using air oxidation schemes sounded attractive as a semi industrial route. What I

found was that there are limitations to the air oxidation schemes. Perhaps this might be useful in some way for the production of the TM on this

forum.

"The autoxidation of p-xylene is known to proceed through a free radical process. The Mn(III) and Co(III) metals alone are not strong enough oxidizers

to start the radical chain reaction, but instead initiate it by forming bromine radicals from the ions in solution. These bromine radicals then

decompose hydroperoxides that are ligated to the metals as well as abstract hydrogens from the methyl groups on p-xylene to form free radicals and

propagate the reaction. The following are the proposed initiation, propagation and terminations steps for the first of four oxidations involved in the

autoxidation:" [https://en.wikipedia.org/wiki/Terephthalic_acid]

An initial study was run using a heated catalyst surface with different transition element oxides and a promoter. p-xylene vapour and air were passed

through the reaction zone and condensed then returned to the flask. Runs were about 6hrs each with 50mls p-xylene, and the flask then distilled to

observe the quantity and nature of the residue. The quartz reactor (from an old heater) has a nichrome filament inside and a glass fiber soaked in

catalyst wrapped on the outside and held in place with nichrome. The catalyst surface reached a maximum temperature of 350C.

In all cases only a very small amount of oxidised residue was formed, 5ml at the most, catalysts tested were- in order of perceived activity:

V2O5/FeCl3, Co2O3/FeCl3, Ni2O3/FeCl3, Fe2O3/FeCl3, SnO/FeCl3.

The quick and dirty conclusion is that surface areas need to be huge in order to generate any meaningful quantity in a reasonable time. Optimising the

choice of catalyst/promoter and cleaning the inlet air to prolong the catalyst activity is a secondary concern with regards to the practicality of the

scheme.

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

Quote: Originally posted by Jimmymajesty  | I have other ideas that I want to try out like, oxidizing the toluene with NO2 I just have to take a break when handling these aromatics, gas mask or

not I just can not avoid getting some when handling it... also when I try to identify the product my only instrument is my nose and my gf smelled

something gasoline-ish in my breath when I spent the whole day in my lab... my fume hood sucks like a hooker since it can only accomodate a test tube

confortably, so most of my time goes with silver recovery from relays and such benigh things.

As for the glassblower mine just diagnosed with cancer so I do not really know who to turn to if he can not work anymore... so I feel your situation.

I always use the local flea market search engines with the words "lab, labware, lab instrument, flask, chemistry, chemical, etc. from week to week

there is a hit and usually the seller do not know what they are selling so the glass comes fairly cheap I bought this on the weekend for 4USD do not

know what to do with it but it sure looks lovely isnt it?

|

That's a sort-of steam-distillation bulb/head. I've seen it in Vogel's OChem. Basically, you stick the long part into a flask where the boiling

solution surrounds the test-tube-like bulb with the glass tube inside. The vapors go down into the 'test tube' via the curved glass tube, and bubble

through there (which should already contain the liquid you are to steam distill). They exit containing what is to be stilled over with the vapors at

the top ground glass port. The stopcock is to ensure that the process of cooling doesn't suck the compound you are steam distilling into the solvent

(or vice versa, I forget).

|

|

|

Booze

Hazard to Others

Posts: 121

Registered: 26-2-2017

Member Is Offline

Mood: No Mood

|

|

Could you use nitric acid as an oxidiser?

|

|

|

moonbeamstudio

Harmless

Posts: 4

Registered: 18-12-2016

Member Is Offline

Mood: Enthusiatic

|

|

A common mistake in all these atemts posted here is that activated MnO2 has to be used!! It is simply done with MnSO4 and Potassium

manganate(VII)...

I have the procedure if someone wants it.

Greetings to you all, freaks!  ) )

|

|

|

sykronizer

Harmless

Posts: 18

Registered: 16-12-2017

Member Is Offline

Mood: omnivorous

|

|

I remember reading about the air oxidation of Toluene to benzaldehyde. The catalyst was V2O5 and the the Toluene vapor and air was sent through that

quickly with the catalyst being a tube that was heated to 700 Celsius...I'm wondering if one could simply use a high Vanadium-steel tube instead of

any other fancy catalyst. Surface area is not an issue when you have a vapor mixture buzzing around in there at a dull red heat, and it needs to move

through pretty quickly too other wise pyrolysis will just wreck Toluene not to mention the aldehyde. Yields are low but the range of byproducts were

minimal, the parameters were optimized so the rest of the process was a distillation and recycling of the toluene. But, I doubt this process is still

used industrially given the availability of other feed-stocks and lower energy cost's required for the conversion, such as side chain halogenated

Toluene, but as everyone knows that process is another example of what works on large scale is nothing but an absolute nightmare on the lab bench, and

I suspect tweaking this air oxidation method may also be a bit like that.

|

|

|

KiWiki

Harmless

Posts: 12

Registered: 30-11-2017

Member Is Offline

Mood: No Mood

|

|

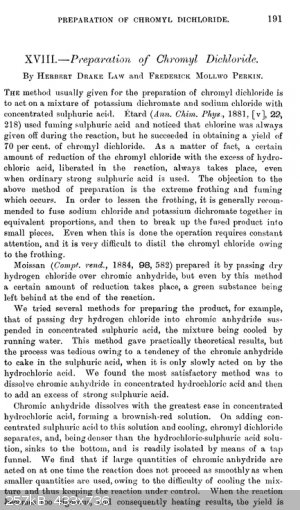

Preparation of (substituted) benzaldehydes

Did someone try one of the Drake and Perkin methods:

1. Electrolytic oxidation of toluene, ortho-, meta-, para- xylene in acid solution is a very easy way to prepare the corresponding

benzaldehyde. However, in alkaline solution toluene and meta-xylene will oxidize to carbon dioxide and water.

Source: Trans. Faraday soc., 1905, 1, 31, 251

2. Oxidation with chromyl chloride (see preparation in attachment) to the corresponding benzaldehyde. *

Source: Herbert Drake Law, Frederick Mollwo Perkin, "Oxidation of Hydrocarbons of the benzene series" , J. Chem. Soc. 91, 258, (1907)

*the modern alternative for chromyl chloride might be PCC in Silica gel for this method. I don't have access to these full articles...

Are there already experimental results that cover these two interestring methods?

EDIT: (by Antrax):

Perform the electrochemical oxidation with 200 to 300 mL acetone to dissolve toluene or xylene. The addition of sodium bisulfite prevents further

oxidation of benzaldehyde. Use 5% to 10% 200 mL H2SO4.

70 A/h /50 g toluene or xyl. Yields are not great as sulphate ions stick to the anode and the fact that benzyl alcohol is formed.

Yields are not higher then 20%, I don't report exact experimental yields and sometimes I even don't give these yields for academic research.

[Edited on 2-1-2018 by KiWiki]

|

|

|

sykronizer

Harmless

Posts: 18

Registered: 16-12-2017

Member Is Offline

Mood: omnivorous

|

|

The Toluene of commerce here in NZ and Oz is contaminated with some sulfur compounds, a sulfuric acid wash gives a dark red layer, so what ever method

of oxidation we may try, I strongly suggest a clean up of the Toluene first.

After a few failures I am going to have another go at the Etard reaction, using methylene chloride as the solvent, although it's low boiling point is

not ideal. It is reasonably convenient because the chromyl chloride can be prepared without having to resort to using a retort, for distilling it off.

A word of caution though, do not take short cuts with solvent amounts, ie; make certain you are using at least a 25 percent dilution of the chromyl

chloride to solvent, ditto for the Toluene as well, and constant stirring and cooling. My initial run was a disaster, I was too reckless, and added

the chromyl far too quickly, which resulted in a sudden rise in temperature, that combined with my low boiling point solvent resulted in a stirred

suspension of the adduct going from liquid to solid in about 1 to 2 seconds immediately followed by a mild explosion that covered about 4 square

meters of green lumpy crap , I was uninjured thanks to my safety glasses.

|

|

|

phenyl

Harmless

Posts: 2

Registered: 8-1-2017

Member Is Offline

Mood: No Mood

|

|

probably the easiest synthesis from toluene, is direct oxidation using persulfates salts and a Fe+2/Cu+2 catalyst to promote oxidation in the biphasic

reaction mixture. the primary alcohol co-solvent seems to somewhat prevent over oxidation too. Can't remember the original reference but it's probably

here on SM somewhere. The product needs to be purified by adduct or vacuum fractionation to remove excess toluene, but it does work with subst.

toluenes with a reasonable yield.

(modified from original?!)

purified toluene (7.6 g, 0.082 mol)

ferrous sulfate (110 mg)

cupric acetate (80 mg)

ammonium persulfate (45 g, 0.197 mol) dissolved in ~150 mL DH2O

primary alcohol EtOH or MeOH (58 mL total)

the catalyst is dissolved in DH2O (35 mL) and ethanol (8 mL), to this toluene is added. persulfate is dissolved in water with ethanol (50 mL) and is

added to an equalised addition funnel. the mixture is heated to 65-70 degrees celsius on a water bath with good stirring, before addition is started.

addition should take 45 min with refluxing being continued for ~1-2 hrs after addition. the aqueous layer is separated and washed with 3x25 mL DCM

which is combined with the organic layer and the DCM was evaporated.

yield ~ 8 g crude benzaldehyde (slightly yellow in colour)

* product is usually colourless if an inert atmosphere is used

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Online

Mood: Most of the ducks are in a row

|

|

This is nearly the same procedure quoted on the first page of this thread. My attempt recently was not really a success but with a bit of perseverence

I should get there. See video on my yt channel if interested.

I need a better source of persulfate.

|

|

|

phenyl

Harmless

Posts: 2

Registered: 8-1-2017

Member Is Offline

Mood: No Mood

|

|

yeah it is, just recalculated based on NH4 rather than Na, with ethanol instead of methanol. PCB etchant is usually the pure ammonium salt (~98%),

it's easy to find at any good electronics store. on a side note some acetaldehyde is produced as a side product in the reaction.

also benzaldehyde is fairly soluble in methanol/ethanol aqueous solutions.

"Ethanol increases the solubility of hydrophobic substrate such as benzaldehyde"

Breslow, Ronald, and Richard V. Connors. "Quantitative antihydrophobic effects as probes for transition state structures. 1. Benzoin condensation and

displacement reactions." Journal of the American Chemical Society 117.24 (1995): 6601-6602.

[Edited on 7-2-2018 by phenyl]

[Edited on 7-2-2018 by phenyl]

|

|

|

j_sum1

Administrator

Posts: 6320

Registered: 4-10-2014

Location: At home

Member Is Online

Mood: Most of the ducks are in a row

|

|

Alas. There is no such thing as a good electronics store where I live. But Na2S2O8 is available in hardware stores as a pool oxidant. Apparently it is

less pure than I thought.

|

|

|

sykronizer

Harmless

Posts: 18

Registered: 16-12-2017

Member Is Offline

Mood: omnivorous

|

|

I have tried that persulfate method, sticking exactly to the method and reagents and all I got was the detection of that horrid carcinogenic

formaldehyde..and lots of it. I really do have to wonder about this procedure, I mean, doesn't it seem obvious that this specific system, the

persulfate and iron/copper couple will oxidize methanol a damn site quicker than it will Benzyl Hydrogen's ? . I also tried changing the metal

couple, I used silver Nitrate alone, silver nitrate and cupric also no go...just more stench of embalming fluid...So what appears easy on paper in

terms of procedure and ease of reagent acquisition is not all it's cracked up to be. Most refs that detail different oxidation methods, at least older

material, seem to suggest that the Etard is always consistent in giving a yield, not necessarily a repeatable yield, but at least a REPRODUCIBLE

yield, it's really been bugging me for a while, how much trouble this one synthesis has been for me.

|

|

|

Chemetix

Hazard to Others

Posts: 375

Registered: 23-9-2016

Location: Oztrayleeyah

Member Is Offline

Mood: Wavering between lucidity and madness

|

|

The Maggione patent using persulphate redox pair co catalyst is obviously leaving a lot out of the patent if it works at all. I left out th e lower

alcohol solvent and got some yield, but nothing like the patent. Perhaps PTC and water? I was going to try it but never got around to it.

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

Walling et al. had some peroxydisulfate success with aq. acetonitrile or acetic acid (acid giving benzyl acetate), at microscale naturally. K10

montmorillonite and KMnO4 is also supposed to work (better on benzyl alcohol obviously), but where to find some.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Entirely out of academic curiosity, has anyone seen any papers stating that someone managed to isolate benzaldehyde from a chromium (VI) oxide

peroxide oxidation of toluene? It seems to me as though it would be possible to do it in reasonable yield, and it can't be that hard, right? But all

of the work I have seen on the subject is theoretical.

|

|

|

| Pages:

1

..

22

23

24

25

26 |