Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

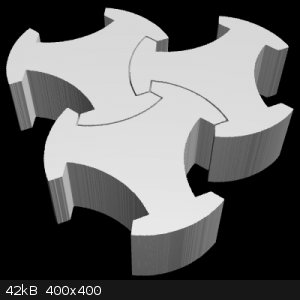

Tiled armour science - trispokedovetiles - three-spoke dovetailing tiles

TRISPOKEDOVETILES by Peter Dow

Possible application to tiled armour

One issue with hexagonal or square armour tiles is that such simple shapes don't interlock sideways, as do jigsaw puzzle pieces.

Whilst a little armour tile movement in the same direction as the bullet (normal to the armour plane) is useful in absorbing the kinetic energy of the

bullet (and much better than the armour tile absorbing the same kinetic energy by shattering), on the other hand, sideways tile movement (tangential

to the armour plane) leaves most unwelcome gaps in the armour in between separated tiles.

So armour tiles shaped like jigsaw puzzle shapes (or some hexagonal variation such as these trispokedovetiles) could perform well in this application.

TRISPOKEDOVETILES

I've named the shape "Trispokedovetile" which is a contraction of "tri-spoke dovetailing tile".

"tri-spoke" because the shape is similar to a 3-spoke motorcycle

wheel with three bites taken out of it.

"dovetailing" because the tiles interlock like a dovetail joint

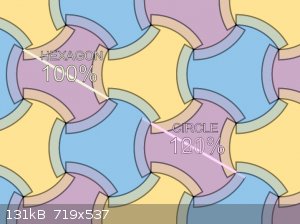

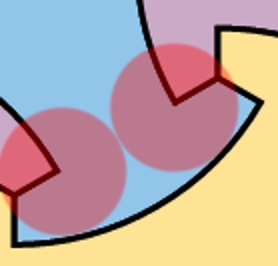

I've programmed a webpage using Javascript to display an animation which shows a range of different trispokedovetiles, each of which can be

specified by a "CIRCLE" percentage, which is the ratio as a percent of two parameters -

A "HEXAGON" parameter length - always nominally "100%"

A "CIRCLE" parameter length - the animation varies this between 100% and 135%, though values up to 150% can be drawn.

You can also use the webpage to specify a "CIRCLE" percentage and click to "Draw TRISPOKEDOVETILES" to generate an image of a tessellation of a

particular shape of trispokedovetiles.

Tutorial on how to create 3D trispokedovetile images

<i>Edit by moderator : Fixed broken links</i>

[Edited on 7-10-2017 by gdflp]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

This an exceptionally Nice idea, and Welcome to ScienceMadness !

The simple geometry is Artful in it's simplicity.

You could cover Acres of a 2-D flat area with carbon tiles of that shape and protect it from crazed welders.

Unfortunately we live in a 3-D universe, with curves, bumps, wiggles etc.

What am i saying ?!?!

I like some of those curves, bumps and wiggles. A lot !

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

Thanks. It's nice to be here.

Well there are more arty tessellations on a similar theme, some of which inspired me to a scientific purpose and more examples of which I have collected together at this link.

Quote: Originally posted by aga  | You could cover Acres of a 2-D flat area with carbon tiles of that shape and protect it from crazed welders.

Unfortunately we live in a 3-D universe, with curves, bumps, wiggles etc.

What am i saying ?!?!

I like some of those curves, bumps and wiggles. A lot !

|

Clearly, it is not the case that "one size fits all".

So different size and shapes of tiles could be made for different applications, smaller, slightly curved tiles for body armour, bigger tiles for

paving stone.

[Edited on 24-11-2016 by Peter Dow]

|

|

|

Maroboduus

Hazard to Others

Posts: 257

Registered: 14-9-2016

Location: 26 Ancho Street

Member Is Offline

Mood: vacant

|

|

Dragon skin armor?

https://www.google.com/url?sa=i&rct=j&q=&esrc=s&...

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

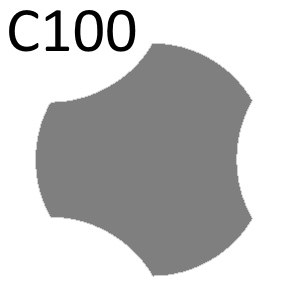

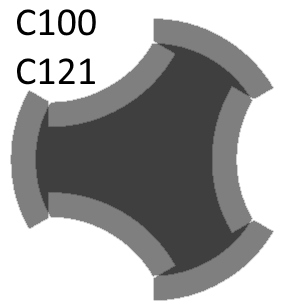

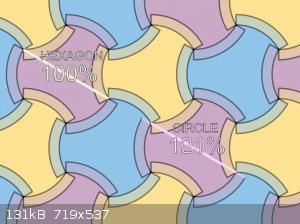

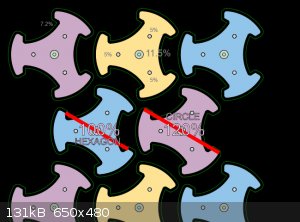

Now to consider the important issue of interlocking trispokedovetiles against movement in the direction normal to the tiled plane, which for the

application of tiled armour would be the normal to the armour surface, in the direction of a bullet's path.

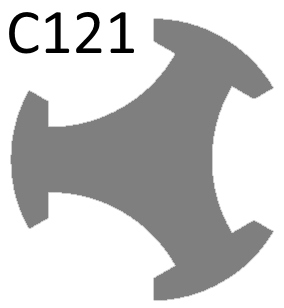

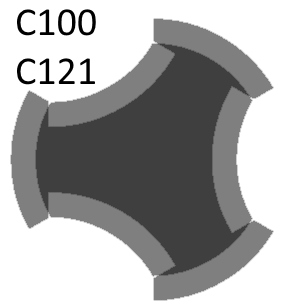

BILAYER TRISPOKEDOVETILES

I propose that the unit armour tile be comprised of 2 joined trispokedovetiles with matching HEXAGON parameters but each with a different CIRCLE

percentage.

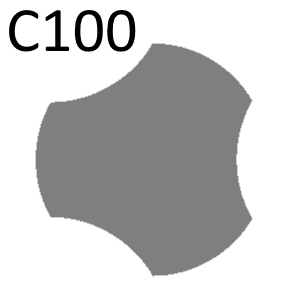

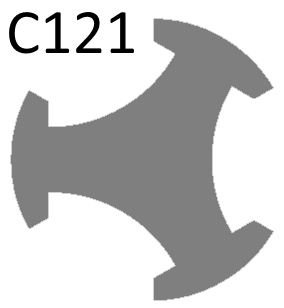

For example, suppose we choose trispokedovetiles with CIRCLE = 100% and 121%.

The reason for choosing C100 for the outer layer of the armour is because its 120 degree angle corners would be more robust.

The reason for choosing C121 for the inner layer of the armour is because CIRCLE = 121% offers the largest percentage where the neck attaching the

outer part rings is at least twice the thickness of the ring, attempting to balance the robustness of the ring parts to the robustness of the neck

versus tensile stresses.

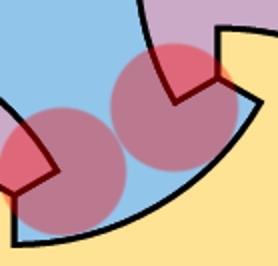

Stacking and joining those together forms a bilayer trispokedovetile, "C100+C121".

Drawing the 2 layers semi-transparently we can see how the bilayer trispokedovetiles would interlock in the normal to the plane.

2/3rds of the tiles can be slotted together, either the yellows and the blues or the yellows and the purples or the blues and the purples.

However the final 1/3rd of the tiles would not simply slot in and would have to be inserted by joining the two halves of the bilayer trispokedovetile

in situ.

|

|

|

Sulaiman

International Hazard

Posts: 3696

Registered: 8-2-2015

Location: 3rd rock from the sun

Member Is Offline

|

|

for inspiration https://www.google.co.uk/search?q=m+c+escher&source=lnms...

CAUTION : Hobby Chemist, not Professional or even Amateur

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

Trispokedovetiles: CNC code to cut tiles

For Computer-Aided Manufacturing of trispokedovetiles, I'm publishing today my new Javascript web-page -

Trispokedovetiles: CNC code to cut tiles web-page G-code generator

- which generates Computer Numerical Control (CNC) code which I've tested with CNC Simulator Pro but not on a real CNC cutter as yet.

<i>Edit by moderator : Fixed broken links</i>

[Edited on 7-10-2017 by gdflp]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Could the tiles be 3D-printed? This might introduce some tolerance issues with the resolution of the print, but it would be a good way to test these

mechanically with different plastics such as ABS and PLA.

Also, could a flexible design be made by curving the interlocking plates somewhat on the z-axis (I don't quite know how to word this) so that each

tile could flex outward and inward from the main body? This would allow the armor to be 'worn' in much the same vein as Kevlar, if the tiles could be

made small enough.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

HOLES!

Now cut trispokedovetiles by CNC laser cutter with (or without) HOLES!

<i>Edit by moderator : Fixed broken links</i>

[Edited on 7-10-2017 by gdflp]

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by elementcollector1  | | Could the tiles be 3D-printed? This might introduce some tolerance issues with the resolution of the print, but it would be a good way to test these

mechanically with different plastics such as ABS and PLA. |

Well don't let me stop you but I think starting off with a strong material in a flat sheet and cutting that up (as with laser cutting) is going to

give stronger and quicker tiles then anything 3D printed.

Quote: Originally posted by elementcollector1  | | Also, could a flexible design be made by curving the interlocking plates somewhat on the z-axis (I don't quite know how to word this) so that each

tile could flex outward and inward from the main body? This would allow the armor to be 'worn' in much the same vein as Kevlar, if the tiles could be

made small enough. |

Dragon Skin armour is a modern variant of scale armour, where the tiles overlap, rather than interlock like jigsaw puzzle pieces.

Whether you could get the same flexibility from smaller interlocking tiles, I don't know. Maybe.

For some applications - armoured vehicles, for example, flexibility is not the number one problem.

[Edited on 11-12-2016 by Peter Dow]

[Edited on 11-12-2016 by Peter Dow]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

3D. Hmm.

Could you design something so that there is a step to the tiles so that a piece overlaps the joints ?

Having a 'crack' at each joint seems like a point of vulnerability.

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by aga  | 3D. Hmm.

Could you design something so that there is a step to the tiles so that a piece overlaps the joints ?

Having a 'crack' at each joint seems like a point of vulnerability. |

I already did just that 4 posts ago.

What part of the overlapping of joints in my bilayer trispokedovetile design in my previous post ...

Quote: Originally posted by Peter Dow  | Now to consider the important issue of interlocking trispokedovetiles against movement in the direction normal to the tiled plane, which for the

application of tiled armour would be the normal to the armour surface, in the direction of a bullet's path.

BILAYER TRISPOKEDOVETILES

I propose that the unit armour tile be comprised of 2 joined trispokedovetiles with matching HEXAGON parameters but each with a different CIRCLE

percentage.

For example, suppose we choose trispokedovetiles with CIRCLE = 100% and 121%.

The reason for choosing C100 for the outer layer of the armour is because its 120 degree angle corners would be more robust.

The reason for choosing C121 for the inner layer of the armour is because CIRCLE = 121% offers the largest percentage where the neck attaching the

outer part rings is at least twice the thickness of the ring, attempting to balance the robustness of the ring parts to the robustness of the neck

versus tensile stresses.

Stacking and joining those together forms a bilayer trispokedovetile, "C100+C121".

Drawing the 2 layers semi-transparently we can see how the bilayer trispokedovetiles would interlock in the normal to the plane.

2/3rds of the tiles can be slotted together, either the yellows and the blues or the yellows and the purples or the blues and the purples.

However the final 1/3rd of the tiles would not simply slot in and would have to be inserted by joining the two halves of the bilayer trispokedovetile

in situ.

|

... did you not understand?

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

TRISPOKEDOVETILES ROUTER CUTTING

My trispokedovetile CAD-CAM webpage now offers an (X,Y,Z) option for router cutting using rotary tool paths between spaced out tiles -

I've simulated the CNC router code -

<i>Edit by moderator : Fixed broken links</i>

[Edited on 7-10-2017 by gdflp]

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Opps. Sorry.

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Just a thought:

could you see if you can find the space key on your computer keyboard?

That will stop people wondering why you have poked these three times

https://www.zazzle.co.uk/ove+tiles

Or you could try some other way to stop it saying

TrisPokedOveTiles

|

|

|

Peter Dow

Harmless

Posts: 9

Registered: 23-11-2016

Location: Aberdeen, Scotland

Member Is Offline

Mood: No Mood

|

|

BEWARE BAD LINKS ABOVE!

I lost my website hosting in January. I was not "hacked" but the gcehosting administrator seems to have gone out of business and the hosting company

he was using (godaddy) is serving various spurious adverts whenever anyone clicks one of my old links.

I have got the following pages back on-line with a different hosting company now so try these links.

LINKS -

I can't edit my earlier posts to correct the old links, sorry.

I've not done anything with this project since January.

|

|

|

gdflp

Super Moderator

Posts: 1320

Registered: 14-2-2014

Location: NY, USA

Member Is Offline

Mood: Staring at code

|

|

The links have been corrected.

|

|

|