| Pages:

1

..

61

62

63

64

65

66 |

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

So I did another test last night and found the fineness and shine of the Mg is really the key factor in my successes. I did a run using 50 ml lamp

oil this time with 3.5g Mg 7g KOH and 1.2 ml tert butanol. Everything was added at the start and I let this run go for 6 hours. There was quite a lot

of small to medium spheres sitting atop the reaction mixture by the end and I'm quite pleased with the results. I was also wondering if anybody has

attempted to recover the used tetralin before? It's kind of expensive an if possible I'd like to recover it for further use. I have around 100 ml and

was thinking about running it through a fine filter and dropping the temp to see if the un used catalyst will solidify for removal. Failing that I

will just heat it to drive the alcohol off first and distill the tetralin that's left.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by NeonPulse  | So I did another test last night and found the fineness and shine of the Mg is really the key factor in my successes. I did a run using 50 ml lamp

oil this time with 3.5g Mg 7g KOH and 1.2 ml tert butanol. Everything was added at the start and I let this run go for 6 hours. There was quite a lot

of small to medium spheres sitting atop the reaction mixture by the end and I'm quite pleased with the results. I was also wondering if anybody has

attempted to recover the used tetralin before? It's kind of expensive an if possible I'd like to recover it for further use. I have around 100 ml and

was thinking about running it through a fine filter and dropping the temp to see if the un used catalyst will solidify for removal. Failing that I

will just heat it to drive the alcohol off first and distill the tetralin that's left.

|

It's believed the catalyst is post-reaction present as K alkoxide (see proposed reaction mechanism, higher up).

I believe filtering after chilling might very well work. Considering the cost of tetralin, its worth trying.

There's some work done by me on recycling, reported higher up in the thread.

[Edited on 7-3-2016 by blogfast25]

|

|

|

NeonPulse

Hazard to Others

Posts: 417

Registered: 29-6-2013

Location: The other end of the internet.

Member Is Offline

Mood: Isolated from Reality! For Real this time....

|

|

I wouldn't say I've discovered anything really new but I found that trying to coalesce all the small spheres of K in a beaker of oil is not easy. They

seem to not want to join. So after thinking a bit about it a good approach is to put the K balls in a test tube with oil and heat. I pushed the balls

together as much as possible but some were still stubbornly refusing to join so I waited to the oil was a bit cooler and pressed the still soft

spheres together and re heated the tube and viola! The potassium welded itself together in a nice little ball.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

I think that some of the molten potassium handling techniques that I use may help.

Your molten metal won't coalesce because it's dirty.

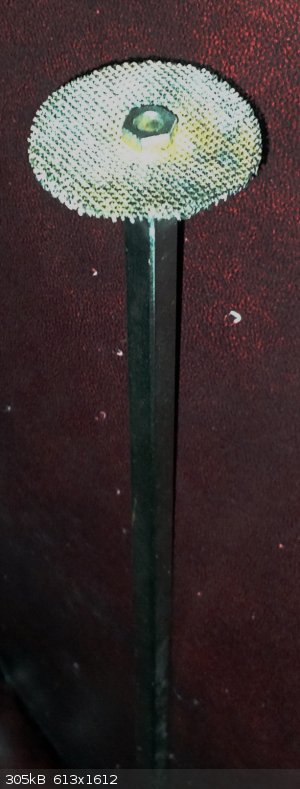

To make my brilliant Na or K ampoules, I pre-process the metals for best results. My first step is to melt the metal in toluene or xylene in a what is

essentially a large test tube. I get a mixture of molten metal and oxidation crud. Then I push a metal rod, fitted with several layers of stiff

stainless steel screen, through this. The brilliant looking metal bubbles up through the screens. Being totally clean, it readily coalesces when I set

the liquid inside rapidly spinning by swirling the tube. Leave the rod in place during cooling. Pull up and remove metal from rod.

The screens are a very close fit to the tube. Done using a belt sander on the very stiff screens.

[Edited on 23-12-2016 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

I can't seem to edit my last entry, so let me add this here instead.

The RHS picture may seem a little confusing due to shadows. The darker part, running down the apparent axis of the tube, is just a shadow of the tube

on the wall behind it. This procedure really is as simple as just pushing a screen through the molten metal.

And, as someone has noted, higher viscosity liquids are not desirable.

Obviously, the re-solidified metal just slides off the pusher rod.

If your starting metal is visually "clean" (no particulates), but is just a bit dull looking, this is all it takes to inhibit coalescence. In this

case, though, the remedy is often even easier than filtering it. You simply add one drop of DRY alcohol to the metal (in toluene, xylene) and the

surfaces will brighten up. Repeat if the metal still isn't bright. The alcohol can be 2-PrOH or EtOH). Most of the product alkoxide sloughs off the

metal surfaces and sinks to the bottom of the tube as green-gray flocculent material.

[Edited on 25-12-2016 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

In case any of you do use the alcohol method of cleaning sodium or potassium there is a minor downside that I forgot to mention. You don't find

details like this in the literature, at least I didn't, despite the fact that the alcohol cleaning trick has been known forever.

Obviously, not all of the alkoxide separates from the metal. There will be some left, but you can't see it. It's still enough to change the behavior

of the molten metal toward dry, clean glass. The molten metal will now wet glass due to the powerful fluxing abilities of the alkoxide. It forms a

sodium (or potassium) mirror.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Bezaleel

Hazard to Others

Posts: 444

Registered: 28-2-2009

Member Is Offline

Mood: transitional

|

|

Quote: Originally posted by Dan Vizine  | (...)

If your starting metal is visually "clean" (no particulates), but is just a bit dull looking, this is all it takes to inhibit coalescence. In this

case, though, the remedy is often even easier than filtering it. You simply add one drop of DRY alcohol to the metal (in toluene, xylene) and the

surfaces will brighten up. Repeat if the metal still isn't bright. The alcohol can be 2-PrOH or EtOH). Most of the product alkoxide sloughs off the

metal surfaces and sinks to the bottom of the tube as green-gray flocculent material.

[Edited on 25-12-2016 by Dan Vizine] |

Quote: Originally posted by Dan Vizine  | (...)

Obviously, not all of the alkoxide separates from the metal. There will be some left, but you can't see it. It's still enough to change the behavior

of the molten metal toward dry, clean glass. The molten metal will now wet glass due to the powerful fluxing abilities of the alkoxide. It forms a

sodium (or potassium) mirror. |

Thanks so much for posting this.

And would repeating the method with the long tube help the potassium get clean enough to make the balls look brilliant? Or is the dry alcohol method

the only method you know of?

|

|

|

Texium

Administrator

Posts: 4675

Registered: 11-1-2014

Location: Salt Lake City

Member Is Offline

Mood: Preparing to defend myself (academically)

|

|

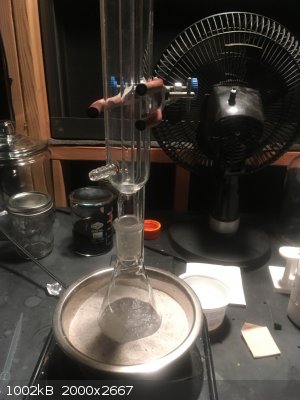

I made an attempt at the reaction for the first time yesterday. Didn't work at all though because I couldn't get the sand bath hot enough. I think the

old hotplate I was using is finally over the hill.

https://texium.wordpress.com/2016/12/29/failed-attempt-at-po...

|

|

|

Bert

|

Thread Split

30-12-2016 at 06:04 |

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

[/rquote]

And would repeating the method with the long tube help the potassium get clean enough to make the balls look brilliant? Or

is the dry alcohol method the only method you know of?

[/rquote]

This depends on your goal. My goal is to make shiny metal samples without solvent.

I've never tried to make brilliant metal in any atmosphere except a vacuum. You can get nice silvery metal in solvents, but it dulls from shiny silver

to "flat" silver kinda' quickly. Potassium, in my hands, always acquires a pale purple tint in solvents after some period of time.

I take this "flat" silvery metal, put it in a tube, remelt in under vacuum, filter through stainless steel wool and collect in another tube which is

sealed under a vacuum. Here's a half pound potassium ampoule made this way:

[Edited on 30-12-2016 by Dan Vizine]

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Ba(ClO3)2

Harmless

Posts: 33

Registered: 30-4-2016

Member Is Offline

Mood: No Mood

|

|

I've tried making potassium several times now with no success what so ever. If someone could possibly give me some advice or tips, it would be greatly

appreciated . Here's a description of my latest attempt: . Here's a description of my latest attempt:

The magnesium was activated by leaving it to stand in a beaker of 5% acetic acid for about 20 seconds. This seemed to be effective at removing the

oxide coating on the magnesium.

To a 500ml round-bottom flask, was added 3.5g of magnesium turnings and 7.3g of 95% potassium hydroxide flakes. Around 60ml of kerosene was then added

in to act as the solvent. As a heating source, I used an oil bath (spent engine oil instead of cooking oil) heated by a hot plate. A liebig condenser,

circulated with water and loosely sealed at the top with Al foil was then attached to the flask. The heat was set to maximum and pretty soon the

kerosene began to reflux steadily in the flask. After 15 minutes of reflux, I added in 1.5ml of tert-butanol though the condenser.

After around 20 more minutes of reflux, another 1.5ml of alcohol were added. The mixture was refluxed for around 5 hours. Upon examining the contents

of the flask, I found no potassium what so ever and the reaction mixture appeared almost completely unchanged. After removing the kerosene, a bit of

water was added to the mixture resulting in no effect at all, confirming the complete absence of potassium . .

It definitely got hot enough, the oil must have been well over 200 C.

Is there anything obviously wrong?

|

|

|

Tsjerk

International Hazard

Posts: 3037

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

Maybe too much water in your KOH, next time you can evaporate a part of your kerosine before adding magnesium and t-butyl alcohol to get rid of the

water.

|

|

|

Ba(ClO3)2

Harmless

Posts: 33

Registered: 30-4-2016

Member Is Offline

Mood: No Mood

|

|

Ok, I'll be sure to try that out next time. My KOH is 95% and I'm not sure if the residual 5% is water or some other junk, but hopefully as long as it

is dry that shouldn't matter.

Thanks for the feedback

|

|

|

Tsjerk

International Hazard

Posts: 3037

Registered: 20-4-2005

Location: Netherlands

Member Is Offline

Mood: Mood

|

|

KOH is quite often labelled as 95 or 99 % referring to everything but the water, which is usually 15%.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Quote: Originally posted by Tsjerk  | | Maybe too much water in your KOH, next time you can evaporate a part of your kerosine before adding magnesium and t-butyl alcohol to get rid of the

water. |

Ba(ClO3)2, did you understand the comment as written? What he meant was to distill a part of your solvent away first. Water will leave with this cut,

due to its much lower bp.

The main solid impurity in this is K2CO3 from inevitable CO2 absorption from the air. And, of course, you can count on at least the 15% water

that Tsjerk suggested.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Ba(ClO3)2

Harmless

Posts: 33

Registered: 30-4-2016

Member Is Offline

Mood: No Mood

|

|

Ah right, I see. Thanks Tsjerk . I'll try doing as you suggested next time. Boil

off some of the kerosene and maybe even fuse the KOH before I use it. . I'll try doing as you suggested next time. Boil

off some of the kerosene and maybe even fuse the KOH before I use it.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

If you fuse it, before you use it, put it into a plastic sandwich bag. A thicker one if you have it. Then wrap with some additional bags, or similar,

and try to pulverize it as best you can.

Boiling off a bit of solvent, with the KOH added, is still a good practice for a couple of reasons.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

Ba(ClO3)2

Harmless

Posts: 33

Registered: 30-4-2016

Member Is Offline

Mood: No Mood

|

|

Cool, looks like I'm back on track again. Thanks for your help.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Nicodem  | I did not read all about this topic, but just wanted to comment that the use of isopropanol is most likely futile. Metal alkoxides containing

alpha-hydrogens are generally not stable up to 200 °C. They tend to decompose via beta-hydride elimination reactions, the rate at which they do so

highly depends on the what metal alkoxide they are. I would expect potassium isopropoxide is not stable at the required conditions. The acetone formed

in the decomposition is most likely to blame for the brown-red coloured crap formed via self condensation. On the other hand, t-BuOK is commonly used

as a stable alkoxide at fairly high temperatures, so it might actually be long living at 200 °C as well. Also, tert-butoxides should be much more

soluble in paraffins, which is another reason to stick to tert-butanol or higher homologues. The formation of t-BuOK should be fairly rapid at the

given conditions, especially if Mg is finely divided and/or activated, so I don't think most of t-BuOH escapes, particularly if stirring is used or

heating up is slow.

As to how this redox works, I have no good idea. I don't see how a "2 t-BuOK + Mg <=> (t-BuO)2Mg + 2 K" reaction could ever be favoured on the

right side. Though at least the other part of the cycle, "(t-BuO)2Mg + KOH <=> 2 t-BuOK + Mg(OH)2" makes sense direction-wise. Quite weird.

Anyhow, I would guess the most important factor is the activation of the Mg metalic surface and the quality&mesh of the metal.

|

Here is a new idea, possibly wrong, as to the reaction mechanism:

The first necessary step is the formation of t-BuOK.

Next an unrelated reaction is the creation of a metal-air battery (Mg/O2) in an appropriate electrolyte. See discussion at https://www.google.com/url?sa=t&source=web&rct=j&... . To quote Wikipedia on the Magnesium battery (link: https://en.m.wikipedia.org/wiki/Magnesium_battery):

"Electrolyte solution have been also obtained by addition of Lewis acids, especially aluminium trichloride, to magnesium compounds such as Grignard

reagents, amides, phenolates, alkoxides, thiolates or magnesium chloride, usually in THF solvent."

I would also note that boiling facilitates mixing with air.

Lastly:

K+ + e- → K

That is, the electrolyte employed here is not stable and is broken down.

In summary, my proposed route argues that magnesium is indirectly responsible for the formation of potassium.

Comments welcomed.

[Edited on 23-5-2017 by AJKOER]

|

|

|

jimmyboy

Hazard to Others

Posts: 235

Registered: 1-3-2004

Location: Texas

Member Is Offline

Mood: No Mood

|

|

you should be able to extract the potassium from your magnesium reduction reaction with dioxane (react and distill ethylene glycol with sulfuric)

.. it works for sodium no problem just raise the temp to 100degC and use a strong stirbar

|

|

|

clearly_not_atara

International Hazard

Posts: 2834

Registered: 3-11-2013

Member Is Offline

Mood: Big

|

|

Are you suggesting that oxygen reduces potassium? This seems highly unlikely. In terms of a potential gradient, O2 > Mg > K, most

likely. But MgO has a favorable lattice energy.

It seems that first KOH must be reduced to K2O, releasing hydrogen (2 KOH + Mg >> H2 + K2O + MgO), and then the reaction K2O + Mg >> 2K +

MgO is thermally favorable, possibly because K2O has a less favorable crystal geometry than MgO, owing to too many large K+ ions.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

No. It doesn't. This is a system in reflux; once the solvent begins to boil the only thing in the head space in solvent vapor. Where would the air

come from?

Joker needs some sort of title to warn newcomers of his antics.

|

|

|

j_sum1

Administrator

Posts: 6374

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

Quote: Originally posted by MrHomeScientist  |

No. It doesn't. This is a system in reflux; once the solvent begins to boil the only thing in the head space in solvent vapor. Where would the air

come from?

Joker needs some sort of title to warn newcomers of his antics. |

I've been here for... how long?? And I never noticed the anagram of his name.

i wonder how much of importance I have missed as well.

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

In my defense, what we have here, in my opinion, is not a classic metal/O2 battery, but a related lesser known rendition with (well, at least prior to

revision, see Thesis link below) the same anodic half reaction cited in the Al/O2 battery.

For those interested, one of my favorite thesis is from 2008, "Alkaline dissolution of aluminum: surface chemistry and subsurface interfacial

phenomena", by Saikat Adhikari, link: https://www.google.com/url?sa=t&source=web&rct=j&...

I believe a similar electrochemical reaction scheme is occuring with Magnesium. Some extracts of interest for the brave, to quote:

"In addition to being a primary corrosion process, dissolution behavior of aluminum and its alloys in alkaline solutions is of

considerable interest because it is the anode reaction in aluminum-air batteries.[4] ......The anodic half-reaction at the Al electrode

is

Al + 4 OH − → Al (OH)4− + 3 e− (1.1)

which exhibits an electrode potential of -2.35 V in alkaline solutions(vs. NHE).

"2 Al + 6 H2O → 2 Al (OH)3 + 3 H2 (1.2)"

....."dissolution of aluminum in alkaline solutions at open-circuit also leads extremely high rates of H-absorption into the metal,

[9-14] ".....

"Another study of the dissolution of aluminum in aqueous solutions by Perrault revealed that the open circuit potential of aluminum

in strongly alkaline solutions corresponds closely to the Nernst potential for oxidation of aluminum hydride to aluminate ions [25]

AlH3 + 7 OH− (aq) → Al (OH)4− + 3 H2O ( aq ) + 6 e− (1.3)

This suggests a role of surface aluminum hydride as a reaction intermediate in the dissolution process. Additional evidence for the

presence of aluminum hydride was provided by Despic and co-workers.[26, 27] They found that aluminum hydride formation was one of

the major processes apart from aluminum dissolution and hydrogen evolution, during the cathodic polarization of aluminum. Titanium

corrosion in alkaline solutions is also thought to proceed through a hydride mediated mechanism.[28-30] "

"He found that the open-circuit potential in strongly alkaline media was determined by the equilibrium of the reaction

AlH3 + 7 OH− (aq) → Al (OH )4- + 3 H2O ( aq ) + 6 e− (3.7)

He obtained a standard chemical potential of 25 kcal/mol for AlH3 from his data, which was in reasonable agreement with prior

thermochemical calculations done by Sinke et al who obtained a value of 11.1 kcal/mol for the chemical potential.[80] ...."

"The anodic reaction 3.7 is accompanied by the cathodic reduction of water to form hydrogen

H2O + e- → OH- + H (3.8)

and the reaction of hydrogen with aluminum to from hydride

Al + 3 H → AlH3 (3.9)"

So, a bit technical but related half cell reactions I would guess for the likes of Magnesium.

-------------------------

One should accept that if some electric current is generated in situ, it is possible for electrons to be solvated in an appropriate organic medium.

This could lead to the decomposition of associated organics, resulting in the release of Potassium. Note, even in aqueous settings, long ago there are

reports of unexplained reactions of various salts with Mg metal, including converting nitrate into nitrite and finally ammonia (see, for example, p.

314 at "Chemical News and Journal of Physical Science, Volumes 87-88, 1903, p. 312-316, link: https://books.google.com/books?id=jvjmAAAAMAAJ&pg=RA1-PA... ).

-----------------------------------------------------------------------

[Edit] Here is an interesting article citing a temperature and Magnesium alloy presence associated with hydride formation: "absorption of hydrogen by

magnesium based alloys", in METAL 2014, link: https://www.google.com/url?sa=t&source=web&rct=j&...

This short discussion on preparing the Mg for interaction with H2 may be of value: https://books.google.com/books?id=NR3OxpSiA60C&pg=PA491&...

[Edited on 24-5-2017 by AJKOER]

[Edited on 24-5-2017 by AJKOER]

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

Quote: Originally posted by Bezaleel  | Quote: Originally posted by Dan Vizine  | (...)

If your starting metal is visually "clean" (no particulates), but is just a bit dull looking, this is all it takes to inhibit coalescence. In this

case, though, the remedy is often even easier than filtering it. You simply add one drop of DRY alcohol to the metal (in toluene, xylene) and the

surfaces will brighten up. Repeat if the metal still isn't bright. The alcohol can be 2-PrOH or EtOH). Most of the product alkoxide sloughs off the

metal surfaces and sinks to the bottom of the tube as green-gray flocculent material.

[Edited on 25-12-2016 by Dan Vizine] |

Quote: Originally posted by Dan Vizine  | (...)

Obviously, not all of the alkoxide separates from the metal. There will be some left, but you can't see it. It's still enough to change the behavior

of the molten metal toward dry, clean glass. The molten metal will now wet glass due to the powerful fluxing abilities of the alkoxide. It forms a

sodium (or potassium) mirror. |

Thanks so much for posting this.

And would repeating the method with the long tube help the potassium get clean enough to make the balls look brilliant? Or is the dry alcohol method

the only method you know of?

|

I apologize for not seeing this earlier. The screen method can be very effective at giving you shiny surfaces. As the screens push through the molten

metal, depending upon how clean or dirty it is, the mesh may start to fill up. I've never had it fill up completely. But as it fills, the filtration

becomes finer, and the retention of impurities even becomes better. The only thing that comes through the mesh seems to be clean metal in all cases.

Since it sounds like you are interested in this let me add a few additional details. The outer edges of the screen are slightly bent so that they make

a tangential approach to the glass walls instead of coming in at a straight 90° angle. This makes it easier to let the screens slide over the walls,

which you want if you're going to have a good seal. I also put more than one screen on the end of the rod. Two seems to be nice. And of course you

have the variable of mesh size to play with. The mesh on this particular screen is a little finer than the stuff you might find in a screen door. It's

much heavier though, and it's stainless steel. That's primarily because that's what I had around. Steel screen would work just fine.

My primary reason for mentioning the alcohol method was because it provides a method that doesn't require the construction of any ancillary pieces.

And of course, as I implied, it's really only good if the metal is clean through and through and simply has a slight oxide coat.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

AJKOER

Radically Dubious

Posts: 3026

Registered: 7-5-2011

Member Is Offline

Mood: No Mood

|

|

Found some support suggesting that the cathodic reaction I detailed previously above proceeds per the Aluminum path cited above with Magnesium,

namely:

H2O + e- → OH- + .H

along with the corresponding reaction of the created monatomic hydrogen radical with Magnesium to form a hydride:

Mg + 2 .H → MgH2

My support is from a reported observation published long ago from "Chemical News and Journal of Physical Science, Volumes 87-88, p. 312, link: https://books.google.com/books?id=jvjmAAAAMAAJ&pg=RA1-PA... , to quote:

"Solutions of the chlorides of barium, strontium, and calcium were acted upon but feebly by magnesium, but ammonium chloride solution was attacked at

a lively rate. "

Also, on page 314, to quote:

"It is especially interesting to note that the alcohol solution IS much more vigorous in its action on magnesium than is pure water. The urea solution

is relatively vigorously attacked, though, as has been stated, ammonia is also formed in this case."

In my opinion, with respect to the above observation of the reaction between Mg metal and aqueous NH4Cl, it is consistent with the reaction of aqueous

NH4+ with e-, creating the hydrogen atom radical:

NH4+ + e- = NH3 + .H

where the above reaction could be viewed as flowing from the better known reaction:

H+ + e- = .H

as upon adding NH3 to both sides of the above: NH3 + H+ (= NH4+) + e- = NH3 + .H as claimed above. Another way of viewing this is that NH4+ is a

very weak acid:

NH4+ = NH3 + H+ (see https://www.google.com/url?sa=t&source=web&rct=j&... )

So, upon adding e- to each side:

NH4+ + e- = NH3 + (H+ + e-) = NH3 + .H

as required. In my opinion, the above reaction could provide an added avenue for the creation the monoatomic hydrogen radical that, especially in near

neutral water as per the reported experimental observation above, could enhance the reaction rate.

With respect to the observation of increased reactivity with alcohol over water, this supports the idea of an anodic half cell reaction (likely

consuming MgH2) forming solvated electrons, as ethanol is a cited preferred medium over water. Further, the chemical breakdown of Urea to NH3 supports

a possible underlying electron transfer mechanism (like via solvated electrons).

Also note, the cited Magnesium employed in the reference above is said to contain a small amount of a transition metal (Iron) and Aluminum oxide. Per

a source (page 127 of a Phd thesis by Anna Grzech, "Hydrogen Storage in Porous Materials and Magnesium Hydrides", available online as a 17.1MB pdf) to

quote:

"some of the transition metals [13], transition metal oxides [14,15] or hydrides, transition metal halides (NbF5, TiF3, FeF3)[16-18] are

widely investigated as additives. These are believed to act as a catalyst for the chemisorption of hydrogen and transport into the

magnesium phase. [2] Among of these TiF3 additive appears to be a particularly effective catalyst. [10,19,20] "

Abstract of the cited reference [13] "It has been revealed that ball-milling of MgH2 powders with small amounts of selected 3d-transition metals M

such as Ti, Nb, … or oxides of 3d-metals (e.g. Cr2O3) leads to marked improvements of the hydrogen absorption/desorption kinetics"

So, I would expect that select transition metals (or their oxide) impurities, or present as alloys, could increase reaction rate.

[Edited on 25-5-2017 by AJKOER]

[Edited on 25-5-2017 by AJKOER]

|

|

|

gdflp

|

Thread Split

18-6-2017 at 07:34 |

| Pages:

1

..

61

62

63

64

65

66 |