Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

2,3-Dibromopropanoic acid from Acrylic acid

I want to prepare some 2,3-dibromopropanoic acid. According to the literature (e.g. Richter vol 1) bromine adds to acrylic acid to give the desired

product but details are always limited. On another page of Richter he states that boiling the dibromo acid with water causes partial hydrolysis to

2-bromoacrylic acid and bromolactic acid. I was going to use the preparation of 2,3-dibromosuccinic acid from fumaric acid given in Org Synth (Coll.

Vol. 2 page 177) as my model but the reaction is carried out in boil water.

So the question is whether water as a medium is best avoided whether it is simply a problem of reaction rates (i.e. addition of bromine to the double

bond is much faster than the hydrolysis reaction) but the Org Synth procedure specifically states boiling water.

Acrylic acid is miscible with chloroform and possibly with dichloromethane so these are possible solvent for the reaction. On the other hand acrylic

acid is a liquid and the resulting dibromo acid melts at 65 C when pure so could I simply use excess acrylic acid as the solvent and then extract the

excess acrylic acid with water at the end.

Does anyone have any experience of, or comments on, this preparation before I try some of the ideas above?

|

|

|

unionised

International Hazard

Posts: 5126

Registered: 1-11-2003

Location: UK

Member Is Offline

Mood: No Mood

|

|

Never done this reaction, but I recall that acetic acid is used as a solvent for brominations.

It should be reasonably easy to remove by distillation afterwards.

|

|

|

subskune

Hazard to Self

Posts: 71

Registered: 30-4-2017

Member Is Offline

Mood: No Mood

|

|

Can you post the full equation of the hydrolysis of 2,3-dibromopropanoic acid.

Consider that acrylic acid polymerizes very well. To avoid that I would use much solvent to lower the acid concentration and lower the risk of

polymerization.

Additionally you need to keep everything cool so use an icebath or a low boiling solvent under reflux.

What I would do:

Use much diethylether as solvent, it dissolves bromine (a bit) and acrylic acid (very well), it boils at ~30C and is therefore self cooling.

Additionally it doesn't produce nearly as much sideproducts as water which forms hydroxides.

[Edited on 2-5-2017 by subskune]

|

|

|

AvBaeyer

National Hazard

Posts: 651

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

Boffis,

You are correct in noting that 2,3-dibromopropionic acid is somewhat unstable at elevated temperature. This is a fairly well known problem with

beta-halo carboxylic acids (see Grob fragmentation). You should be able to brominate acrylic acid in good yield if you have good temperature control.

A better method would be to brominate an ester of acrylic acid if you can use the ester in your follow-on work.

I have attached a lab procedure for bromination of succinic acid which addresses the problem of elimination of HBr on extended boiling in hot water.

You may find it useful or not.

AvB

Attachment: meso-dibromosuccinic acid.pdf (383kB)

This file has been downloaded 1476 times

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@ AvBaeyer, thankyou for your very helpful comments. The detail with the recrystallisation from dilute HCl in the document attached is interesting. I

am going to give this reaction a go at an experimental scale and see how I get on. I also intend to try the fumaric acid bromination as described.

You mention the bromination of the ester. I only have free acrylic acid and I am wary of trying to esterify it as I thought the acidic catalyst may

cause it to polymerize inspite of the inhibitor it contains. How do you esterify acrylic acid or are acrylate ester prepared via indirect routes?

I am basically interested in acetylenic compounds and proxies for them.

|

|

|

CuReUS

National Hazard

Posts: 928

Registered: 9-9-2014

Member Is Offline

Mood: No Mood

|

|

see this -http://onlinelibrary.wiley.com/doi/10.1002/jlcr.1185/full

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

@ CeReUS, thank you very much that ref. is very very helpful. Since acrylic acid is miscible with chloroform I will try this solvent instead of carbon

tetrachloride but I think it should still work.

|

|

|

Dr.Bob

International Hazard

Posts: 2733

Registered: 26-1-2011

Location: USA - NC

Member Is Online

Mood: No Mood

|

|

Using CHCl3 or even DCM might work, acetic acid also works, but is hard to get rid of. But adding Br2 to a double bond is not too hard, just need to

do it slow and keep temp calm. Might need to have a small amount of an acid scavenger present, as traces of HBr are hard to avoid, I think

tertButylamine is common, as are other mild bases,

|

|

|

DrMethyl

Harmless

Posts: 34

Registered: 23-11-2015

Member Is Offline

Mood: No Mood

|

|

yep, as said above chloroform and dichloromethane are the perfect solvent. YOu can easily wash with sulfite or thiosulfate solution to get rid of

excess bromine after the reaction, then wash with dilute (bi)-carbonate solution and finally water.

Nobody mentioned the toxicity of acrylic acid ! THIS IS A VERY VERY IRRITANT AND LACRYMATORY COMPOUND !

Its close than acroleine that has been used as war gas in the WWI and is not a toy at all ! Much more hard to work with than bromine which is also

very nasty !

This reaction need a fumehood and cannot be done in a garage, eventually outside but with a gas mask.

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

OK quick update on my prelimenary experiment. I mixed approximately 11 ml of acrylic acid (measured with a 25ml cylinder) with an equal volume of

dichloromethane, they are completely miscible. To this mixture was added in 7.5-7.7ml of bromine in units of about 0.5 ml. The bromine is absorbed and

the brown mixture turns colourless again fairly quickly, the reaction is only mildly exothermic but as the temperature rises the liquid decolourizes

more quickly. Once all of the bromine had been added the mixture was left to stand in a warm place for about an hour and then filtered to remove a

small amount of soft white gel (presumed to be a polymer). The filtrate was poured into a shallow bowl and left to evaporate. By this time the mixture

had become almost colourless.

I'll be back.... with the results. Tomorrow.

OK I left it to stand overnight and the DCM has evaporated leaving a nearly odourless, colourless, thick liquid that doesn't want to crystallise, any

ideas guys. Possibly triturate with ether or water?

[Edited on 5-5-2017 by Boffis]

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

I tried mixing 0.5ml of the thick syrup like liquid with an equal volume of ether, absolute ethanol and chloroform. All were miscible but no crystals

formed.

However, in the mean time the residue has started to crystallise spontaneously!

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

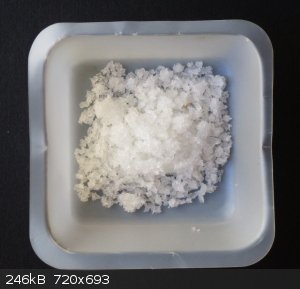

Well after 2 days at 11-13 C no further crystals appeared to form so I filtered off the crystals at the pump and then kept drawing air through the

crystals until they were loose and apparently free of any liquid. I transferred the crystals onto filter paper and pressed them and then left them to

drain for 2 days. The result was 11.74g of pure white, almost dry, prisms of an odourless compound that I have yet to investigate but which look

promising. If this material is the dibromo acid then the yield was about 33% which according to the paper above is rather poor. I will re-crystallise

it as described in the paper above.

The syrup residue was mixed with water but doesn't dissolve though the aqueous phase becomes acidic. The mixture was carefully neutralized with

cooling with 40% sodium hydroxide, it became slightly cloudy but little other signs of reaction were visible. It was left to stand over-night when is

separated into a mobile upper layer and a lower layer of gel. The upper aqueous layer was decanted and evaporated down slowly at low temperature. I am

now waiting to see if any crystals form.

The gel was very insoluble in everything though hot dilute caustic soda decomposes it and render is water soluble very quickly, it was not

investigated further.

It is fairly clear that the acryllic acid that I have, which is many years old, is rich in polymerisation products. I will repeat this preparation in

the near future but before I do I will vacuum distil the acryllic acid.

2,3-Dibormopropanoic acid? 2,3-Dibormopropanoic acid?

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

OK, I have done a great deal more experimentation on this topic and I am now in the process of writing a "Prepublication" section on this topic but it

has required some considerable experimentation.

I found for example that the best solvent is a volume of dichloromethane equal to the volume of acrylic acid, more solvent than this causes the

formation of gummy lumps early on in the bromine addition whereas with the smaller volume of DCM the reaction mixture remain homogeneous. The acrylic

acid must be freshly vacuum distilled to get a decent yield but gummy polymerisation substances are still present in the raw product. The amount of

bromine required is only about 85% of theory suggesting that even the vacuum distilled acid still contains some impurities.

Recrystallisation proved difficult until I discovered that chloroform is the best solvent for this purpose and only 2ml are required to recrystallise

10g of raw dibromopropanoic acid!! Distillation of the residues and washings allowed the recovery of about 70% of the chloroform too. DCM is too

volatile to be practical and various alcohols were tried but their solubility gradients are too flat. The mixed solvent advocated in the paper above

offers no advantage, complicates recovery of the solvent and the alcoholic solutions become viscous if chilled.

I had 3 x 250ml of acrylic acid bought in about 2013 from Mistral NI, an ebay supplier at the time. I had 720ml which I vacuum distilled at 45-50mm Hg

to give me 320g of freshly distilled acid. This should have produced 1030g of dibromo acid, however, I carried out the bromination in two goes and

during the first I filtered off 121g of gummy material before even 20% of the bromine had been added so the yield does not look that bad at a little

under 500g (376g of recrystallised acid plus material still being recovered from the washing and recrystallisation solvent experiments)

Full report shortly!

|

|

|