| Pages:

1

..

19

20

21

22

23

..

25 |

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

Progress report 1:

Improvements to GB1153483, in lieu of GB392845 on the manufacture of Hydrazine Sulfate: A Chlorourea-Ketazine

Process not involving Cl2.

I decided to give GB1153483 a try, just to see whether their 75% claimed yield held any vestiges of truth.

12.6g (0.2 mol) urea was dissolved in 18.9g water. 1.6g of 50% NaOH (0.01 mol) was stirred in and the mixture was placed in the freezer.

When the mixture had dropped to -10C (it froze), 125g of 12.5% commercial NaClO (0.2 mol) at 0C was added in roughly 10ml portions evenly over an

hour. Vigorous stirring and re-chilling followed each addition. The reaction is not very exothermic but any rise in temperature above 5C results in

bubbling, undoubtedly signalling the decomposition of the chlorourea intermediate. The bubbling was most pronounced on the first and last additon,

suggesting that thermal control is difficult with a low reaction mass, and decomposition of the intermediate is fast at high concentrations. The

mixture does not foam.

After the last addition of NaClO, 30.4g of 50% NaOH (0.38 mol) with 0.1g Knox gelatin was added with rapid stirring, causing the light green mixture

to begin foaming. The reaction was heated as quickly as possible, reaching 60C in about 10 minutes and causing foam to add another 1/3 to the volume

of the reaction mix (total about 300ml incl. foam at peak). The color of the liquid gradually became orange/amber. After approximately a minute of

exotherm the foam rapidly subsided, leaving a straw colored, foam-free, hot liquid characteristic of a hydrazine prep.

This was allowed to cool with stirring with a watch glass over the top of the erlenmeyer until it reached approximately 30C. 28.8g (0.4 mol) methyl

ethyl ketone was added and the mixture was allowed to stir for an hour for the azine to form, cooling to room temperature in the process.

The azine layer was extracted and immediately run into 19.6g H2SO4 in 20.9g H2O at about 30C. Hydrazine sulfate precipitated immediately. This was

stirred for 10 minutes, then heated with stirring for about 30 minutes to drive off the MEK. After a loss of 1/3 of its volume, the mixture was placed

in the freezer and chilled to 0C. It was then vacuum filtered and washed twice with 30ml portions of ice water.

The dried filtrate weighed 6.26g, or 21% of theoretical yield, and consisted of dense, pearlescent crystals consistent with hydrazine sulfate.

Some notes:

-All percentages listed are w/w.

-Satuating the reaction mix with NaCl after extracting the azine (30g was added and did not fully dissolve) yielded no more extractable azine, after

24h.

-Theoretical yield would net a volumetric efficiency of 96g hydrazine sulfate per liter of flask volume, including room for foam. The

75% yield in the patent would net 72g/L, 50% would net 48g/L and the current yield was 20.9g/L. The "Mr Anonymous" method requires about 6 liters of

volume for at max 236g of product, an efficiency of 39g/L. Achieving the same yield as Mr. Anonymous (ca. 60%) using this method would result in a

volumetric efficiency 1.48 times greater. The yield stated in the patent would achieve 1.85x over the M.A. method - a marked improvement in both

volumetric efficiency and safety, albeit with judicious temperature control.

- I prefer the ketazine extraction method over direct precipitation. I feel like M.A.'s method has a high level of Na2SO4 contamination.

Things to try on the next run:

- Spread out the addition of the NaClO. Ideally the mix should never rise over -5C. Use a bowl of 30% CaCl2/H2O chilled to -20C as a thermal buffer to

surround the flask and absorb the heat. Regrettably, my lab freezer is too small to set up an addition funnel/stirrer inside, so additions are limited

to small-volume aliquots.

- Make a schedule of additions starting and ending small, max 10ml.

Schedule, ml/5 min intervals, total 1h10m: 5, 5, 5, 10, 10, 10, 10, 10, 10, 10, 10, 5, 5, 5. A volumetric pipette stored in the freezer will help with

this.

- Use fresh NaOCl. The commercial 12.5% has been in my freezer for a year. I went out and purchased 4 gallons of 10% today. The slightly lesser

concentration of hypochlorite will also help with thermal management.

- Stir overnight with MEK to fully form the azine. Not sure about rate of reaction on this.

- Use 10% more MEK to make up for unwanted products formed with unreacted urea/hypochlorite in the basic environment.

- Use a separate gelatin solution rather than the NaOH solution. Gelatin clumping was a problem in the NaOH and its effectiveness as a chelator was

probably compromised. I feel that this is a big factor, per US1959503(A)/GB392845. It may also significantly increase the foam volume, reducing

volumetric efficiency to a point where this method will be inferior to others.

Failing this, I will try a third time with recrystallized urea. It's a pain in the ass to do, so that will be a last resort. I will also double the

scale, and split the reaction mass into two equal portions prior to the hydrazine extraction. One will be azine-extracted and the other will be

directly neutralized/precipitated with HCl/H2SO4, to check the efficiency of the azine process.

A possibly interesting experiment:

- What happens if all NaOH is added to urea to form essentially cold conc. ammonia first, then add hypochlorite slowly at -10C? What happens when this

is done with MEK present in the ammonia?

[Edited on 8-10-2015 by Praxichys]

|

|

|

Pimmental

Harmless

Posts: 2

Registered: 10-5-2016

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by vmelkon  | COPPER IS EVIL! Cu2+

Just for your info:

I redid this experiment --- the Nurdrage method : mix 2-butanone and ammonia solution. Then drip NaClO slowly.

The glassware in which I had my NaClO was contaminated by a copper compound.

My yield was 0%.

Definitely, the presents of Cu2+ messes it up.

------------------------

From

http://www.lookchem.com/Chempedia/Chemical-Technology/Inorga...

2 NH2Cl + N2H4 → N2 + 2 NH4Cl

This reaction is particularly catalyzed by copper. A large excess of ammonia and the addition of complexing agents such as ethylenediaminetetra-acetic

acid (EDTA) are used as countermeasures.

|

lookchem.com is a business network from the Chinese government to earn more money from Western countries with their own asian companies. For

professional business profiles only, NOT a website for chemists. Not a good source of information.

The last post: ammonia dissolve better in cold water but what is the reaction mechanism between urea and sodium hydroxide, without hypochlorite ?...

|

|

|

chemplayer...

Legendary

Posts: 191

Registered: 25-4-2016

Location: Away from the secret island

Member Is Offline

Mood: No Mood

|

|

Praxichys - thanks, that is an interesting experiment.

We also tried a variant method from the literature (don't have the exact reference though) which involved bubbling Cl2 gas through a urea solution

containing some dissolved gelatine in order to produce chlorourea. The chlorine was absorbed pretty well and a yellow coloured solution resulted. We

tried to use about 1.1 x the stoichiometric amount of Cl2 gas needed.

The solution was fairly concentrated - about 30g of urea in 60ml of water, plus about 0.3g gelatine.

Then this was added to a chilled solution of sodium hydroxide (24g in 50ml deionised water). There was a STRONGLY exothermic reaction at this point

(easily reached 90C without much difficulty) and some foaming.

Once this died down, HCl was then added until gas evolution stopped, at which point there was a crystalline white precipitate (we assume NaCl) which

we filtered off.

The filtrate was then acidified with 50% sulfuric acid and chilled. We got some crystalline hydrazine sulfate, but not much, probably only a few

grams.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Uh huh ....I see, you "feel" .....say what ? ! Hmmmph

Try the improved method with the bulk neutralization using HCl followed by the H2SO4 ....that was designed to soothe feelings

The interesting thing for followup would be the use of a manganese salt to increase yields as reported by Russians.

See these posts linked

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

|

|

|

Praxichys

International Hazard

Posts: 1063

Registered: 31-7-2013

Location: Detroit, Michigan, USA

Member Is Offline

Mood: Coprecipitated

|

|

Quote: Originally posted by Rosco Bodine  |

Uh huh ....I see, you "feel" .....say what ? ! Hmmmph

Try the improved method with the bulk neutralization using HCl followed by the H2SO4 ....that was designed to soothe feelings

|

I "feel" things when I can't be bothered to generate data.

I only have concerns about contamination because the solubility curves of the two suggest that they probably coprecipitate to some degree.

Precipitating hydrazine sulfate from a sodium sulfate or even sodium chloride solution is going to warrant recrystallization at the least. I'd be

curious to assay the hydrazine content of that, just to see. It would be virtually impossible to judge the purity of such a mixture by eye since the

crystals can be made similarly dense and granular using the precipitation methods given.

The azine extraction method removes pretty much all ionic contaminants by nature. Granted, it does use more glass and has some toxic intermediates,

but I'd rather do a L/L extraction over a recrystallization anyway. I do not doubt that your method is optimized for high yield - I just prefer to

work it up differently out of concern for contamination.

|

|

|

nitro-genes

International Hazard

Posts: 1048

Registered: 5-4-2005

Member Is Offline

|

|

Also prefered the MEK-azine extraction, really brings peace of mind to know there are no contaminants in there!  Besides... during acid neutralization of the entire reaction mixture, the CO2 effervescence is really strong and

creates an aerosol which will likely also contain some hydrazine. So this is not something that should be performed without safety measures IMO. Besides... during acid neutralization of the entire reaction mixture, the CO2 effervescence is really strong and

creates an aerosol which will likely also contain some hydrazine. So this is not something that should be performed without safety measures IMO.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Trace sodium chloride as a spectator ion is a pretty low concern in most reactions where the hydrazine sulfate would be later used. And there is a

chance some of the hydrazine is sequestered as carbonate disrupted by acidification, which could benefit yield.

|

|

|

Rhodanide

Hazard to Others

Posts: 348

Registered: 23-7-2015

Location: The 80s

Member Is Offline

Mood: That retro aesthetic

|

|

Quote: Originally posted by Al Koholic  | The fumes smelled relatively ammoniacal but also had a distinct sweetish component. /rquote]

In my experience, N2H4 smelled of Ammonia mixed with woodsmoke.

Like a sweet mesquite BBQ undertone. Too bad it's so toxic.

|

|

|

|

The jersey rebel

Hazard to Self

Posts: 76

Registered: 27-5-2016

Location: Jersey Fresh

Member Is Offline

Mood: dealing with excessive change

|

|

Quote: Originally posted by Al Koholic  | As a matter of fact, I ran into exactly the same problems. The bubbling upon supposed neutralization of the hopefully hydrazine solution is most

perplexing. I did not notice a green gas but more of a thick cloudy white vapor of some kind during my neutralization. I also used a somewhat large

excess of NH3...

Lets think about this...I did not use gelatin or EDTA and still I get the bubbling upon warming of the solution and neutralization. You used both

gelatin and EDTA and notice similar bubbling although noting the presence of chlorine by smell which I did not notice. Perhaps some side reactions

are occuring in both of our cases with different outcomes? Seems unlikely...

Did you notice a really bad smell when you added the H2SO4 to the solution for neutralization? It was bad in the sense that rotting food is

bad...nauseating...not like the pungent sting of Cl2.

[Edited on 3-12-2003 by Al Koholic] |

The bleach could have chlorate prehaps. So the gas could be chlorine

dioxide

[Edited on 20-4-2017 by The jersey rebel]

|

|

|

gdflp

|

Thread Split

18-6-2017 at 07:37 |

Rexona

Harmless

Posts: 3

Registered: 1-5-2018

Member Is Offline

Mood: No Mood

|

|

Dihydrazine Sulfate

How to prepare Dihydrazine Sulfate(H10N4O4S) ?

|

|

|

RadicallyStabilized

Harmless

Posts: 35

Registered: 3-10-2018

Member Is Offline

|

|

Protocol: Synthesis of hydrazine sulfate from bleach and urea

I recently made hydrazine sulfate from household bleach and urea according to NileRed's method (posted on Youtube).

TL;DR: The bleach had a much lower concentration than expected but in the end it worked out.

Experimental:

About 500 ml of < 5% household bleach (assumed to be about 5% concentration) were put into a 1 l beaker and stirred in an ice bath. 32 g of sodium

hydroxide pellets were added in small portions, not allowing the temperature to rise beyond 14 °C. The solution was then left to cool to 7.5 °C. A

solution of 22 g of urea (Honeywell, p. a.) in about 25 ml of water was prepared and heated in the microwave for about 30 seconds to dissolve

everything. A solution of 0.75 g of gelatin powder in about 10 ml of water was made and warmed in the microwave for about 15 seconds. After cooling

these two solutions were combined.

In the fume hood: The cooled alkaline sodium hypochlorite solution was strongly stirred on a hotplate. The gelatin/urea solution was added all at once

and the beaker covered with plastic foil. After a short while strong bubbling occurred which gave the solution a turbid appearance. Foaming was not a

problem. The bubbling gradually subsided after about one hour of stirring, so the hotplate was turned on and the solution (which was slightly yellow)

was heated up to 85 °C. After a few minutes at this temperature the solution gradually lost its yellow hue. When no change in color could be observed

any more the solution was taken off the hotplate and left to cool to room temperature. It was put into an ice bath and cooled to about 7 °C. About

120 ml of cold 50% sulfuric acid (-15 °C) was added carefully with stirring and the solution gradually warmed up to about 25 °C. No precipitate

formed. The solution was again put into an ice bath. At about 10 °C white crystals began to form. More sulfuric acid was added but there was no

additional precipitation. The solution was kept in a fridge for about an hour but no more crystals formed. The precipitate was vacuum filtered off.

The yield when wet was 9.60 g. The mass was put into a vacuum desiccator and dried over calcium chloride for about two days. The final yield of white

crystals was 9.05 g corresponding to about 21.4% of the theoretical.

Titration of the bleach:

To help explain the low yield the concentration of the bleach was determined as follows:

The sodium hypochlorite solution was titrated using sodium thiosulfate after mixing with a potassium iodide/starch indicator, according to the

procedure specified in [2].

The volume of the samples was 5 ml. 40 ml of indicator solution were added to each sample.

The necessary volume of 0.1 mol/l Na2S2O3*5H2O solution was 31.5 ml in each run.

The concentration of active chlorine was determined to be (see [2]):

C(Cl2) = 31.5 ml * 0.1 mol/l * 35.4257 g/mol / 5 ml = 22.32 g/l = 2.23% [wt% available Cl2]

According to [3] this corresponds to a weight content of NaOCL of 1.05 * 2.23 [wt% NaOCl] = 2.34%.

The specific gravity of the bleach was found to be 1.04 g/ml which is off the chart in [3] but the value seems to work out.

It is therefore obvious that the sodium hypochlorite concentration was much lower than expected.

NileRed's yield in [1] was 20.25 g (48%) when using a bleach concentration of 4.9%. This corresponds to a gram yield per bleach concentration percent

of 20.25 g / 4.9% = 4.13 g/%.

The value in this experiment was 9.05 g / 2.34% = 3.86 g/% which is a bit lower but quite close (6.5% difference).

Testing the result:

A small amount of the product was heated in a test tube. The mass began to foam and smoke emerged. In the upper portion of the test tube white and

yellow precipitates began to form and there was a smell of sulfur dioxide. A little transparent, colorless residue remained that was soluble in water

and gave no color with phenolphthalein.

As a comparison a sample of anhydrous sodium hydrogen sulfate was subjected to the same test. There was little white precipitate but no yellow could

be seen. The salt melted in the bottom of the test tube and left a white residue that was soluble in water and gave no color with phenolphthalein.

A tiny amount of the hydrazine sulfate was burned in a bunsen flame which showed the typical color of sodium. The sample evaporated quickly without

leaving any residue. It was concluded that there was at least some small amount of sodium contamination.

The Tollens test was done by adding about 2 ml of a weak ammonia solution to about 1 ml of silver nitrate solution, until the white precipitate of

silver hydroxide had dissolved. To this was added a small spatula of the hydrazine sulfate. Immediately a silver mirror began to form in the test tube

even in the cold. There was slight evolution of gas. It was concluded that the substance was indeed highly reducing and likely to be hydrazine sulfate

of a reasonable purity.

To determine the purity of the hydrazine sulfate the following iodometric titration was performed using the solutions made for titration of the

bleach:

5 ml of bleach were put into an Erlenmeyer flask and about 30 ml of the potassium iodide/starch solution were added. The solution took on a dark

color. Some more solid potassium iodide was added to ensure that all iodine was fully liberated (KI/starch solution had run out). With strong stirring

sodium hydrogen carbonate was added until the foaming stopped, plus an additional spatula for a slight excess of NaHCO3[4]. The approximate amount of

hydrazine sulfate necessary for reduction of the formed iodine was calculated as follows:

Titration with sodium thiosulfate:

2 S2O3(2-) + I2 => S4O6(2-) + 2I-

Therefore two moles of sodium thiosulfate reduce one iodine molecule.

The amount of I2 in the solution can be reduced by 31.5 ml * 0.1 mol/l Na2S2O3*5H2O = 31.5 * 0.1/1000 mol/ml = 0.00315 mol. Therefore, 0.001575 mol of

I2 were released by the bleach.

Hydrazine reduces iodine to iodide according to the following equation:

N2H5+ + 2 I2 => N2 + 4 HI

One mole of hydrazinium ion is required to reduce two moles of iodine. Therefore, 0.0007875 mol of hydrazine sulfate (130.12 g/mol) are required which

is about 0.102 g. To account for possible impurities the amount was chosen to be 0.20 g.

0.20 g of hydrazine sulfate were dissolved in 50 ml of distilled water. The iodine solution was titrated. Though the endpoint was kind of hard to

determine because the solution remained slightly pink titration was stopped when 22.2 ml had been added. After this point no color change could be

noticed any more.

This result was a bit surprising because this amount was less than the theoretical minimum amount (about 25 ml). The solution might have contained

less than the theoretical amount of iodine, possible due to the reaction with the alkaline solution. Perhaps the excess of sodium hydrogen carbonate

had been too great, and pH had not been checked (according to [4] the pH should be 7.4 for optimum results). It is also possible that the sodium

thiosulfate titration (which is said to be unreliable, see [4]) was not very accurate.

In any case the hydrazine sulfate was assumed to be pure enough to further work.

Some of the hydrazine sulfate was further used in the synthesis of 2,4-dinitrophenylhydrazine with satisfactory results.

Conclusions:

- It is better to know the concentration of your starting solutions beforehand.

- Even though urea was present in large excess this didn't seem to influence the yield very much.

- The excess of sulfuric acid might have been helping with purifying the hydrazine sulfate by converting the sodium sulfate into sodium hydrogen

sulfate which has more than six times greater solubility in water. Also, there was about twice the volume of water in the solution. Together, this

might have reduced the sodium sulfate impurities even though the solution had been cooled in the fridge (contrary to original recipe recommendations).

Next time:

- Use twice the amount of this bleach or half of the other reagents.

- Use EDTA instead of gelatin to avoid foaming.

- Use battery acid instead of making 50% sulfuric acid from concentrated acid.

References:

[1] NileRed (Youtube): Making Hydrazine Sulfate from Urea and Bleach

[2] Titration Of Active Chlorine, Antenna Foundation; https://www.antenna.ch/wp-content/uploads/2017/03/Titration-...

[3] OxyChem Sodium Hypochlorite Handbook; https://www.oxy.com/OurBusinesses/Chemicals/Products/Documen...

[4] K. S. Panwar, N. K. Mathur, S. P. Rao, Hydrazine As A Titrimetric Reagent in Iodometry Part 1, Jodhpur, 1960 (doi:10.1016/0003-2670(61)80114-1)

[Edited on 10-10-2018 by RadicallyStabilized]

Everyday consciousness classifies and subordinates, coerces under patterns of easy manipulation and disregards the essential.

|

|

|

j_sum1

|

Thread Closed

6-1-2019 at 00:55 |

j_sum1

|

Thread Opened

6-1-2019 at 01:11 |

Σldritch

Hazard to Others

Posts: 310

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

Hydrazine Sulfate synthesis with Calcium Hypochlorite

Reagents:

50g Ca(OCl)2 (granules, pool chlorine)

100g KOH (90%)

40g Urea (granules, deiceing agent)

80g NaHSO4 (pool ph lowering agent, probably the monohydrate)

HCl (30%, technical with green impurity)

Procedure:

50g of Calcium Hypochlorite granules were mostly dissolved at room temperature in 300ml of tap water. 100g of KOH was dissolved in a small amount of

tapwater (estimated 200ml total volume after dissolution). A small amount of Potassium Hydroxide solution was added to the Calcium Hypochlorite

solution and both solutions were then placed in a freezer to cool. After some time addition of Potassium Hydroxide was completed. It too was placed in

a freezer to cool but this time for several hours. At the same time 40g of Urea granules were also placed in a freezer to cool.

40g of cold urea granules were added to the hypochlorite solution with vigorous stirring after both were removed from the freezer and placed on a

magnetic stirrer. Manual stirring was used as well to beat down foam. After some time the reaction slowed down and the solution was heated until the

reaction was completed with continued stirring. The resulting hydrazine solution was left to cool in a freezer.

Calcium Carbonate was vacuum filtered off the solution and to the filtrate the Sodium Hydrogen Sulfate was added carefully. The solution was then

acidified with hydrochloric acid until it cleared and cooled in a freezer. 26g of dense white crystals were filtered of the cooled solution giving a

yield of 28%.

Discussion:

This is my second successful attempt of Hydrazine Sulfate with Calcium Hypochlorite so some mistakes were made: I did not use cold water to dissolve

the Calcium Hypochlorite which may have prevented some decomposition and similarly i was too hasty with the addition of the Hydroxide and allowed to

solution to heat up a lot. Likely with a similar outcome. Also i did not use distilled water but it seems to work anyway, which is nice.

And here are some observations: when the urea reactions with the hypochlorite solution it goes through a color change even with no gelatin present.

First it turns slightly yellow and then towards reddish just before the colour disappears. Final volume before filtering the Hydrazine Sulfate was

600ml. Foam reached only 800ml. Heating the product leaves a small amount of nonvolatile residue therefore real yield is probably lower.

And some notes for anyone who may try this: make sure to cool the hydrazine solution well before you filter of the Calcium Carbonate so that you do

not vaporize any more toxic hydrazine than necessary. Using distilled water is probably better too even though it seems to work without it.

And some general thoughts: I think i prefer using Calcium Hypochlorite over Sodium Hypochlorite/Gelatin. Calcium Hypochlorite is so easy to get at

good concentration and it does not need gelatin. Which also means it is possible to add solid urea reducing the amount of water even further. And

butanone is incredibly expensive here too so i think this procedure is much more accessible.

[Edited on 5-8-2019 by Σldritch]

|

|

|

Boffis

International Hazard

Posts: 1879

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Nice work Eldritch. Why does the calcium hypochlorite method not need gelatine or something similar? Does gelatine precipitate with calcium salts?

Given the way calcium hypochlorite is produced industrially I would have thought that there was more likelyhood of heavy metal contaiminents in this

salt than in sodium hypochlorite.

|

|

|

Pumukli

National Hazard

Posts: 708

Registered: 2-3-2014

Location: EU

Member Is Offline

Mood: No Mood

|

|

Congrats for the synth!

I'd like to second Boffis' amazement on omitting gelatine. My exact thoughts were as he stated, the way Ca-hypochlorite is produced makes it more

likely to get contaminated with various metal ions. My understanding is gelatin is used as a complexing agent to hold up these ions which would

otherwise accelerate the decomposition of hydrazine!

|

|

|

Σldritch

Hazard to Others

Posts: 310

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

In short; it is because Calcium Hydroxide is in fact something similar to gelatine, why it works im not entirely sure.

Long answer is that gelatine is believed to chelate metal or immobilize transition metals preventing their catalytic decomposition of hydrazine or

some intermediate(s). Calcium Hydroxide should act in a similar way by some combination of incorporation of transition metals into its crystal

structure (many transition metals are +2 just as calcium) and intercalation of transition metals between the layers in its crystal structure (check

the crystal structure on wikipedia). Any transition metals present in the Calcium Hypochlorite should meet the same fate as those in the tap water

when alkali hydroxide is added. Also if it is in fact an intermediate that is decomposed tap water may not actually make a difference to the reaction

as long as you do not add more water before the reaction and your urea is pure. Assuming all metal ions are trapped in the Calcium Hydroxide too.

|

|

|

Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

hydrazine from chlorourea, failure report

Based on the posts by garage chemist and ordenblitz as well as patent US3454361A I attempted the chlorourea process with the change of using MEK instead of direct neutralization with sulfuric acid.

Disclaimer:

I found this process unreliable, but maybe I am just missing a crucial detail.

Silver mirror test:

A small sample is dissolved in 9% ammonia with some drops of silver nitrate solution. After a while a silver mirror forms and confirms the reducing

agent.

Attempt 1:

Following garage chemists post, I used the same amounts and just adjusted for using sodium dichloroisocyanurate (NaDCCA) instead of TCCA.

Chlorine: 15.2 g NaDCCA, 30 g 30% HCl

Urea: 20.5 g CO(NH2)2 + 0.2 g gelatin in 40 ml

Sodium hydroxide: 16 g NaOH in 40 ml of water

Extraction using MEK, yielded 33 g of ketazine phase

The gelatin was first dissolved into the boiling hot water, which was dumped onto the urea, instantly dissolving and giving a luke-warm solution which

was left to cool to room temp. for a bit.

The chlorine absorption was great and even tho the chlorine bubbled fast through the solution, no chlorine smell was observed, as well as next to no

suckback. After all acid was added, the chlorine generator was heated until no more gas evolved.

The chlorourea was added into the lye solution inside a 1000 ml erlenmeyer flask, the foam only filled up about 200 ml. It was left stirring then

heated, turing yellow and then more clear again, was left cooling in the water bath and then stirred with the MEK for a short time.

Yield was about 4.56 g of hydrazine sulfate after hydrolyzing the ketazine with 38% sulfuric acid, 25% based on chlorine (the limiting reagent).

Then I attempted the procedure from the patent.

Attempt 2:

Slightly modifying the procedure from the patent, I increased the ratio of chlorine to urea to about 1/1. I also added some NaHCO3 to catch some of

the HCl that forms. The foaming was unbearable and the addition of chlorine took almost 3h when it took half an hour before.

Chlorine: 36.4 g NaDCCA, 63 g 30% HCl

Urea: 20 g urea + 0.2 g gelatin + 9 g NaHCO3 in 40 ml

Sodium hydroxide: 16 g NaOH in 40 ml of water

Extraction using MEK, yielded 44 g of ketazine phase

The chlorourea solution had an unpleasant chlorine-like smell, somewhat sweeter, possible the smell of chloramines. It evolved gas on its own, nearly

blowing out a stopper once. It foamed strongly when pouring it into an addtion funnel.

Addition into the hydroxide produced a massive amount of foam and lots of white smoke and a lot of heat. It had to be added in several small amounts,

yet the foam almost reached the top of the 1000 ml erlenmeyer flask several times.

After the hydrolysis nothing could be recovered from the hydrolyzed ketazine.

Upset about this I thought about giving this a last chance.

Attempt 3:

Following garage chemists post again but on 2x scale and with some modifications I used these amounts:

Chlorine: 30.4 g NaDCCA, 60 g 30% HCl

Urea: 41 g CO(NH2)2 + 0.4 g gelatin in 40 ml

Sodium hydroxide: 32 g NaOH in 80 ml of water

Extraction using MEK, yielded 22 g of ketazine phase

This time I cooled the urea solution in the freezer before passing the chlorine into it.

The reaction flask for the final addition was a three necked 1000 ml RBF with addtion funnel and reflux condenser. Both the chlorourea and the lye

solutions were cooled to about 5 °C beforehand. With strong stirring, the chlorourea solution in the addition funnel was drained into the lye,

heating the soltion to 40 °C instantly and foaming up to roughly about 2x the liquid volume. The solution was stirred for a bit, but no change in

bubbling seemed to occur, so the mix was heated to about 80 °C for a few minutes. Still barely any change, it was cooled to 70 °C before I added the

(ca. 40 g) MEK via the addition funnel. The mix turned first yellow and then red. Cooling in the water bath to 20 °C and stirring strongly for 2h (I

suspected the earlier attempt to fail because I didn't stir long enough to form the ketazine) gave a very red solution (should have let the solution

cool more) and a yellow layer on top. To improve the recovery of ketazine, some K2CO3 was added and 25 ml of washing gasoline which gave 30 ml of

slightly yellow liquid, another washing gave 27 ml from 24 ml. The gasoline washes were processed separately.

On hydrolysis the this time very yellow ketazine phase gave nothing but a deeply red, awfully smelling solution. The gasoline washes deposited a small

amount of what looked like hydrazine sulfate which was confirmed using the silver mirror test.

Attempts at saving the hydrolyzed ketazine solutions:

I suspected I added not enough sulfuric acid, so I added some more and boiled the ketazine from attempt 2 and 3 down even further. This yielded bigger

crystals that didn't look like the small crystals of hydrazine sulfate.

However, the silver mirror test confirmed both crystals to contain hydrazine.

Conclusions:

A big issue is the self-heating when mixing the chlorourea and the lye.

I have found this method to be unreliable and low yielding, giving 25%, 0% and 0% in the three attempts as well as something that doesn't seem to be

hydrazine sulfate but still reducing somehow.

Maybe there is also some issue with the ketazine extraction. Maybe the crystals are some different salt of hydrazine, maybe they just look different.

Maybe the gelatin gets destroyed by the chlorine and should be added later. Overall I think making bleach from the chlorine is more worthwhile.

However, urea seems to at least work as a good chlorine scrubber.

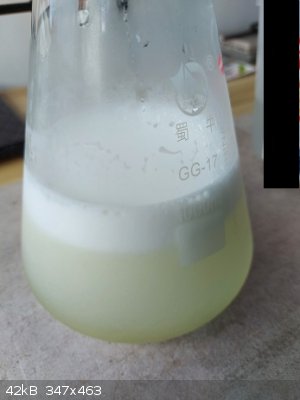

Left to right: Samples of the products of attempt 1, 2 and 3.

we apologize for the inconvenience

|

|

|

Diachrynic

Hazard to Others

Posts: 226

Registered: 23-9-2017

Location: western spiral arm of the galaxy

Member Is Offline

Mood: zenosyne

|

|

improvement of the ketazine extraction using washing gasoline

I have run the synthesis of hydrazine sulfate from NileRed and Chemplayer with the change of using MEK to extract the hydrazine.

I found two improvements to the process:

The first is to let the MEK stir in for a longer time like several hours.

The second one is after the ketazine layer is drained from the aqueous solution, the solution can be reextracted with washing gasoline, I did this two

times with 40-50 ml each.

I did the synth. with a total of 1325 ml of 4% NaOCl.

Using this, I obtained 27.44 g of hydrazine sulfate from the ketazine phase and additional 6.69 g from the gasoline upon adding sulfuric acid.

For purity reasons for recovering the MEK, the washing gasoline extract should be treated separately.

Note: I didn't come up with this idea, in this thread Nurdrage suggested toluene, but as washing gasoline is cheaper and OTC for me I used that. It

seems to be higer boiling stuff tho. Despite boiling at 110 °C it seems quite volatile. Odd.

we apologize for the inconvenience

|

|

|

B.D.E

Hazard to Self

Posts: 97

Registered: 5-8-2019

Member Is Offline

Mood: Oscillating

|

|

I'm not sure if anyone posted it here yet, but I found a new book(2014) dedicated only to Hydrazine and some of its Derivatives.

Inorganic Hydrazine Derivatives: Synthesis, Properties and Applications

http://gen.lib.rus.ec/book/index.php?md5=F936C2D44CE90B02568...

|

|

|

MadHatter

International Hazard

Posts: 1347

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

Hydrazine And Its Derivatives

I had the book once before and it

was lost due to unfortunate circumstances.

I found another copy on eBay and

awaiting its arrival. I'll let you know.

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

MadHatter

International Hazard

Posts: 1347

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

Your book

B.D.E, anytime you can find a book who's

focus is 1 compound and its derivatives,

that's definitely a KEEPER ! I wish there

more books like that around. I'm still waiting

on Hydrazine And Its Derivatives. I consider

myself very lucky to have found this treasure

again. I'll be scanning this 1 in - AGAIN !

Let me know about the details of your

book when you have a chance. I would

be very grateful and certainly appreciate

any effort on your part.

Next replacement book - The Merck Index

Thank You

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

MadHatter

International Hazard

Posts: 1347

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

The Merck Index

The Merck Index should arrive within the

next few days. It'll be scanned in if I can't

find any comparable link online. These

materials will be available under the REFERENCE

section of the LIBRARY when I get the FTP

server booted up. Wish me luck !

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

Σldritch

Hazard to Others

Posts: 310

Registered: 22-3-2016

Member Is Offline

Mood: No Mood

|

|

Wild speculation on the function of gelatin

I have been thinking on and off on the origin of the yellow and red color i observed when making hydrazine and i think i may have come up with a good

candidate: the red and yellow color is from the aminoxyl radical. Look at the color of TEMPO:

https://en.wikipedia.org/wiki/TEMPO#/media/File:Sample_of_TE...

Almost identical, and in dilute solution it could very well be yellow. With this i speculate that gelatine actually has two functions in the hydrazine

synthesis because of the difference of the colour i observed in my gelatine free hydrazine synthesis and what is usually reported from the hydrazine

synthesis.

1. Trapping radical producing transition metals.

2. Trapping radicals by reacting with them (probably oxidation of proline, other amines and sulfur)

If it is not present, such as in the Calcium Hypochlorite version i did, the solution turns red because the concentration of the radicals is high

while with gelatine a yellow color is usually observed because the concentration is lower. The unstable aminoxyl radical seems to quickly decompose,

probably yielding nitrogen gas and carbamic acid which further decomposes to ammonia and Carbon Dioxide:

2 CO(NH2)NHO* ---> 2 COOHNH2 + N2 (1)

COOHNH2 ---> CO2 + NH3 (2)

But really there are a lot of stuff that can form when radicals is involved, hydrazine(derivatives) too but in the Hoffmann degredation i think it is

undesireable. So if this is true we should not only be looking for chelating agents but radical scavengers too. While i have not had much success

finding a readily available radical scavenger i did find this paper which is quite interesting assuming radicals is a major reducer of yield:

https://www.ncbi.nlm.nih.gov/pubmed/30243703

While they use Hydrogen Peroxide similar chemistry should be seen with hypochlorite though chloride may compete more with chelating agents for

complexation with copper. After some quick searching for the catalyzed decomposition of hypochlorite by transition metal i did not find much except

that it likely follows the reaction:

2 ClO- ---> Cl- + O2 (3)

Now imagine singlet oxygen is formed, not too far-fetched considering the reaction of Hydrogen Peroxide and hypochlorite, and consider the following

reaction producing the aforementioned aminoxyl radical:

CO(NH2)2 + 1O2 ---> CONH2NHO* + H2O (4)

Neat, but i do not think this makes that much sense unless the aminoxyl radical has an extremely strong color or reaction 3 is an equilibrium and the

removal of singlet oxygen causes an increased rate of decomposition of hypochlorite according to le chatlier's principle. Option one seems somewhat

reasonable but i can not make a strong argument for it. Anyway i should probably stop now seeing as i can not test any of this right now.

|

|

|

artemov

Hazard to Others

Posts: 181

Registered: 22-8-2018

Member Is Offline

|

|

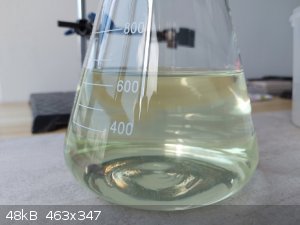

Synthesis and Questions

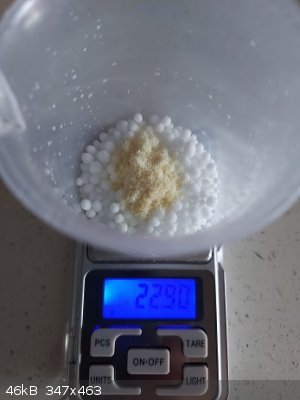

My hydrazine sulfate synthesis using the standard urea+bleach+sulfuric acid method. This is the 2nd run, I was too scared during the 1st run to take

any pic

Pic 1 30g of NaOH is first dissolved in 30ml of DW

Pic 2 (which is then added to ) ~550ml cold household bleach (assumed 5% concentration)

Pic 3 ~22g of urea and <1g of gelatine is dissolved in 20ml of warm DW

Pic 4 the initial foaming started in about 5 seconds after combination of reactants

Pic 5 heating in water bath after initial foaming died down; solution turned a darker shade with more foaming

Pic 6 stop heating after foaming ceased; solution is pale yellow

Pic 7 ppt before neutralization; NaCl? Na2CO3?

Pic 8 neutralization with 110ml of 55% cold sulfuric acid; ppt disappeared!; extra sulfuric acid will not affect yield right?

Pic 9 "yield" from 1st run; very fine crystals, frankly I can't tell if it's hydrazine sulfate, Na2SO4 or NaCl ...

I am assuming there will be Na2SO4 impurity, this will not affect the freebasing of hydrazine with NaOH/ethanol right?

Cheers. It was fun.

[Edited on 8-4-2020 by artemov]

|

|

|

B(a)P

International Hazard

Posts: 1139

Registered: 29-9-2019

Member Is Offline

Mood: Festive

|

|

What was your percentage yield?

You can use the silver mirror test if you have silver nitrate (or can readily make it) http://www.sciencemadness.org/smwiki/index.php/Hydrazine_sul...

As long as you filtered before it got too cold you won't get much Na2SO4.

Na2SO4 is what you will be filtering out after the freebasing so it does not matter.

edit, fixed the link

[Edited on 8-4-2020 by B(a)P]

|

|

|

artemov

Hazard to Others

Posts: 181

Registered: 22-8-2018

Member Is Offline

|

|

Unfortunately I dun have any silver salts, too expensive lol ....

I haven't dry them yet, and I'll be combining yields from both runs. Hoping to get >30g (with impurity) for the azide synthesis.

I'm cooling them down to ~5C in the fridge, since Na2SO4 doesn't matter in the freebasing, I'll try to get as much hydrazine sulfate out of the

solution as possible. Too tired to do a 3rd run

Thanks, will update with the final yield.

[Edited on 8-4-2020 by artemov]

|

|

|

| Pages:

1

..

19

20

21

22

23

..

25 |