| Pages:

1

2

3 |

underground

National Hazard

Posts: 703

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

Markx i have already polybutene (not PIB) from bird repellant (read my above posts) but did not worked well

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

I haven't tried the bird repellant, but PIB from tape works fine in combination with oil even at 90% solids.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Underground you need this: http://www.ebay.co.uk/itm/Toolcraft-Poly-Isobutylene-PIB-Aut...

Is it tested, working, nothing problem. No cutting. Normal 2 meter to gasoline tape as snake. No filtration. Tape can be ( is it better), as one snake

in gasoline. For all times. As dead worm. In long (30 days+) concentration increasing. PIB is pretty expensive, therefore is better let the snake in a

glass. And concentration determine again. After a long time, it is possible to pull out the whole snake from the glass. Stretch between the fingers.

Filtration is almost impossible. Dishes and destroyed everything around. All times tested. And 1:1 with oil, of course.

Liptakov.

|

|

|

VladimirLem

Hazard to Others

Posts: 204

Registered: 24-5-2010

Member Is Offline

Mood: Have no fear <Vlad> is here.

|

|

I think/hope so...

I think im going to try this (95%ETN, 5 vaseline)...its not some kind of plasic explosive, but should work pretty good to get a high density (but,

with alots of tests before, casue shit is pretty sensitive) without that much work

However...anyone already did ETN/Vaseline?

|

|

|

underground

National Hazard

Posts: 703

Registered: 10-10-2013

Location: Europe

Member Is Offline

|

|

Vladimir if you are going to try this, please tell us the results

[Edited on 26-12-2015 by underground]

|

|

|

pdb

Hazard to Self

Posts: 90

Registered: 8-4-2004

Member Is Offline

Mood: No Mood

|

|

Sebacate impact : none ?!

After purchasing bis(2-ethylhexyl) sebacate, I started testing around 20 combinations, with the follwing protocol :

- PETN 85% in all recipes (when/if I find a satisfactory formula, I will increase PETN percentage point by point until it becomes non usable)

- 15% built by mixing 3 ingredients : Blu-Tack binder 8-15% + sebacate 0-5% + oil SAE 10W 0-5%

My findings so far :

- oil softens the plastic but makes it sticky to fingers (same as with vaseline). Difficult to get ride of when on your skin

- Blu-Tack binder yields a moldable product, while 3M self-amalgaming tape binder gives something hard and crumbly, which does not stick to itself

- I didn't see any difference with & without sebacate, which puzzles me.

I know lots have been discussed on this forum about platicizing PETN or RDX, but nothing definitive. I would be interested to hear from someone having

experienced with sebacate.

Thanks.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

plasticizer

You watching this: https://www.youtube.com/watch?v=-Brs1bqr_7M

Only 8% - 10% plastificator is possible used for all materials. ...LL...

Conditions are using tape and oil 5W40. Usually 1:1.

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

plasticizer

For this energetic material was used PETN a basically fraction 0,1 x 0,1 mm. Milled through sieve (0,1 ) as dry material. EM content (estimate) a very

fine parts, 0,01 mm cca 10% from all. Content PIB from self-amalgamating tape 6%, synthetic motor oil 5W40 same, 6%. Plasticizer together 12%. Used

watercolor - acrylate red and orange, mixed after plastification. Maybe 0,7 to 1,5 % in dry form. ...LL...

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

plasticizer

New link on basic preparation plastic material. https://www.youtube.com/watch?v=euVUa7C5rAM

........LL........

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

greenlight

National Hazard

Posts: 753

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

That looks great LL.!

I will have to try it as a replacement for using polybutene bird repellent as the binder as it takes hours of rolling and doesn't get to that

plasticity.

Good work.

Be good, otherwise be good at it

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Well, this tape is I mean best. Has ideal molecule weight, respectively long of molecular chains is ideal for purpose as plastic binder. Bird

repellent has short chains, (low molecular weight) therefore is difficult or impossible preparation good binder. Thanks for

watching,.......LL........

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

greenlight

National Hazard

Posts: 753

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Yes, the end product looks very good.

I cannot get the bird repellent PE to pull apart and stretch like that without breaking.

One question I have is what is the final density of your plasticized explosive?

Is it as high as you can get with bird repellent like 1.4-1.45.

Be good, otherwise be good at it

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

plasticizer

Well. In video is not explosive, but only fine the flour. But with some material (1,77) can be in plastic consistence about 1,4. At handle pressing.

With ratio 8% PIB + 4% oil, can be density 1,5g /cm3. However material will has low plasticity. But for filling shaped charge is better just using

hard plastic. There can increase density on 1,6g /cm3. This method was measured. And confirmed 1,58g /cm3.......LL.........

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

greenlight

National Hazard

Posts: 753

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Thats sounds good as the plastic I am using at the moment is @ density 1.45 but using about 14% inert material.

I just ordered some of the same tape and I will give it a go with the next batch as you have convinced me.

Thanks LL....

[Edited on 8-1-2017 by greenlight]

Be good, otherwise be good at it

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Quote: Originally posted by Laboratory of Liptakov  | Well. In video is not explosive, but only fine the flour. But with some material (1,77) can be in plastic consistence about 1,4. At handle pressing.

With ratio 8% PIB + 4% oil, can be density 1,5g /cm3. However material will has low plasticity. But for filling shaped charge is better just using

hard plastic. There can increase density on 1,6g /cm3. This method was measured. And confirmed 1,58g /cm3.......LL......... |

If I do the calculation right...

Density of PIB and oïl is 0,90 g/cm³; content 12%

Density of the explosive powder is 1,77 g/cm³; content 88%

so

Density of mix 12/88 = (0,90*12%)+(1,77*88%) = 1,6656 g/cm³

You write 1,4 --> Where does the 16% gap come from (1,4/1,6656 =0,8405)? Air?

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

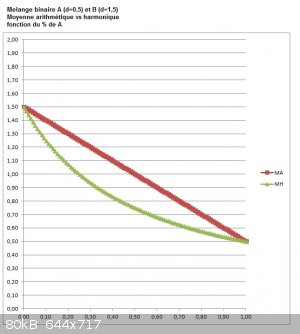

Almost!

The density of the mixture is not the arithmetic mean, it's the harmonic mean. Which gives

1/(0.12/0.9+0.88/1.77) = 1.59 g/cm3.

It's still 12% air by volume though - it might be suboptimal grain geometry but I have a feeling it enters while you knead the plastic (just like when

candy canes are made).

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

I know, seems it that is it all unusual, according arithmetic mean should by 1.66 g /cm3. However only in machine pressing in thick metal cavity. At

normal use is all always worse. Therefore PETN 88/12 with density (in cavity shaped charge) 1,58 is very good result. And even it is almost precise,

what describe Dornier. .....LL.......

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Quote: Originally posted by Dornier 335A  | Almost!

The density of the mixture is not the arithmetic mean, it's the harmonic mean. Which gives

1/(0.12/0.9+0.88/1.77) = 1.59 g/cm3.

It's still 12% air by volume though - it might be suboptimal grain geometry but I have a feeling it enters while you knead the plastic (just like when

candy canes are made).

|

Wow! I didn't knew this and was wrong for so much time.

Thank you Dornier 335A, I was really missing that information...especially if working onto detonic parameters what are strongly density dependant...

The bigger the density difference between A and B into a binary mix, the bigger the effect (lower bending of the harmonic mean vs the arithmetic one).

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

DubaiAmateurRocketry

National Hazard

Posts: 841

Registered: 10-5-2013

Location: LA, CA, USA

Member Is Offline

Mood: In research

|

|

Hmm, isnt the % of air also dependent on viscosity of the plasticizer/polymer?

|

|

|

Laboratory of Liptakov

International Hazard

Posts: 1405

Registered: 2-9-2014

Location: Technion Haifa

Member Is Offline

Mood: old jew

|

|

Also I am thanks for Dornier. Harmonic mean.....1/(0.12/0.9+0.88/1.77) = 1.59 g/cm3.....is a new thing, information for my. Very

interesting.......LL........

Development of primarily - secondary substances CHP (2015) Lithex (2022) Brightelite (2023) Nitrocelite and KC primer (2024)

|

|

|

Dornier 335A

Hazard to Others

Posts: 231

Registered: 10-5-2013

Location: Northern Europe

Member Is Offline

Mood: No Mood

|

|

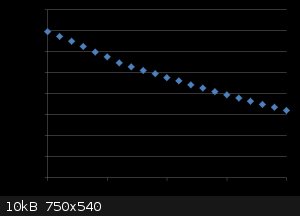

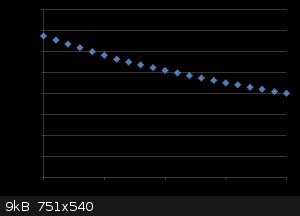

To get an idea of how much the plasticizer hurts performance, I plotted calculated detonation velocity and pressure of a PETN/paraffin mix vs fraction

paraffin:

Detonation velocity:

Detonation pressure:

|

|

|

greenlight

National Hazard

Posts: 753

Registered: 3-11-2014

Member Is Offline

Mood: Energetic

|

|

Nice, where did you get the data from?

I use a PETN PE at the moment with 14% binder/plasticizer and I calculated the detonation velocity to be around 7000 m/s which agrees with what you

have on your VOD graph.

[Edited on 10-1-2017 by greenlight]

Be good, otherwise be good at it

|

|

|

Fulmen

International Hazard

Posts: 1725

Registered: 24-9-2005

Member Is Offline

Mood: Bored

|

|

Interesting, but also misleading (I think). I assume you're using theoretical density here, and in reality that's very hard to accomplish.

We're not banging rocks together here. We know how to put a man back together.

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

Do those graphs only take into account the density variation (for example playing with Kamelet's and the simple harmonic mean of densities of paraffin

wax and PETN) or also the impact of the paraffin wax onto the oxygen balance and the overal energy output?

Can you share a little the calculations behind the plot/graph?

Funny to see that the attenuation becomes less with the increasing % wax --> at 40% must be close to 5 km/s and stil over 100 kbar...I wonder to

see extrapolation up to 100% wax...theorically should be positive VOD and pressure by extrapolation... while practically of course should be 0...

Would be nice to turn your plot from .png to .jpg sothat your plot doesn't show at first preview like a black board (this dissappear if you click on

it).

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

Having seen vacuum degassing used to eliminate or at least minimize bubbles and voids when casting composite rocket fuel grains, I wonder if anyone

has tried adapting vacuum processing to plastic explosive manufacture?

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

| Pages:

1

2

3 |