| Pages:

1

..

20

21

22

23

24 |

Atrum

Hazard to Self

Posts: 73

Registered: 7-12-2014

Member Is Offline

Mood: Tired AF

|

|

@blogfast25

Thanks, I will give that a go.

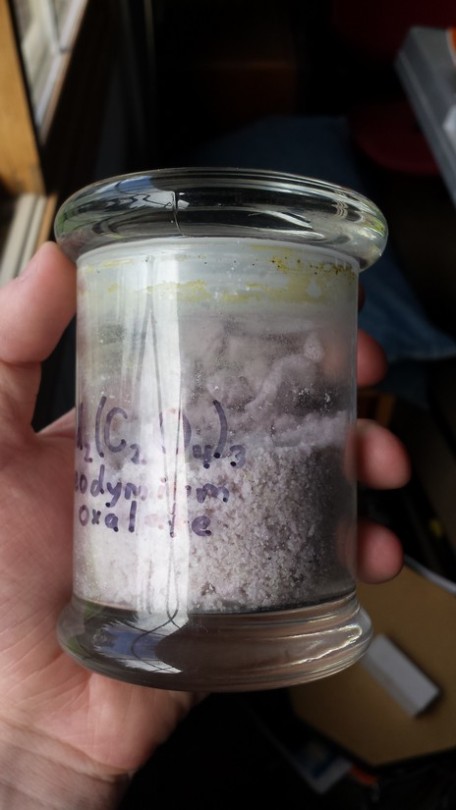

Here is a photo of the precipitate that I centrifuged to wash it. Filtering was impossible. Very Very fine precipitate. It goes through filter paper

like water through a sieve.

"Experience is my one true mistress and I will cite her in all cases. Only through experimentation can we all truly know anything." ~Leonardo da Vinci

My inventory

Recently acquired elements: Iodine , Cobalt, Tungsten, Silicon |

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Atrum  | @blogfast25

Thanks, I will give that a go.

Here is a photo of the precipitate that I centrifuged to wash it. Filtering was impossible. Very Very fine precipitate. It goes through filter paper

like water through a sieve.

|

Well, you you've got enough for that test.

|

|

|

Atrum

Hazard to Self

Posts: 73

Registered: 7-12-2014

Member Is Offline

Mood: Tired AF

|

|

Quote: Originally posted by blogfast25  | Quote: Originally posted by Atrum  | @blogfast25

Thanks, I will give that a go.

Here is a photo of the precipitate that I centrifuged to wash it. Filtering was impossible. Very Very fine precipitate. It goes through filter paper

like water through a sieve.

|

Well, you you've got enough for that test. |

Yeah, that is just one tube out of 4 that have the same amount. Hopefully I will be able to extract the rest of the nd from it. I am hoping for some

large crystals of the sulfate eventually.

"Experience is my one true mistress and I will cite her in all cases. Only through experimentation can we all truly know anything." ~Leonardo da Vinci

My inventory

Recently acquired elements: Iodine , Cobalt, Tungsten, Silicon |

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

This was probably obvious to everyone else, but I felt it was worth noting:

-I've left a solution of oxalic acid and precipitate of iron/neodymium oxalate to chelate the iron out for over a year now. Not much happened, so I

thought to just let time do the work.

-Put in some concentrated hydrogen peroxide yesterday, after seeing other users' experience with oxalates. Within 24 hours, most of the iron had

leached out of the precipitate, leaving the supernatant solution a vivid green and the precipitate an increasingly lighter shade of whitish-pink.

Given that I started with about 8 hard drive magnets, this leaves me with quite a bit of oxalate to work with. Hopefully I can calcine it at a low

enough temperature that it won't become inert like the previous stuff...

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Atrum

Hazard to Self

Posts: 73

Registered: 7-12-2014

Member Is Offline

Mood: Tired AF

|

|

Quote: Originally posted by elementcollector1  | This was probably obvious to everyone else, but I felt it was worth noting:

-I've left a solution of oxalic acid and precipitate of iron/neodymium oxalate to chelate the iron out for over a year now. Not much happened, so I

thought to just let time do the work.

-Put in some concentrated hydrogen peroxide yesterday, after seeing other users' experience with oxalates. Within 24 hours, most of the iron had

leached out of the precipitate, leaving the supernatant solution a vivid green and the precipitate an increasingly lighter shade of whitish-pink.

Given that I started with about 8 hard drive magnets, this leaves me with quite a bit of oxalate to work with. Hopefully I can calcine it at a low

enough temperature that it won't become inert like the previous stuff... |

So, I am curious. How many different solvents have you tried when trying to dissolve Nd oxalate?

"Experience is my one true mistress and I will cite her in all cases. Only through experimentation can we all truly know anything." ~Leonardo da Vinci

My inventory

Recently acquired elements: Iodine , Cobalt, Tungsten, Silicon |

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Quote: Originally posted by Atrum  |

So, I am curious. How many different solvents have you tried when trying to dissolve Nd oxalate? |

None but water, actually. I didn't figure oxalate would be soluble in much. At any rate, my pink neodymium oxalate is currently filtering out, and

looking very nice while doing so.

I do still have the results of my attempt to dissolve the previous, calcined stuff - the precipitate's turned a sandy pink, and the solution itself is

quite clear. Could this be neodymium sulfate, or just 'wet', unreacted neodymium oxalate? Hard to tell.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Atrum  |

So, I am curious. How many different solvents have you tried when trying to dissolve Nd oxalate? |

It's not really a question of 'How many different solvents have you tried'.

1. Nd oxalate is supremely insoluble, that makes it hard to dissolve in anything including strong acids.

2. Oxalic acid is not volatile: no matter what acid you throw at it, the oxalate ions are always there.

One's 'best bet' is to transform the oxalate, e.g. by oxidising it. Permanganate oxidises H2Ox to CO2 (leaving you also

with Mn(II), of course).

Hypochlorite (bleach) might also do it but would probably slow because thin bleach contains only a few w% of ClO-.

[Edited on 13-7-2016 by blogfast25]

|

|

|

Atrum

Hazard to Self

Posts: 73

Registered: 7-12-2014

Member Is Offline

Mood: Tired AF

|

|

Quote: Originally posted by blogfast25  | Quote: Originally posted by Atrum  |

So, I am curious. How many different solvents have you tried when trying to dissolve Nd oxalate? |

It's not really a question of 'How many different solvents have you tried'.

1. Nd oxalate is supremely insoluble, that makes it hard to dissolve in anything including strong acids.

2. Oxalic acid is not volatile: no matter what acid you throw at it, the oxalate ions are always there.

One's 'best bet' is to transform the oxalate, e.g. by oxidising it. Permanganate oxidises H2Ox to CO2 (leaving you also

with Mn(II), of course).

Hypochlorite (bleach) might also do it but would probably slow because thin bleach contains only a few w% of ClO-.

[Edited on 13-7-2016 by blogfast25] |

That sounds like it could be interesting to try out. I appreciate the information blogfast.

"Experience is my one true mistress and I will cite her in all cases. Only through experimentation can we all truly know anything." ~Leonardo da Vinci

My inventory

Recently acquired elements: Iodine , Cobalt, Tungsten, Silicon |

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

This source:

http://www.nrcresearchpress.com/doi/pdf/10.1139/v61-211

... indicates oxidation of oxalate with HClO (acidic conditions) is possible, with high activation energy (heating required, basically):

| Quote: | | There is some indication that, if the reaction is relatively exothermic, the activation energy is lower. This is perhaps to be expected, since if the

new bond to oxygen is strong, this would tend to lower the energy of the activated complex as it is formed. However, this trend is not universal; for

instance, the very exothermic oxidation of oxalate [by HClO] has quite a high activation energy. This particular reaction may be a little

different from the others, since it is apparently not an oxygen transfer but an electron transfer; although it could be formulated either way.

|

A combination of bleach and a weak acid (like vinegar) + some heat and time, might just slowly dissolve an insoluble oxalate to

chloride/acetate.

[Edited on 14-7-2016 by blogfast25]

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

A picture of the neodymium oxalate:

Still has oxalic acid crystals in it, but I don't particularly mind - those should simply decompose upon heating, right?

I think I'll take this to the university this fall and calcine it there, with their temperature-controlled furnace - what's the lowest temperature I

can do this at? The furnaces typically run for 24 to 48 hours, so time is not imperative.

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

The Volatile Chemist

International Hazard

Posts: 1981

Registered: 22-3-2014

Location: 'Stil' in the lab...

Member Is Offline

Mood: Copious

|

|

That's quite a lot...is the neodymium oxalate itself very crystalline, or just the oxalic acid mixed in with it - it's hard to tell in the picture.

|

|

|

Atrum

Hazard to Self

Posts: 73

Registered: 7-12-2014

Member Is Offline

Mood: Tired AF

|

|

I am slowly building up a good amount of Nd Oxalate. It seems to me that it is the best method to get it free of iron contamination. I am still

playing around though.

On the side I am trying to get a crop of nice green Iron(III)Oxalate crystals. I find the thermochromism of iron oxalate to be interesting. Bright

Green when cold, brownish red when hot.

"Experience is my one true mistress and I will cite her in all cases. Only through experimentation can we all truly know anything." ~Leonardo da Vinci

My inventory

Recently acquired elements: Iodine , Cobalt, Tungsten, Silicon |

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

I'm considering using sodium metal to reduce my neodymium fluoride. This would presumably be rammed into a graphite crucible, followed by the

neodymium fluoride, followed by external heating from a propane blowtorch. Does anyone see any problems with this method?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

I did some calculations a while back that suggested sodium won't work as well. It's probably back a few pages in the thread somewhere, so here they

are again:

∆H values:

NdF3 = -1657 kJ/mol

MgF2 = -1124..2 kJ/mol

NaF = -576.6 kJ/mol

LiF = -616.0 kJ/mol

For Mg

2NdF3 + 3Mg = 3MgF2 + 2Nd

∆Hrxn = 3(-1124.2) – 2(-1657) = -58.6 kJ/mol

For Na

NdF3 + 3Na = 3NaF + Nd

∆Hrxn = 3(-576.6) – (-1657) = -72.8 kJ/mol

For Li

NdF3 + 3Li = 3LiF + Nd

∆Hrxn = 3(-616) – (-1657) = -191 kJ/mol

So lithium produces quite a bit more heat than the others, though I’m not sure how that number corresponds with actual reaction temperature. It at

least suggests that Li should favor the easiest reaction conditions.

Also I built my setup to deliver inert atmosphere to the crucible, mostly because I'll be using lithium but also to protect the newly formed Nd from

the air. It's possible it will sink to the bottom of the melt and be protected anyway, but it's something to consider.

God I need to finish this project. I finally have all the pieces in place and can proceed at any time. I just need to get off my ass and do it.

|

|

|

blogfast25

International Hazard

Posts: 10562

Registered: 3-2-2008

Location: Neverland

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by MrHomeScientist  |

So lithium produces quite a bit more heat than the others, though I’m not sure how that number corresponds with actual reaction temperature. It at

least suggests that Li should favor the easiest reaction conditions.

Also I built my setup to deliver inert atmosphere to the crucible, mostly because I'll be using lithium but also to protect the newly formed Nd from

the air. It's possible it will sink to the bottom of the melt and be protected anyway, but it's something to consider.

God I need to finish this project. I finally have all the pieces in place and can proceed at any time. I just need to get off my ass and do it.

|

Li is the go to reducing agent in this case.

Na might work but will need stronger heating.

Both will need strong heat + inert blanket (Ar), to obtain the Nd as a regulus.

Powdered Nd in a alkali metal fluoride matrix will be inseparable, unless you heat to to well above 1000 C: the liquid Nd will then separate out.

No matter how you play it, you'll need to heat to close to 1000 C, with adequate Ar blanket.

It might be tempting to remove heat after reaction has taken place but it's probably not a good idea, if you want adequate metal/slag separation.

[Edited on 1-8-2016 by blogfast25]

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

The last problem I had to solve was connecting the Ar tank to "The Gavel" (my inert atmosphere crucible). For some reason the fittings for argon tanks

don't connect with regular pipe, so I had to order a special adapter.

The next problem I foresee is being able to heat to the proper temperature. The Gavel won't fit in my mini propane furnace, so I bought some kaowool

to wrap it in. If that won't hold in heat well enough, I'll have to spring for a larger, perhaps custom-made, furnace setup.

|

|

|

Dan Vizine

National Hazard

Posts: 628

Registered: 4-4-2014

Location: Tonawanda, New York

Member Is Offline

Mood: High Resistance

|

|

I've been constructing furnaces that operate to 1200 C with ceramic fiber board, Alumel wire, some high-temp. ceramic adhesives or (even furnace

cement) and ceramic coil forms for many years. I'd estimate you could buy everything needed to bring a 200 to 300 cubic inch space to 1200 C for $150.

Control is a whole different issue. I bought a $25 PID controller on eBay and a $10 high current solid state relay for $10. I had a K thermocouple

just laying around. This will give you a nice furnace with years of service. Of course, gas-heated rigs are cheaper but control is limited and of

course, there are exhaust issues...

If you seriously consider the electric option and want some pointers, I've made all the mistakes that you can make, I've got it down to a reliable

formula.

"All Your Children Are Poor Unfortunate Victims of Lies You Believe, a Plague Upon Your Ignorance that Keeps the Youth from the Truth They

Deserve"...F. Zappa

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

I'd love to learn from your experiences. An electric furnace would be a very valuable thing to have, not just for this particular experiment.

|

|

|

Brain&Force

Hazard to Lanthanides

Posts: 1302

Registered: 13-11-2013

Location: UW-Madison

Member Is Offline

Mood: Incommensurately modulated

|

|

I think I may have accidentally come across a much better separation method for neodymium from magnets.

I've been experimenting with gadolinium, terbium, and holmium acetates, which are conveniently non-hygroscopic but very soluble in water. They are

also quite poorly soluble in ethanol, though crystals of the acetates will fall apart in it.

Contrast this behavior with boric acid, iron(III) acetate and nickel acetate, which are highly soluble in ethanol.

I recommend you test this method (I'm about to test this myself). Dissolve a neodymium magnet in acetic acid and hydrogen peroxide. Remove the

supernatant and evaporate it to dryness. Redissolve the material in ethanol. The neodymium acetate should remain as a powder. Filter with ethanol

rinses and you should get quite pure neodymium acetate (of course there could be other lanthanides).

I haven't tried this myself, but theoretically it should get rid of nickel, iron, and boron in the magnets.

At the end of the day, simulating atoms doesn't beat working with the real things...

|

|

|

j_sum1

Administrator

Posts: 6321

Registered: 4-10-2014

Location: At home

Member Is Offline

Mood: Most of the ducks are in a row

|

|

That's some good thinking B&F. I like where that is going.

I have been pondering recently how easy it is too overlook acetic acid for reacting with metals. Sure, it tends to be slow but it has a lot of plus

sides.

|

|

|

Brain&Force

Hazard to Lanthanides

Posts: 1302

Registered: 13-11-2013

Location: UW-Madison

Member Is Offline

Mood: Incommensurately modulated

|

|

Yeah, the non-hygroscopic salts but very water-soluble salts are the biggest advantage IMO. Just a quick note - keep the concentration of acetic acid

low. I've found that highly concentrated acetic acid will not solubilize the acetates, and that glacial acetic acid does not appreciably attack

holmium at room temperature for thirty minutes. (I suggested hydrogen peroxide to keep iron as iron(III) acetate which retains extremely high

solubility in ethanol). I think iron(II) acetate will also be soluble in ethanol, so that should be another bonus.

Also, I think you can form a soluble neodymium acetate ethanol complex with strong heating, so I'd avoid heating it while it's in ethanol. That is

definitely the case in methanol for dysprosium acetate.

At the end of the day, simulating atoms doesn't beat working with the real things...

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Okay, time to try this again. Me and Brain&Force have been discussing possible alternative amateur routes to pure neodymium salts for a while now,

and while I ran an earlier attempt this year, it culminated just a week ago in utter failure. So, this time, I'm going to post my method(s)

beforehand, in the hopes that somebody will be able to spot problems before they occur.

Also, this might turn into my senior thesis.

The goal of this series of tests is to identify which chemical separation route provides the most promising results for the amateur when trying to

isolate neodymium compounds from magnets. Several separation methods will be evaluated, consisting of the potassium oxalate route, the ethanol route,

and the selective precipitation route. From there, the oxalate will be further tested for its solubility in ionic neodymium(III) salts, as according

to this source.

The reaction idea is as follows:

First, a 2"-by-2"-by-1" neodymium magnet (approximate formula Nd2Fe14B) is heated to 500 degrees Fahrenheit (approx. 260 degrees

Celsius) in a standard convection oven for 1 hour to at least partially demagnetize it (for ease of processing). Once done, the nickel casing is

stripped away as best as possible, leaving only the sintered material underneath. The approximate weight of this material, assuming none has been lost

so far, should be 478.5 to 491.6 grams, assuming the reported density of 7.3-7.5 grams/centimeter cubed is correct. This results in an estimated

neodymium content of 127.7 to 131.2 grams.

This material is then dissolved in an excess of 25% acetic acid (diluted from glacial acetic acid) to form green iron(II) acetate tetrahydrate,

Fe(C2H3O2)2(H2O)4, pale mauve neodymium(III) acetate tetrahydrate,

Nd(C2H3O2)3(H2O)x, and an unknown boron product (possibly elemental boron, 'boron

acetate,' or boric acid, or a mixture). Assuming the boron product is mostly insoluble, it is filtered off, along with any plastic or organic binding

material that may have been used in the manufacture of the magnet.

Nd2Fe14B (s) + HC2H3O2 (aq) ->

Fe(C2H3O2)2(H2O)4 (aq) +

Nd(C2H3O2)3(H2O)4 (aq) + (unknown boron compound, likely boric acid?)

Finally, this mixture is treated with an excess of approx. 11-14% hydrogen peroxide solution, which has been freeze-distilled from topical grade 3%.

This oxidizes the iron(II) acetate to iron(III) acetate, also known as basic iron acetate,

Fe3O(C2H3O2)6(H2O)3]C2H3O3. The hydrogen peroxide

does not affect the neodymium(III), because it is a more stable ion.

Fe(C2H3O2)2(H2O)4 (aq) +

Nd(C2H3O2)3(H2O)4 (aq) + H2O2 (aq) ->

Fe3O(C2H3O2)6(H2O)3]C2H3O3 (aq) +

Nd(C2H3O2)3(H2O)4 (aq)

The solution thus far is split into three equal parts.

The first third of the solution is mixed with an excess of aqueous potassium oxalate (K2C2O4) to precipitate

neodymium oxalate (Nd2(C2O4)3), chelating the iron(III) into soluble, vivid green potassium ferrioxalate

(K3(Fe(C2O4)3)3). The pale pink neodymium oxalate is filtered off, washed, and dried to remove

any excess water.

3 Fe(C2H3O2)2(H2O)4 (aq) + 2

Nd(C2H3O2)3(H2O)4 (aq) + 6 K2C2O4

(aq)-> Nd2(C2O4)3 (s) +

K3(Fe(C2O4)3)3 (aq) + 3 KC2H3O2 (aq)

(This reaction is not properly balanced.)

This oxalate is then split once again into three equal parts by mass. The first part is calcined with a torch, forming pale blue neodymium oxide

(Nd2O3) and carbon dioxide according to the following reaction:

2 Nd2(C2O4)3 + 3 O2 -> 12 CO2 + Nd2O3

This is weighed to determine the yield of Nd, assuming a perfect 1/6 of the Nd from the magnet was in the starting oxalate. Theoretical perfect yield,

therefore, is approximately 24.85 to 25.5 grams of neodymium oxide, representing 21.3 to 21.9 grams of neodymium.

The second portion of the oxalate is weighed and placed in a pre-prepared solution of aqueous neodymium chloride, and left to dissolve. Because this

test is more qualitative than quantitative, results will depend on how much, if any, of the oxalate remains.

The third portion, as with the second, is weighed and placed in a pre-prepared aqueous solution of pure neodymium acetate, to see if a similar

complexing reaction occurs.

Returning to the second portion of the mixed iron and neodymium acetates, it is boiled to dryness and mixed with ethanol. According to

Brain&Force's suggestion, this should result in the iron(III) acetate dissolving in the ethanol, leaving behind insoluble neodymium acetate

tetrahydrate. This acetate is then dried, weighed and compared to the theoretical yield of 128.4 to 132.0 grams. This is then dissolved in water, and

tested with thiocyanate for iron content.

The third and final portion of the initial mix of iron and neodymium acetates is subjected to NurdRage's method of selective precipitation, to see if

it works between iron and neodymium. This would be done by taking about half of the solution and precipitating out the hydroxides with NaOH, followed

by adding the washed hydroxide mixture back into the other half of the solution. The reactions are as follows:

Fe3O(C2H3O2)6(H2O)3]C2H3O3 (aq) +

Nd(C2H3O2)3(H2O)4 (aq) + NaOH (aq) -> Nd(OH)3

(s) + Fe(OH)3 (s)+ NaC2H3O2 (aq)

Nd(OH)3 (s) + Fe3O(C2H3O2)6(H2O)3]C2H3O3

(aq) -> Fe(OH)3 (s) + Nd(C2H3O2)3(H2O)4 (aq)

While this has never been tested to my knowledge, the difference in electropositivity between iron and manganese (+0.28) is less than the difference

in electropositivity between iron and neodymium (+0.69), which from my admittedly ignorant interpretation means that this reaction will go forward

with greater ease than its manganese counterpart. If the reaction does indeed work, then this would be an easy alternative to both the oxalate and the

ethanol route for separating iron from neodymium. The resultant solution would be filtered, and tested with thiocyanate for presence of iron.

The eventual goal, once all has been said and done, is to convert any soluble neodymium salts produced into NdF3, which will be then

converted into Nd metal.

Questions so far:

-Why does basic iron acetate have such a ridiculously complex formula?

-Is there anything in this post that strikes you as partially or completely incorrect?

[Edited on 11-26-2016 by elementcollector1]

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Some comments:

To demagnetize the magnets, all that's needed is to blast them with a propane torch for a minute or two until they separate from the metal tongs

you're holding them with. But perhaps you wanted a more repeatable process for your procedure.

I don't believe 25% acetic acid would do anything to elemental boron, so your first step is probably just B as a product.

Once you've made Nd<sub>2</sub>O<sub>3</sub>, it will likely be difficult to transform it into anything else. I seem to

remember Woelen saying his commercial sample was impervious to just about everything.

This is a great project for a thesis. So many things to experiment with and test. The ultimate extraction method would be from the paper I've

attached: "Direct Extraction and Recovery of Neodymium Metal from Magnet Scrap". The apparatus is a little tough to build though!

Attachment: Direct Extraction and Recovery of Neodymium Metal from Magnet Scrap.pdf (257kB)

This file has been downloaded 814 times

Every time I see a post in this thread I get a little kick to finish my part of the experiment. I need to beat everyone else to Nd!

|

|

|

elementcollector1

International Hazard

Posts: 2684

Registered: 28-12-2011

Location: The Known Universe

Member Is Offline

Mood: Molten

|

|

Sadly, I lack a propane torch. One of the many drawbacks to trying to do chemistry while at university...

In that case, the boron can be easily filtered off and saved for later.

I actually have a commercial sample on the way as we speak, so that I can give comparisons between what I isolate from the magnets and the 'pure'

substances. From what I've studied, the trend seems to be that the reactivity largely depends on the thermal history - the lower the decomposition

temperature of the oxalate, the better.

That paper's fascinating, but you're right, the setup's nearly impossible! It requires molten magnesium, for one thing, which I'm almost certain is

pyrophoric, and for another, it requires essentially that the magnesium/neodymium mix be distilled in a stainless steel container. I bet the apparatus

could be simplified, and if I ever get my furnace working it's definitely something to try, but I doubt this is the most practical route for an

amateur. On a related note, though, how soluble are the other lanthanides in molten magnesium?

Elements Collected:52/87

Latest Acquired: Cl

Next in Line: Nd

|

|

|

Tomo

Harmless

Posts: 1

Registered: 28-11-2016

Member Is Offline

Mood: No Mood

|

|

Same thing here, I think I need some stronger beakers. Did you give it another try?

[Edited on 29-11-2016 by Tomo]

|

|

|

| Pages:

1

..

20

21

22

23

24 |