| Pages:

1

..

6

7

8

9

10

..

18 |

darkflame89

Hazard to Others

Posts: 255

Registered: 1-3-2004

Location: With probability 1, "somewhere" in this

Member Is Offline

Mood: No Mood

|

|

Would melting sodium hydroxide in aluminium container cause that much problem? Certainly yes if the temperatures were much higher, but at about 300

degrees? Even if reactions were to occur, it would be the fusing of the surface of aluminium in contact with the molten sodium to form sodium

aluminate which would form sort of a protective layer, since it melts at extremely high temperatures.

Ignis ubique latet, naturam amplectitur omnem.

|

|

|

tumadre

Hazard to Others

Posts: 172

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

please read my previous post before answering this question.

Will propane react with the released CL2 in a non explosive manner as methane does? I am comsidering using propane as the shealding gas instead of co2

because three pounds of cl2 every five hours is too much, but 6-10 pounds of HCL and clorofoam is more easly disposed of/ or dissapated into the ...

|

|

|

BromicAcid

International Hazard

Posts: 3272

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Of course you wouldn't get chloroform, you'd get CCl4 and other chlorinated but that is a minor point, the reaction of Cl2 with butane is

rapid at 30C in the presence of light and the reaction of methane with Cl2 is explosive (if stoichiometric) in the presence of light, but it's

hard to initate without light (or so I've been lead to belive) however.... it all depends on the tempreatures involved (which in your case are

~500 - 600C) so I'm at a loss for the specifics but I would say there is at least a noticable danger factor involved.

Why the need for a shielding gas? The Cl2 producing chamber is separated and even if it does react with some of the NaCl it will just electrolyze

again. H2 makes a good shielding gas for Na however it would explode from contact with Cl2.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

I don't think activation energy is a problem, flames are awfully hot.

Does CCl4 decompose with heating? Is HCl preferred?

Tim

[Edited on 8-6-2005 by 12AX7]

|

|

|

BromicAcid

International Hazard

Posts: 3272

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Carbon tet is fairly thermally stable, hence its old use in fire extinguishers but there is bound to be some decomposition at these temperatures.

Attached is THE ELECTROLYTIC PREPARATION OF THE AMALGAMS OF THE ALKALI AND ALKALI-EARTH METALS.

G. McP. Smith, H. C. Bennett;

J. Am. Chem. Soc.; 1909; 31(7); 799-806.

Kind of 'Cold Electrochemical Sodium' really but it is an interesting read and there has been somewhat significant intrest in the

preparation of sodium amalgams.

[Edited on 6/8/2005 by BromicAcid]

Attachment: alkalimetalamalgams.pdf (566kB)

This file has been downloaded 1497 times

|

|

|

Polverone

Now celebrating 21 years of madness

Posts: 3186

Registered: 19-5-2002

Location: The Sunny Pacific Northwest

Member Is Offline

Mood: Waiting for spring

|

|

While browsing through one of the volumes of <i>A Treatise on Chemistry</i> (thanks, S.C. Wack!) I noticed under an entry on potassium

that one suggested method for its electrochemical preparation is the electrolysis of fused KCN, by melting it completely, inserting electrodes,

waiting for the surface to form a crust of solid KCN as it cools, and then passing current. KCN has a lower melting point than the chloride, and has

the advantage that (unlike the hydroxide or chloride) the anode should not suffer attack. Might it work with NaCN as well?

But that actually wasn't the recommended method. The recommended method was to use a mixture of KCl and CaCl2 mixture with control of the heating

flame so that the area around the anode remained freely molten to expel chlorine, and the area around the cathode did not. After a period of current

passage, the mass of salts would be cooled and broken under liquid hydrocarbon to reveal potassium metal substantially free of calcium. It might be

possible to do the same with sodium compounds instead of potassium, and it would certainly be easier to prepare small amounts of sodium if no inert

shielding gas needs to be used.

PGP Key and corresponding e-mail address

|

|

|

Oxydro

Hazard to Others

Posts: 152

Registered: 24-5-2004

Location: NS, Canada

Member Is Offline

Mood: distracted

|

|

I was just browsing the eutectic-finder at http://ras.material.tohoku.ac.jp/~molten/molten_eut_query1.p... and I was wondering, what exactly is the problem with the GaCl3-NaCl mix? MP of

75-25 mixture is 55C -- I would assume that at that point gallium contamination would be a problem, but say at 50/50? what would happen?

"Our interest's on the dangerous side of things" -- Browning

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Gallium has the lower reduction potential, also any sodium formed would react with it.

Tim

|

|

|

Oxydro

Hazard to Others

Posts: 152

Registered: 24-5-2004

Location: NS, Canada

Member Is Offline

Mood: distracted

|

|

Pah. I posted without thinking.

Edit: or maybe with thinking backwards. I was leaving for work, so I don't really remember. Anyways obviously only such things as lithium,

potassium and calcium can be used, the only higher potentials according to the list I looked at.

[Edited on 23-6-2005 by Oxydro]

"Our interest's on the dangerous side of things" -- Browning

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Calcium yes, lithium maybe (you would probably get lithium instead), potassium no (this is a classic ohshititshoulntdothat moment in the making). You

cannot electrolyse a molten salt mixture of potassium and sodium to eather metal seperatly. Ive posted the reasons before as well as why try this is

particulally dangerous to try.

[Edited on 23-6-2005 by Marvin]

|

|

|

Cyrus

Hazard to Others

Posts: 397

Registered: 24-4-2004

Location: Ancient Persia

Member Is Offline

Mood: No Mood

|

|

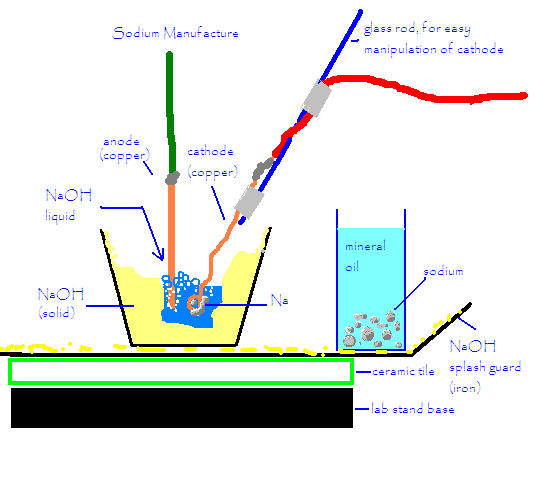

Ahh! I typed a long response and the computer ate it. To put it simply, I used patu's method with an ATX 12v power supply, red devil lye, and a

copper anode and cathode. I used a propane torch to melt the NaOH around the anode and cathode, and then kept only the center of the NaOH molten

during the reaction. This prevents ALL corrosion from the outside container and prevents the sodium from overheating and forming that "grey

stuff". If the sodium hydroxide gets too hot, it will just melt more NaOH.

The copper anodes and cathodes held up much better than iron, and although the molten NaOH was turned blue, blue is a beautiful color (much better

than a brownish rusty color), and it didn't seem to affect anything.

There was splattering and popping, mostly at the beginning, after the loop on the cathode was mostly submerged, the popping was almost gone. I got a

few miniscule splats of NaOH on my gloves and arms (and face shield) but only one really hurt. It took off a few mm of skin in as many seconds.

I really recommend this method to make a bit of sodium- it's easy, inexpensive, and really pretty safe. Sure, you can get a tiny bit of NaOH on

you, but the reaction is very slow and controllable and so there's no danger of any deflagrations or anything spewing flaming mineral oil onto

people's heads...

Here's a diagram.

Cyrus

[Edited on 30-7-2005 by Cyrus]

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

"Liver of sulfur"

Has anyone tried electrolyzing Na2S? Chatting with someone and mentioned its low MP...

Tim

|

|

|

darkflame89

Hazard to Others

Posts: 255

Registered: 1-3-2004

Location: With probability 1, "somewhere" in this

Member Is Offline

Mood: No Mood

|

|

Low m.p. ?

Hardly, checking up its melting point via google reveals that it has a melting point of about 1000 degrees C, decomposing at that point.

The low "melting point" comes from the sodium sulfide monohydrate, having 50 degrees C. Beyond this, and the salt dehydrates.

Ignis ubique latet, naturam amplectitur omnem.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Ah. I'll have to slap my contact then

Tim

|

|

|

tumadre

Hazard to Others

Posts: 172

Registered: 10-5-2005

Member Is Offline

Mood: No Mood

|

|

i am still here!

It has been a while, but this time I think I have the answer to this eight page question

sodium tetracloroaluminate.NaAlCl4.

It has a mp of just 151 C.

All I know about it is that it was first developted for liquid sodium-zinc and/or sodium-sulfur batterys, so why not just "charge the battery and

continualy draw off the sodium and add more NaCl or other sodium salts?

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

That sounds like a hard substance to get. Anhydrous aluminum ions are tricky to make.

|

|

|

BromicAcid

International Hazard

Posts: 3272

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

Even if it is made it does not guarentee any properties that would be condutive to electrolysis, namely conductivity, anhydrous aluminum halides are

non-conductive, and although the sodium chloride makes itself into this compound, it may possess more covalent character then would allow for

electrolysis, its presence in these batteries being more as an overall solvent or what is being electrolyzed rather then something that can be

individually attacked with current to give sodium metal.

But it might be worth a shot, add NaCl to anhydrous AlCl3 probably right?

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

If nothing else, if you assume it as AlCl3 in solution of molten NaCl, any Na formed will reduce the Al, forming Al metal, which I'm assuming is

your goal. If kinda inappropriate for this thead...

So yeah you can't make an NaX eutectic with anything but alkali and alkaline earth salts with a higher reduction potential, namely, Li, K, Rb,

Cs, Ca, Sr and Ba.

Hmm, most of those aren't that hard to come by. A quaternary or pentanary eutectic between Li, Na, K, Ca, Sr and Ba may melt as low as 200C.

Tim

|

|

|

Marvin

National Hazard

Posts: 995

Registered: 13-10-2002

Member Is Offline

Mood: No Mood

|

|

Mixtures of sodium and potassium salts bring the mp down spectaculally, but on electrolysis alloys are produced that are rather dangerous. You cannot

produce pure sodium or potassium metal from a mixture of the salts.

Sodium sulphide has a very high melting point, but it and sodium hydroxide have a eutectic thats a little lower than pure hydroxide, this has been

patented but I dont have the details.

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

I tried the standard electrolysis today: 5V, ~20A, 20mL liquid NaOH (red devil brand), all in a nickel crucible. The annode and cathode were both very

thick copper wire.

Electrolysis commenced with the standard period of violence and then progressed into a steady electrolysis with production of sodium and lots of tiny

NaOH droplets flying around (and landing on my hotplate, probably reducing its lifetime considerably).Temperature control was hard, but I think I

managed to keep it within acceptable limits for the most part.

I got that black solution early on, although this might have been a result of bismuth stuck to the crucible wall or temperature problems. It

didn't seem to give me any major problems.

The sodium formed at an appreciable rate, but here was my problem: I couldn't get it out very well. The eyedropper I had quickly got clogged with

NaOH and became unusable. My wire loop couldn't hold very much sodium because of its very low surface tension. Liquid NaOH kept solydifying on

it, so I had to keep breaking of this crust. As a result, I couldn't remove the forming sodium fast enough. I eventually switched to sticking

tweezers in the sodium and hoping to get as much sodium as I could where the NaOH solidified. I'll try to somehow recover my sodium tomorrow.

Is there something I'm missing here? I can't come up with a good way of removing the Na as fast as it forms.

I have and idea to fix this: confine the cathode (where the metal forms) in a glass tube with both ends open. The Na should form there and float at

the surface where it could collect without fear of shorting the circuit out. The only problem is how long would the glass tube last? I know that

liquid NaOH is notorious for destroying glass, but I don't know what kind of timeframe I'm looking at here (seconds, minutes, hours.) Also,

would the eroding glass interfere with the electrolysis?

P.S.

One more thing. When I was cleaning up my equiptment, I noticed that most things stayed basic after repeated washings. Does anyone anticipate any

problems with just leaving a small amount of NaOH there and letting the atmosphere do its work?

[Edited on 24-11-2005 by neutrino]

|

|

|

BromicAcid

International Hazard

Posts: 3272

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

A glass tube could be used. It will not just dissolve quickly into your melt, likely your melt will solidify around the glass and not really attack

it, the problem being that if this happens the liquid within the tube will likely solidify as well, and if thats the case your sodium will rise up and

just go to the sides of the test tube, so you'd probably need a tube a little bit wider then you would expect.

[Edited on 11/24/2005 by BromicAcid]

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

Why would the NaOH solidify? Heating from the electric current should easily keep it molten, right?

|

|

|

BromicAcid

International Hazard

Posts: 3272

Registered: 13-7-2003

Location: Wisconsin

Member Is Offline

Mood: Rock n' Roll

|

|

It was just my reasoning, that although glass is not really that conductive to heat, it might still be enough to wisk away some of the heat from the

melt and thereby cool it where it touched the glass causing it to freeze. However this may not be the case as the resistance from the heating of the

melt is right beneath the glass tube and the heat would rise and thereby melt the solid that would form there. So I guess you should just be wary

that something might happen along those lines.

|

|

|

neutrino

International Hazard

Posts: 1583

Registered: 20-8-2004

Location: USA

Member Is Offline

Mood: oscillating

|

|

I tried my idea a few days ago. In about a half hour of operation, the glass was eaten severely, some places had holes where I gently washed the

tubes.

My electrodes were both thick copper wire, both were submerged about 3cm into the melt. My yield was zero, I guess this has to do with those current

density issues mentioned higher up. How much 1mm diameter wire should be in my melt? The PSU was 20A @ 5V.

The NaOH turned blue after operation, indicating the annode was dissolving, although it doesn't look any thinner. The cathode was coated with a brown

substance, probably some copper that had plated on, albeit not well.

Temperature control was a problem here because everything kept freezing in my 40mL melt. I guess it doesn't help that it was below zero when I did

this. Next time I am doing it on a hot plate.

I did two successful runs with the loop method. I managed to collect about 1.5g of sodium of some unknown purity. It formed visible crystals when it

solidified under its oil. Does anyone know what sort of purity I might have here? I will upload a picture if anyone wants to see it.

|

|

|

12AX7

Post Harlot

Posts: 4803

Registered: 8-3-2005

Location: oscillating

Member Is Offline

Mood: informative

|

|

Probably 99.9% or better, metals are pretty pure when they form a squarely crystalline regulus.

I've only seen it for example in 99.99% (1099 alloy) aluminum, which makes crystal formations up to 1/4" wide.

Tim

|

|

|

| Pages:

1

..

6

7

8

9

10

..

18 |