| Pages:

1

2 |

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Using an Electric Drill as an Overhead Stirrer

I have been looking at purchasing an overhead stirrer, and it looks to me as though they are outrageously priced. For this reason, I am thinking about

using an electric drill as an overhead stirrer.

I plan to mount the drill in a condenser clamp and put a PTFE stirrer paddle in the chuck, using a tapered PTFE stirrer bearing. The particular drill

I plan to use will allow locking the trigger in the on position. I can modulate the drill speed with a triac dimmer.

I think this setup will function ok for a short while, but I'm not sure how long an electric drill will last when used as an overhead stirrer. Has

anyone ever used a drill as an overhead stirrer before?

|

|

|

hissingnoise

International Hazard

Posts: 3940

Registered: 26-12-2002

Member Is Offline

Mood: Pulverulescent!

|

|

Have you considered a magstir?

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Sometimes, mixtures are too thick for magnetic stirring.

|

|

|

NedsHead

Hazard to Others

Posts: 409

Registered: 9-12-2014

Location: South Australia

Member Is Offline

Mood: No Mood

|

|

I've been thinking about getting one of these from a second hand/thrift shop and modifying it, I see them quite often, I wouldn't mix anything

flammable with it though

|

|

|

skip

Hazard to Self

Posts: 54

Registered: 16-5-2015

Member Is Offline

Mood: No Mood

|

|

I was thinking of the same exact thing, but instead of a electric drill use a pnumatic type drill, That way no boom.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Quote: Originally posted by skip  | | I was thinking of the same exact thing, but instead of a electric drill use a pnumatic type drill, That way no boom. |

I like that idea... I see a lot of sparks inside the drill I have been thinking of using. I don't have a good source of compressed air, though....

Putting an electric drill at the top of a column of refluxing ether might not be such a great idea... but I could lead the vapors outside pretty

easily.

|

|

|

Bert

Super Administrator

Posts: 2821

Registered: 12-3-2004

Member Is Offline

Mood: " I think we are all going to die. I think that love is an illusion. We are flawed, my darling".

|

|

There is a discussion of this in EM, as part of a nitroglycerin synthesis thread.

http://www.sciencemadness.org/talk/viewthread.php?tid=949&am...

It worked. But you should think through the ramifications if setting up improvised equipment... Here are a couple, off the top of my head:

Pneumatic drills are capable of very high RPM but have very low torque @ low speeds, in my experience. Also consider how adding several cubic

feet/minute of exhaust to your hood might change the airflow, as such drills are not usually plumbed for an air exhaust hose to take the spent

compressed air elsewhere-

Non totally enclosed, fan cooled electric motors are obviously bad for an explosive or flammable environment. Such devices were also not designed to

protect bearings and electrical contacts from corrosive atmospheres, so they may have a shortened service life.

A lot of electric motors are NOT designed to run with a "wave chopper" as a speed control. If dropping the voltage increases the curent in the circuit

(motor winding), you will have an overheating issue- especially if your process runs continuously for a longer time than a homeowner grade tool was

designed for. Such tools are designed around "duty cycles", homeowner grade may be only intended to run 20% of the time or so over a 10 minute

interval. The expensive professional grade ones may be needed for a 100% cycle.

Rapopart’s Rules for critical commentary:

1. Attempt to re-express your target’s position so clearly, vividly and fairly that your target says: “Thanks, I wish I’d thought of putting it

that way.”

2. List any points of agreement (especially if they are not matters of general or widespread agreement).

3. Mention anything you have learned from your target.

4. Only then are you permitted to say so much as a word of rebuttal or criticism.

Anatol Rapoport was a Russian-born American mathematical psychologist (1911-2007).

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Here's some bedtime reading for you:

http://www.sciencemadness.org/talk/viewthread.php?tid=41539

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

According to the manual, the drill I have been considering for this application (a $20 Ryobi drill) is designed for continuous duty but only at high

speed. It recommends running the drill at top speed if there are any issues with high temperatures. It does work at lower speeds with a triac, but I

think overheating could be an issue if run at low speeds for long periods of time.

I don't relish the idea of using a stepper motor in a stirrer, but I do have some gear motors and components that could be used to wire up control

circuitry... as well as stepper motors. Stepper motors do have an advantage in that they don't give off sparks, which is probably a good thing in

environments with explosive vapor, and I'm not sure about my gear motors... I'll check when I get back to the lab.

Of course, none of my motors are designed for corrosive environments... TBH, I don't think most stirrer motors really are either.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I have used my stepper motor stirrer once since assembling it. It performed well but I could have used more rpm - its limit is 220rpm using 12vdc.

With an 18vdc I could get 700rpm which would surely be enough for most all of my syntheses.

I would feel comfortable using it in an application with an ether solvent as long as my hood fan was on.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

dermolotov

Hazard to Others

Posts: 114

Registered: 13-12-2014

Location: Toronto, Canada

Member Is Offline

Mood: Free

|

|

What's an example? I've never come across a solution that couldn't simply be thinned out by adding a solvent+ larger reaction vessel. Or in turn,

heating it.

www.alchemylabsupply.com/

Product Director

Canadian Chemical Legal Liaison

Sales Expert

Amateur Munitions/Explosive Expert

Safety Coordinator

Walking Oxymoron

|

|

|

arkoma

Redneck Overlord

Posts: 1763

Registered: 3-2-2014

Location: On a Big Blue Marble hurtling through space

Member Is Offline

Mood: украї́нська

|

|

Quote: Originally posted by JJay  | Putting an electric drill at the top of a column of refluxing ether might not be such a great idea... but I could lead the vapors outside pretty

easily.

|

Ever had a fire? I have. Scary shit. An induction (brushless) motor would be the way I tried to go and with a semi Rube Goldberg-ish linky set of pulleys and a belt (think drill press) the speed could slowed way down and torque increased to usable amounts. I've been thinking of

needing stirring too, and hotplates are ridiculously priced, especially when one can get "obtanium"

"We believe the knowledge and cultural heritage of mankind should be accessible to all people around the world, regardless of their wealth, social

status, nationality, citizenship, etc" z-lib

|

|

|

dermolotov

Hazard to Others

Posts: 114

Registered: 13-12-2014

Location: Toronto, Canada

Member Is Offline

Mood: Free

|

|

I'm still cleaning off the residue from the fire extinguisher off my glassware.

It's more annoying than anything.

www.alchemylabsupply.com/

Product Director

Canadian Chemical Legal Liaison

Sales Expert

Amateur Munitions/Explosive Expert

Safety Coordinator

Walking Oxymoron

|

|

|

solo

International Hazard

Posts: 3975

Registered: 9-12-2002

Location: Estados Unidos de La Republica Mexicana

Member Is Offline

Mood: ....getting old and drowning in a sea of knowledge

|

|

.....even overhead stirrers get contaminated and begin to malfuntion, i've considered an air drill with a small roofing compressor, running it, this

way no electrilcal contacts , no danger of explosions and it would last longer as for the torque, it would depend on the air pressure running

it.......solo

It's better to die on your feet, than live on your knees....Emiliano Zapata.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

Oh you compulsive diy types..doesn't the synthesis offer enough challenge? I've got a spare conical drive stir motor you could buy for lab trader

prices

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Quote: Originally posted by dermolotov  |

What's an example? I've never come across a solution that couldn't simply be thinned out by adding a solvent+ larger reaction vessel. Or in turn,

heating it. |

Seriously?? Aren't you a professional chemist?

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Quote: Originally posted by arkoma  | Quote: Originally posted by JJay  | Putting an electric drill at the top of a column of refluxing ether might not be such a great idea... but I could lead the vapors outside pretty

easily.

|

Ever had a fire? I have. Scary shit. An induction (brushless) motor would be the way I tried to go and with a semi Rube Goldberg-ish linky set of pulleys and a belt (think drill press) the speed could slowed way down and torque increased to usable amounts. I've been thinking of

needing stirring too, and hotplates are ridiculously priced, especially when one can get "obtanium" |

Yeah, I've had some small fires but never one that got out of hand. IMHO, the best kind of motor to use would be an oil-filled one.

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

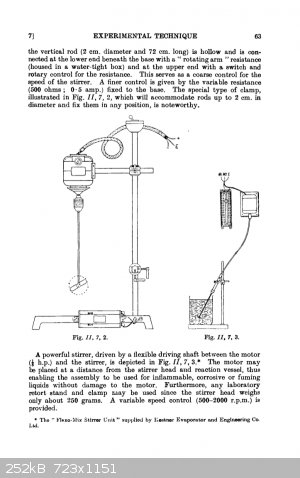

Vogel suggested using a flexible shaft to protect the stirrer from fires and corrosive vapors.

|

|

|

CuReUS

National Hazard

Posts: 928

Registered: 9-9-2014

Member Is Offline

Mood: No Mood

|

|

hope this helps

https://www.erowid.org/archive/rhodium/chemistry/equipment/o...

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

Some kitchen mixers spark so much that they could probably be used as part of an ozone generation apparatus....

Using a cork lubricated with glycerine is a bit ghetto for my tastes... I plan on using a PTFE bearing unless I need something that is really tightly

sealed... Vogel recommends a mercury-filled bearing.

I wonder if a kitchen mixer would hold up better under continuous duty than an electric drill. The rubber tubing coupling is a good idea.

|

|

|

zed

International Hazard

Posts: 2284

Registered: 6-9-2008

Location: Great State of Jefferson, City of Portland

Member Is Offline

Mood: Semi-repentant Sith Lord

|

|

The Parr pressure reactor utilizes an offset motor, several feet lateral to the reactor itself.

This works well and provides lots of torque, but it is not inherently explosion proof. In theory, flammable or explosive vapors, are isolated inside

of the sealed reactor itself.

Still, a drill press could be re-purposed to become an overhead stirrer. It has an offset motor-mount.....AND, a higher speed air motor, could be

geared down to provide lower speed and higher torque, via the drill press's pulley system. Static discharge might still be a concern, but compared to

the hazard a sparking, standard AC motor produces, danger is vastly decreased.

Got a good sized, standard, un-motored, drill press you can modify? Of course, as a propellant, an explosion proof DC motor would also serve, in lieu

of an air motor. http://www.harborfreight.com/8-in-5-speed-bench-drill-press-...

Oh, yeah, Parr....once upon a time, such systems were available used, on e-bay, at reasonable prices. Haven't seen a decent offering in a while.

Quite possibly, private individuals are being blocked from freely selling these items.

http://www.ebay.com/itm/Parr-Reactor-System-500-ML-Hast-C-10...

[Edited on 29-12-2015 by zed]

[Edited on 29-12-2015 by zed]

[Edited on 29-12-2015 by zed]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I found an oil-filled stepper gear motor, 12 volts, 1/64 step, 19:1 gear ratio. I'm a little concerned that it might overheat, but other than that it

looks sufficient.

I'm going to try the drill first since it is so easy to rig and if it starts to overheat, I'll prepare a controller for the motor.

|

|

|

careysub

International Hazard

Posts: 1339

Registered: 4-8-2014

Location: Coastal Sage Scrub Biome

Member Is Offline

Mood: Lowest quantum state

|

|

Quote: Originally posted by zed  |

Still, a drill press could be re-purposed to become an overhead stirrer. It has an offset motor-mount...

|

A variable speed tabletop drill press plus a flexible shaft might be a really good stirrer set-up (throat clearance would generally be insufficient

without). Torque galore.

There is of course the famous Chinese 5-speed drill press sold by many companies but cheapest from Harbor Freight for $70 or less (depending of

coupons and special sales), and often available on Craig's List. It has a 1/2 HP motor and speeds from 760 to 3070 RPM. That slowest speed is not real

slow, but within the range of overhead stirrers. If you are mechanically inclined perhaps you could set up a speed reduction gear linkage.

When we people start discussing explosion-proof set-ups, of course everything in the vicinity has to be "explosion proof": all connections to heaters,

lights, etc. have be secure from sparking in the "vapor zone" to prevent ignition.

[Edited on 29-12-2015 by careysub]

|

|

|

JJay

International Hazard

Posts: 3440

Registered: 15-10-2015

Member Is Offline

|

|

I stirred a refluxing mixture with a drill held at 25% power with a triac dimmer for about an hour. The drill became perceptibly warm but not hot. I

conclude that a drill does indeed make an effective overhead stirrer, if proper precautions are taken.

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

I use glass shafts with PTFE shaft holders and flexible shaft through glass adapter. Both work depending on the conditions. Some mixture are too dense

to work with stir bars and some reactions require constant effective stirring. Using silica substrates are one example; STAB works better when well

stirred. We should stir more and use less solvent IMHO.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

| Pages:

1

2 |