| Pages:

1

2

3

4

..

11 |

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

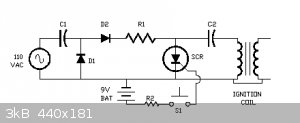

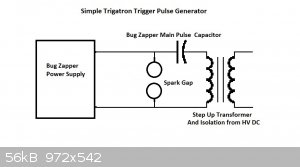

Simple Trigatron Trigger Pulse Generator From Bug Zapper Power Supply

Yeah, I knew you meant Cooper. Thanks for that compressed file, it has a lot of good stuff in it. I have been mulling the triggered switch thing over

for the last couple of days. Just about ready to give something a try.

I already linked to this page earlier, but after looking at the one-shot trigatron pulse generator on that page I got a couple of ideas.

http://hotstreamer.deanostoybox.com/ross/projects/Pulse/puls...

Here is an image of the one-shot pulse generator from that page:

In order to keep things really simple the SCR was replaced with a static spark gap and the AC input and voltage doubler stage were replaced with the

ubiquitous bug zapper power supply. A single bug zapper supply, with proper adjustment, can easily charge a suitable capacitor to over a 1000 volts if

needed. The capacitor is charged through the primary winding of the transformer until the breakover voltage of the spark gap is reached which then

arcs over and dumps the stored charge through the transformer primary very rapidly which transfers the pulse by electromagnetic induction to the

transformer secondary and the trigatron trigger electrode.

If more precise firing times are required replace the static spark gap with an SCR. Multiple circuits like this could be fired simultaneously using

SCRs. SCRs are sensitive to overvoltage, with ones I have commonly seen being rated for max 400V or sometimes 600V, so the capacitor and charging

circuit would need to be designed carefully so as not to create an over voltage situation unless very high voltage SCRs could be obtained. A pulse

capacitor charged to a lower voltage and a transformer with lower turns ratio (more voltage gain) would be needed.

I avoided winding a transformer by taking one from a switching supply, which seems to have a couple windings with a turns ratio (# turns in primary/#

turns in secondary) of 1/2-1/4 (estimated by spark gap length at secondary). This transformer is not designed to be used at several thousand volts,

but so far it seems to be holding up just fine. When I actually get it put together more properly I will post a picture or two.

BTW, a couple people have mentioned capacitor charging current limiting resistors. They are not needed when using the bug zapper supplies, since the

transformers themselves are made to be current limiting (or it just happened that way maybe).

I am pretty sure I can get by with just three bug zapper power supplies, as long as I go no higher than 3-4kV and a few uF of capacitance. Two in

series to charge the capacitor bank and one to fire the trigatron. If I was more clever, or motivated, I probably wouldn't even need the third one,

but they are only $3 each at the local dollar store anyway.

[Edited on 15-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

The last "single pulse" circuit with the spark gap will generate a very high frequency hv ac on the transformer secondary (the capacitor and primary

winding form a LC resonant circuit as the gap fires and shorts the cap through the inductance)....it is actually the most classic setup for spark

triggered tig welder arcstarters. The high frequency ac is transferred to the welder circuit by an air core transformer. In fact the resonant ac is

usually of such high frequency that it will flow by the semiconductor junctions (paracitic capacitance of the junction will conduct it) and will not

harm them. It will also not produce a classic electric shock in you body if you should touch the secondary while the gap fires. Actually one can

barely feel it due to the skin effect....it still can burn your skin if enough power is applied.

Exact science is a figment of imagination.......

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Interesting, it should work fine then. I have seen the same thing done with stunguns, which is where I got the idea. The stun gun I made this way sure

had one hell of a bite to it though. It is current not voltage that does the damage and the arc starter probably had very low current as well as high

frequency. From what I have seen, it takes very little current to trigger a trigatron as well. The above linked to website suggested using a 1uF,

400v, pulse cap before the automotive ignition coil, they were using, which would then boost the voltage up to as high as 30kV, so the current was

really very low and it sounded from the description that an even smaller capacitor could probably be used with good results. Those guys were playing

with some big capacitor banks and trigatrons too (coin shrinking, etc).

Thought I would mention that from what I have read so far voltages below the main electrode (capacitor(s)) voltage are normally used to fire the

trigatron and that using voltages well above are not needed and can actually cause problems.

[Edited on 16-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Sorry if i have this backwards, but you guys just want a localised high voltage pulse no ?

Why is it necessary to waste all that energy along long wires ?

Why not incorporate some cpu power/battery nearer to the device you want to detonate, and put that in control of the detonation ?

The wire, or wireless part of the system would be standard comms stuff.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Unless you are going to replace the capacitor bank and main high voltage & high current switch with every shot fired there needs to be at least

some distance between the main power module and the blast. Yes, the capacitor bank discharge (the switch) could be controlled remotely through small

gauge wire. That is how it is done by the professionals when they need to put more distance between them and the blast than is practical with the

heavy low loss lines from what I understand. There is a page in that compression file, posted by Jock88, which shows or describes a commercial

blasting box being controlled remotely by wire, but there still always needs to be at least some wire between the box and the blast unless you don't

mind losing it as I said (preferably low resistance, low inductance, HV wire for low losses).

A battery or regular power supply can't supply nearly a large enough di/dt. There needs to be a massive pulse of current with extremely fast rise time

to get a shock wave from the exploding wire capable of initiating a secondary explosive. I think you are thinking of regular low voltage resistive

type electric detonators. And in that case I would use/have used one or more long extension cords and a cordless drill battery. Even from a couple

hundred feet away or more it works perfectly since an amp or less is all that is needed to fire them properly. However, we are then back to using

primaries again.

1200V, 25A SCR

It seems higher voltage SCRs are not that hard to get and they can be quite affordable too. I think I will be replacing the spark gap in the trigatron

trigger pulse generator with one of these SCRs either set up as a one shot for precise firing times or set up for repetitive pulses triggered by a

DIAC.

http://www.ebay.com/itm/10-pcs-NEW-ST-TYN1225-SCR-25A-1200V-...

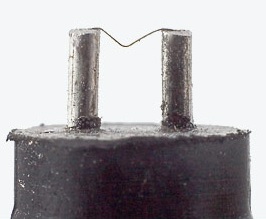

Constructing Bridgewire Heads

It can be a bit challenging attaching the bridgewires to the lead posts/wires when constructing a bridgewire head. One of the big problems I have

noticed was that solder will tend to flow out onto the copper bridge wire when soldering. I found a good webpage which describes methods to

effectively prevent solder from flowing where it is not wanted.

http://www.ganoksin.com/borisat/nenam/solder-flow-clb.htm

Here is a copy/paste from there:

"

While goldsmiths normally strive to have their solder flow easily, there are times you don't want it to flow, such as spilling over a decorated

surface, if it 'freezes' a mechanism, or if it threatens to open a gap in a seam soldered earlier in a construction.

The best way of not melting earlier seams is to learn heat control and use heat sinks creatively to suck heat from the immediate area where the

threatened join is. I use small blocks of steel for this purpose. Repair jewelers sometimes use stacks of copper pennies as heat sinks - but make sure

they are pre-1974 or so ( as later ones have zinc cores which can melt out suddenly with unfortunate consequences. A solder's melting temperature

rises every time it is heated so there is the (admittedly mostly mental) assistance of earlier seams melting at a higher temperature than the same

solder you are using again for a join.

Heat sinks won't work well with silver objects, as silver conducts heat so rapidly. Instead, for silver constructions and for especially delicate jobs

a solder flow retardant can be really useful. A paint-on solder flow retardant is easiest to use.

There are commercial solder flow retardants, but I've never needed to use them. Here are some of the ways that goldsmiths use to prevent solder

flowing.

Polishing Machine Rouge: Some people use a little rouge powder from the polishing machine dust mixed with a small amount of oil which works well. Jeff

Demand of Toronto likes to make a heat the rouge until it melts and then paint it on.

Pencil Lead: a graphite stick or soft pencil will leave a barrier that solder won't flow across. Pencil leads also work to line up tube sections when

constructing a hinge. Liquid graphite lubricant that can be found in for automotive supply stores can be used.

Scrap of Rubber: One can take a small piece of rubber (vulcanized mold chunk, a slice off a piece of an old torch hose etc) and, holding it in

tweezers, rub it on the metal part to be protected while it is hot. The rubber melts on with a truly nasty smell (use ventilation) and leaves a brown

slimy coat on the metal. This too works well.

Yellow Ochre: Old timers used yellow ochre with water. I find that it has a tendency to "bleed" into the flux and make the soldering problematic. It

is somewhat better mixed with a little oil instead of water but I find it difficult to remove from the piece and do not use it.

Maalox® and "White-Out": My favorite is Papermate© correction fluid. There are solvent based and solvent-free water based versions. In my experience

the water based version does not come off the metal after soldering as easily as the solvent based one. I like the solvent based one for this reason.

I wrote to the Papermate company listing all the metals, chemicals and temperatures that their product would come in contact with in standard use by

metalsmiths. In their return letter no mention of chemical interactions with the white pigment was made and they felt the main danger lay in the

solvent used: 1.1.1. trichloroethylene which is a mutagen and carcinogen. This leads me to think that the white material is something inert (chalk).

1.1.1. trichloroethylene breaks down when heated to form chlorine gas, hydrogen chloride and phosgene gas, all highly toxic. Their lab ran evaporation

rate tests and found that because it skins over the solvent does not evaporate as quickly as they had thought. About twenty minutes after application

the solvent will for all intents and purposes have evaporated. There is a safety problem here: it would be wise to use water rather than solvent based

materials. Ceramist's 'kiln wash' might work in the same way.

I have a suspicion that Papermate® and similar products are mostly calcium carbonate, what print makers call 'whiting;' and what the rest of us call

'chalk'. The cheapest source by volume for chalk in solution is probably Maalox® though I have not yet tried it as a solder flow retardant.

Robert Kaylor of Boise, Idaho uses China White, a standard graphic artists material made mostly of chalk as an effective solder flow retardant. It

comes as a liquid in a tube or in a dry cake which one uses like a water color cake with a brush and a little water. "

I think I will be using White-out to prevent the bridgewire from getting soldered in the middle and then removing it with solvent after soldering. I

solvent wash would be a good thing after soldering anyway I think.

[Edited on 16-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

pcb bridge wire

Hi everyone I might have an idea that I think will make fabricating the bridge wire part more easier and more consistent .

We make a small round circuit board with two pads to connect the wires to then have the bridgewire connecting between the pads the bridgewire can be

etched as small as needed and it can be gold plated and you can stencil resist over areas where you want to keep the solder if you make a double sided

board you can connect on one side of the board and the via will connect to the bridgewire side

Cheers nuxy

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

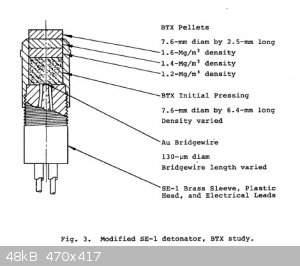

I think the bridgewire should be up on posts with low density fine secondary explosive all around it. I was thinking along similar lines as you for a

while though. The other thing is that the bridge wire is normally 0.001 inch to 0.003 inch in diameter; 40 AWG is actually slightly bigger than 0.003

inch in diameter and that is tricky enough to deal with. Gold has less than half the tensile strength of copper, so it must need very special handling

equipment especially when it gets down to 0.001 inch.

Then again maybe I am not right, here is a document showing the bridgewire positioned more or less right up against the plug.

Attachment: High Temperature EBW Detonator.pdf (317kB)

This file has been downloaded 910 times

[Edited on 17-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

jock88

National Hazard

Posts: 505

Registered: 13-12-2012

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by markx  | | The last "single pulse" circuit with the spark gap will generate a very high frequency hv ac on the transformer secondary (the capacitor and primary

winding form a LC resonant circuit as the gap fires and shorts the cap through the inductance)....it is actually the most classic setup for spark

triggered tig welder arcstarters. The high frequency ac is transferred to the welder circuit by an air core transformer. In fact the resonant ac is

usually of such high frequency that it will flow by the semiconductor junctions (paracitic capacitance of the junction will conduct it) and will not

harm them. It will also not produce a classic electric shock in you body if you should touch the secondary while the gap fires. Actually one can

barely feel it due to the skin effect....it still can burn your skin if enough power is applied. |

This would work OK so long a the 'ubiquitous bug zapper device' is dc (not ac). I don't know what they are?

As far as the 'best' wire to use, there was a patent put up on the board that had no bridge wire at all. The patent was restricted at the time because

it was when the bomb was being developed. It was filed in (about 44) and published in the seventies (about).

I'll have a look for if some time.

[Edited on 17-4-2015 by jock88]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The bug zappers have a tiny flyback transformer in them, which produces AC, but the output is rectified to DC with HV diodes (the diode(s) also come

with the zappers). It has to be DC because the energy is stored in a capacitor like a coiled spring waiting for the unsuspecting bug to get between

the conductive mesh contacts and then to ride the lightning.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

0.3g of ETN Initiated With 40 Gauge Copper EBW

EBW Head:

A half inch or so of hot melt glue stick was sliced off on a cutting board, drilled once and then drilled a second time, for lead wires, using a

previously made jig/spacer made from a piece of circuit board to give precise hole spacing. The bridge wire was ca. 40AWG copper of about 2 to 2.5mm

length. The white-out solder flow retardant worked beautifully preventing any solder from flowing out onto the middle of the bridgewire. It could also

be easily removed with acetone which made it very soft so that it could be gently wiped away. A fine cotton swab soaked in acetone would likely be

effective and gentle. Once a few tricks are learned EBW head construction is not that difficult. The EBW head was pressed into the fluffy ETN with

light finger pressure only.

Charge:

0.3g of ETN pressed in three increments into a 7.6mm Al casing; 0.1g at about 30lbs, 0.1g at about 15lbs and 0.1g with only finger pressure to remove

voids and settle the ETN. The ETN was very light and fluffy, the result of rapid precipitation from dilution of a well mixed solution in methanol with

water.

Transmission Line:

12ft of RG-6 coax (satellite/cable television coax) and 1ft of 18AWG speaker wire. Total 13ft of transmission line.

Capacitor Bank:

6X 1uF, 1000V connected to give 0.67uF and 3000V. The bank was charged to only 2300V for this test. The voltage divider allows a much lower and very

safe proportional voltage to be monitored with a regular multimeter/volt meter and from a distance with a fine sensing wire if desired. The voltage

divider also doubles as a bleeder resistor ensuring that the capacitor bank is fairly quickly discharged after use.

Switching:

Switching was accomplished by the very crude and inefficient method of touching the center conductor of the coax to the speaker wire connected to the

capacitor bank.

Target:

Ca. 2.6mm steel plate.

Results:

It was a very loud boom, which I could tell clearly even though I was wearing earmuffs (I was only 10ft away of course). The result, in terms of steel

penetration & shattering, would have been better if the bottom increment(s) of ETN had been pressed to much higher density with a press and of

course if more ETN had been used. This test was simply proof of concept.

Very large capacitors are not needed at all. The most important thing is to have low impedance cable that isn't too long, good low inductance &

resistance connections and high voltage. I have 100ft of RG-213 ordered which I will have soon, as well as enough new pulse capacitors to make a low

ERS capacitor bank of 1.2uF and 4000V. I don't think I will have any trouble initiating these homemade EBW detonators through 100ft of RG-213 since it

is a very low loss cable.

BTW, a good source of ca. 40AWG copper magnet wire is the little door and window alarms which are often available at dollar stores and hardware

stores, etc. Don’t let the small size fool you, the inductor that is in them holds a lot of magnet wire. About ten years ago I decided to make a

2-3V relay from a reed switch and the magnet wire on one of those inductors. It seemed like I was winding for hours though I guess it couldn’t have

been; it was really surprising how long the wire was that makes up those windings. The insulation can be easily burned off with a low flame of a small

butane torch. Even a mini butane torch can melt the fine copper wire if care is not used.

[Edited on 18-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

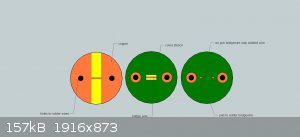

Hi I've drawn up a drawing of how I see the bridgewire head made from a fiberglass pcb cheers nuxy

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Interesting ideas. I can see the third one working, but I think it would be very difficult for most amateurs to accurately and precisely make

0.001-0.003inch diameter strips in comparison to just obtaining some fine gauge wire with consistent diameter.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

nux vomica

Hazard to Others

Posts: 267

Registered: 18-7-2013

Member Is Offline

Mood: No Mood

|

|

I realise that most people would be put off making there own pcb,s but I have made them at home that had all smt components on them I made the uv

resist transparency's and the solder paste stencils myself.

Also there is a lot of free programs online (eagle cad is one) for free that you can draw up your board then send it off to a pcb manufacture in

china and get it fabricated very cheaply nowadays.

I've got a cnc router at home so I can mill the board, I've got some carbide bits that are .5mm in dia , but I admit the stencil for the green resist

coat is a bit more challenging to fabricate.

cheers nuxy.

|

|

|

jock88

National Hazard

Posts: 505

Registered: 13-12-2012

Member Is Offline

Mood: No Mood

|

|

You can purchase very fine Nichrome wire. It may the more resistant to corrosion for a more long term device. Copper is somewhat reactive with a very

thin wire(or is it?).

The extra resistance of the tiny piece of Nichrome would be irrelevant.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Energy Injected to the Wire During the First Current Pulse

The following snip-it and table were taken from, "Electric Explosion of Wires as a Method for Preparation of Nanopowders" by Yu A. Kotov. The article

is attached below as well.

"

The energy W injected to the wire during the first current pulse was found to be

W = (hb * W0 * S^2 * Z)^0.5

where W0 = 1/2CVo^2 is the stored energy, J; Vo is the capacitor charging voltage, kV; Z = (L/C)^0.5 is the circuit characteristic impedance, Ohm; L is the discharge circuit

inductance, μH; C is the capacitance, μF; S = 1/4 * pi * D^2 is the wire cross-sectional area, mm2 (D being the wire diameter, mm); hb has the dimensionality of A^2 * s / mm4 and represents the pre-explosion specific ‘action’ or thermal toughness

of the material heated with a current pulse (Anderson&Neilson, 1959; Cnare & Neilson, 1959; Cnare, 1961). This notion was used earlier

(Rudenberg, 1950) for calculation of safety fuses. The obtained hb values (Anderson & Neilson, 1959;

Cnare&Neilson, 1959; Tucker&Neilson, 1959; Cnare, 1961; Kotov et al., 1990) are given in Table 1."

Attachment: Electric Explosions of Wires as a Method of Preparation of Nanopowders.pdf (208kB)

This file has been downloaded 1205 times

hb(Copper) / hb(Gold) = ca. 4

All other things being equal, it seems as though it takes roughly four times the energy to explode a copper bridgewire than it takes for a gold one.

Of course, all other things being equal, a change in the diameter of the bridge wire by a factor of two would change the burst energy by a factor of

sixteen.

Quote: Originally posted by jock88  |

You can purchase very fine Nichrome wire. It may the more resistant to corrosion for a more long term device. Copper is somewhat reactive with a very

thin wire(or is it?).

The extra resistance of the tiny piece of Nichrome would be irrelevant. |

Nichrome is much more corrosion resistant, but is not very suitable other than that from the few things I have read (very high resistivity for one).

Copper is quite suitable, except for the corrosion issue and its much lower density than gold as well.

[Edited on 19-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

jock88

National Hazard

Posts: 505

Registered: 13-12-2012

Member Is Offline

Mood: No Mood

|

|

"All other things being equal, it seems as though it takes roughly four times the energy to explode a copper bridgewire than it takes for a gold one."

Since nickle has a value closer to gold (and assuming chromium's figure is not too bad) then nichrome should not be too bad?

Patent of spark gap detonator (no wire 'ebw') attached.

The filed and publication dates are very different.

Attachment: US3955505.pdf (188kB)

This file has been downloaded 848 times

[Edited on 18-4-2015 by jock88]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

40 gauge nichrome wire resistance at 20C = ca. 70 ohms/ft

40 gauge gold wire resistance at 20C = ca. 1.49 ohms/ft

40 gauge copper wire resistance at 20C = ca. 1.05 ohms/ft

I = V / R

Initial current flow = voltage of capacitor(s) / resistance of system

Using nichrome resistance wire would add a lot of unwanted resistance to the system which would greatly decrease current flow for a given voltage.

Even a 2mm long nichrome bridge wire (40 gauge) would add about 0.46 ohms of resistance to the system, while 100ft of RG-213 cable only adds about 0.3

ohms of resistance. The tiny 2mm long nichrome wire could easily have more resistance than the whole rest of the system!

Attachment: Initiation of Exposives by Exploding Wires I (Effect of Circuit Inductance).pdf (1.7MB)

This file has been downloaded 950 times

Attachment: Initiation of Explosives by Exploding Wires II (Effect of Circuit Resistance).pdf (1.1MB)

This file has been downloaded 894 times

Attachment: Initiation of Explosives by Exploding Wires III (Effect of Wire Diameter).pdf (1.1MB)

This file has been downloaded 853 times

Attachment: Initiation of Explosives by Exploding Wires IV (Effect of Wire Length).pdf (755kB)

This file has been downloaded 788 times

Attachment: Initiation of Explosives by Exploding Wires V (Effect of Wire Material).pdf (1.3MB)

This file has been downloaded 956 times

Attachment: Initiation of Explosives by Exploding Wires VI (Further Effects of Wire Material).pdf (1.2MB)

This file has been downloaded 813 times

Attachment: Initiation of Explosives by Exploding Wires VII (Effect of Energy Termination).pdf (1.2MB)

This file has been downloaded 872 times

Attachment: Initiation of Explosives by Exploding Wires VIII (Effect of Moderate Voltage Levels).pdf (865kB)

This file has been downloaded 891 times

[Edited on 19-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

This has some useful information in it, though quite general.

Attachment: High Voltage Surge Generators - HV Engineering Chapter 8.pdf (207kB)

This file has been downloaded 1573 times

From "Military Explosives" page 8-17, regarding compatibility of PETN and copper.

"

At temperatures up to about 50°C, dry PETN does not react with copper, brass, aluminum, magnesium, magnesium-aluminum alloys, stainless steel, mild

steel, mild steel coated with acid proof black paint, and mild steel plated with copper, cadmium, nickel or zinc. Wet PETN does not react with

stainless steel, and aluminum is affected only slightly after long periods of storage. However copper, brass, magnesium, magnesium-aluminum alloys,

mild steel, mild steel coated with acid-proof black paint, and mild steel plated with cadmium, copper, nickel or zinc are affected. PETN is used in

the explosive core of industrial detonating fuses, in the charge of commercial blasting caps, and as the entire explosive charge in exploding bridge

wire detonators."

[Edited on 19-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

markx

National Hazard

Posts: 646

Registered: 7-8-2003

Location: Northern kingdom

Member Is Offline

Mood: Very Jolly

|

|

I see you still refuse to show mercy to this mangled corpse of a witness plate....hasn't the poor bastard suffered enough already?

Cool capacitor bank btw...

Exact science is a figment of imagination.......

|

|

|

jock88

National Hazard

Posts: 505

Registered: 13-12-2012

Member Is Offline

Mood: No Mood

|

|

It's a very holy plate.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I am going to use it for a strainer when I am done.

No, seriously, it seems when I go looking for a witness plate that one keeps turning up. Just like a bad penny!

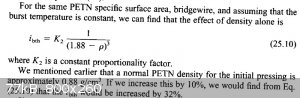

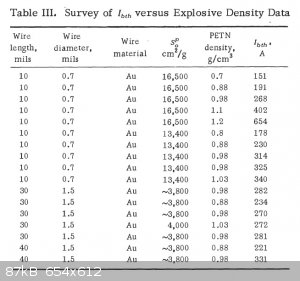

Here are a couple snip-its which show how even relatively small increases in explosive density make initiation of secondary explosives by EBW much

more difficult. The first snip-it is from Cooper and the second is from "Exploding Wires Vol 4".

[Edited on 21-4-2015 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Sorry if this sounds dense.

To detonate [whatever] are you just looking for a hot wire, or a Very hot wire that gets very hot very fast, or an Extremely hot wire that gets hot

extremely fast ?

I know nothing about explosives, but do know about wires getting hot.

[Edited on 20-4-2015 by aga]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

The following are the first ten pages from one of the RISI technical sections from their site. Read page three for a good basic description of the

difference between regular low power electrical igniters and exploding bridge wire secondary explosive initiators.

Attachment: page1.pdf (28kB)

This file has been downloaded 855 times

Attachment: page2.pdf (33kB)

This file has been downloaded 918 times

Attachment: page3.pdf (32kB)

This file has been downloaded 983 times

Attachment: page4.pdf (40kB)

This file has been downloaded 1066 times

Attachment: page5.pdf (33kB)

This file has been downloaded 738 times

Attachment: page6.pdf (35kB)

This file has been downloaded 935 times

Attachment: page7.pdf (33kB)

This file has been downloaded 897 times

Attachment: page8.pdf (30kB)

This file has been downloaded 1045 times

Attachment: page9.pdf (29kB)

This file has been downloaded 881 times

Attachment: page10.pdf (159kB)

This file has been downloaded 795 times

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

WOW.

Thanks for the references.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

You are welcome.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

| Pages:

1

2

3

4

..

11 |