| Pages:

1

2 |

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Preparation of Acetyl Chloride

A. Introduction Back in 2009 I had found a preparation for acetyl chloride in Helvetica Chimica Acta, 1953. Precursors

were acetic anhydride (AA) and calcium chloride. The article was in German so I asked garage chemist (GC) to check my Babelfish translation. My

translation was OK but he didn’t like the preparation due to poor yield and recommended an alternative. GC’s method reacts dry HCl gas with AA.

Acetic acid is a by-product:

1 mole AA + 1 mole HCl ---> 1 mole acetyl chloride + 1 mole acetic acid

Two days ago I finally got around to trying his method.

B. Equipment and Reagents

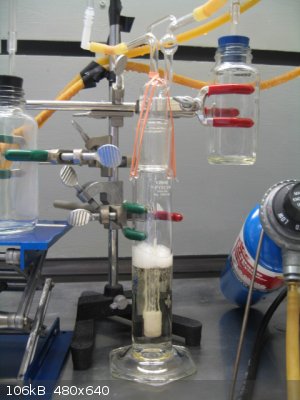

1. Dry HCl Gas Generator This preparation is a challenge only due to the need to safely produce a controlled flow of dry HCl gas.

My method for doing this was to heat an equimolar dry mixture of NaCl (non-iodized, food grade) and NaHSO4 (95%, swimming pool grade). With careful

heat modulation using a bunsen burner a steady, prolific stream of HCl was produced. I dried the HCl by sparging it into con H2SO4 using 5cm of

submergence of a glass tube with a fritted end. This puts all glassware and connections upstream of this sparge tube under 10 cmH2O gas pressure. The

tricky part is the plumbing. Selecting good materials and providing secure connections are critical. Any leak will spew copious amounts of HCl gas.

Due to the large thermal mass of the mixed salt in the generator this gas flow will not stop soon even when the heat is removed. (See note 1.)

Generating HCl gas

My tubing was 3/16”ID Tygon, which holds up well to dry HCl. It will even tolerate some minor exposure to con H2SO4 in the event of a foamover (See

note 2). Tygon will form a very tight compression seal to glass tubing by using a shrink fit. Heating it in boiling water will facilitate shoving

the end onto the glass tubing. Due to different glass tubing sizes I had to use some 3/16” x ¼” adapters. These were made of Nylon which is not

a real good choice as they did suffer significant deterioration/partial plugging in dry HCl and even more deterioration in cold con H2SO4 during a

foamover. I used some ¼”ID natural rubber to make connections also. This deteriorates (turns brown) in HCl gas but holds up sufficiently for this

short term use.

I placed a trap on each side of the H2SO4 absorber: upstream to protect from suckback, and downstream to protect from H2SO4 foamover. Rubber

two-hole stoppers were used in each.

Drying HCl gas with H2SO4

2. Reactor My reaction vessel was a 250 ml 2-neck RBF. The center neck was equipped with a reflux condenser topped with a CaCl2

guard tube. In the side neck was placed a sparge tube with a fritted glass end. The reactor was stirred with a magnetic stirrer. The reactor was

charged with 102.1g (1 mole) of AA.

Sparging AA with HCl gas

C. Preparation

I made up the salt mix by mixing 100g of NaCl and 216.3g of 95%NaHSO4. This was placed in a 1000 ml RBF generator. I ended up using 2 batches.

The first day I had a massive gas leak right off due to my own negligence and lack of obsevation: I neglected to clamp a glass taper connection at

the top of my gas generator. Fortunately the fugitive gas was sucked away by my fume hood. Without a good hood I would have had to evacuate. I

sparged for 4 hours, not always under good control as I was recovering from the gas leak and learning how to modulate the heat. When finished I

weighed my pre-weighed reactor. Uptake was only 14g. Theoretical requirement is 36.5g (1 mole).

On the next day my gas sparging was very well controlled. I sparged until the salt was producing very little gas, about 5 hours. Total uptake now

was 35.9g!

I also noted that the liquid volume had increased significantly in the reactor. The charged volume of AA was 94.4ml. The additive volume of 1 mole

of acetic acid and 1 mole of acetyl chloride is 57.25ml + 71.04ml = 128.3 ml, not accounting for any change in volume due to mixing. Also there were

droplets of liquid forming on the headspace wall of the reactor even though it had only warmed slightly. I took this as acetyl chloride as it has the

relatively low boiling point of 51-52°C compared to AA (140°C) and acetic acid (118.1°C).

D. Fractional Distillation Although the boiling point separation between acetyl chloride and both AA and acetic acid is quite large

I decided to use a fractionation column (20cm Hempel, broken glass packing) just to assure a clean cut. I protected the vacuum take-off vent with a

CaCl2 guard tube. Just as GC had warned there was a lot of HCl dissolved in the product mix. This revealed its presence by forming a fog on the

beaker in which I had placed the guard tube. This also lowered the boiling point of the acetyl chloride distillate. Consequently I captured

distillate in the condensation range of 42-49°C. I could likely clean this up by a 2nd distillation.

Fractionating for acetyl chloride

E. Yield Yield of the crude product is 55g. This is a 70.1% yield not considering any dissolved HCl.

F. Conclusions Although quite time consuming I feel that this is an interesting and reasonably productive preparation. However,

anyone using it must be confident of his HCl gas generating system and how to control it. Use of a good fume hood is vital as a safety backup.

G. Notes

1. Rhodium’s archive provides a good survey of dry HCl generating methods. His preferred method would eliminate the large thermal mass of my

method.

2. I use the term “foamover” to indicate a flow of H2SO4 foam into the downstream trap. It is the result of an excessive HCl gas generation

rate.

Questions, comments, and recommendations are welcomed, as usual.

[Edited on 28-8-2014 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Pyro

International Hazard

Posts: 1305

Registered: 6-4-2012

Location: Gent, Belgium

Member Is Offline

Mood: No Mood

|

|

very interesting. again a great writeup!

if you feel like it there is a procedure in vogel's 3rd detailing the synthesis of acetyl chloride with PCl3 and GAA or POCl3 and anhydrous NaAc.

page 367-368

either (or both) would make a nice addition to this as POCl3 or PCl3 might be easier to get/make for some people than AA

all above information is intellectual property of Pyro.  |

|

|

DJF90

International Hazard

Posts: 2266

Registered: 15-12-2007

Location: At the bench

Member Is Offline

Mood: No Mood

|

|

Congratulations magpie. You may find a reflux period (ice cold water) with CaCl2 guard tube in place suitable for the removal of excess HCl. I too had

seen that method using calcium chloride and,acetic anhydride in Feiser 1, but like you on digging out the reference was not best pleased about the

12(?)% yield.

This current method is said to give excellent yield (complete converion IIRC) and you have demonstrated that with a little optimisation it ought to be

possible.

I think this deserves a home in prepub, by the way.

|

|

|

Oscilllator

National Hazard

Posts: 659

Registered: 8-10-2012

Location: The aqueous layer

Member Is Offline

Mood: No Mood

|

|

Thats an interesting choice of HCl gas generator you have there. Why did you decide to use NaHSO4 instead of H2SO4? I would have thought that slow

addition of the sulfuric acid would provide good control of the HCl flow rate, although I don't have any personal experience with that method.

Wonderful write-up though, as always.

|

|

|

aroma princess

Harmless

Posts: 4

Registered: 23-8-2014

Member Is Offline

Mood: No Mood

|

|

why not going for instant route? reation of acetic acid with thionyl chloride? Use DMF in catalytic amount as it forms imidochloride complex and

accelerates reaction. yield ~ 70%

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thanks, Pyro.

Quote: Originally posted by Pyro  |

...either (or both) would make a nice addition to this as POCl3 or PCl3 might be easier to get/make for some people than AA |

Unfortunately this is not true for those home chemists who live in "the land of the free."

Thank you DJF90. I remember seeing that you had made acetyl chloride with the CaCl2 method. I used ice-cold water in the condenser and in the bath

holding the receiver. That probably just helped keep the HCl in solution. But refluxing like you say should kick that HCl out of solution. For now

I'm not going to worry about it. If I find a synthesis in which the HCl would be a problem then I'll expel it.

Thanks Oscillator. I used the salt method as I had some previous experience with it. I looked at the sulfuric acid/muriatic acid method in Vogel and

Brauer but it looked cumbersome and I didn't have a long tube at hand. But Rhodium prefers this method and has an equipment modification (he uses a

mag stirrer) that would obviate my objections. You do need two mag stirrers, however, which I don't have at this time.

Aroma Princess: This is a forum for home chemists. Thionyl chloride and PCl3 are CWC and are not purchaseable and/or shipable to the US home

chemist.

[Edited on 27-8-2014 by Magpie]

[Edited on 28-8-2014 by Magpie]

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

aroma princess

Harmless

Posts: 4

Registered: 23-8-2014

Member Is Offline

Mood: No Mood

|

|

1)absolutely correct oscillator..i always use sulfuric acid for generation of dry HCl...(*caution : very controlled addition is required to avoid

runaway situations) and dont forget to put some sodium chloride in HCl).

2) dear magpie : Put a reflux divider over fractionation column and allow self reflux for a while(atleast 20 mins) before you start collecting acetyl

chloride.

best of luck..!!

3) Acetic anhydride is not restricted? well... in my country it is classified under psychotropic substance category as its main precursor of heroin

and is not available.

[Edited on 28-8-2014 by aroma princess]

[Edited on 28-8-2014 by aroma princess]

|

|

|

PHILOU Zrealone

International Hazard

Posts: 2893

Registered: 20-5-2002

Location: Brussel

Member Is Offline

Mood: Bis-diazo-dinitro-hydroquinonic

|

|

In principe, cetene can also add HCl to form acetyl chloride.

CH2=C=O + HCl --> CH2=CCl(OH) <-==> CH3-CCl=O

PH Z (PHILOU Zrealone)

"Physic is all what never works; Chemistry is all what stinks and explodes!"-"Life that deadly disease, sexually transmitted."(W.Allen)

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Surprisingly enough acetic anhydride is available to the home chemist in the US.

PHILOU: I tried to make AA by making ketene once but my synthesis did not work. Also I was very concerned about ketene's toxicity so decided not to

try again.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

AvBaeyer

National Hazard

Posts: 651

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

Magpie,

Very nice piece of work! Thank you very much.

AvB

|

|

|

Zyklon-A

International Hazard

Posts: 1547

Registered: 26-11-2013

Member Is Offline

Mood: Fluorine radical

|

|

Great write-up, as usual Magpie. I want to try this as soon as I can get some more AA, I'm nearly out.

Quote: Originally posted by Oscilllator  | Thats an interesting choice of HCl gas generator you have there. Why did you decide to use NaHSO4 instead of H2SO4? I would have thought that slow

addition of the sulfuric acid would provide good control of the HCl flow rate, although I don't have any personal experience with that method.

|

Yes, I have used 98% sulfuric acid + calcium chloride/sodium chloride to generate dry HCl (g) several times. It's quite simple, all one needs is a

pressure-equalized addition funnel, a two-neck RBF, HCl resistant tubing, and the reagents of course.

Although I haven't tried the sodium bisulfate method, I think sulfuric acid makes the job much easier, as the gas comes out completely anhydrous, and

no heating is required. Just be sure to keep the acid dripping slowly.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you both. Zyklon-A could you give a more detailed description of your dry HCl gas generation method? Thanks.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Zyklon-A

International Hazard

Posts: 1547

Registered: 26-11-2013

Member Is Offline

Mood: Fluorine radical

|

|

Sure, although my discription won't be better than Rhodium's or the one I followed, which I have forgotten unfortunately.

To prepare one mole of HCl gas:

58.4 grams (one mole) NaCl is placed in a two-neck RBF (I probably used a 500 mL flask, but I'm unsure). One neck is fitted with a pressure-equalized

addition funnel, the other with an adaptor for an HCl(g) resistant rubber tube, which is then fitted on/in.

Then, slightly over one mole (~100 grams IIRC) 98% sulfuric acid is placed in the addition funnel.

The rubber tube is then placed wherever it's needed, and the setup is complete.

Sulfuric acid is added drop by drop on the salt, where this reaction occurs:

H2SO4 + NaCl --> NaHSO4 +HCl (g)

The generated HCl gas shouldn't contain any water, due to the extremely hydroscopic nature of sulfuric acid.

Note: Although I have not, it would, of course, be most economical to use half a mole of sulfuric acid, and then heat the resulting

sodium chloride/bisulfate mixture as you have done previously, to harvest all available HCl.

The main reason I tried this method is because I don't have any sodium bisulfate, but I may give it a go when I get some.

[Edited on 30-8-2014 by Zyklon-A]

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Rhodium drops muriatic acid (~31% HCl) onto con H2SO4 but also uses a con H2SO4 bubbler not only to monitor gas flow but to absorb any traces of water

that the HCl(g) may contain.

I agree that if you are using dry NaCl and concentrated H2SO4 there should not be any water in the HCl(g). Have you any evidence that this is indeed

true?

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by Zyklon-A  | | Although I haven't tried the sodium bisulfate method, I think sulfuric acid makes the job much easier, as the gas comes out completely anhydrous, and

no heating is required. Just be sure to keep the acid dripping slowly. |

This has not at all been the case for me. Whenever I run one of these generators, the HCl is produced painfully sluggishly and I have to heat after

adding all the acid to produce a steady stream of gas.

I always powder the NaCl, so I don't think it's a surface area issue and I use ~95% drain cleaner acid.

With regards to the original post, very nice work. Acyl halides are lovely things, such as for the FC acylation. The anhydrides consume an entire

additional equivalent of AlCl3. Acetyl chloride in particular can also halogenate trityl alcohol to the chloride per orgsyn Vol. 23, p.100 (1943).

[Edited on 8-31-14 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

AvBaeyer

National Hazard

Posts: 651

Registered: 25-2-2014

Location: CA

Member Is Offline

Mood: No Mood

|

|

Here is another method for HCl generation using hydrochloric acid and calcium chloride.

AvB

Attachment: Convenient Way To Generate Hydrogen Chloride.pdf (868kB)

This file has been downloaded 1241 times

|

|

|

Zyklon-A

International Hazard

Posts: 1547

Registered: 26-11-2013

Member Is Offline

Mood: Fluorine radical

|

|

Quote: Originally posted by Magpie  |

I agree that if you are using dry NaCl and concentrated H2SO4 there should not be any water in the HCl(g). Have you any evidence that this is indeed

true? |

No, I have not. I always used an excess of sulfuric acid, and just assumed it to be dry. If I was doing a delicate reaction which could be ruined by

trace amounts of water, I would have done so, or at least bubbled it through sulfuric acid again.

Unintentional Chaos, I think that may have to do with the difference in concentration. Although 95% is quite conc., with this

specific reaction, the acid must contain very little water. I heard somewhere that 90% is the minimum for it to produce any HCl(g), that

figure may be wrong, but it's pretty close.

|

|

|

Templar

Hazard to Self

Posts: 82

Registered: 17-8-2014

Location: The Sprawl, Titan

Member Is Offline

Mood: No Mood

|

|

guys what was wrong with using cyanuric chloride with ethanoic acid as per the attached patent?

Attachment: TCT acetyl chloride.pdf (952kB)

This file has been downloaded 1030 times

He who fights with monsters should be careful lest he thereby become a monster. And if thou gaze long into an abyss, the abyss will also gaze into

thee.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

My guess is that cyanuric chloride is not available to the home chemist, at least not in the US.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

Oscilllator

National Hazard

Posts: 659

Registered: 8-10-2012

Location: The aqueous layer

Member Is Offline

Mood: No Mood

|

|

I would just like to point out a possible improvement on the H2SO4/NaCl gas generator: Instead of using a pressure-equalising addition funnel, you

could just use a normal one. This may seem counter-intuitive, but is has a number of advantages:

-You cannot accidentally add too much sulfuric acid and have a runaway reaction. This is because the faster you add the sulfuric acid, the faster the

HCl is generated and this has a feedback loop slowing down the sulfuric acid addition, because the HCl has to come out the same hole the sulfuric acid

goes in.

-The HCl is bubbled through the entire column of sulfuric acid, thoroughly drying it. this advantage is lessened the further on the addition goes but

it is still a advantage, since it negates the (possible) need to have a separate drying tube.

-Monitoring of flow rate: Since the HCl is being bubble through the H2SO4, it is easy to monitor the flow rate of HCl

I have used this method to generate Chlorine gas with considerable success for a number of experiments, although in this case the normal addition

funnel was used out of necessity, not choice.

|

|

|

Dr.Bob

International Hazard

Posts: 2732

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

I would be afraid that any surge in pressure could cover me with sulfuric acid, using a normal addition funnel. I prefer the idea of a drying tube

inline somewhere, and if you add the acid slowly, it should generate gas at a steady rate. And as stated above, 90-90% sulfuric acid will not act

nearly as well in dehydrating the HCl, although it should work eventually, but the HCl may just dissolve in the 95% sulfuric acid instead of bubbling

off.

|

|

|

CaptainPike

Hazard to Self

Posts: 68

Registered: 21-12-2012

Member Is Offline

Mood: No Mood

|

|

First off, like many have already stated REALLY COOL POST! And I like the dry generator – I have a whole bunch of NaHS04 around here, both with the

green specks (pool pH modifier) and some "reagent grade product". It's handy stuff, acid in a bag, man!

Also, I have had just awful trouble with gas leakage from my HCL generator – had to leave the room choking, as my makeshift fume hood was inadequate

and I had trouble with my gas mask. It seemed like the HCl gas would go ANYWHERE but through my solution (doing a TsOH prep).

Reading magpie's post here has re-enthusiasticiated me! I'm re-rigging my fume hood and going to do this prep (while the weather is still nice LOL).

Thank you.

What I want to understand is how the HCl gas exits the generator in Oscillator's version? That is, where does the gas come out of the non-equalizing

dropping funnel? Through the top? Or use a 2 neck flask?

|

|

|

Oscilllator

National Hazard

Posts: 659

Registered: 8-10-2012

Location: The aqueous layer

Member Is Offline

Mood: No Mood

|

|

It comes out through the top of the addition funnel.

Also @Dr.Bob: One of the advantages is that it's impossible to have a surge of gas. Even if you open the stopcock completely, the flow of gas upwards

prevents excessive amounts of sulfuric acid dropping down.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

Thank you for the kind words Captain. I have spent some time since working on the problems I identified in my plumbing for this experiment - I too

hate gas leaks! I think I have now selected materials for the plumbing that will provide reliable leak free gas production for both HCl

and Cl2. Once I test this system I will post the details.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

hanjo

Harmless

Posts: 3

Registered: 19-9-2014

Member Is Offline

Mood: No Mood

|

|

Can the same thing be made with another anhydride for example benzoic anhydride or other

|

|

|

| Pages:

1

2 |