HeYBrO

Hazard to Others

Posts: 289

Registered: 6-12-2013

Location: 'straya

Member Is Offline

Mood:

|

|

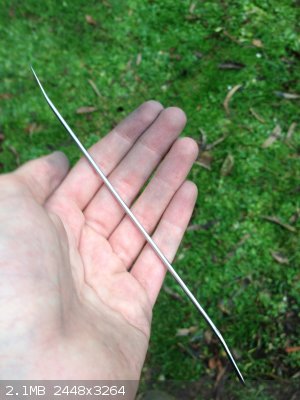

Construction of a steel laboratory spatula.

Introduction.

Laboratory spatulas are useful instrument in any scientific setting. They are an excellent tool for transferring small quantities of reagents,

scratching the sides of a flask to induce crystallisation and can be used as a platform for the deflagration of small amounts of pyrotechnic

mixtures. Although cheap, finding high quality lab spatulas can, for some, be difficult and often through international sources, which entails

shipping rates etc. This report will demonstrate the simplicity of designing and building one's own spatula for minimum costs at home.

Purpose

To built a laboratory spatula with minimum funds.

Materials

- 2 mm steel wire (free)

- butane torch (already had)

- hammer (already had)

- hard steel surface [anvil or bench vice] (already had)

- file(already had)

- sand paper, steel wool and or sanding sponge (already had)

- safety glasses and heavy duty gloves (already had)

Safety considerations

Because steel will be heated to high temperatures, caution must be used when handling the hot material. Keep a burn relief kit nearby and wear safety

giggles and heavy duty gloves to protect from burns. Do this in a well ventillated area!

Procedure

1.Measure out about 18.5 cm of the steel wire.

2. Begin heating with the torch until you obtain a cherry red, then begin hammering and flattening out the end of the wire (until roughly ~2 cm has

been flattened)

3.A technique known as "hot filing" maybe implemented to shape the spatula. Heat the end and start filling. Use caution. It is useful to thin out the

spatula a little at this point.

4.Once the final shape has been achieved, heat the end of the spatula and quench it to harden the tip.

5.Repeat steps 1-4 for the other side with the desired shape.

6.Once hardened, the work up of the spatula may begin. use rough sand paper, then go to a finer grade and finish with a sanding block.

Discussion

The spatula came out with very satisfactory results. The main limitations of the spatula is that it is not stainless steel, hence it is mainly useful

for only rough qualitative work and reactions that will not react with iron. It is also important to wash the spatula after every use and to dry it

well to prevent corrosion.

Conclusion

The main goal of the procedure was achieved without major complication.

|

|

|

Chemosynthesis

International Hazard

Posts: 1071

Registered: 26-9-2013

Member Is Offline

Mood: No Mood

|

|

Nicely done.

|

|

|

Magpie

lab constructor

Posts: 5939

Registered: 1-11-2003

Location: USA

Member Is Offline

Mood: Chemistry: the subtle science.

|

|

I find that my 3 different shaped ss spatulas are among my most useful lab tools.

I have a 2mm diameter ss welding rod that has proved very handy at times also. I made a spiral in one end to remove packing from a narrow column, and

a small loop in the other end for some use I can't now recall.

Maybe you could get a friend who does welding to give you a ss welding rod to make ss spatulas.

The single most important condition for a successful synthesis is good mixing - Nicodem

|

|

|

HeYBrO

Hazard to Others

Posts: 289

Registered: 6-12-2013

Location: 'straya

Member Is Offline

Mood:

|

|

I too have three, a micro wedge style, a round spatula with red handle and another one similar to what i made.

Quote: Originally posted by Magpie  | I have a 2mm diameter ss welding rod that has proved very handy at times also. I made a spiral in one end to remove packing from a narrow column,

and a small loop in the other end for some use I can't now recall.

Maybe you could get a friend who does welding to give you a ss welding rod to make ss spatulas. |

perhaps it

was for hanging the tool up? That's a good idea, I'll see what I can do!

Thanks!

|

|

|

Pyro

International Hazard

Posts: 1305

Registered: 6-4-2012

Location: Gent, Belgium

Member Is Offline

Mood: No Mood

|

|

niceley done!

one should try this with a nickel rod. nickel spatulas cost a furtune

[Edited on 22-7-2014 by Pyro]

all above information is intellectual property of Pyro.  |

|

|

Morgan

International Hazard

Posts: 1705

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

Why is it realitively pure nickel coins from Canada are so cheap but a simple nickel rod on Amazon or ebay tremendously expensive?

http://www.vincentmetals.com/Daily_Nickel_Prices.html

[Edited on 22-7-2014 by Morgan]

|

|

|

Pyro

International Hazard

Posts: 1305

Registered: 6-4-2012

Location: Gent, Belgium

Member Is Offline

Mood: No Mood

|

|

id use this:

http://www.ebay.com/itm/10ft-Jewelry-Making-German-Nickel-Si...

might be a fun project to try to make one from a quarter

BTW:why rubber gloves when working with hot metal?

[Edited on 22-7-2014 by Pyro]

all above information is intellectual property of Pyro.  |

|

|

Manifest

Script Kiddie Asshole

Posts: 229

Registered: 7-12-2012

Member Is Offline

Mood: No Mood

|

|

Nice post!

|

|

|

HeYBrO

Hazard to Others

Posts: 289

Registered: 6-12-2013

Location: 'straya

Member Is Offline

Mood:

|

|

I was doing something else in the lab before and i forgot to take them off... I know, i know, look at me, the hypocrite

|

|

|

chemrox

International Hazard

Posts: 2961

Registered: 18-1-2007

Location: UTM

Member Is Offline

Mood: LaGrangian

|

|

Why would you do this? I appreciate tinkering but those rulers are worth a lot more than micro spatulas that you can by all day on ebay.

"When you let the dumbasses vote you end up with populism followed by autocracy and getting back is a bitch." Plato (sort of)

|

|

|

HeYBrO

Hazard to Others

Posts: 289

Registered: 6-12-2013

Location: 'straya

Member Is Offline

Mood:

|

|

Quote: Originally posted by chemrox  | | Why would you do this? I appreciate tinkering but those rulers are worth a lot more than micro spatulas that you can by all day on ebay.

|

thanks for the response.

Firstly, I'm a litte confused by your somewhat contradictory statement and question; if you appreciate it why do you choose to point out "flaws"?

Secondly, if you re-read my original post more carefully you would see the answer to your question:

Quote: Originally posted by HeYBrO  |

Introduction.

Although cheap, finding high quality lab spatulas can, for some, be difficult and often through international sources, which entails shipping rates

etc. This report will demonstrate the simplicity of designing and building one's own spatula for minimum costs at home. |

Besides that, this is just a nice thread to spark ideas such building from different materials etc. This project was free and took less than two

hours, I would have to wait two weeks if I bought it online. Why do you have to justify building something so useful and simple if the means for doing

so are at your disposal? Surely that is the spirit of amateur chemistry?

|

|

|

Manifest

Script Kiddie Asshole

Posts: 229

Registered: 7-12-2012

Member Is Offline

Mood: No Mood

|

|

I agree, you shouldn't be asking why, but why not.

This post fits the quality we should all be aiming to post and fits within the theme of amateur chemistry.

|

|

|

MrHomeScientist

International Hazard

Posts: 1806

Registered: 24-10-2010

Location: Flerovium

Member Is Offline

Mood: No Mood

|

|

Sometimes I get the safety giggles too

Kidding aside this is a pretty neat idea. Looks like it turned out well! I'd be interested to see how long it lasts before corroding. With careful

care and cleaning it should do pretty well.

It sounds like chemrox thought you hammered the ruler into a spatula? It was a metal wire that was used - the ruler was just there to measure, as they

usually are.

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

If you can get nickel wire/rod, you could make quite a few of these. Stainless won't work too well. The heating tends to ruin the

corrosion-resistance.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Morgan

International Hazard

Posts: 1705

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

If anyone knows a relatively low-cost source for pure nickel rod that would be nice. Nickel is starting to approach 9 dollars a pound but rods of it

seem to cost quite a bit more.

|

|

|

Metacelsus

International Hazard

Posts: 2539

Registered: 26-12-2012

Location: Boston, MA

Member Is Offline

Mood: Double, double, toil and trouble

|

|

I have 2 nickel rods (somewhere, I hope I can find them), and a heat source. I'm going to try making a nickel spatula right now!

Update: Well, I ran the induction heater at 48 volts, the nickel started glowing, I took it out and hammered on it, put it back in, and then one of my

MOSFETs had a critical existence failure (aka magic smoke).

Now I have a slightly more pointy nickel rod!

[Edited on 24-7-2014 by Cheddite Cheese]

|

|

|

Morgan

International Hazard

Posts: 1705

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

I suppose the train lines would frown on this but if you affixed a small piece of wire to the track with a spot of super glue or used a 1981 or older

Canadian nickel which is 99.9 % nickel it would form the metal to some extent. Maybe one could join a flattened nickel to a nickel rod, making a large

pure nickel spatula spoon.

1964–1981 4.54 g 21.21 mm, round 99.9% nickel

http://en.wikipedia.org/wiki/Nickel_(Canadian_coin)

Coins on the Track

https://www.youtube.com/watch?v=VitmL070-vQ

http://www.capecentralhigh.com/perry-county/coins-on-the-tra...

Here's a pretty shape.

http://www.instructables.com/id/Teardrop-Pendant/?ALLSTEPS

|

|

|

aga

Forum Drunkard

Posts: 7030

Registered: 25-3-2014

Member Is Offline

|

|

Excellent !

Very well done, and nice photos.

There needs to be much more of this - actually making stuff, and using some imagination.

Ignore chemrox - clearly read very little of your post and just saw a word or two and a picture.

If you manage to get some Stainless rod, just try hitting it with a hammer a lot.

Allow it a little Time between sessions and you might find it works, albeit slowly.

|

|

|

Morgan

International Hazard

Posts: 1705

Registered: 28-12-2010

Member Is Offline

Mood: No Mood

|

|

This shine is fairly impressive for an ordinary nickel. I wonder how a Canadian 99.9% nickel would do? If it polished up as well, it would be possible

to make a reflective spoon shape of some sort that could be attached to a rod for an artistic scoop-like spatula at one end.

How to polish, in real time

https://www.youtube.com/watch?v=n3Mc4NkCeo0

http://orgchem.colorado.edu/Technique/Equipment/Benchequip/S...

http://www.ajaxscientific.com/wp-content/uploads/2012/08/Lab...

http://strauchfiber.typepad.com/the-wool-goes-round/2010/02/...

|

|

|