kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

reduction of nitrobenzene -> p-aminophenol

It is commonly known transformation, no need to write about theoretical apects here.

Paragraph from "Ullmann's Encyclopedia of Industrial Chemistry" about aminophenols gives patent references (numbers in attached paper). In general,

these patents describe procedures of reduction(+ rearrangement) of nitrobnezene to p-aminophenol.

E.g. nitrobenzene in acid solution (or rather suspension) + heating + Zn or Al -> more than 70% of p-aminophenol.

My question: has anybody (from SM) ever tried this or similar procedure to obtain aminophenos ?

[Edited on 11-12-2013 by kmno4]

Attachment: 9.pdf (72kB)

This file has been downloaded 682 times

Слава Україні !

Героям слава !

|

|

|

Nicodem

Super Moderator

Posts: 4230

Registered: 28-12-2004

Member Is Offline

Mood: No Mood

|

|

I'm only aware of Scr0t's report: Reduction of Nitrotoluenes via Al/H2SO4 (US2533203 & US2446519

…there is a human touch of the cultist “believer” in every theorist that he must struggle against as being

unworthy of the scientist. Some of the greatest men of science have publicly repudiated a theory which earlier they hotly defended. In this lies their

scientific temper, not in the scientific defense of the theory. - Weston La Barre (Ghost Dance, 1972)

Read the The ScienceMadness Guidelines!

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Thanks Nicodem, I missed this report during forum searching.

That is all I wanted to know, please delete my topic.

I have just found some nitrobenzene in my collection, so I will give some experimental results (if any) in Scr0t's report.

Слава Україні !

Героям слава !

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Patent US2525515A gives very promissing procedure:

---------------------------------------------------

12.3 g. of nitrobenzene were mixed with 150

grams of water in which 40 grams of oxalic acid

were dissolved. The mixture was heated to and

maintained at about 95°C., and then 4.5 g. of

aluminium fiakes were slowly added with vigor-

ous stirring during about one hour. No nitro-

benzene remained after 2 further hours' heating

and stirring.

The reaction mixture was filtered

hot and then made alkaline to brilliant yellow

with sodium sulfite and sodium carbonate. On

cooling and standnig 8 hours, p-aminophenol

precipitated. There was some odor of aniline but

none separated out. The aluminium did not

precipitate from the alkaline solution as it was

kept in solution as a complex oxalate compound.

The p-aminophenol was filtered off and recrys-

tallized from a small amount of water. It melted

at 184°C. Yield 73 per cent.

---------------------------------------------

I tried this on 1/3 scale.

Everything looks fine, Al dissolves and the solution becomes deeply brown. Some Al (miligrams) remains, steam dist. gives 0,2-0,3g of unreacted

nitrobenzene.

To this filtered and steam distilled mixture Na2SO3 was added (~0,2 g), giving strong odour of SO2, pH of solution was below 2.

[This procedure, with slight modifications, was repeated 5 times, with the same results]

Then solid NaOH was added in several portions.....

From this moment all stops looking fine

Results from the latest run:

5,29g NaOH were added in several portions: SO2 odour dissapears, pH rises (to about 4-5). After 24h standing, solution was filtered and 50 mg of black

something left.

Next, another 0,5g NaOH was added (and so on...) 1,1g of bright precipitate was collected. Another 0,2g NaOH -> 0,34g of brown something left.

Another 0,2g portions (six) of NaOH give ~1,9g of precipitate at every time. These precipitates are dark when wet, after drying they are bright grey

and look like Al(OH)3. Obtained powders, when agitated with water, give deeply brown solutions with sediment.

Remaining solution is still dark brown, with weak aniline smell.

The most striking thing - it was impossible to obtain pH higher than 5,5-6 without Al precipitation. Every portion of NaOH gives temporary rise of pH

(during minutes), but then it drops and Al salts precipitates.

I expected to obtain clear cut between precipitation of aminophenol and Al(OH)3 but it was only a dream.

Слава Україні !

Героям слава !

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

I am aware that I am somewhat off-topic here, but is acetaminophen not commonly available where you are? The procedures covered in scr0t's thread look

interesting but for unsubstituted p-aminophenol it seems like a lot of effort.

If the oxalate is claimed to complex the aluminum and prevent it's precipitation, perhaps citrate would also be effective, or moreso as it is

tridentate.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

killer_lapin

Harmless

Posts: 47

Registered: 23-7-2010

Location: Qc, CAN

Member Is Offline

Mood: No Mood

|

|

UC is right, 500mg acetaminophen weight 513 mg on average so it's almost pure, the amino group is even protected so you can alkylate the phenol

selectively.

|

|

|

Nickdul

Hazard to Self

Posts: 96

Registered: 13-2-2012

Location: Bulgaria

Member Is Offline

Mood: No Mood

|

|

p-aminophenol is the developing agent in Rodinal, a concentrated b/w film developer that has been commercially available since the 1880s. I don't know

is you insist on going via the nitrobenzene route (IIRC, only amidol (2,4-Diaminophenol) is still made by reduction of m-nitroaniline, also in the

patent above), but if you want to obtain p-aminophenol, base hydrolysis of paracetamol with alkali hydroxide and subsequent precipitation of

4-aminophenol by neutralizing the alkali metal p-aminophenolate salt is used. This was my original route to glycin (n,n-hydroxyphenylglycine), before

I could acquire commercial p-aminophenol.

I'd have to find my notes, but the hydrolysis was carried out at RT for about a week, and it still resulted in a dark-tea-colored soln. due to aerial

oxidation. Maybe in an inert environment or under hydrogen it can be heated and refluxed to speed up the cleavage of the -COOH group.

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

Quote: Originally posted by Nickdul  |

I'd have to find my notes, but the hydrolysis was carried out at RT for about a week, and it still resulted in a dark-tea-colored soln. due to aerial

oxidation. Maybe in an inert environment or under hydrogen it can be heated and refluxed to speed up the cleavage of the -COOH group.

|

Use HCl instead and then precipitate the product by neutralization. Anilines are stable to oxidation under acidic conditions whereas base makes the

brown tarry stuff. Acetanilide falls apart with acid treatment. You need not even reflux for complete reaction to acetic acid and anilinium chloride.

I can't see acetaminophen being much different.

[Edited on 12-29-13 by UnintentionalChaos]

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|

Nickdul

Hazard to Self

Posts: 96

Registered: 13-2-2012

Location: Bulgaria

Member Is Offline

Mood: No Mood

|

|

Both HCl and H2SO4 will work, one document (attached, p15.) suggests 1M H2SO4 and refluxing for 1h. If you use HCl and convert to the hydrochloride

salt, neutralize with sodium or potassium carbonate with 1-5% sodium sulfite to prevent oxidation.

[Edited on 29-12-2013 by Nickdul]

Attachment: Paracetamol_rsc.pdf (1.4MB)

This file has been downloaded 1600 times

off-topic P.S: UnintentionalChaos, love your video channel, I wish you all the best with it.

[Edited on 29-12-2013 by Nickdul]

|

|

|

S.C. Wack

bibliomaster

Posts: 2419

Registered: 7-5-2004

Location: Cornworld, Central USA

Member Is Offline

Mood: Enhanced

|

|

So...is there p-aminophenol that can be isolated...at all?

Giving people money for making tylenol is crazy. No way, not even for a purer product...

Can the phenylhydroxylamine two step (not counting electricity) and dealing with the sludge work better than alleged patent shortcuts?

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Yes, currently it is under investigation. I still have some nitrobenzene for experiments, citrate (citric acid) can be solution of mentioned problem

with Al precipitation, because it forms much stronger complexes with Al. There is interesting, experimental paper about it, but maybe later.....

Possibly, direct replacing oxalic acid with citric acid wil work, but now I have to play with freshly cooked (oxalic) solution

| Quote: | | reduction of nitrobenzene -> p-aminophenol |

Do you see here APAP, paracetamol,tylenol,acetaminofen,Rodinal...

Or p-nitrophenol ?

No, nitrobenzene only.

Слава Україні !

Героям слава !

|

|

|

Random

International Hazard

Posts: 1120

Registered: 7-5-2010

Location: In ur closet

Member Is Offline

Mood: Energetic

|

|

I can say that once you make copper citrate you'll have a hard time getting that to precipitate into it's hydroxides or carbonates. It might be same

for Al.

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Another run:

14 g of oxalic acid dihydrate* + 50 g of H2O + 4,1 g.

Stirring, boiling, filtering....

This time small modification: 4 g of citric acid** was added to final solution.

Slightly more than 5 g of NaOH were added (+0,17 g of Na2SO3), at some point bright-brown particles start to separate, liquid becomes clear but still

brown, aniline smell appears but nothing more, pH is around 6.

Brown sediment was filtered and washed with water. After drying, 1.9 g of very delicate, cocoa-coloured powder was obtained. The powder is without any

odour and melts ~170 C. During melting, under microscope are visible some transparent particles, not melting in this temperqture - possibbly some

inorganic salts. The rest of powder melts to black liquid (decomposition).

Additional portion (~0,2 g) of NaOH was added to filtrate - nothing separates but it was left for some time in a cooler.

After few hours, larger amount of precipitate appears, but it looks diffrent than earlier.

During filtration and washing it turn out that it is suluble in water, so it is not wanted product.

A sample of it was collected. After drying, the sample turn to hard mass with brown surface, but it is only tiny layer and whole mass inside is white.

The most posibbly, the solution just became supersaturated.

If even this 1,9 g would be pure p-aminophenol (but it is not), it is still far from 70% yield.

Some black tar stuck to mag. dipol but it was max 0,1 g. Seems that the rest of reduced nitrobenzene turn to other by-produsts, causing brow

coloration of solution. After standing in open air, this colour becomes more intensive, surely because of oxidation.

Maybe intermediate phenylhydroxylamine is not fully converted to p-aminophenol ?? Hard to say...

* the patent says "oxalic acid"; it seems that it does not matter if I use 13,5 g or 19 g of dihydrate, reaction in both cases goes in the same way,

with very not sharp phenol-salts separation during neutralisation with NaOH.

** rater anhydrous, not melting in 100 C, but its particles become a little sticky at this temp.

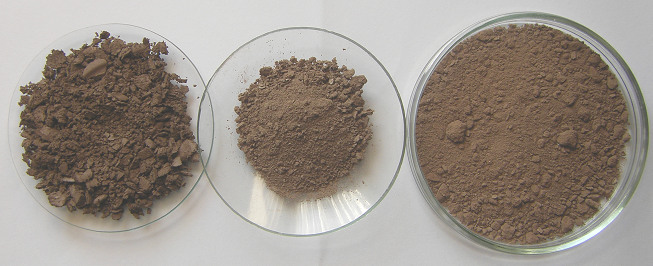

On the picture: left - mass from the second crop , right - main product.

Слава Україні !

Героям слава !

|

|

|

Dr.Bob

International Hazard

Posts: 2732

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

para-aminophenol is highly unstable to air oxidiation, and will oxidize to imino-quinones readily. I make similar materials often, via hydrogenation

of para-nitroamines to produce paradiamines, and they are clear once filtered from the Pd/C, but within minutes they start turning dark from air

oxidation, even if I attempt to keep them under N2. Since they are not real stable, the best solution is to react them as fast as you can to the

next step. I work up my diamines and react them in the next step as fast as I can, once they are acylated or otherwise stablized, then they are just

fine.

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

In this particular case, p-aminiophenol is stable enough to be purified by dissolving in hot water and cooling (with or without antioxidants), also

stable in solid state, at least for a longer time (especially kept in cold and dark place)

For example, see this paper:

http://shodhganga.inflibnet.ac.in/bitstream/10603/3233/15/15...

Слава Україні !

Героям слава !

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

.... and in this way I used up all my nitrobenzene (prepared long time ago and forgotten).

Another raw products on the picture (for comparation, earlier prepared on the right). Generally, they look the same: more or less greyish, bright

brown powders.

Last runs were made in H2SO4 (proportions also from patent).

Citric acid was added to shift the pH of Al hydroxide precipitation, but when sufficient amount of NaOH was added, large amount of some inorganic salt

precipitaded out on cooling. It was filtered and raw aminophenol precipitated from filtrate by adding NaOH.

Yield about ~50%, as in earlier (oxalate) runs.

When another portions of NaOH were added to remaining filtrate, pH goes above 7. No Al-salts precipitate, there is some suspension, but only small

amount (<0,1g) of brown-black sediment was recovered. The final filtrate is still red-coloured, but no p-aminophenol can be precipitated from it.

I also tried to use citric acid instead of oxalic or sulfuric acid.

Unfortunately, reaction is very sluggish, Al reacts very slowly, solution becomes turbid, nitrobenzene layer becomes red.

After 5 hours of cooking, no progress was noticed and mixture went to WC.

In attachment an aticle: "INFLUENCE OF ACETATE, OXALATE, AND CITRATE ANIONS ON PRECIPITATION OF ALUMINUM HYDROXIDE"

Attachment: 31-1-65.pdf (256kB)

This file has been downloaded 899 times

Слава Україні !

Героям слава !

|

|

|

Dr.Bob

International Hazard

Posts: 2732

Registered: 26-1-2011

Location: USA - NC

Member Is Offline

Mood: No Mood

|

|

It may be that aminophenol forms intramolecular salts, where the amine is protonated by the phenol to form a salt that is more stable. Most of my

molecules are para-diamines, but they are electronically similar. But forming any salt of the amine will make it much more stable to storage. It's

not that these materials cannot be isolated as much as they often turn colored quickly with oxidation products. Of course that is true for many

simple anilines as well, just faster in diamines and aminophenols.

|

|

|

JAVA

Hazard to Self

Posts: 71

Registered: 9-1-2014

Member Is Offline

Mood: No Mood

|

|

Why you made it more difficult if a simple highly acidic reduction with iron and much concentrated HCl works? Simply distill under Vacuo for quite a

long time, then in the cold, neutralize it to get the freebase directly in your extraction solvent. Store in HCl solution, otherwise you get a red

product.

So, why using Al instead of Fe? That's the question..

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

At least few reasons:

- Al is not ferromagnetic: no problems with magnetic stirring

- Al has lower molecular weight than Fe

- Fe gives more aniline than aminophenol (see patent US2446519A)

Why not HCl ?

Again few reasons:

- no HCl vapours during heating

- HCl attacks Al very quickly, partially without nitrobenzene reduction

- HCl gives large amounts of p-chloroaniline as by-product

Extraction ? Very good idea

With what ?

PS.

I have prepared fresh sample of distilled nitrobenzene (~45g) and I am going to do additional tests, with sligtly different experimental conditions.

However, this nitrobenzene freezes below benzene m.p. and incompletely

So, first I have to distill it again to make it purer.

[Edited on 29-1-2014 by kmno4]

Слава Україні !

Героям слава !

|

|

|

Boffis

International Hazard

Posts: 1867

Registered: 1-5-2011

Member Is Offline

Mood: No Mood

|

|

Some nice experiment chemistry reported above, thank you kmno4!

A couple of years ago I acquired two jars of aminophenol, one of 2 and the other 4-aminophenol. They were both produced at about the same time in 1997

and both came from the same supplier (Fisons). Labels on the back of the jars gave details of the laboratory policy of the organisation to which they

were supplied; any unused material was to be disposed of after 5 years or 2 years once opened, which ever was the shorter. I don't know where they

were between 2002 and me acquiring them but the 2 aminophenol was medium violetish brown crystals and when dissolved in alcohol and treated with

active charcoal resulted in a pale brown solution which reacted as required in several syntheses I carried out.

The 4 aminophenol on the other hand was a fine black powder resembling charcoal, when dissolved in alcohol and filtered no amount of active carbon

would remove the colour. After some experimentation I found that a good proportion of the aminophenol could be recovered by dissolving in a

significant excess of hot 10% HCl and adding small amounts of zinc powder until the colour was greatly reduced. The result was a violet brown solution

that gave abundant dark brown crystals on cooling. There was a point beyond which further Zn addition had no effect and other reducing agent such as

Na metabisulphite had no effect either. However, after two treatments of the hot HCl solution with BDH active carbon the colour was reduced to a pale

violet brown from which pale amethyst coloured crystals formed. I left about 1g on a watch glass on my lab bench for almost 2 month and observed only

very slight darkening; it would appear, therefore, that the hydrochloride salt is a great deal more stable than the free base.

There is only one thing that worries me and I haven't tested yet and that is how much zinc has precipitated with the hydrochloride salt. Zinc chloride

in HCl forms a tetrachlorozincate ion that crystallises with some organic bases (check out some of the older Skraup quinoline procedures) so there may

be some zinc in the product, however, the amount of zinc used was far too small for all of the aminophenol to be converted in a chlorozincate. I will

investigate this when I treat the remaining 180g or so of material. This zinc could easily be removed but for me this contaminant is not actually a

problem as my main use for this compound is the preparation of quinone derivatives. For chloranil preparation it may not be necessary to even bother

with the above procedure.

[Edited on 30-1-2014 by Boffis]

|

|

|

JAVA

Hazard to Self

Posts: 71

Registered: 9-1-2014

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by kmno4  |

...

Fe gives more aniline than aminophenol (see patent US2446519A)

->Thank you, didn't read the title full. Obviously, you believe that every procedures in scientific text are true. This

isn't the case, that's also my experience. The grey product seems like Al(OH)3

Why not HCl ?

Again few reasons:

- no HCl vapours during heating ->use ammonia to neutralize the HCl

- HCl gives large amounts of p-chloroaniline as by-product Source?

Extraction ? With what ?

-> Extraction (3 to 4 times) with toluene for example, but rapidly destill it under high vacuum/low temperatures since

it get slightly yellow soon. p-aminophenol is only stable in a acid environment and get red under alkaline conditions.

PS.

I have prepared fresh sample of distilled nitrobenzene. However, this nitrobenzene freezes below benzene m.p. and incompletely

So, first I have to distill it again to make it purer.

-> Not at all, wash it 3 times with cold MeOH to remove the ortho - isomer. However not all the ortho form is removed.

You might do a recrystallisation of the slight yellow crystals with a great smell. To puryfying read this BUT keep every layer during the extraction

because the layers switch (upper/lower) during the purification:

READ (lol):

6530kg mixed acid consisting of 30% HNO3, 56% H2SO4 and 14% H2O are placed in a reaction vessel and 3500kg chlorobenzene are added with constant

stirring. Temperature is held at 40°C at first, later at 55°C and after the addition is complete the whole is warmed to 70-80°C within two hours,

still stirring constantly.

The phases are then separated while still warm and the spent acid extracted once with chlorobenzene, the extract is used directly as the feed for the

next nitration (Note: you can probably just dilute the acid to separate the dissolved product instead of extracting it). The organic phase is washed

with water, Na2CO3 solution and water again and then dried by warming in vacuo. 4850kg crude isomeric mixture is obtained, with a "melting point" of

52°C. The mixture is cooled very slowly and then held at a temperature of 20°C for 25 hours to effect the crystallization of p-nitrochlorobenzene.

The crystals are filtered by suction and then washed three times with methanol (2000-4000l MeOH for 14000-15000l of crude mixture). The first methanol

portion has already been used twice for washing, the second portion once, and the third washing is done with fresh methanol. The crystals now are,

after drying, industrial grade p-nitrochlorobenzene with a melting point of 82-82,5°C. If the melting point requirement is not fulfilled, the washing

must be repeated (or the product recrystallized). The liquid filtrate goes to the vacuum fractionation process. I washed thrice with fresh ice-cold

methanol, thus I had larger losses, but my product was purer.".

[Edited on 29-1-2014 by kmno4] |

Answers are given in the text. But back to the original thread: do you analyze that substance on the photo? Where are the evidences!

[Edited on 30-1-2014 by JAVA]

|

|

|

kmno4

International Hazard

Posts: 1496

Registered: 1-6-2005

Location: Silly, stupid country

Member Is Offline

Mood: No Mood

|

|

Quote: Originally posted by Boffis  |

The 4 aminophenol on the other hand was a fine black powder resembling charcoal, when dissolved in alcohol and filtered no amount of active carbon

would remove the colour. After some experimentation I found that a good proportion of the aminophenol could be recovered by dissolving in a

significant excess of hot 10% HCl and adding small amounts of zinc powder until the colour was greatly reduced. The result was a violet brown solution

that gave abundant dark brown crystals on cooling. |

I also got brown crystals from cooled (intensively brown) solution of aminophenol in water, however no violet colour was observed.

These crystals, when smashed appear as light brown powder, very similar to product from photograph in paper about hydrogenation (link above)

I have impression that this crystallization does not give much purer product than raw aminophenol (but m.p. of product rises slightly). Seems that my

raw aminophenol is not so bad (bright brown powder) and possibly suitable for my purposes.

I woud buy it, but sellers I know want too much, and import from PRC costs 300$

I can efford it , but it is against my rules - too big money for some plain compound.

Synthesis from nitrobenzene is very cheap and simple, even with 50% yield.

- HCl gives large amounts of p-chloroaniline as by-product Source?

For example see here: J.Chem.Soc.,Perkin Trans. 2 1981; 298

No procedure for reduction of nitrobenzene (with rearrangement) to p-aminophenol I know, uses hydrochloric acid. In ~90% it is H2SO4. Ask yourself,

why.

Maybe your aminophenol is extractable with toluene, but mine is not. See literature (Ullmann), and also paper I posted - they wash their raw product

with toluene to remove soluble impurities.

Besides - why shall I extract precipitated product, when I can do simple filtration ?

Quote: Originally posted by JAVA  | | -> Not at all, wash it 3 times with cold MeOH to remove the ortho - isomer. However not all the ortho form is removed. You might do a

recrystallisation of the slight yellow crystals with a great smell. To puryfying read this BUT keep every layer during the extraction because the

layers switch (upper/lower) during the purification: (...) |

Do you understand (or at least feel) the difference -nitrobenzene and p-nitrochlorobenzene ?

Слава Україні !

Героям слава !

|

|

|

UnintentionalChaos

International Hazard

Posts: 1454

Registered: 9-12-2006

Location: Mars

Member Is Offline

Mood: Nucleophilic

|

|

You may want to look into this electrolytic prep (given for 3-chloro-4-aminophenol as an intermediate).

http://www.orgsyn.org/Content/pdfs/procedures/cv4p0148.pdf

Also (and I don't think it's in this thread) but there is this handy paper by (apparently) our very own Len1 with regards to the purple color:

www.sciencemadness.org/talk/files.php?pid=219850&aid=157...

On working up some p-aminophenol from acetaminophen hydrolysis, I found that a solution in HCl obtains an intense violet color on standing open to the

air. In basic media, the (different) degradation product is brown.

Department of Redundancy Department - Now with paperwork!

'In organic synthesis, we call decomposition products "crap", however this is not a IUPAC approved nomenclature.' -Nicodem

|

|

|