| Pages:

1

..

8

9

10

11

12

..

18 |

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

This is very interesting. I will keep my eyes open and see if I can find anything pertaining to the subject. I didn't really look much farther than

the alcohol methods when I first learned to make azides. I was very happy and contented when I learned how to make it work. Though a large amount of

costly alcohol is used those methods are very reliable and robust, solidly proven as you have described.

I will keep my eyes open for alternative methods. The azides really are so many times better than the other primaries I was experimenting with prior

to.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Yes azides are definitely a subject of interest for which a good practical working knowledge is a priority for anyone interested in the scientific art

associated with initiating explosives. It could be prioritized as "Explosives 101" kind of fundamental must have knowledge buried and hidden among

that voluminous work they would not dare to teach in college  , a deficiency

and oversight which any aspiring "blaster" would then seek to remedy as knowledge gotten from "independent further research". Of course that would be

the point to not "spoon feed" every secret thing to the student, but only sufficient knowledge to operate as a provocation to the student who must

then solve any remaining mystery for themself. We are taught only to a point, and thereafter we are self-taught and this is probably by design. The

impatient to know would criticize the design and question its necessity, question the teachers, question the intelligence of the design. It is what

it is. , a deficiency

and oversight which any aspiring "blaster" would then seek to remedy as knowledge gotten from "independent further research". Of course that would be

the point to not "spoon feed" every secret thing to the student, but only sufficient knowledge to operate as a provocation to the student who must

then solve any remaining mystery for themself. We are taught only to a point, and thereafter we are self-taught and this is probably by design. The

impatient to know would criticize the design and question its necessity, question the teachers, question the intelligence of the design. It is what

it is.

If we stick with the well proven non-aqueous methods there would still seem to be improvements possible to be made in the manipulations. My personal

impression is that a scheme which uses the dihydrazine sulfate prepared in advance as the material which will be freebased into alcohol, very likely

would represent such an improvement. Isopropyl alcohol is a good choice for the alcohol as described for the method of microtek and its variations.

There possibly could be advantage for use of different organic nitrites other than isopropyl nitrite, or maybe not. Surveying the possibilities there

are other organic nitrites which may have lower vapor pressure and possibly adequate stability, and which will either react directly with the

hydrazine in isopropanol or will transesterfy in situ to the isopropyl nitrite which will allow the desired reacton to proceed. Depending upon

availability other alternative solvent alcohols are also workable. So it appears that the "alcohol solvent method" is general and may be subject to

variations at the technicians discretion which may serve as refinement applied to the same basic method.

Ultimately there will be found several slightly different but still related methods all of which are workable with each approach having its advantages

or disadvantages compared with another variation. What will ultimately prove to be the "best" all around combination of solvent alcohol, organic

nitrite ester, and base, and hydrazine salt precursor material, is left to be sorted out with further experiments, while encouraged to know that

decent yields are probable to be gotten from any of the variations, as whatever variations are tested to try to optimize the particular combination.

There is plenty there to digest when surveying the "process chemistry" involved, plenty of food for thought there for the hungry mind of the curious

experimenter.

[Edited on 1-4-2013 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

This is what I had of Microtek’s; there may be other posts that I am unaware of. Keep in mind these posts are almost 10 years old.

From E&W

"Microtek

September 9th, 2004, 12:00 PM

For sodium azide production I use a method which gives hydrazine in alcohol (from hydrazine sulfate) with little or no water:

- 1 mol dry HS is placed in a flask along with a suitable amount of anhydrous isopropanol.

- 1 mol of NaOH pellets are added and the contents are triturated with a glass rod until they begin to react, forming a slurry of hydrazine hydrate

and NaHSO4. This doesn't mix with the iPrOH, but forms a sticky goo on the glass.

- Another 1 mol NaOH is added which converts the NaHSO4 to Na2SO4 ( and forms a mol of water ) which separates cleanly as a white powder.

I would think that the Na2SO4 is a good enough dessicant to dry out the solution which can then be decanted.

- Another extraction or two with dry iPrOH recovers most of the hydrazine.

This alcoholic solution of hydrazine works well for producing sodium azide with isopropyl nitrite."

I also have this from E&W (2005), part 2 of his azo-clathrate synthesis.

"2) Production of hydrazine hydrate: 13 g hydrazine sulfate is placed in a suitable vessel along with 15 mL IPA, 99%. 4 g solid NaOH is added and the

pellets are crushed and triturated with the HS. After a few minutes, the powdered reactants will attain the appearance of a paste as the produced

NaHSO4 stubbornly holds on to the produced hydrazine hydrate. The paste is worked through a little more to ensure complete reaction, and then another

4-5 g solid NaOH is added and worked into the paste to convert the NaHSO4 into Na2SO4 which separates cleanly as a crisply dry powder.

The IPA solution of hydrazine hydrate is removed by decatation or with a syringe, and

the remaining powder is extracted a further two times with 10 mL IPA.

The advantage of using only IPA is that there is no possibility of cross-esterification during the reaction of isopropyl nitrite with hydrazine

hydrate, so there is no need to carry out the operation under pressure. Also, the practically anhydrous conditions causes the sodium azide to

precipitate completely and instantaneously from the reaction mixture as the nitrite is added."

A lot of what he said was very helpful, but what I also found was that I had to use a lot more isopropyl alcohol in order to dissolve the amount of

sodium hydroxide necessary to balance the reaction equation. I also found that the product was not produced immediately, but took half an hour or more

at room temperature before much of any product was seen and then 2 or more days to approach completion. He may have done many things differently to

control the reaction conditions, but I have not seen those posts. When operating at room temperature, I found using KOH to be a big improvement.

I think this part is mine, though I am sure somebody somewhere has done it before.

It may seem like a simple modification (and it is), but using potassium hydroxide in place of sodium hydroxide when using isopropyl alcohol as the

solvent provides a huge economy in alcohol (since KOH is much more soluble than NaOH in isopropyl alcohol) and time (since the reactants are at a much

higher initial concentration).

You can lead a horse to water, but you can't make him drink (I'll give you that). Not all knowledgeable people are generous with their knowledge

either though. Like you say these things are probably natural, even with large amounts of spoon feeding generally people need to work with the

material in order to really grasp what is going on.

[Edited on 31-3-2013 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

franklyn

International Hazard

Posts: 3026

Registered: 30-5-2006

Location: Da Big Apple

Member Is Offline

Mood: No Mood

|

|

A passing thought I had

Ammonium Nitrate is decomposed by Hydrazine , replacing and liberating

Ammonia to form Hydrazinium Nitrate

NH4NO3 + N2H4 => NH3 + N2H4•HNO3

so what about Ammonium Nitrite to form Hydrazinium Azide.

Nitrite will oxidize Hydrazine just the same as it does Urea.

NH4NO2 + 2 N2H4 => NH3 + N2H4 + N2H4•HNO2 => NH4OH + H2O + N2H4•HN3

on Ammonium Nitrite

www.sciencemadness.org/talk/viewthread.php?tid=23807

www.sciencemadness.org/talk/viewthread.php?tid=6650

______________________________________________

Upon further reflection ( and meta search ) it appears things are

not as straight forward as one can hope for. According to The

Encyclopedia of Explosives & Related Items - PATR 2700

Hydrazinium Nitrite is a known stable salt , making it's further

transition to azide dubious.

H 196

Hydrazine (or Hydrazinium) Nitrite. N2H4•HNO2 ;

mw 79.06, N 53.15%; decomp or explodes on rapid heating;

colorless to yellowish hygr solid; sol in w & alc; insol in eth;

may be prepd by mixing solns of barium nitrite and neutral

hydrazine sulfate, as described in Mellor (Ref 1).

Explodes violently on impact and less so when rapidly heated.

When heated slowly it decomposes according to the equation:

N2H4•HNO2 => NH3 + N20 + H20

and this decompn is greatly accelerated by nitrous acid.

Refs:

1) Mellor 8, 472-3 (1946)

2) F.Sommer, ZAnorgChem 83, 119 (1913)

3) Clark, Hydrazine (1953), p 6

the often cited reaction of hydrazine with nitrite to form azide is

also clearly stated

H 192

Hydrazine is used for the preparation of hydrazoic acid according to:

N2H4 + HNO2 => HN3 + 2H20

or for the preparation of sodium azide (Ref 14).

14) Ulmann, 6, 206, Encyklopädie der Technischen Chemie (1951)

the essence of what I propose above is clearly mentioned also

A 606

pure NaN3, made from N2H4 and NH4NO2

(Ref 54) J.Nelles, Ber 65B, 1345-7 (1932) & CA

as is the reaction analogous to hydrazine with ammonium nitrate

A 537 - Hydrazinium Azide

prepd by pouring hydrazine hydrate over ammonium azide

and evapg the mixt in a flat dish placed in a desiccator. This

latter method of prepn was patented by Miller in 1936 (Ref 10).

10) E.Müller, GerP 634688 (1936) & CA 31, 511 (1937)

so what is one to think, experimentation will tell.

____________________________________

If someone is wondering about that apparent nonsequitor referring to

Ethylene Glycol Dinitrite posted by Rosco Bodine below, see _

www.sciencemadness.org/talk/viewthread.php?tid=6395&goto...

.

[Edited on 1-4-2013 by franklyn]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Quote: Originally posted by Rosco Bodine  | | If we stick with the well proven non-aqueous methods there would still seem to be improvements possible to be made in the manipulations. My personal

impression is that a scheme which uses the dihydrazine sulfate prepared in advance as the material which will be freebased into alcohol, very likely

would represent such an improvement. |

Hmmm, why didn't I think of that? I've caught myself reinventing the wheel while reviewing the matter. The original patents regarding freebasing

hydrazine into alcohol were in fact done using dihydrazine sulfate, which would simplify things as I have been thinking. So the freebasing done from

the monohydrazine sulfate has been taking a short cut, which causes twice the byproduct water from neutralization and increases the amount of alcohol

being needed for the extraction.

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

These are some pertinent references

GB900397 Freebasing hydrazine in ethanol

GB876038 Frebasing hydrazine in methanol

US3015542 US issue of GB900397

US2166698 ethylene glycol dinitrite

Attachment: GB900397 hydrazine extract using ethanol.pdf (284kB)

This file has been downloaded 934 times

Attachment: GB876038 Hydrazine extract in alcohol.pdf (249kB)

This file has been downloaded 1138 times

Attachment: US3015542 Hydrazine in Ethanol from dhydrazine sulfate.pdf (113kB)

This file has been downloaded 2315 times

Attachment: US2166698 ethylene glycol dinitrite and glycerin nitrite esters.pdf (175kB)

This file has been downloaded 1043 times

[Edited on 1-4-2013 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I remember you bringing up dihydrazine sulfate a year and a half ago or more. It is a good idea which reduces the amount of water produced by half. I

am not quite sure why more water would require that there to be more alcohol used for extraction. I thought the water was a problem because it caused

more of the sodium or potassium azide product to be dissolved or lost in the reaction mixture.

There seemed to be an indication from some of the earlier posts that the sodium sulfate produced during freebasing may be absorbing much of the water

produced, but I don't know. The idea of using desiccants might be a good one.

Description of Drierite taken from http://www.chem.ucla.edu/~bacher/Specialtopics/Drying%20Agen...

Calcium sulfate (n=0.5, e=0.004 mg/L) is a neutral and good drying agent. However, it does not have a high capacity, which makes it useless for very

wet solutions. The commercially available Drierite contains cobalt chloride as indicator (dry: blue, wet: pink), which can be leached out into various

solvents i.e. ethanol, DMSO, DMF, ethers, etc. Drierite is often used in desiccators. If the compound is pink, the water can be removed by heating the

compound to 210 oC for an hour.

The text "Purification of Laboratory Chemicals" says isopropyl alcohol can be dried by adding CaSO4.

Could calcium sulfate or some other desiccant be added before or during the extraction process to remove water?

I know Rosco mentioned Glauberite [Na2Ca(SO4)2] in some previous posts.

[Edited on 1-4-2013 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

I was having a little fun earlier with some folks here, probably with Len in mind more than others, sorry I couldn't resist

Look again at the titling on that post paragraph linked above usual behavior of hydrated salt does not apply and you will understand

why it would be of limited usefulness to try to use any ordinary dessicants to try to dry an alcohol solution of hydrazine hydrate. The hydrazine

hydrate tenaciously holds onto water and wins the tug of war for the water unless some special approach is used like distillation fractionation or

azeotroping a solvent / water mixture, or in the alternative to use chemically reactive schemes like an alcoholate such as sodium ethoxide or sodium

methoxide as a part of the neutralization scheme in place of simply using a base like NaOH simply dissolved in the alcohol.

The speculation which I was making about Glauberite was more intended towards a cleaner precipitation of the sulfate byproduct of the freebasing

having a more compact crystalline form, than was it meant to address at all the byproduct water, which Glauberite would not do anyway since Galuberite

is an anhydrous double salt. The Glauberite would likely have its greatest utility in the prelimary conversion of the monohydrazine sulfate to

dihydrazine sulfate where the dihydrazine has such great solubility in water, and before an alcohol system is later used for the freebasing scheme

applied to a previously isolated and dried dihydrazine sulfate. It is possible the Glauberite may have utility also in the freebasing scheme, but it

would not be any dehydrating property that is the reason. The lowered solids content would make for easier physical manipulation to stir a slurry of

sulfate byproduct, and by working with dihydrazine sulfate there will only be half the bulk of byproduct sulfate, as well as half the byproduct water

in the freebasing and extraction stage.

The added quantity of alcohol for the more shortcut scheme is simply the relative amount of alcohol being greater to have an end resulting solution

having a comparable concentration of water. Twice as much alcohol is required for the shortcut scheme (at least) and maybe even a little more in

comparison to the proposed scheme which involves an easier manipulation for physical reasons.

If an alcoholate is contemplated being used also as a chemically reactive dehydration, there is benefit there also because only half as much byproduct

water is encountered when freebasing the dihydrazine sulfate as is gotten by the "one pot" shortcut method. For a bulk synthesis expecially where a

larger amount of material will be made, these refinements would be of greater concern with regards to the efficiency of the process. For small scale

syntheses, the simplicity of the "short cut" method makes waste of solvent or inefficiency less concern, but for any scaling up of the process, the

usefulness of the refinements would become apparent. Since I tend to work medium scale then I am more aware of these kinds of "process" efficiencies,

which could also be applied to the smaller scale if it was estimated to be worth the extra effort on the smaller scale.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Ok, now that I am looking at the reaction equations I see that all the water produced is bound to the hydrazine forming hydrazine hydrate. For some

reason I was thinking of unbound water (it has been over a year since I really looked at this at all, and I'm not really a chemist).

When using isopropanol the amount of alcohol used is dictated by its rather low ability to dissolve the hydroxide. The saving grace seems to be that

the azide products also seem to be very insoluble in isopropanol.

Yeah, efficiency really isn't a great big concern for me because I am usually only making a few grams for some caps. When you are only using 0.3g per

cap, a few grams can go quite a long way. If it costs me an extra buck or something to make a small batch it is no big deal, especially if it saves me

time and effort. I can see how my methods would be very uneconomical large scale though.

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

To expound upon what I am trying to communicate it would be good to see the following post in the dedicated hydrazine thread. It further describes

what is contemplated as a method for virtually anhydrous hydrazine in isopropanol possible to be gotten by freebasing dihydrazine sulfate using

aluminum isopropoxide in isopropanol. I do not know if this has ever been done. But it appears to be the logical progression that such a proposed

route is possible.

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

As an aside there is also some modification of the hydrazine synthesis reportedly using manganous sulfate as a catalyst. The "Russian method"

from a Russian textbook Practical_Inorganic_Chemistry.Vorobyova.O.I_Dunaeva.K.M_Ippolitova.E.A_Tamm.N.S.1987

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

There is a patent reported US3227753 Biurea or Hydrazine from Hypochlorite and Urea which describes a similar process so this may be of interest as a

possible further refinement on the hypochlorite urea process.

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

Scale absolutely has bearing on the choice of methods used for convenience. Shortcuts are allowed for small scale work, and I never really explained

before that was what was deliberately done to make a "one pot" method from a generally more complicated industrial process. It is good to know this

however, because it can apply if any scaleup is contemplated or if problems are encountered with the small scale "one pot" methods, then those

problems may be resolved by the longer route or other measures done to refine the process.

Brainstorming is allowed also. For example I just thought of the possible refinement of using aluminum isopropoxide in ethanol, denatured alcohol to

do the freebasing of dihydrazine sulfate, resulting in anhydrous hydrazine in ethanol with a small percentage of byproduct isopropanol, a solvent

system being mostly ethanol in which the NaOH would be highly soluble. Then for the nitrosation a low volatility nitrite like diethylene glycol

dinitrite, or alternately butyl nitrite or amyl nitrite, or if stability of glyceryl di or trinitrite is sufficient, then the glyceryl nitrite could

be used.

Such a scheme could lead to a quantitative yield for the process regardless of scale.

So now you know where "Mr. Anonymous" was going with all of this that took ten years to get said ....connecting all the dots. Dots are hereby

declared "connected".

I really wanted to get all these details down before the next forum backup so the communication transmission would be complete. I'm sure there was an

article or two missed along the way, but that is pretty much all I've got on this to this point, for the "hydrazine chronicles" or Martian (lander)

chronicles, or azide / tetrazole chronicles ....whatever.  It has been a long

ride, but a lot of fun sharing. It has been a long

ride, but a lot of fun sharing.

[Edited on 1-4-2013 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

Thanks for sharing. Contributors like you, Microtek and some others have definitely helped me develop some of the skills I now possess.

As Microtek originally said isopropanol is good in the sense that there is no possibility of cross esterification. What I need to figure out is a way

to add the reactants (or at least the sodium/potassium hydroxide) to the reaction mixture, in the isopropanol solvent, in small increments instead of

all at once. If I could do that the process would require a lot less alcohol. I suppose at the scale that I am working at this sort of process, with

increased complexity, is probably not going to be much of an advantage all costs including time considered.

[Edited on 2-4-2013 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

If anybody had told me that an anonymous post here would lead to a ten year incremental tour of the literature with review of experiments and proposed

experiments involving hydrazine and related compounds, I would have chuckled and said sure, 10 years huh, you gotta be kidding me. But truth is

stranger than fiction. This has got to be an internet discussion forum record of some kind. This azide thread should get a sticky IMO. It seems to be

the main thread for azides, and along with tetrazoles seems to be a natural related interest energetic material for the general topic of hydrazine.

The process refinement priority for the alcohol reaction system which seems most promising would be preparing and isolating the dry dihdrazine sulfate

in advance as the precursor for freebasing.

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

I have been wondering for a long time why this thread was not stickied.

Since brainstorming is allowed, I have another idea.

Notes on the Preparation of Absolute Isopropanol

Lewis Gilson

J. Am. Chem. Soc., 1932, 54 (4), pp 1445–1445

Publication Date: April 1932

Attached jpeg of the note on concentrating isopropanol.

I don't know but it looks like maybe the isopropanol could be used over and over again. Just remove water and use it again. Again probably not worth

the bother, but it might be worth saving the solvent and doing it in large batches.

I suppose since the isopropanol is used in such large proportion compared to what is used in the case of ethanol or methanol, the solvent could

probably just be recharged with reactants and used again.

[Edited on 2-4-2013 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

In an earlier post I was speculating that aluminum isopropoxide could be useful for freebasing hydrazine from dihydrazine sulfate, but thinking more

about this it seems like the use of that reagent could be problematic a couple of different ways. I don't know if this first possible complication

would occur but it does seem possible.

http://www.sciencemadness.org/talk/viewthread.php?tid=1128&a...

The possibility of a complication presented by the insolubility in the isopropanol of any transitional Al(OH)3 which may be needed to function as the

reactive base, exists IMO and may prevent the formation of the aluminum sulfate from a direct reaction of the soluble alkoxide and the dihydrazine

sulfate. The aluminum isopropoxide would I think be fine however for drying the isopropanol and / or stripping the H2O content from an already

freebased hydrazine hydrate in solution in the isopropanol, and the insoluble Al(OH)3 byproduct could be filtered leaving the anhydrous hydrazine in

anhydrous isopropanol. This would probably be better targeted to a slightly less than anhydrous solution in order to avoid any excess of unreacted

aluminum isopropoxide which would then contaminate the azide wished to be produced later as only the sodium salt.

Bearing these two potential complications in mind, it points to sodium ethoxide as the better choice for such a scheme, probably even if it is to be

used as the substituted NaOH "base" dissolved in isopropanol, unless a sodium isopropoxide may be formed similarly and as easily as is the sodium

ethoxide. The sodium alcoholate is easier to make and requires no distillation.

Sodium ethoxide related reading here

http://www.sciencemadness.org/talk/viewthread.php?tid=17074&...

and here

http://www.sciencemadness.org/talk/viewthread.php?tid=2656

See US1978647 attached.

Continuing with the "brainstorming" on this the aluminum isopropoxide may be useful for preparation of the sodium isopropoxide, simply by reacting

with NaOH. Evidently the sodium isopropoxide is much more soluble in the isopropanol than is NaOH so this would address the low solubility issue for

NaOH in isopropanol. It is possible and likely the sodium isopropoxide could be used for the base in the nitrosation stage as well. Attached is a

product sheet showing sodium isoproxide sold as a 12% solution in isopropanol and what may be its additional solubility I don't know but it is at

least 12%.

http://www.sciencemadness.org/talk/viewthread.php?tid=13212&...

Attachment: US1978647 Acetone Precipitation of Sodium Ethoxide.pdf (201kB)

This file has been downloaded 891 times

Attachment: Sodium_Isopropoxide.pdf (74kB)

This file has been downloaded 1082 times

[Edited on 3-4-2013 by Rosco Bodine]

|

|

|

Polverone

Now celebrating 21 years of madness

|

Thread Topped

3-4-2013 at 01:01 |

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

A few more dots yet to connect about sodium azide

My earlier declaration about having fully connected the dots on the matter of sodium azide synthesis was a bit premature.

It seems there is some more yet to say about this.

Two patents in particular, US1628380 and US5208002 are especially relevant and were mentioned in my first anonymous e-mails to Polverone 10 years ago.

http://www.sciencemadness.org/talk/viewthread.php?tid=470&am...

The later patent represents an improvement over the earlier patent. In the 10 years interim neither patent has been attached until now. Hmmm.

Something useful has there been hidden in plain sight, or perhaps overlooked. Compare the two patents and the technical difficulty in particular, for

the anhydrous technique which resorts to even use of sodium ethoxide to maintain a low water content and facilitate a more complete reaction and

easier isolation of the product in some better yield, but the price paid for that being more difficult manipulations. Obviously the process is still

entirely workable even for the reaction system where water content is substantial. Here the more modern patent looks at the economics which arguably

show it is easier to simply increase the batch size and use less rigorous conditions to offset any lesser yield, and showing by example 3 that the

implementation of the simpler conditions is entirely workable on a lab scale.

US1628380 Azide from hydrazine and organic nitrite via low H2O content reaction system

Attachment: US1628380 Azide from hydrazine and organic nitrite via low H2O content reaction system.pdf (163kB)

This file has been downloaded 915 times

US5208002 Azide from organic nitrite and hydrazine via high H2O content reaction system

Attachment: US5208002 Azide from organic nitrite and hydrazine via high H2O content reaction system.pdf (159kB)

This file has been downloaded 829 times

So there really are 2 entirely valid approaches where the same chemistry applies but the manipulations are easier for the more modern method. It

would seem perfectly well adaptable to a dropwise addition of an organic nitrite, and should work with other alcohols as well, even though the

quantities may have to be adjusted because the model reaction of example 3 of the patent describes the work using methanol. Refinements would seem

possible beyond what the more modern patent describes. I will study this further, to estimate how most conveniently to approach similar reaction

system conditions as described for the later patent's less rigorous conditions, having easier manipulations involving the freebasing of hydrazine

tolerating a higher level of hydration which evidently poses no obstacle to producing a good yield, but only changes the manipulations involved in

isolation of the product, requiring some evaporation and concentration of the completed reaction mixture due to the product azide being in significant

amount but not completely dissolved in the completed reaction mixture due to the water content. Dealing with simply concentrating the reaction

mixture to crystallize out the dissolved product is a routine manipulation which presents no special difficulty.

http://www.youtube.com/watch?v=lJiznhUEc8g

<iframe sandbox width="640" height="480" src="http://www.youtube.com/embed/lJiznhUEc8g" frameborder="0" allowfullscreen></iframe>

[Edited on 4-4-2013 by Rosco Bodine]

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

The point of adding the NaOH in two portions, is that the first formation of the paste of NaHSO4, hydrazine hydrate and alcohol is that the hydroxide

does not need to dissolve in the alcohol (at least this is my intuition; I haven't really analysed the reaction to be certain).

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

What is the reason why you think the acid sulfate of sodium is the initial neutralization byproduct? I don't believe that is correct. I believe the

byproduct is the normal sulfate ....start to finish. I am pretty certain the dihydrazine sulfate forms progressively as the first half of the base is

added by observation of the liquification of half the solids of the slurry, which seems to melt to a thinnest viscosity when fairly hot ~85C est. not

measured.

At the half neutralization this is what I think you get

2 NH2NH2-H2SO4 + 2 NaOH ---> (NH2NH2)2-H2SO4 + Na2SO4 + 2 H2O

solubility for monohydrazine sulfate 3.4 g per 100ml H2O @ 25C

solubility for dihydrazine sulfate 202.2 g per 100ml H2O @ 25C freezing point / m.p. 45-55 C

Then during the freebasing stage of the remaining base addition

(NH2NH2)2-H2SO4 + 2 NaOH ----> 2 NH2NH2-H2O + Na2SO4 + ( Na2SO4 + 2 H2O from above )

It was my thought that in the freebasing stage is where it may be an advantage to use 1 mole of Ca(OH)2 in place of the 2 moles of NaOH hoping to

form the double salt CaSO4-Na2SO4 via reaction with the Na2SO4 from the first reaction above. The double salt is anhydrous and would not pull water

of crystallization which here is mixed with hydrazine hydrate. It was my thought this "glauberite" double salt may be a more dense material and would

also reduce any impurity of sodium sulfate in the supernatant aqueous hydrazine hydrate....with or without alcohol. But I think the freebasing using

the calcium hydroxide would not be favored by much alcohol because of the low solubility of that base in alcohol and low enough solubility already in

H2O which would be worsened by alcohol. The alcohol would be added

after the freebasing is completed to take up the freebased hydrazine hydrate in water which will be the liquid phase of the "glauberite" slurry,

extracted using the alcohol swirled with the slurry, and decanted from the solids. I think this would probably work. If not, then we know straight

sodium hydroxide works with or without alcohol.

On that you are correct no alcohol is required for the neutralization of monohydrazine sulfate to begin with contact with solid NaOH, a single drop of

H2O will cause an exothermic reaction between the solids to initiate and it will continue from its own heat of reaction kicked further by the heat of

solution of the solid NaOH dissolving in the byproduct H2O. A large mass of the solids will get really hot really fast in the same way as does solid

NaOH react with sulfur and it will form a melted very hot slurry from the exotherm. The heating is so great it could be dangerous with really large

batches of several moles. Even with a 2 mole batch a portionwise neutralization approach is what I do because of the exotherm.

[Edited on 4-4-2013 by Rosco Bodine]

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

I base my hypothesis on the supposition that the sodium ion essentially would replace the hydrazinium in the mono-hydrazinium sulfate. The reason that

I formulated this hypothesis to begin with was because I had observed a very marked difference between the mix at the two points (after the addition

of one equivalent and after addition of the second equivalent).

Your hypothesis would explain that as well. I haven't looked at equilibrium constants because, frankly, I was more interested in the fact

that it worked than why it worked (though if you wanted to explore the reaction further, the "why" does obviously

becomes important).

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Actually I would amend what I said above about the normal sulfate forming from start to finish. What you are saying about the acid sulfate formation

could certainly be mathematically possible for the reaction from the very beginning of the base additions up to the point where 25% of the

neutralization occurs, which would be the midpoint of the first half reaction. It was just my first thought that it likely did not happen, but

looking at it further it would certainly be possible if the kinetics allow for it. I knew the dihydrazine sulfate formation was what was desired to

form and does form completely by the midpoint of the reaction, in either case. But theoretically in the first 25% of the overall neutralization the

math does work for the formation of an acid sulfate as a transient intermediate, also having 1 H2O byproduct at that point. In practical terms it

really makes no difference to the process by the time the midpoint has been reached, where the acid sulfate would have then been converted to the

normal sulfate before the freebasing could begin. but it is an interesting technical detail that the sulfate could initially be the acid sulfate

during the first 25% of the overall neutralization. What you are describing would be a two stage reaction leading to the midpoint, with the second

reaction below indicating the midpoint of the overall reaction.

2 NH2NH2-H2SO4 + NaOH ---> (NH2NH2)2-H2SO4 + NaHSO4 + 1 H2O ( midpoint of the first half-reaction )

(NH2NH2)2-H2SO4 + NaHSO4 + NaOH ----> (NH2NH2)2-H2SO4 + Na2SO4 + 1 H2O + ( 1 H2O from above )

( midpoint of overall reaction )

Thereafter as per shown earlier:

Then during the freebasing stage of the remaining base addition

(NH2NH2)2-H2SO4 + 2 NaOH ----> 2 NH2NH2-H2O + Na2SO4 + ( Na2SO4 + 2 H2O from above )

The simplified but really oversimplified summary equation which could be wriiten for the reaction overall would be

NH2NH2-H2SO4 + 2 NaOH ----> NH2NH2-H2O + Na2SO4 + H2O

Most people would just look at the summary equation and it does not accurately reflect the stepwise intermediate reactions which are occurring as

detailed above. The summary equation only shows the relative proportions of reactants overall, but is deceptive oversimplification about the reaction

mechanisms leading to that summary reaction which is not really showing the operative reactions as do actually occur.

It threw me a curve when you mentioned the formation of free hydrazine which certainly can only appear after the midpoint in the reaction, where by

that point there could not be any acid sulfate present. Some trace water I think is probably necessary to initiate the reaction which rate increases

as a result of its own byproduct water. The water allows dissolution of the solids which being solids are physically separated and isolated but

progressively dissolve and react in a local zone of solution that is the liquid phase provided by the small amount of water. Without any solvent, I

think the dry reactants would not quickly react at all because the subdivision of the materials is insufficient to bring the reactants into homogenous

contact, and the surface reaction limitation aspect would slow or possibly stop the reaction from continuing. The slurry of solid particles

dissolving into and byproducts precipitating from the solvent allows the reaction to proceed through the mass of reacting solids. And here the most

reaction enabling solvent is necessarily water at least in part, even when alcohol is also an additional solvent.

[Edited on 4-4-2013 by Rosco Bodine]

|

|

|

Microtek

National Hazard

Posts: 869

Registered: 23-9-2002

Member Is Offline

Mood: No Mood

|

|

| Quote: |

Some trace water I think is probably necessary to initiate the reaction which rate increases as a result of its own byproduct water. The water allows

dissolution of the solids which being solids are physically separated and isolated but progressively dissolve and react in a local zone of solution

that is the liquid phase provided by the small amount of water.

|

Yes, this is what I meant, and also why it is not necessary or desirable to use a large amount of alcohol to dissolve the hydroxide. I believe that

the intimate contact between reactants in the slurry that forms until the midpoint is reached allows for a more complete (and faster) reaction than an

alcoholic solution of the hydroxide would.

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Earlier in the thread S.C. Wack posted links for some German publications which may be helpful and I would ask for any German speakers to look at this

particularly the patent DE205683

I am curious about the use of ammonium sulfate mentioned in the patent.

If I understand the German patent describes distillation of the product as aqueous hydrazoic acid. Of course, while requiring special technique,

distillation would eliminate problems of isolation and purification of the intended product from an aqueous mixture where byproducts are in solution

or coprecipitated. Also there are reactions where the recreation of the free hydrazoic acid is done in situ using sodium azide and an acid for

further reaction such as with dicyandiamide to produce 5-aminotetrazole, so if this or ammonium azide as two examples were the ultimate intended end

product, the process may be adaptable for making use of the distillate directly, or to use its precursor mixture in some alternate scheme.

http://www.sciencemadness.org/talk/viewthread.php?tid=1987&a...

Curtius und Rissom Neue Untersuchungen uber Stickstoffwasserstoff N3H Journal fur praktische Chemie Oct. 1898 (attached)

Attachment: DE205683 Azide patent Stolle.pdf (109kB)

This file has been downloaded 1023 times

Attachment: Curtius und Rissom Journal fur praktische Chemie Oct. 1898.pdf (1.8MB)

This file has been downloaded 1340 times

[Edited on 12-4-2013 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

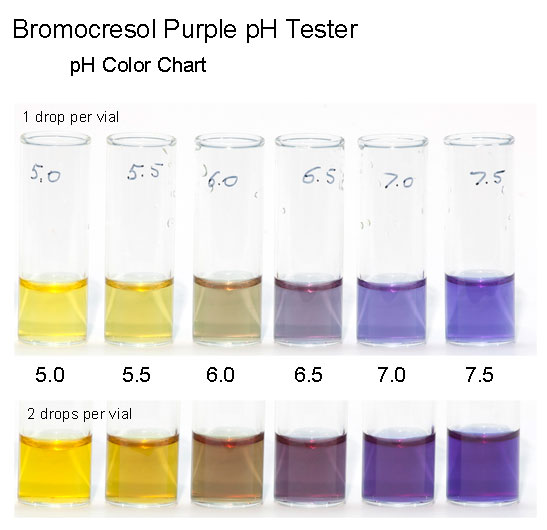

Hodgkinson patent related

In my first communication 10 years ago I mentioned the Hodgkinson patents, which have been posted about maybe 3 or 4 times since obtaining copies of

those patents. GB128014 is still intriguing. Hodgkinson indicates it is a fickle reaction occurring in a very specific narrow range of pH but is

somewhat cryptic about giving that pH a number.

http://www.sciencemadness.org/talk/viewthread.php?tid=874&am...

The reaction between an alkali nitrite and the neutral hydrazine salt is described to occur in an only slightly acidic solution not so acidic as to

redden litmus which would be a lower limit of 5 pH or perhaps 4.5 pH. Hodgkinson mentions the reaction as comparable to the pH of a solution of boric

acid but does not specify the strength of the example solution of boric acid, which even at about half of saturation at room temperature would be on

the threshold of being too low pH and would definitely redden litmus. So Hodgkinson is being mysterious while claiming yields of 85% for his

mysterious aqueous system process. There are recent patents claiming reaction of free hydrazine and an organic nitrite in an aqueous system in the

presence of a base.

And there are some early art references mentioning use of a inorganic nitrite in reaction with a hydrazine salt but the references describe acidic

conditions, some of them highly acidic conditions. There appear to be 2 different mechanisms and possibly 3 different mechanisms and the mechanism

involving a highly acidic reaction mixture is an oxidation, having about one third of the potential yields of the alternate scheme of nitrosation or

diazotization done in an alkaline reaction system. Hodgkinson seems to teach that the nitrosation mechanism will still occur if the reaction system

is only very slightly acidic, and does proceed in an aqueous reaction system. The pH range would seem to be in the range of bromocresol green or

bromocresol purple or alizarin. Hodgkinson offers no help on process monitoring indicators except for mention of litmus. Hopefully that can be

updated to an indicator having a sharp transition for process monitoring any experiments. What coloration may occur in the reaction mixture could be

a factor but is unknown.

Hodgkinson is cryptic also about the needed amount of alkali which he supposes must be present to maintain the precise acidity and specific pH for the

reaction system. Stoichiometry reveals that a full molar equivalent of NaOH or probably better NaHCO3 would be required along with the NaNO2 in order

for the reaction to remain close to neutral. But the description given by Hodgkinson states that the small impurity of alkali expected to be present

in the sodium nitrite would provide adequate buffering ....when the reaction stoichiometry does not suggest this would hold true. Hodgkinson hedges

his description by conceding that some added amount of alkali may be required if sufficient alkali is not present in the nitrite , when the

stoichiometry suggests that such need for additional alkali is a certainty. My own reckoning of what would be needed is an equivalent of NaOH or

NaHCO3, and probably what would be more workable still would be some replacement of that equivalent with a not yet predicted but probably small amount

of NaOAc which would serve as a buffer to maintain the highly specific pH requirement described by Hodgkinson.

This azide synthesis described by Hodgkinson continues to be intriguing to me, particularly because of the reported high yields from what appears to

be a mild reaction condition, but a fickle reaction requiring great precision to accomplish ...IF indeed it works as described or can be made to work

by some slight modification of what is described, after ascertaining what little secrets Hodgkinson may not have mentioned while describing the

process. I do not think it was just "inventors euphoria" or wishful thinking that would have Hodgkinson apply for 2 patents and associate the

invention with the Ordnance College of England, so there is probably some validity to the patent, even though it is clearly NOT a patent which makes

"full disclosure" of all the factual particulars in great detail. This leaves the matter art which must be puzzling to more persons than just myself,

with regards to ascertaining the full details of precisely how such a reaction must be conducted in order to work as described only generally. I have

tried in the past to make this process work and it failed, but I was not observant of the highly specific pH which evidently is THE absolutely

imperative requirement.

Studying the reaction and doing experiments possibly could lead to formulating exacting proportions of the required ingredients so that the target pH

would be achieved by

buffering and then the process would be reliable and reproducible.

Attached are some related reference materials which may help trying to model the reaction, particularly with regards to the proposed buffering aspect

for the nitrite in admixture with NaOH or more likely NaHCO3, and NaOAC which might be required to make the process workable. In place of NaOAC,

NH4OAc, borax, or ammonium borate might also be workable as part of the reasonably believed to be required buffering scheme which Hodgkinson neglected

to describe in full detail.

One thing of collateral interest which Hodgkinson did describe is the conversion of the slightly soluble hydrazine acid salt to the highly soluble

neutral salt. That much is something I and others have confirmed does occur.

Attachment: GB128014 Hodgkinson azide patent 1.pdf (185kB)

This file has been downloaded 967 times

Attachment: NO2 generation by NaNO2 plus Boric Acid solutions.pdf (81kB)

This file has been downloaded 1298 times

Attachment: pds-borates-optibor.pdf (88kB)

This file has been downloaded 1091 times

Attachment: pds-borates-ammoniumpentaborate.pdf (54kB)

This file has been downloaded 937 times

This would seem to be a likely candidate indicator

Further investigation of the Hodgkinson azide synthesis by experimental modeling and if possible by historical research into the process as conducted

looking at any industrial records or additonal writings of Hodgkinson or others employing the process, would make an excellent PhD dissertation and

thesis for some graduate student .... you know ...just sayin' this would be a cracker jack good one for some poor soul trying to think up something,

anything worthy as a subject for that important research paper.

Nothing like stirring the pot  Maybe this Hodgkinson azide synthesis will

intrigue somebody else as "lost art" which has far too long been missing from the literature and textbooks, seeing that odd omission should be

remedied with full disclosure which will remove it from obscurity as lost art, found once again. Now there's a doctoral thesis idea for ya. Maybe this Hodgkinson azide synthesis will

intrigue somebody else as "lost art" which has far too long been missing from the literature and textbooks, seeing that odd omission should be

remedied with full disclosure which will remove it from obscurity as lost art, found once again. Now there's a doctoral thesis idea for ya.

Biographical for Hodgkinson

William Richard Eaton Hodgkinson, Ph.D.

(1851–1935)

Professor of Chemistry and Physics, Ordnance College, Woolwich. Cotton Professor of Chemistry and Physics, R.M.A., Woolwich.

FYI & FWIW

http://parazite.nn.fi/roguesci/index.php/t-3211.html

(attached)

Attachment: Azides from Hydrazine Salts GB128014 and GB129152 [Archive] - The Explosives.pdf (28kB)

This file has been downloaded 1061 times

Also there was some discussion between myself and PHILOU Zrealone, ( Louis , Ph Z ) at the old alt.engr.explosives news group years ago regarding

uncertainties about the Hodgkinson patent which remains mysterious

http://alt.engr.explosives.narkive.com/hUjeaYs1/azides-from-...

(attached)

Attachment: Azides from Hydrazine Salts GB128014.pdf (265kB)

This file has been downloaded 855 times

[Edited on 13-4-2013 by Rosco Bodine]

|

|

|

Hennig Brand

International Hazard

Posts: 1284

Registered: 7-6-2009

Member Is Offline

Mood: No Mood

|

|

When I was discussing dissolving all the hydroxide in the alcohol I was talking about the reaction producing azide not freebasing.

N2H4 + CH3CH(NO2)CH3 + NaOH → NaN3 + CH3CH(OH)CH3 + 2H2O

or

N2H4 + CH3CH(NO2)CH3 + KOH → KN3 + CH3CH(OH)CH3 + 2H2O

I think I am right to dissolve all the hydroxide in the alcohol before adding the nitrite (right?).

Regarding freebasing I also use only a small amount of water (few drops) to start the freebasing. There definitely are two distinctly different

products produced during freebasing. IIRC viscous, translucent, gel like material is produced during the first half of the neutralization and then dry

crunchy white powder at the end. I always assumed the consensus on the forum was that it was first sodium bisulfate produced and then later sodium

sulfate. The mechanism where dihydrazine sulfate is the intermediate could be very useful, if that is what is actually happening.

If the Hodgkinson patent method does work then wouldn't it be a very desirable commercial process? Rosco, you haven't been able to make it work right?

I am not saying that it can't work, as I am not an expert, but from my limited experience there is a lot of bull or at the very least inaccuracies in

the patent literature.

[Edited on 16-4-2013 by Hennig Brand]

"A risk-free world is a very dull world, one from which we are apt to learn little of consequence." -Geerat Vermeij

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Right. I couldn't make the Hodgkinson process work and I definitely tried using careful technique and different approaches and using pH test strips

frequently.

I think a variation on what Hodgkinson has described may possibly work but I have not figured it out yet. It is like a rubicks cube, I pick it up and

mentally play with it from time to time as a WTF is going on there kind of mental exercise  I don't like it when a patent stumps me. But some of them do, and this wouldn't be the first to come out of a "war college" laboratory,

there was another one called Emmansite IIRC which was actually just picric acid with an HNO3 of crystallization. Similar kinds of cryptic stuff is

sprinkled a few places with typographical errors in PATR that have caused perplexing misinterpretations, where the reader must become the proofreader

and editor to get the actual facts. I don't like it when a patent stumps me. But some of them do, and this wouldn't be the first to come out of a "war college" laboratory,

there was another one called Emmansite IIRC which was actually just picric acid with an HNO3 of crystallization. Similar kinds of cryptic stuff is

sprinkled a few places with typographical errors in PATR that have caused perplexing misinterpretations, where the reader must become the proofreader

and editor to get the actual facts.

Lately I have been reviewing some of the original and antique literature on azides and will be posting some of it here.

The method which I described for freebasing hydrazine hydrate into methanol, and the variation of Microtek for isopropanol are perfectly valid

syntheses for a lab scale sort of "one pot" method. The nearer anhydrous is the reaction system done in alcohol the better will be the yield and

simplifies things greatly since it can simply be filtered out of the spent reaction mixture. Towards that end of keeping the final water content

minimum I think the best approach is to use the base or the greatest portion of the base in the form of the alcoholate made separately. I believe

there may be a lower practical limit for the water content due to at least a tiny portion of water being needed in the freebasing of the hydrazine

sulfate.

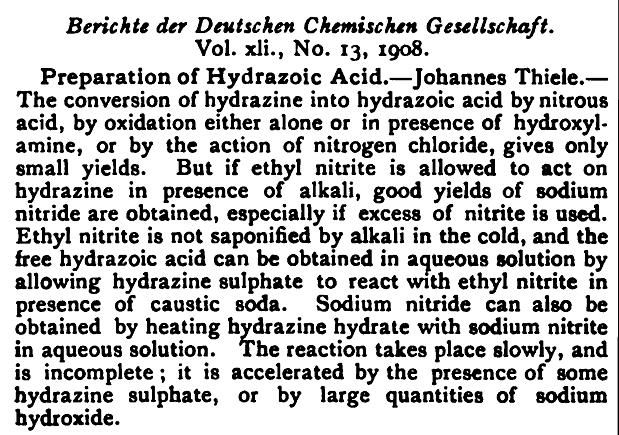

One of the early researchers Thiele actually performed the reaction of hydrazine and ethyl nitrite using sodium methylate as the base and dehydrating

agent, both in excess with respect to hydrazine, and the reaction solvent being ether, Thiele obtained approximately quantitative yield based upon the

hydrazine. So this pretty well proves that for a one pot and single pass method, the "dry solvent" approach works for ether or alcohol.

The disadvantage of the aqueous system methods is needing to recycle unreacted materials, and having a heavy mixture of byproducts requiring some

scheme for separation, which presents isolation difficulties. Even for the aqueous system methods, in contrast with Hodgkinson other investigators

report that the organic nitrite ester and a basic reaction system provides a more rapid reaction and better yield than the alternative which

Hodgkinson describes incompletely, and that finding by others makes Hodgkinson even more doubtful.

I think the benefit of Hodgkinson is that some of the things suggested there may have validity ...and usefulness but in other context...so you can

make use of those parts, while thinking about the rest as dubious. Hodgkinson was getting on up in years ( 67 ) when the azide patents were

published, so there may be some sense of humor injected by the old man into those patents, the kind of humor that might arise with some senility  Old Ph.D's don't go nutters with age, they only become "eccentric" Old Ph.D's don't go nutters with age, they only become "eccentric"

Much of the German is understandable from recognizing the chemistry, but any help with actual translation to English of these articles is welcome and

appreciated.

Zur Darstellung der Stickstoffwasserstoffsaure

Johannes Thiele

Berichte der deutschen chemischen Gesellschaft

Volume 41, Issue 2, pages 2681–2683, Mai–August 1908

(attached)

Attachment: Thiele Berichte.pdf (175kB)

This file has been downloaded 1279 times

Uber die Einwirkung von Salpetrigsaureestern auf Hydrazin, Phenylhydrazin und Benzhydrazid in alkalischer Losung

R. Stolle

Berichte der deutschen chemischen Gesellschaft

Volume 41, Issue 2, pages 2811–2813, Mai–August 1908

(attached)

Attachment: Stolle Berichte.pdf (161kB)

This file has been downloaded 920 times

Also here is an older article by Curtius which is more general about azides

Attachment: Curtius Journal_of_the_Switchmen_s_Union.pdf (691kB)

This file has been downloaded 760 times

[Edited on 17-4-2013 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

DE205683 Translation to English

Thanks to DerAlte for translation assistance. I think this is pretty accurate but welcome any input from German speakers also understanding the

chemistry. The claims part is not included.

DE205683 Translation to English of Stolle azide patent

The reaction of nitrous acid with hydrazine gives hydrazoic acid in a known fashion. However, the yield of this compound is only small. It is now

found that HN3 is accessible from easily gotten Hydrazine hydrate or salts when one treats these compounds with nitrous acid ester, such as amyl

nitrite or ethyl nitrite, from nitrous acid and the alcohol, in alkaline solution (alcoholate, hydroxide, etc.) in appropriate solvents. Thus one

obtains up to 80% yield when one heats hydrazine hydrate in alcoholic solution with amyl nitrite and sodium methylate under reflux.

Otherwise it suffices to shake for a long time hydrazine sulphate with potassium hydroxide with added water, and adding to this solution some alcohol

and amyl nitrite. To isolate the resulting hydrazoic acid from the reaction products, the alcohol is distilled off , excess amyl nitrite and amyl

alcohol was blown off by steam and thereupon the alkaline solution distilled with appropriate amounts of ammonium sulphate and sulfuric acid. The

addition of ammonium sulphate avoids decomposition of HN3 by HNO2 (caused by amyl nitrite derived alkaline nitrite from its saponification, then freed

by sulfuric acid) and thus to prevent a loss.

Examples:

[1] Hydrazine hydrate 1kg was heated 25 hours with 4 kg amyl nitrite and a solution of 3 kg KOH in 15 kg alcohol the alcohol distilled off, the amyl

alcohol removed by steam distillation, the residue made up with 10 liters water solution and heated with about 3kg ammonium sulphate for 3 hrs, 1 kg

sulphuric acid added and distilled. Yield, 70-80% of theoretical (~640 g HN3)

[2] 1 kg hydrazine sulphate, 1 kg KOH, in 2 liters H2O were stirred for 5 hrs, with 4 liters alcohol 1 kg KOH and 1.5 kg amyl nitrite added and

stirred or shaken for 40 hours the alcohol distilled off, 0.75 kg ammonium sulphate added, the alcohol then steam distilled off, 5 liters H2O added,

and 0.5 kg sulphuric acid, and distilled. Yield 60-70% theoretical about 220 g HN3)

[3] 1 kg hydrazine sulphate 1 kg KOH 4 liters H2O stirred or shaken 5 hrs, 1 kg KOH and 2 kg amyl nitrite added, shaken or stirred for 100 hrs, the

amyl alcohol steam distilled off, residue heated 3 hrs with 0.75 kg ammonium sulphate, mixed with 5 liters H2O, and 0.5 kg H2SO4 added and distilled.

Yield 40-60% theoretical about 200 g HN3.

Attachment: Translation of DE205683 Stolle Azide patent.pdf (9kB)

This file has been downloaded 1755 times

[Edited on 17-4-2013 by Rosco Bodine]

|

|

|

Rosco Bodine

Banned

Posts: 6370

Registered: 29-9-2004

Member Is Offline

Mood: analytical

|

|

Possible novel variation on Hodgkinson

The conditions which are described by Hodgkinson seem possibly adaptable and applicable to use of different reagents in a similar reaction scheme,

which I am uncertain will work. The variation which I have contemplated involves addition of isopropyl nitrite to an aqueous solution of acetone

azine, with the expectation that the organic nitrite will react with free hydrazine present from hydrolysis of the acetone azine to produce hydrazoic

acid, with a specific pH being maintained by concurrent addition of a base, perhaps sodium bicarbonate or ammonium bicarbonate or their respective

acetates in some combined buffer scheme. I believe that within a very specific and narrow range of pH that a similar reaction scheme as described by

Hodgkinson may occur and if workable would have advantages particularly in excluding unwanted byproducts.

Theory / Hypothesis / Experimental : When the dimethylketazine is dissolved in water, there is sufficient hydrolysis to cause the solution to become

basic due to the presence of free hydrazine as the hydrate with 2 molecules of byproduct ketone, in this case acetone, which results in a quaternary

system in hydrolytic equilibrium, consisting of hydrazine hydrate, water, and acetone, along with unhydrolyzed dimethylketazine. When isopropyl

nitrite is added to the alkaline system it should react with the hydrazine hydrate to form hydrazoic acid, and this will have the effect of lowering

the pH which favors further hydrolysis of the reserve lode of dimethylketazine, producing more hydrazine hydrate for further reaction with incoming

isopropyl nitrite. In the slightly alkaline pH range is where the reaction would be anticipated to proceed as described, where the hydrazine would be

present as the freebase hydrate, reactive with the isopropyl nitrite. The natural tendency of the reaction would be to become increasingly acid from

the hydrazoic acid, which would tend to interfere with the desired reaction, unless there is additional base added concurently along with the

isopropyl nitrite to neutralize the hydrazoic acid and maintain the slightly alkaline pH. If the pH were allowed to go too far acidic it would tend

to quench the desired reaction, because free hydrazine would itself act as a base to neutralize the hydrazoic acid forming hydrazine azide, and

another issue would arise with reactivity of the isopropyl nitrite with the acetone as in the acidic condition the hydrazine would compete to be

nitrosated, while nitrosation of the acetone would be favored in the acidic reaction mixture. Even though the reaction may be quenched by

insufficient neutralizing, it should recover and proceed when the pH is raised again into the operative range of alkalinity. The only foreseeable

issue for improper buffering is that some undesired byproduct may occur for the nitrosation of acetone which had not been avoided by allowing pH to

transiently range too low, but there would be no hydrazine loss and only a wastage of isopropyl nitrite as the consequence. The reaction should be

manageable using a color pH indicator dye, and pacing the additions of isopropyl nitrite and neutralizing base solution at a metered rate which keeps

the pH in the desired range of slightly alkaline. This is completely hypothetical, and has not been tested, nor can I find anything in the literature

for guidance. However, it seems that the natural hydrolysis of the dimethylketazine could be exploited as described to form an azide, as the sole non

volatile product, if the reaction proceeds in the correct pH range. If this hypothetical reaction proceeds with sufficient velocity is a big unknown,

and if it will work at all as anticipated is also unknown. It may work fine or not at all.

It seems like it would work. So that makes this hypothetical experiment intriguing, especially if it is novel, when it doesn't seem like somebody

else should not have thought of this possible? reaction before. I would have looked it up in the "Journal of Experiments that Seemed like they might

work but Failed" but I haven't been able to locate that huge compendium encyclopedic work anywhere.

An interesting observation which I would make is that dimethylketazine could find usefulness as a sort of buffer in the orginal Hodgkinson reaction

scheme using a neutral hydrazine salt being gradually reacted with an alkali nitrite, because as that reaction becomes acidic it would tend to tie up

the hydrazine and quench the reaction, but the presence of dimethylketazine would tend to regulate that falling pH by additional hydrazine being freed

by the increasing acidity due to hydrolysis of the dimethylketazine. This suggests it may be possible that both the original Hodgkinson reaction

scheme, and the variation contemplated using dimethylketazine as the hydrazine source, might be possible to carried out in mixture as a system, where

the kinetics would favor the formation of azide.

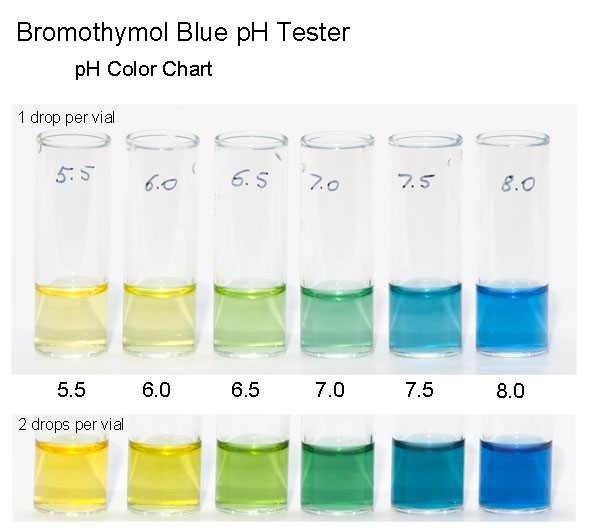

For a possible color pH indicator I am thinking bromothymol blue would be about right

Thanks to gsd for the following article (attached)

STUDIES ON HYDRAZINE. THE HYDROLYSIS OF DIMETHYLKETAZINE AND THE EQUILIBRIUM BETWEEN HYDRAZINE AND ACETONE

E. C. Gilbert

J. Am. Chem. Soc., 1929, 51 (11), pp 3394–3409

DOI: 10.1021/ja01386a032

Publication Date: November 1929

Attachment: STUDIES ON HYDRAZINE.pdf (933kB)

This file has been downloaded 1048 times

[Edited on 21-4-2013 by Rosco Bodine]

|

|

|

| Pages:

1

..

8

9

10

11

12

..

18 |

|