| Pages:

1

2

3

4 |

janger

Harmless

Posts: 40

Registered: 20-8-2004

Member Is Offline

Mood: No Mood

|

|

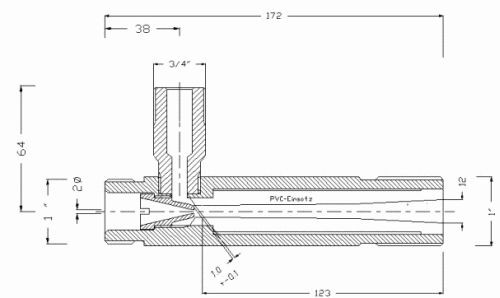

I made mine sort of like this:

I used an irrigation hose t-fitting, and various bits of pvc pipe to get it working. The water goes through the small pipe. In reality this pipe is a

larger diameter and connects to the tap, but a small jet is on the end. The vacuum is created on the side inlet.

There was a bit of playing with diameters and positions of the various pieces, but it _does_ work that way. And you may notice it is very similar to

your diagram, but with the vacuum/water connections reversed.

|

|

|

mick

Hazard to Others

Posts: 338

Registered: 3-10-2003

Member Is Offline

Mood: No Mood

|

|

This is probably obvious

Once you have got all the pipe sizes sorted if you are going to pull a vacuum on sealed kit you will need a non-return ball valve or something to

prevent the chance of water sucking back. In a recirculating water pump the water get warm fairly quick, loss of vacuum pulling power and every thing

fills with water. To keep the water cool add water+overflow pipe (or add ice). Can get down to about 15 mm Hg with cold water being pumped fast enough

which is usually better than an old oil pump. Just thinking, if you could add some gelling agent to the water to reduce the vapour pressure, with the

pump you have got you might be able to get below that.

Mick

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

I would be very happy with a 200mmhg vacuum. It' enough to boil ethanol at 50ºC (that's my main target) and for vacuum filtrations.

I found this diagram of a venturi (attached), but I can't read what's beside "PVC": Einsotz or Einbotz or something, does that

make sense to anyone?

EDIT: OOOPS! I just found out that this topic (homebrew aspirators) has been discussed in the "homebrew aspirator" thread.

Sorry administrators!

[Edited on 30-8-2004 by Tacho]

[Edited on 30-8-2004 by Tacho]

[Edited on 30-8-2004 by Tacho]

|

|

|

mick

Hazard to Others

Posts: 338

Registered: 3-10-2003

Member Is Offline

Mood: No Mood

|

|

I had not seen that .

I know this is some where , but a reasonable fish tank diaphragm pump is OK for most filtrations because they do not pull all the solvent off under to

much vac. Some do not like acetone and other solvents on the outside though. Low pressure ones can be used to pump air/gas into equipment without

worries of over pressurising the kit.

Mick

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

| Quote: | Originally posted by Tacho

I would be very happy with a 200mmhg vacuum.

[Edited on 30-8-2004 by Tacho] |

I think a vacuum cleaner would supply at least that much vacuum.

Try a Hoover!

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

vulture

Forum Gatekeeper

Posts: 3330

Registered: 25-5-2002

Location: France

Member Is Offline

Mood: No Mood

|

|

A vacuum cleaner cools itself by its airflow. It's going to burn itself down if you get what I mean.

Tacho, the water should flow in a straight line vertically down. You're losing water pressure and velocity in the curve.

The vacuum should be sucked from the side.

EDIT: Merged the threads.

[Edited on 30-8-2004 by vulture]

One shouldn't accept or resort to the mutilation of science to appease the mentally impaired.

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

| Quote: | Originally posted by vulture

A vacuum cleaner cools itself by its airflow. It's going to burn itself down if you get what I mean.

|

I was thinking about that actually, before I got my vacuum pump off ebay.

I even picked up an old upright gratis, but never have yet got around to trying it.

I think that it would be possible to use the suction of the vacuum without plugging the nozzle entirely, sorta like a turbocharger uses a wastegate to

avoid boom!

If you were to place the smaller intake hose of your vacuum "needs" into the throat of the household vacuum and partially block the

hose.....

You'd have a localized low-pressure zone and still a percentage of flow-through to allow cooling.

Still............ it might work better up here than in brazil?

You would definitely want to monitor the heat of the motor with the side of your hand, perhaps it would be like having a vacuum source with a

duty-cycle, just like a cheapo stick welder?

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

Organikum

resurrected

Posts: 2339

Registered: 12-10-2002

Location: Europe

Member Is Offline

Mood: frustrated

|

|

A vacuum cleaner is by no way explosion proof. And needs some air to cool itself.

That will be fun!

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Humm... it's true. A vacuum cleaner might get 200 mmHg... I never thought of that.

But, as Organikum pointed out, ethanol vapours passing through a brush motor would really be fun! A jet engine!

Besides, after spending something like U$60 on that 1/4hp pump, I would feel a pain in the pocket if I could not get any vacuum from it.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Forget vacuum cleaners!

Mine is a pretty powerfull one and it could only pull 640mmHg.

200mmHg is the maximum I could get with my old refrigerator compressor. Even if my abused vacuum gauge is imprecise, I don't think a vacuum

cleaner is of any use in the lab.

Some catalogues say that aspirators could pull down to 25mmHg. That's impresive! Could those delicate glass ones bear such diferential pressure?

Yesterday I built another one using an arrangement of concentric PVC pipes: Failure! I can describe it further if anyone is interested in knowing what

NOT to do.

Finally I decided to get scientific and built a test setup, using a huge syringe barrel, stopcorks and different tubes. I cut one end of the barrel so

I had this almost transparent tube. It looked like the setup janger pictured (nice picture btw), only it had a stopcork in the bottom too. The vacuum

conection was on the side. The water flowed in a straight direction down.

The lower tube had a diameter of about 10mm and the upper one about 7mm. Both could slide in the stopcorks.I tried every relative position possible. I

got myself soaked (stopcorks would escape from time to time), but no arrangement I tried gave me more than 650 mmHg. This record was obtained sticking

the upper tube halfway inside the lower one.

Look at those glass aspirators! They are so simple! No glassblower could be that careful about distances and diameters! Are you guys sure they can

pull that much vacuum? Are you sure its just Bernoilli priciple, I'm having the impression there is some mechanical action, like the water jet

stream "carrying" the air bubbles away. I saw this picture of a glass aspirator (in an old Aldrich catalog) where the upper tube was

twisted, as if to put some rotation to the water stream.

Hey, Hermes, have I told you that hydrodynamics is extremely complex?

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Water Jet Pumps

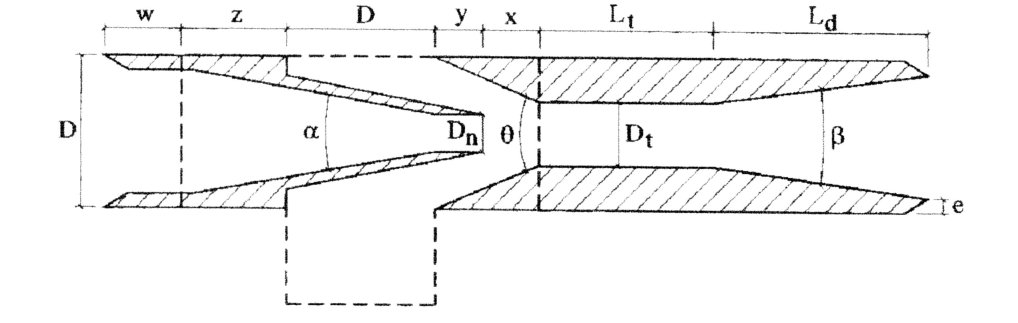

There are 2 configurations: the venturi pump and the jet ejector pump. The former operates more closely to the Bernoulli Effect, but is far less

efficient. Anyway, the Bernoulli equation applies to frictionless and incompressible fluids with no turbulence. It is a good approximation in some

situations.

Most lab. pumps are of the jet ejector design, which entrains air molecules within the jet.

To get a dynamic pressure drop of 1 atmosphere in water, the Bernoulli equation says you need at least 15 m/s. For a 10 L/s supply, this equates to a

nozzle diameter of 3.6 mm. For a nice smooth flow, the jet nozzle should be tapered down to 3.6 mm at a 20 degree angle.

The throat to receive the water jet should be 6 mm diameter with a 45 degree flare at the receiving end. The jet nozzle should be inside the flare but

standing off from the throat itself by 4 mm. The throat should be 50 mm long, followed by a gradual widening.

These are partly calculated and partly empirical figures. They agree with frogfot's homemade pump.

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Schematic

The Water Jet Ejector, dimensions as above

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Thanks a lot!

Great information!

I knew there was something very strange with those designs.

I'll do my search in the net, but do you have online (or ftp) references for these pumps?

What frogfot's homemade pump? I searched but could find nothing.

|

|

|

The_Davster

A pnictogen

Posts: 2861

Registered: 18-11-2003

Member Is Offline

Mood: .

|

|

This is Frogfot's vaccum pump.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Wow, I'm speechless!

Thank you again HRH and thank you rogue chemist.

Organikum,

I just managed to install a .rar unpacker in my computer and the material you posted is, as usual, excelent. You deserve to get much more sex than you

do now!

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Pump Schematic

I have a pdf of a research paper on jet ejector pumps somewhere at home. I'll post it if I can find it.

The limiting pressure is the vapour pressure of water - not from Bernoulli's equation but because the vacuum chamber gets wet and outgases at

this rate.

Frogfot shows you can do it successfully DIY. His pumping speed is a little less than commercial pumps but his jet nozzle and throat are smaller too.

I think, if he increased the dimensions, he would achieve the same pumping speed (typically 67 ml/s = 0.14 cfm).

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

| Quote: | Originally posted by Tacho

Mine is a pretty powerfull one and it could only pull 640mmHg.

200mmHg is the maximum I could get with my old refrigerator compressor. Even if my abused vacuum gauge is imprecise, I don't think a vacuum

cleaner is of any use in the lab.

Hey, Hermes, have I told you that hydrodynamics is extremely complex? |

You're a funny guy tacho, I am glad someone finally put a guage to one of those things, I've always been curious!

EDIT: curious about science...SCIENCE..no more U2U's O.K. guys?

....and Orgi.....I feel sorry for that poor cat of yours! I wonder if he'll

ever walk again? I wonder if he'll

ever walk again?

EDIT: This last joke was made without prior knowledge of chemoleo's black cat thread and now seems a little morbid.

[Edited on 1-9-2004 by Hermes_Trismegistus]

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Water Jet Pump Design Paper

I couldn't find the paper I was after, but I did have this one - where the schematic came from.

Attachment: agricultural jet pump design.pdf (135kB)

This file has been downloaded 9611 times

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

MadHatter

International Hazard

Posts: 1347

Registered: 9-7-2004

Location: Maine

Member Is Offline

Mood: Enjoying retirement

|

|

Faucet adaptor

Polverone asked about adapters for faucets to use hydroapsirators. I found my at

Ace Hardware. Goes from a threaded to a barbed end. Works Great !

From opening of NCIS New Orleans - It goes a BOOM ! BOOM ! BOOM ! MUHAHAHAHAHAHAHA !

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Major success!

I built a jet ejector pump folowing the directions given by HRH. What a huge success! My gauge read 20mm Hg (20 Torr) quick! I simply didn't

believe it (I still think the gauge is inacurate) so I tested it in a round bottom flask with ethanol, to see if it would boil with my hand's

heat. It boiled even at room temperature (about 26°C today)!

It is similar to frogfot pump, since it's made of brass fittings and copper tubes. I attached detailed drawing of it. When I saw frogfot page, I

was a bit skeptical, considering my previous failures, but now it's clear that HRH "recipe" works wonders. Thanks for that paper too

HRH, ironically it was made in an university near where I live.

Hydrodynamics is extremely complex, but an obtuse mind with obsessive will and a screwdriver can do miracles!

"Ignorance is Power!"(George Orwell, out of context).

EDIT: I just noticed that, in my drawing, I mention 3/4" to 3/8" somewhere. Make that 1/2" to 3/8". Maybe it doesn't make a

diference, but the "T" is 1/2", therefore all fittings are 1/2".

[Edited on 2-9-2004 by Tacho]

Attachment: vjetpump.pdf (17kB)

This file has been downloaded 6600 times

|

|

|

Hermes_Trismegistus

National Hazard

Posts: 602

Registered: 27-11-2003

Location: Greece, Ancient

Member Is Offline

Mood: conformation:ga

|

|

possible edit?

| Quote: | Originally posted by Tacho

Major success!

Hydrodynamics is extremely complex, but an obtuse mind with obsessive will and a screwdriver (and a seven page design pdf

complete with performance comparator graphs) can do miracles!

|

Arguing on the internet is like running in the special olympics; even if you win: you\'re still retarded.

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Performance Measurements

Outstanding work, Tacho!

Can you get some performance measurements:

1. Rate of water consumption in litres/minute

2. Pumping speed. (Preferably by measuring the time to evacuate a known volume to a known pressure).

Pumping Speed, S = (V/t)ln(P0/P)

V = volume (cubic metres)

t = time (seconds)

P0 = starting pressure (atmospheric) (Pa)

P = final pressure (Pa)

If you use SI units throughout, you get the speed in cubic metres/second. Convert to litres/minute.

Commercial pumps are typically 4 L/min pumping speed and consume 10 L/min of water.

I

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

Tacho

National Hazard

Posts: 582

Registered: 5-12-2003

Member Is Offline

Mood: No Mood

|

|

Well, Hermes... Touché. He, he, he.

HRH,

I'll do my best. First I'll buy a new gauge, I simply don't trust my abused one to give precise measures. 20 Torr is simply too good to

be true. I think I can easily measure water consumption and how fast a given volume is brought to a given vacuum.

The only catchy detail in my pump is to make the epoxy exit with a gradual widening. I don't even know if that is crucial or not: Frogfot's

doesn't seem to have one. I did mine slowly rotating the tube with the proper inclination while the fluid epoxy set. I used the stepper motor

driver I described in an old thread. It was a bit messy and I had to drill away the excess epoxy that cloged the 6,3mm copper tube. Next time I may

try some paraffin insert that gets melted away.

Alignment and centralization of the tubes seems to also require care.

|

|

|

frogfot

Hazard to Others

Posts: 212

Registered: 30-11-2002

Location: Sweden

Member Is Offline

Mood: happy

|

|

Why is 20 torr "to good to be true"?!?! lol It's easy to get the pressure down to waters vapour pressure.. (I've measured

everything with digital lab monometer)

To take away confusion, just wanned to mention that I let the water in the side of the pump, so the nozzle becomes circular (I guess principal is

still the same, can anyone calculate on this???)

This was done because I couldn't make it to work the "normal" way (water comes from above).. but now when you've explained the

optimal measures it seems obvious why it didn't.. Need more difference between ejector and nozzle throat areas..

Gonna try it the normal way with measures you've suggested!! Didn't know that drilling/enlarging hole in brass nipples was that easy, now

these pumps can be really massproduced

Btw, is converging part on exit really necessary?

[Edited on 2-9-2004 by frogfot]

|

|

|

HRH_Prince_Charles

Hazard to Self

Posts: 92

Registered: 29-6-2004

Location: Clarence House, London

Member Is Offline

Mood: Bombastic

|

|

Diverging Water Outlet

I don't think this is strictly necessary, but it creates a nice streamline flow going into the outlet pipe (if there is one). I think the throat

and throat flare dimensions are much more important.

Bunsen's orginal water jet design was configured like yours, Frogfot (with the water entering the main chamber).

Loather of monstrous carbuncles, lover of organic melons and servant girls.

|

|

|

| Pages:

1

2

3

4 |